How to Measure Phase Change Hysteresis and Supercooling in Candidate PCMs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Hysteresis Background

Phase Change Materials (PCMs) have gained significant attention in recent years due to their ability to store and release large amounts of thermal energy during phase transitions. This property makes them valuable for various applications, including thermal energy storage, building temperature regulation, and electronic cooling. However, the effectiveness of PCMs is often limited by two critical phenomena: hysteresis and supercooling.

Hysteresis in PCMs refers to the difference in melting and solidification temperatures observed during the phase change process. This temperature gap can significantly impact the performance of PCM-based systems, as it affects the material's ability to absorb and release heat efficiently. The hysteresis effect is particularly pronounced in certain types of PCMs, such as salt hydrates and some organic compounds.

Supercooling, also known as subcooling, is another crucial factor affecting PCM performance. It occurs when a liquid PCM cools below its freezing point without solidifying. This phenomenon can lead to delayed or incomplete crystallization, reducing the material's heat storage capacity and overall efficiency. Supercooling is especially prevalent in materials with a high degree of purity or those lacking sufficient nucleation sites.

Understanding and quantifying these phenomena is essential for the development and optimization of PCM-based thermal management systems. Accurate measurement of hysteresis and supercooling is crucial for several reasons. Firstly, it allows researchers and engineers to select the most suitable PCMs for specific applications, considering the operating temperature range and required thermal performance. Secondly, it enables the development of strategies to mitigate these effects, such as the addition of nucleating agents or the modification of PCM compositions.

The measurement of phase change hysteresis and supercooling in candidate PCMs involves a combination of experimental techniques and analytical methods. Differential Scanning Calorimetry (DSC) is one of the most widely used techniques for characterizing PCMs, providing information on melting and solidification temperatures, latent heat, and specific heat capacity. However, DSC measurements alone may not fully capture the dynamic behavior of PCMs in real-world applications.

To address this limitation, researchers have developed more sophisticated measurement approaches. These include the T-history method, which allows for the simultaneous measurement of multiple PCM samples under realistic heating and cooling conditions. Additionally, advanced thermal analysis techniques, such as modulated DSC and step-scan DSC, can provide more detailed insights into the phase change behavior of PCMs.

Hysteresis in PCMs refers to the difference in melting and solidification temperatures observed during the phase change process. This temperature gap can significantly impact the performance of PCM-based systems, as it affects the material's ability to absorb and release heat efficiently. The hysteresis effect is particularly pronounced in certain types of PCMs, such as salt hydrates and some organic compounds.

Supercooling, also known as subcooling, is another crucial factor affecting PCM performance. It occurs when a liquid PCM cools below its freezing point without solidifying. This phenomenon can lead to delayed or incomplete crystallization, reducing the material's heat storage capacity and overall efficiency. Supercooling is especially prevalent in materials with a high degree of purity or those lacking sufficient nucleation sites.

Understanding and quantifying these phenomena is essential for the development and optimization of PCM-based thermal management systems. Accurate measurement of hysteresis and supercooling is crucial for several reasons. Firstly, it allows researchers and engineers to select the most suitable PCMs for specific applications, considering the operating temperature range and required thermal performance. Secondly, it enables the development of strategies to mitigate these effects, such as the addition of nucleating agents or the modification of PCM compositions.

The measurement of phase change hysteresis and supercooling in candidate PCMs involves a combination of experimental techniques and analytical methods. Differential Scanning Calorimetry (DSC) is one of the most widely used techniques for characterizing PCMs, providing information on melting and solidification temperatures, latent heat, and specific heat capacity. However, DSC measurements alone may not fully capture the dynamic behavior of PCMs in real-world applications.

To address this limitation, researchers have developed more sophisticated measurement approaches. These include the T-history method, which allows for the simultaneous measurement of multiple PCM samples under realistic heating and cooling conditions. Additionally, advanced thermal analysis techniques, such as modulated DSC and step-scan DSC, can provide more detailed insights into the phase change behavior of PCMs.

