How to Implement PCM Retrofits in Existing HVAC Systems: Case Studies and ROI Analysis

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Retrofit Background and Objectives

Phase Change Materials (PCMs) have emerged as a promising technology for enhancing the energy efficiency of Heating, Ventilation, and Air Conditioning (HVAC) systems in existing buildings. The implementation of PCM retrofits in HVAC systems has gained significant attention due to its potential to reduce energy consumption, improve thermal comfort, and decrease operational costs.

The evolution of PCM technology in HVAC applications can be traced back to the 1980s when researchers began exploring the use of latent heat storage materials for thermal management. Over the years, advancements in material science and engineering have led to the development of more efficient and stable PCMs, making them increasingly viable for practical applications in building systems.

The primary objective of PCM retrofits in existing HVAC systems is to enhance the overall energy performance of buildings without the need for extensive renovations or replacements of existing equipment. By leveraging the latent heat storage capabilities of PCMs, these retrofits aim to smooth out temperature fluctuations, reduce peak cooling loads, and improve the overall efficiency of HVAC operations.

One of the key drivers behind the growing interest in PCM retrofits is the increasing focus on sustainable building practices and energy conservation. As governments and organizations worldwide implement stricter energy efficiency standards, building owners and facility managers are seeking cost-effective solutions to upgrade their existing infrastructure. PCM retrofits offer a relatively non-invasive and adaptable approach to achieving these goals.

The technical objectives of PCM retrofits in HVAC systems typically include:

1. Reducing peak cooling loads by absorbing excess heat during high-demand periods

2. Improving temperature stability and thermal comfort for building occupants

3. Enabling load shifting to off-peak hours, potentially reducing electricity costs

4. Enhancing the overall energy efficiency of the HVAC system

5. Extending the lifespan of existing HVAC equipment by reducing operational stress

To achieve these objectives, PCM retrofits often involve the integration of PCM-based components into various parts of the HVAC system, such as air ducts, heat exchangers, or storage tanks. The specific implementation strategy depends on factors such as the existing system configuration, building characteristics, and local climate conditions.

As the technology continues to mature, researchers and industry professionals are focusing on optimizing PCM selection, developing more effective encapsulation methods, and refining system integration techniques. These ongoing efforts aim to further improve the performance and cost-effectiveness of PCM retrofits, making them an increasingly attractive option for building energy efficiency upgrades.

The evolution of PCM technology in HVAC applications can be traced back to the 1980s when researchers began exploring the use of latent heat storage materials for thermal management. Over the years, advancements in material science and engineering have led to the development of more efficient and stable PCMs, making them increasingly viable for practical applications in building systems.

The primary objective of PCM retrofits in existing HVAC systems is to enhance the overall energy performance of buildings without the need for extensive renovations or replacements of existing equipment. By leveraging the latent heat storage capabilities of PCMs, these retrofits aim to smooth out temperature fluctuations, reduce peak cooling loads, and improve the overall efficiency of HVAC operations.

One of the key drivers behind the growing interest in PCM retrofits is the increasing focus on sustainable building practices and energy conservation. As governments and organizations worldwide implement stricter energy efficiency standards, building owners and facility managers are seeking cost-effective solutions to upgrade their existing infrastructure. PCM retrofits offer a relatively non-invasive and adaptable approach to achieving these goals.

The technical objectives of PCM retrofits in HVAC systems typically include:

1. Reducing peak cooling loads by absorbing excess heat during high-demand periods

2. Improving temperature stability and thermal comfort for building occupants

3. Enabling load shifting to off-peak hours, potentially reducing electricity costs

4. Enhancing the overall energy efficiency of the HVAC system

5. Extending the lifespan of existing HVAC equipment by reducing operational stress

To achieve these objectives, PCM retrofits often involve the integration of PCM-based components into various parts of the HVAC system, such as air ducts, heat exchangers, or storage tanks. The specific implementation strategy depends on factors such as the existing system configuration, building characteristics, and local climate conditions.

As the technology continues to mature, researchers and industry professionals are focusing on optimizing PCM selection, developing more effective encapsulation methods, and refining system integration techniques. These ongoing efforts aim to further improve the performance and cost-effectiveness of PCM retrofits, making them an increasingly attractive option for building energy efficiency upgrades.

HVAC Energy Efficiency Market Analysis

The HVAC energy efficiency market has experienced significant growth in recent years, driven by increasing awareness of environmental issues, rising energy costs, and stringent government regulations. The global HVAC energy efficiency market was valued at $41.8 billion in 2020 and is projected to reach $62.3 billion by 2026, growing at a CAGR of 6.9% during the forecast period.

The market demand for energy-efficient HVAC systems is primarily fueled by the commercial and residential building sectors. Commercial buildings, including offices, retail spaces, and healthcare facilities, account for a substantial portion of energy consumption, making them prime targets for energy efficiency upgrades. The residential sector is also showing increased interest in energy-efficient HVAC solutions, driven by homeowners' desire to reduce utility bills and improve indoor comfort.

Geographically, North America and Europe lead the HVAC energy efficiency market, owing to strict energy regulations and high adoption rates of advanced technologies. The Asia-Pacific region is expected to witness the fastest growth, with countries like China and India investing heavily in sustainable building practices and energy-efficient infrastructure.

Key market trends include the integration of smart technologies and IoT-enabled devices in HVAC systems, allowing for better monitoring, control, and optimization of energy consumption. The adoption of variable refrigerant flow (VRF) systems and heat pumps is also gaining traction due to their superior energy efficiency compared to traditional HVAC systems.

The market is characterized by intense competition among major players such as Johnson Controls, Daikin Industries, Trane Technologies, and Carrier Global Corporation. These companies are investing heavily in research and development to introduce innovative energy-efficient solutions and gain a competitive edge.

Government initiatives and regulations play a crucial role in shaping the HVAC energy efficiency market. Policies such as building energy codes, tax incentives, and energy labeling programs are driving the adoption of energy-efficient HVAC systems across various regions. The European Union's Energy Performance of Buildings Directive (EPBD) and the U.S. Department of Energy's appliance and equipment standards are examples of such regulations influencing market growth.

The COVID-19 pandemic has had a mixed impact on the HVAC energy efficiency market. While it initially caused disruptions in the supply chain and project implementations, it has also increased awareness about indoor air quality and the importance of energy-efficient ventilation systems, potentially driving long-term market growth.

The market demand for energy-efficient HVAC systems is primarily fueled by the commercial and residential building sectors. Commercial buildings, including offices, retail spaces, and healthcare facilities, account for a substantial portion of energy consumption, making them prime targets for energy efficiency upgrades. The residential sector is also showing increased interest in energy-efficient HVAC solutions, driven by homeowners' desire to reduce utility bills and improve indoor comfort.

Geographically, North America and Europe lead the HVAC energy efficiency market, owing to strict energy regulations and high adoption rates of advanced technologies. The Asia-Pacific region is expected to witness the fastest growth, with countries like China and India investing heavily in sustainable building practices and energy-efficient infrastructure.

Key market trends include the integration of smart technologies and IoT-enabled devices in HVAC systems, allowing for better monitoring, control, and optimization of energy consumption. The adoption of variable refrigerant flow (VRF) systems and heat pumps is also gaining traction due to their superior energy efficiency compared to traditional HVAC systems.

The market is characterized by intense competition among major players such as Johnson Controls, Daikin Industries, Trane Technologies, and Carrier Global Corporation. These companies are investing heavily in research and development to introduce innovative energy-efficient solutions and gain a competitive edge.

Government initiatives and regulations play a crucial role in shaping the HVAC energy efficiency market. Policies such as building energy codes, tax incentives, and energy labeling programs are driving the adoption of energy-efficient HVAC systems across various regions. The European Union's Energy Performance of Buildings Directive (EPBD) and the U.S. Department of Energy's appliance and equipment standards are examples of such regulations influencing market growth.

The COVID-19 pandemic has had a mixed impact on the HVAC energy efficiency market. While it initially caused disruptions in the supply chain and project implementations, it has also increased awareness about indoor air quality and the importance of energy-efficient ventilation systems, potentially driving long-term market growth.