PCM Market Analysis

The Phase Change Material (PCM) market has been experiencing significant growth in recent years, driven by the increasing demand for energy-efficient solutions across various industries. The global PCM market size was valued at approximately $1.5 billion in 2020 and is projected to reach $3.5 billion by 2026, growing at a CAGR of 15.2% during the forecast period.

The construction and building sector represents the largest application segment for PCMs, accounting for over 40% of the market share. This is primarily due to the growing emphasis on sustainable building practices and the need for improved thermal management in both residential and commercial structures. PCMs are increasingly being integrated into building materials, such as wallboards, insulation, and concrete, to enhance energy efficiency and reduce heating and cooling costs.

The electronics and telecommunications industry is another rapidly growing segment for PCMs, driven by the need for effective thermal management in electronic devices and data centers. As the demand for high-performance computing and 5G technology continues to rise, the use of PCMs in these applications is expected to increase significantly.

The automotive sector is also emerging as a promising market for PCMs, particularly in electric vehicles (EVs) and battery thermal management systems. With the global shift towards electrification, PCMs are being utilized to regulate battery temperatures, extend battery life, and improve overall vehicle performance.

Geographically, North America and Europe currently dominate the PCM market, collectively accounting for over 60% of the global market share. This is attributed to the stringent energy efficiency regulations, government incentives for sustainable technologies, and the presence of key market players in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing investments in energy-efficient technologies.

Key market players in the PCM industry include BASF SE, Honeywell International Inc., Croda International Plc, and Entropy Solutions LLC. These companies are focusing on research and development activities to enhance the performance of PCMs and expand their application areas. Additionally, strategic partnerships and collaborations with end-user industries are being pursued to gain a competitive edge in the market.

The construction and building sector represents the largest application segment for PCMs, accounting for over 40% of the market share. This is primarily due to the growing emphasis on sustainable building practices and the need for improved thermal management in both residential and commercial structures. PCMs are increasingly being integrated into building materials, such as wallboards, insulation, and concrete, to enhance energy efficiency and reduce heating and cooling costs.

The electronics and telecommunications industry is another rapidly growing segment for PCMs, driven by the need for effective thermal management in electronic devices and data centers. As the demand for high-performance computing and 5G technology continues to rise, the use of PCMs in these applications is expected to increase significantly.

The automotive sector is also emerging as a promising market for PCMs, particularly in electric vehicles (EVs) and battery thermal management systems. With the global shift towards electrification, PCMs are being utilized to regulate battery temperatures, extend battery life, and improve overall vehicle performance.

Geographically, North America and Europe currently dominate the PCM market, collectively accounting for over 60% of the global market share. This is attributed to the stringent energy efficiency regulations, government incentives for sustainable technologies, and the presence of key market players in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing investments in energy-efficient technologies.

Key market players in the PCM industry include BASF SE, Honeywell International Inc., Croda International Plc, and Entropy Solutions LLC. These companies are focusing on research and development activities to enhance the performance of PCMs and expand their application areas. Additionally, strategic partnerships and collaborations with end-user industries are being pursued to gain a competitive edge in the market.

Current Measurement Challenges

Measuring phase change hysteresis and supercooling in candidate Phase Change Materials (PCMs) presents several significant challenges that researchers and engineers must overcome to obtain accurate and reliable data. One of the primary difficulties lies in the precise control and monitoring of temperature during the phase transition process. The temperature must be carefully regulated to capture the subtle differences between melting and solidification temperatures that characterize hysteresis.

The rate of temperature change is a critical factor that can significantly influence the observed hysteresis and supercooling effects. Too rapid heating or cooling can lead to thermal gradients within the sample, resulting in non-uniform phase changes and potentially skewing the measurements. Conversely, excessively slow rates may not accurately represent real-world applications of PCMs, where faster thermal responses are often required.

Another challenge is the accurate detection of the onset of phase change, particularly during supercooling. The metastable liquid state that occurs during supercooling can persist for varying durations, making it difficult to determine the exact point at which crystallization begins. This uncertainty can lead to inconsistencies in supercooling measurements across different experiments or between different researchers.