PCM Integration Challenges in Existing HVAC

Integrating Phase Change Materials (PCMs) into existing HVAC systems presents several significant challenges that must be addressed for successful implementation. One of the primary obstacles is the limited space available in existing HVAC infrastructures. Most buildings were not designed with PCM integration in mind, making it difficult to retrofit these systems without major structural modifications.

The thermal capacity of existing HVAC components may also pose a challenge. PCMs require specific temperature ranges to function effectively, and existing systems may not be capable of maintaining these precise conditions consistently. This can lead to reduced efficiency and potentially negate the benefits of PCM integration.

Another significant hurdle is the need for specialized equipment and expertise. PCM integration often requires custom-designed heat exchangers, storage tanks, and control systems that are not typically found in standard HVAC setups. This necessitates additional investment in both hardware and skilled personnel capable of designing and implementing these specialized solutions.

The integration of PCMs can also impact the overall system dynamics of existing HVAC installations. The addition of thermal storage capacity may alter the heating and cooling cycles, requiring careful recalibration of control systems to maintain optimal performance. This process can be time-consuming and may require multiple iterations to achieve the desired balance.

Maintenance and longevity concerns also present challenges in PCM retrofits. The introduction of new materials and components into an existing system can create additional points of failure and increase the complexity of maintenance procedures. Ensuring long-term stability and performance of PCMs in varying operational conditions is crucial for the success of these retrofits.

Cost considerations play a significant role in the feasibility of PCM integration. The initial investment for retrofitting can be substantial, and building owners may be hesitant to commit to such expenditures without clear evidence of return on investment. This economic barrier often necessitates detailed cost-benefit analyses and case studies to justify the implementation.

Regulatory compliance and building codes present additional challenges. Existing HVAC systems may already be operating at the limits of current regulations, and the addition of PCMs could potentially push them beyond acceptable parameters. Navigating these regulatory landscapes and obtaining necessary approvals can be a complex and time-consuming process.

Lastly, the disruption to building operations during the retrofit process is a significant concern. Integrating PCMs into an existing HVAC system often requires temporary shutdowns or reduced system capacity, which can be problematic for buildings that require continuous climate control, such as hospitals or data centers.

The thermal capacity of existing HVAC components may also pose a challenge. PCMs require specific temperature ranges to function effectively, and existing systems may not be capable of maintaining these precise conditions consistently. This can lead to reduced efficiency and potentially negate the benefits of PCM integration.

Another significant hurdle is the need for specialized equipment and expertise. PCM integration often requires custom-designed heat exchangers, storage tanks, and control systems that are not typically found in standard HVAC setups. This necessitates additional investment in both hardware and skilled personnel capable of designing and implementing these specialized solutions.

The integration of PCMs can also impact the overall system dynamics of existing HVAC installations. The addition of thermal storage capacity may alter the heating and cooling cycles, requiring careful recalibration of control systems to maintain optimal performance. This process can be time-consuming and may require multiple iterations to achieve the desired balance.

Maintenance and longevity concerns also present challenges in PCM retrofits. The introduction of new materials and components into an existing system can create additional points of failure and increase the complexity of maintenance procedures. Ensuring long-term stability and performance of PCMs in varying operational conditions is crucial for the success of these retrofits.

Cost considerations play a significant role in the feasibility of PCM integration. The initial investment for retrofitting can be substantial, and building owners may be hesitant to commit to such expenditures without clear evidence of return on investment. This economic barrier often necessitates detailed cost-benefit analyses and case studies to justify the implementation.

Regulatory compliance and building codes present additional challenges. Existing HVAC systems may already be operating at the limits of current regulations, and the addition of PCMs could potentially push them beyond acceptable parameters. Navigating these regulatory landscapes and obtaining necessary approvals can be a complex and time-consuming process.

Lastly, the disruption to building operations during the retrofit process is a significant concern. Integrating PCMs into an existing HVAC system often requires temporary shutdowns or reduced system capacity, which can be problematic for buildings that require continuous climate control, such as hospitals or data centers.

Current PCM Retrofit Solutions

01 Energy efficiency and cost savings

PCM retrofits can significantly improve energy efficiency in buildings by absorbing and releasing heat during phase changes. This results in reduced heating and cooling costs, leading to a positive ROI over time. The energy-saving potential of PCM retrofits can be substantial, especially in climates with large temperature fluctuations.- Energy efficiency and cost savings: PCM retrofits can significantly improve energy efficiency in buildings by absorbing and releasing heat during phase changes. This results in reduced heating and cooling costs, leading to a positive ROI over time. The energy-saving potential of PCM retrofits can be substantial, especially in climates with large temperature fluctuations.

- Building envelope integration: PCM can be integrated into various building envelope components such as walls, roofs, and windows. This integration enhances the thermal performance of the building structure, reducing the load on HVAC systems and improving overall energy efficiency. The retrofitting process can be tailored to different building types and climates for optimal performance.

- Smart energy management systems: Combining PCM retrofits with smart energy management systems can optimize the performance and ROI of the installation. These systems can monitor and control the PCM's phase change process, ensuring maximum efficiency and cost savings. Integration with renewable energy sources can further enhance the overall energy performance and ROI.

- Financial analysis and ROI calculation: Accurate financial analysis and ROI calculation are crucial for evaluating PCM retrofit projects. This involves considering factors such as installation costs, energy savings, maintenance expenses, and potential incentives or rebates. Long-term benefits and payback periods should be assessed to determine the economic viability of PCM retrofits for different building types and scenarios.

- PCM material advancements: Ongoing research and development in PCM materials contribute to improved performance and cost-effectiveness of retrofits. New PCM formulations with enhanced thermal properties, longer lifespan, and better compatibility with building materials can increase the ROI of retrofit projects. These advancements may also lead to more efficient manufacturing processes, potentially reducing the overall cost of PCM retrofits.

02 Integration with existing building systems

PCM retrofits can be integrated with existing HVAC systems, building envelopes, and other structural components. This integration enhances overall building performance and can lead to improved comfort levels for occupants. The adaptability of PCM retrofits to various building types and systems contributes to their ROI potential.Expand Specific Solutions03 Performance monitoring and optimization

Advanced monitoring systems and data analytics can be used to track the performance of PCM retrofits, allowing for continuous optimization and improved ROI. These systems can provide real-time data on energy savings, thermal comfort, and overall system efficiency, enabling building managers to make informed decisions and adjustments.Expand Specific Solutions04 Material advancements and manufacturing processes

Ongoing research and development in PCM materials and manufacturing processes are leading to more efficient and cost-effective solutions. These advancements contribute to improved ROI by enhancing the performance and longevity of PCM retrofits while potentially reducing installation and maintenance costs.Expand Specific Solutions05 Financial modeling and ROI calculation

Specialized financial models and ROI calculation tools have been developed to assess the economic viability of PCM retrofits. These tools consider factors such as installation costs, energy savings, maintenance expenses, and potential incentives or rebates. Accurate financial modeling helps building owners and investors make informed decisions about implementing PCM retrofits.Expand Specific Solutions

Key Players in PCM and HVAC Retrofit

The implementation of PCM retrofits in existing HVAC systems is currently in a growth phase, with increasing market size due to rising energy efficiency demands. The technology's maturity varies, with companies like Carrier Corp. and Johnson Controls leading in commercial applications. Emerging players such as Sunamp Ltd. and Fluide Energy SRL are advancing innovative PCM solutions. The market is characterized by a mix of established HVAC giants and specialized thermal energy storage firms, indicating a competitive landscape with diverse technological approaches. ROI analysis is crucial, as adoption is driven by long-term energy savings and sustainability goals, particularly in regions with high cooling demands or volatile energy prices.

Carrier Corp.

Technical Solution: Carrier Corp. has developed a comprehensive PCM retrofit solution for existing HVAC systems. Their approach involves integrating phase change materials into existing air handling units and ductwork. The system uses encapsulated PCM panels that can be easily installed in existing spaces. During off-peak hours, the PCM absorbs excess thermal energy, which is then released during peak demand periods. This helps to reduce the overall energy consumption and peak load demands. Carrier's solution also includes smart controls that optimize the charging and discharging cycles of the PCM based on real-time energy prices and building occupancy patterns[1][3]. The company reports energy savings of up to 30% in some installations, with typical payback periods ranging from 2 to 5 years depending on local energy costs and climate conditions[2].