Sample size and geometry also play crucial roles in measurement accuracy. Larger samples may exhibit more pronounced thermal gradients, while smaller samples might be more susceptible to surface effects that could influence the phase change behavior. The shape of the sample container can affect heat transfer patterns, potentially altering the observed hysteresis and supercooling characteristics.

Impurities and nucleation sites within the PCM samples can significantly impact phase change behavior, particularly supercooling. Even trace amounts of contaminants or variations in surface roughness of the container can act as nucleation points, potentially reducing supercooling effects and complicating the interpretation of results. Ensuring sample purity and consistency across experiments is a persistent challenge.

The choice of measurement technique itself presents challenges. Differential Scanning Calorimetry (DSC) is commonly used but may not always accurately represent the behavior of PCMs in larger-scale applications. Alternative methods, such as T-history or thermal probe techniques, each have their own limitations and potential sources of error that must be carefully considered and mitigated.

Lastly, the repeatability and reproducibility of measurements pose significant challenges. PCMs may exhibit slight variations in behavior over multiple thermal cycles or between different batches of the same material. Developing standardized protocols that can account for these variations while still providing meaningful and comparable results across different studies remains an ongoing challenge in the field of PCM characterization.

The rate of temperature change is a critical factor that can significantly influence the observed hysteresis and supercooling effects. Too rapid heating or cooling can lead to thermal gradients within the sample, resulting in non-uniform phase changes and potentially skewing the measurements. Conversely, excessively slow rates may not accurately represent real-world applications of PCMs, where faster thermal responses are often required.

Another challenge is the accurate detection of the onset of phase change, particularly during supercooling. The metastable liquid state that occurs during supercooling can persist for varying durations, making it difficult to determine the exact point at which crystallization begins. This uncertainty can lead to inconsistencies in supercooling measurements across different experiments or between different researchers.

Sample size and geometry also play crucial roles in measurement accuracy. Larger samples may exhibit more pronounced thermal gradients, while smaller samples might be more susceptible to surface effects that could influence the phase change behavior. The shape of the sample container can affect heat transfer patterns, potentially altering the observed hysteresis and supercooling characteristics.

Impurities and nucleation sites within the PCM samples can significantly impact phase change behavior, particularly supercooling. Even trace amounts of contaminants or variations in surface roughness of the container can act as nucleation points, potentially reducing supercooling effects and complicating the interpretation of results. Ensuring sample purity and consistency across experiments is a persistent challenge.

The choice of measurement technique itself presents challenges. Differential Scanning Calorimetry (DSC) is commonly used but may not always accurately represent the behavior of PCMs in larger-scale applications. Alternative methods, such as T-history or thermal probe techniques, each have their own limitations and potential sources of error that must be carefully considered and mitigated.

Lastly, the repeatability and reproducibility of measurements pose significant challenges. PCMs may exhibit slight variations in behavior over multiple thermal cycles or between different batches of the same material. Developing standardized protocols that can account for these variations while still providing meaningful and comparable results across different studies remains an ongoing challenge in the field of PCM characterization.

Existing Measurement Techniques

01 Supercooling reduction in PCMs

Various techniques are employed to reduce supercooling in phase change materials, including the use of nucleating agents, surface modification, and nanoparticle additives. These methods help initiate crystallization at temperatures closer to the material's melting point, improving the overall efficiency of thermal energy storage systems.- Supercooling reduction in PCMs: Various techniques are employed to reduce supercooling in phase change materials, including the use of nucleating agents, surface modification, and nanoparticle additives. These methods help initiate crystallization at temperatures closer to the material's melting point, improving the overall efficiency of thermal energy storage systems.

- Phase change hysteresis mitigation: Strategies to mitigate phase change hysteresis in PCMs involve optimizing material composition, enhancing heat transfer properties, and developing novel encapsulation techniques. These approaches aim to reduce the temperature difference between melting and solidification, thereby improving the reversibility and efficiency of the phase change process.

- Nanocomposite PCMs for improved performance: Incorporating nanoparticles or nanostructures into PCMs can significantly enhance their thermal properties, including reduced supercooling and hysteresis. These nanocomposites often exhibit improved heat transfer rates, thermal conductivity, and phase change stability, making them suitable for various energy storage applications.