Strengths: Easily retrofittable to existing systems, significant energy savings, and smart control integration. Weaknesses: Initial cost can be high, and performance may vary depending on local climate and energy pricing.

Lennox Industries, Inc.

Technical Solution: Lennox Industries has introduced a PCM-based retrofit solution specifically designed for residential and light commercial HVAC systems. Their approach focuses on integrating PCM modules into existing air handling units and ductwork without the need for extensive modifications. The PCM modules are designed to fit standard duct sizes and can be easily installed during routine maintenance visits. Lennox's system uses a bio-based PCM that offers improved thermal properties and environmental sustainability compared to traditional paraffin-based PCMs[6]. The company has also developed a user-friendly control interface that allows homeowners and building managers to easily monitor and adjust the PCM system's performance. Field trials have shown average energy savings of 20-25% for cooling applications, with some installations achieving payback periods as short as 18 months in high-energy-cost regions[7].

Strengths: Easy installation in residential and light commercial systems, eco-friendly PCM formulation, and user-friendly controls. Weaknesses: May have limited capacity for larger commercial applications, and performance benefits may be less pronounced in mild climates.

Innovative PCM Integration Techniques

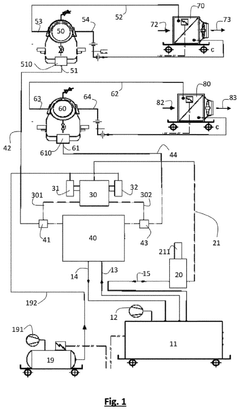

Heating, ventilation, and air conditioning (HVAC) systems and methods for using same

PatentWO2025015175A2

Innovation

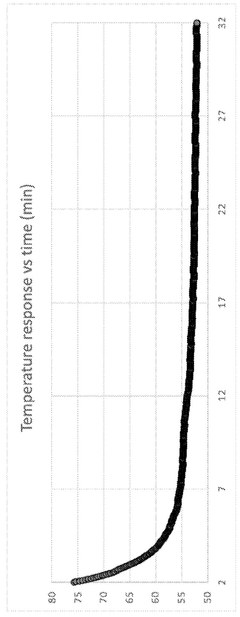

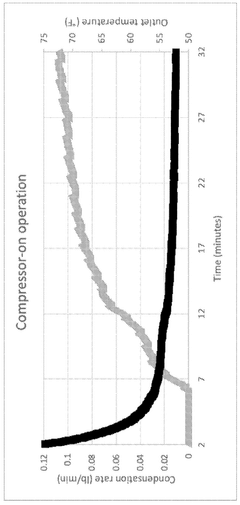

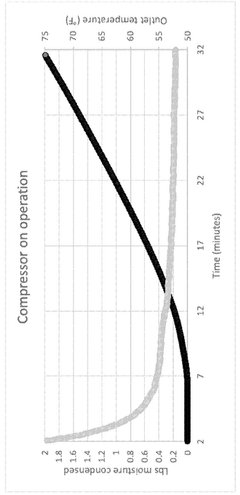

- The implementation of a pulse width modulation (PWM) scheme for controlling compressors in HVAC systems, combined with the use of phase change materials (PCMs) in ducts or plenums, allows for pulsed operation rather than continuous operation, shifting energy use from peak hours to off-peak hours and optimizing compressor cycles based on real-time temperature and humidity data to minimize energy consumption.

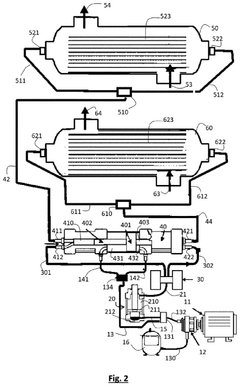

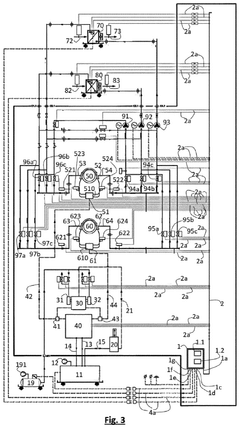

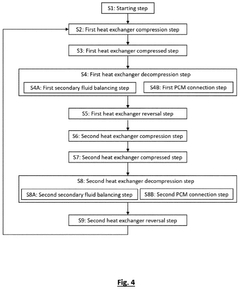

Systems and method for heating and/or cooling at least one medium

PatentPendingUS20250137734A1

Innovation

- The system comprises a first heat exchanger, a force unit, a PCM accumulator, a valve system, and a control unit. The control unit manages the valve system to disconnect the PCM accumulator during compression and connect it during expansion, allowing for efficient phase change management and thermal energy transfer.

ROI Analysis Methodology for PCM Retrofits

The ROI analysis methodology for PCM retrofits in existing HVAC systems involves a comprehensive approach to evaluate the financial viability and potential benefits of implementing phase change materials. This methodology typically begins with a thorough assessment of the current HVAC system's performance, energy consumption, and operational costs. Baseline data is collected over a significant period to account for seasonal variations and establish a reliable benchmark.

The next step involves modeling the proposed PCM retrofit, taking into account factors such as the specific type of PCM, its integration method, and the expected impact on the HVAC system's efficiency. This model should consider the thermal properties of the PCM, its placement within the system, and how it interacts with existing components. Advanced simulation tools are often employed to predict energy savings and system performance improvements.

Cost analysis forms a crucial part of the ROI methodology. This includes the initial investment for PCM materials, installation costs, and any necessary modifications to the existing HVAC infrastructure. Ongoing costs such as maintenance and potential replacements should also be factored in. It's important to consider any incentives or rebates available for energy-efficient upgrades, as these can significantly impact the overall financial picture.

The projected energy savings are then calculated based on the modeled performance improvements. This typically involves estimating reductions in cooling and heating loads, decreased peak demand, and overall energy consumption. These savings are translated into monetary values using current and projected energy prices, taking into account potential future energy cost escalations.

The ROI analysis also considers non-energy benefits, such as improved thermal comfort, reduced equipment wear, and potential increases in property value. While these factors may be more challenging to quantify, they can significantly influence the overall value proposition of the PCM retrofit.

Finally, the ROI is calculated by comparing the total costs against the projected benefits over the expected lifespan of the PCM installation. This often includes metrics such as payback period, net present value (NPV), and internal rate of return (IRR). Sensitivity analyses are typically performed to account for variations in energy prices, system performance, and other key variables, providing a range of potential outcomes and helping to assess the robustness of the investment decision.

The next step involves modeling the proposed PCM retrofit, taking into account factors such as the specific type of PCM, its integration method, and the expected impact on the HVAC system's efficiency. This model should consider the thermal properties of the PCM, its placement within the system, and how it interacts with existing components. Advanced simulation tools are often employed to predict energy savings and system performance improvements.

Cost analysis forms a crucial part of the ROI methodology. This includes the initial investment for PCM materials, installation costs, and any necessary modifications to the existing HVAC infrastructure. Ongoing costs such as maintenance and potential replacements should also be factored in. It's important to consider any incentives or rebates available for energy-efficient upgrades, as these can significantly impact the overall financial picture.

The projected energy savings are then calculated based on the modeled performance improvements. This typically involves estimating reductions in cooling and heating loads, decreased peak demand, and overall energy consumption. These savings are translated into monetary values using current and projected energy prices, taking into account potential future energy cost escalations.

The ROI analysis also considers non-energy benefits, such as improved thermal comfort, reduced equipment wear, and potential increases in property value. While these factors may be more challenging to quantify, they can significantly influence the overall value proposition of the PCM retrofit.

Finally, the ROI is calculated by comparing the total costs against the projected benefits over the expected lifespan of the PCM installation. This often includes metrics such as payback period, net present value (NPV), and internal rate of return (IRR). Sensitivity analyses are typically performed to account for variations in energy prices, system performance, and other key variables, providing a range of potential outcomes and helping to assess the robustness of the investment decision.