- PCM encapsulation techniques: Advanced encapsulation methods are developed to address issues related to phase change hysteresis and supercooling in PCMs. These techniques include microencapsulation, shell material optimization, and multi-layer encapsulation, which help maintain the PCM's thermal properties and prevent leakage during phase transitions.

- Thermal cycling and stability enhancement: Improving the long-term stability and performance of PCMs under repeated thermal cycling is crucial for practical applications. Research focuses on developing PCM formulations and additives that maintain consistent phase change behavior, reduce degradation, and minimize changes in thermal properties over numerous melting-solidification cycles.

02 Hysteresis mitigation in PCMs

Strategies to mitigate phase change hysteresis in PCMs involve optimizing material composition, enhancing heat transfer properties, and developing novel encapsulation techniques. These approaches aim to reduce the temperature difference between melting and solidification, thereby improving the reversibility and efficiency of the phase change process.Expand Specific Solutions03 PCM composites for enhanced thermal properties

Composite PCMs are developed by combining traditional phase change materials with other substances such as graphene, carbon nanotubes, or metal foams. These composites often exhibit improved thermal conductivity, reduced supercooling, and enhanced phase change stability, leading to more efficient thermal energy storage and management systems.Expand Specific Solutions04 Encapsulation techniques for PCMs

Advanced encapsulation methods are utilized to improve the performance of PCMs, including micro- and nano-encapsulation, shell material optimization, and multi-layer encapsulation. These techniques help prevent leakage, enhance thermal stability, and reduce supercooling and hysteresis effects in phase change materials.Expand Specific Solutions05 PCM applications in thermal management

Phase change materials are increasingly used in various thermal management applications, such as building materials, electronic cooling, and renewable energy systems. The development of PCMs with reduced supercooling and hysteresis effects has led to more efficient and reliable thermal energy storage solutions across multiple industries.Expand Specific Solutions

Key PCM Industry Players

The competition landscape for measuring phase change hysteresis and supercooling in candidate PCMs is in a developing stage, with growing market potential as energy storage technologies gain importance. The market size is expanding due to increased focus on thermal energy management across industries. Technologically, while established methods exist, there's ongoing innovation to improve accuracy and efficiency. Companies like Sunamp Ltd. and Samsung Electronics are at the forefront, leveraging their expertise in thermal storage and materials science. Academic institutions such as Hebei University of Technology and Indian Institute of Technology Delhi are contributing significantly to research advancements. The field is characterized by a mix of commercial players and research institutions collaborating to overcome technical challenges and develop more sophisticated measurement techniques.

Sunamp Ltd.

Technical Solution: Sunamp Ltd. has developed advanced phase change materials (PCMs) for thermal energy storage. Their approach to measuring phase change hysteresis and supercooling involves using differential scanning calorimetry (DSC) and T-history methods. The DSC technique allows precise measurement of heat flow during phase transitions, enabling the quantification of hysteresis and supercooling effects[1]. Sunamp's T-history method involves cycling PCM samples through melting and freezing processes while continuously monitoring temperature changes. This method provides insights into the material's behavior under conditions more representative of real-world applications[2]. Sunamp also employs advanced thermal imaging techniques to visualize phase change processes in their PCM products, allowing for a more comprehensive understanding of hysteresis and supercooling phenomena[3].

Strengths: Precise measurement capabilities, real-world application focus, and visual analysis of phase change processes. Weaknesses: Potential limitations in scaling up measurement techniques for large-scale PCM applications.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a sophisticated approach to measure phase change hysteresis and supercooling in PCMs, particularly for their advanced memory technologies. Their method involves using high-precision electrical resistance measurements combined with temperature-controlled environments. By applying controlled voltage pulses and measuring the resulting current, Samsung can detect minute changes in the material's phase state[4]. This technique allows for real-time monitoring of phase transitions, enabling precise quantification of hysteresis and supercooling effects. Samsung also utilizes advanced in-situ transmission electron microscopy (TEM) to directly observe structural changes during phase transitions, providing valuable insights into the mechanisms underlying hysteresis and supercooling[5]. Additionally, they have developed custom-built testing platforms that can simulate various thermal cycling conditions, allowing for comprehensive characterization of PCM behavior under different operational scenarios[6].