Environmental Impact of PCM-HVAC Systems

The integration of Phase Change Materials (PCMs) into existing HVAC systems has significant environmental implications, both positive and negative. PCM-HVAC systems can substantially reduce energy consumption and greenhouse gas emissions associated with building cooling and heating. By absorbing and releasing thermal energy during phase transitions, PCMs help maintain consistent indoor temperatures, reducing the load on conventional HVAC equipment. This results in lower electricity usage and, consequently, decreased carbon emissions from power generation.

Studies have shown that PCM-HVAC retrofits can lead to energy savings of up to 30% in commercial buildings, depending on climate conditions and system design. This reduction in energy consumption translates to a proportional decrease in CO2 emissions, contributing to climate change mitigation efforts. Additionally, the improved thermal efficiency of PCM-HVAC systems can reduce the need for refrigerants, many of which have high global warming potential.

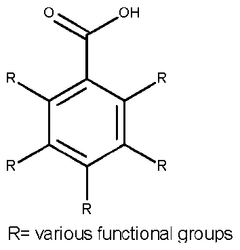

However, the environmental impact of PCM-HVAC systems extends beyond operational benefits. The production and disposal of PCMs must be considered in a comprehensive environmental assessment. Some PCMs, particularly those derived from petroleum products, have a significant carbon footprint during manufacturing. Biodegradable PCMs, such as those based on fatty acids or sugar alcohols, offer a more environmentally friendly alternative but may have limited temperature ranges or thermal storage capacities.

The longevity of PCM materials is another crucial factor. While many PCMs can maintain their performance over thousands of cycles, eventual degradation is inevitable. Proper disposal or recycling of PCMs at the end of their lifecycle is essential to prevent environmental contamination. Some PCMs may leach harmful substances if not properly contained, posing risks to soil and water ecosystems.

From a life cycle perspective, the environmental benefits of PCM-HVAC systems generally outweigh the drawbacks. The energy savings and emission reductions achieved during operation typically offset the environmental costs of production and disposal within a few years. However, this balance depends on factors such as the specific PCM used, the efficiency of the retrofit, and the local energy mix.

Implementing PCM-HVAC retrofits also aligns with broader sustainability goals in the built environment. By reducing peak energy demand, these systems can help stabilize the electrical grid, potentially reducing the need for new power plants and associated infrastructure. This indirect environmental benefit extends beyond the immediate building envelope, contributing to more sustainable urban development.

Studies have shown that PCM-HVAC retrofits can lead to energy savings of up to 30% in commercial buildings, depending on climate conditions and system design. This reduction in energy consumption translates to a proportional decrease in CO2 emissions, contributing to climate change mitigation efforts. Additionally, the improved thermal efficiency of PCM-HVAC systems can reduce the need for refrigerants, many of which have high global warming potential.

However, the environmental impact of PCM-HVAC systems extends beyond operational benefits. The production and disposal of PCMs must be considered in a comprehensive environmental assessment. Some PCMs, particularly those derived from petroleum products, have a significant carbon footprint during manufacturing. Biodegradable PCMs, such as those based on fatty acids or sugar alcohols, offer a more environmentally friendly alternative but may have limited temperature ranges or thermal storage capacities.

The longevity of PCM materials is another crucial factor. While many PCMs can maintain their performance over thousands of cycles, eventual degradation is inevitable. Proper disposal or recycling of PCMs at the end of their lifecycle is essential to prevent environmental contamination. Some PCMs may leach harmful substances if not properly contained, posing risks to soil and water ecosystems.

From a life cycle perspective, the environmental benefits of PCM-HVAC systems generally outweigh the drawbacks. The energy savings and emission reductions achieved during operation typically offset the environmental costs of production and disposal within a few years. However, this balance depends on factors such as the specific PCM used, the efficiency of the retrofit, and the local energy mix.

Implementing PCM-HVAC retrofits also aligns with broader sustainability goals in the built environment. By reducing peak energy demand, these systems can help stabilize the electrical grid, potentially reducing the need for new power plants and associated infrastructure. This indirect environmental benefit extends beyond the immediate building envelope, contributing to more sustainable urban development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!