Strengths: High-precision electrical measurements, direct observation of structural changes, and ability to simulate various operational conditions. Weaknesses: Techniques may be primarily optimized for memory applications, potentially limiting broader PCM research applications.

Innovative PCM Analysis Methods

Phase change materials and methods of regulating temperature

PatentWO2017042530A1

Innovation

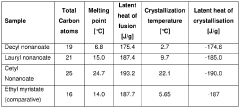

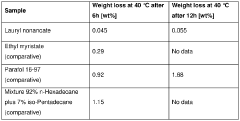

- A PCM composition comprising an ester of a linear alcohol with at least 4 carbon atoms and a linear carboxylic acid with at least 4 carbon atoms, with a total carbon range of 13 to 31, which reduces evaporation rates and improves melting point, thereby enhancing containment and performance.

Standardization of PCM Testing

The standardization of PCM testing is crucial for ensuring consistent and reliable measurements of phase change hysteresis and supercooling in candidate Phase Change Materials (PCMs). This process involves establishing uniform protocols and methodologies that can be universally applied across different laboratories and research institutions.

One of the primary challenges in standardizing PCM testing is the wide variety of materials and their diverse thermal properties. To address this, a comprehensive classification system for PCMs based on their chemical composition, melting temperature range, and intended application has been proposed. This classification serves as a foundation for developing specific testing procedures tailored to each PCM category.

The measurement of phase change hysteresis and supercooling requires precise temperature control and monitoring. Standardized testing equipment, such as differential scanning calorimeters (DSC) and T-history apparatus, have been identified as essential tools for accurate measurements. Calibration procedures for these instruments have been established to ensure consistency across different testing facilities.

A key aspect of standardization is the development of uniform sample preparation techniques. This includes guidelines for sample size, shape, and encapsulation methods, which can significantly influence the observed thermal behavior of PCMs. Standardized cycling procedures have also been implemented to simulate real-world conditions and assess the long-term stability of PCMs.

Data analysis and reporting protocols form another critical component of PCM testing standardization. Agreed-upon methods for calculating hysteresis and supercooling from raw experimental data have been established, along with standardized formats for presenting results. This facilitates easier comparison of data between different studies and enhances the reproducibility of experiments.

Interlaboratory comparison studies have played a vital role in refining and validating standardized testing procedures. These studies involve multiple laboratories performing identical tests on the same PCM samples, allowing for the identification and resolution of discrepancies in measurement techniques or data interpretation.

The development of international standards for PCM testing has been an ongoing collaborative effort involving academic institutions, industry partners, and standardization bodies. Organizations such as the International Energy Agency (IEA) and the American Society for Testing and Materials (ASTM) have been at the forefront of these efforts, publishing guidelines and standards that are continually updated to reflect advancements in PCM technology and measurement techniques.

One of the primary challenges in standardizing PCM testing is the wide variety of materials and their diverse thermal properties. To address this, a comprehensive classification system for PCMs based on their chemical composition, melting temperature range, and intended application has been proposed. This classification serves as a foundation for developing specific testing procedures tailored to each PCM category.

The measurement of phase change hysteresis and supercooling requires precise temperature control and monitoring. Standardized testing equipment, such as differential scanning calorimeters (DSC) and T-history apparatus, have been identified as essential tools for accurate measurements. Calibration procedures for these instruments have been established to ensure consistency across different testing facilities.

A key aspect of standardization is the development of uniform sample preparation techniques. This includes guidelines for sample size, shape, and encapsulation methods, which can significantly influence the observed thermal behavior of PCMs. Standardized cycling procedures have also been implemented to simulate real-world conditions and assess the long-term stability of PCMs.

Data analysis and reporting protocols form another critical component of PCM testing standardization. Agreed-upon methods for calculating hysteresis and supercooling from raw experimental data have been established, along with standardized formats for presenting results. This facilitates easier comparison of data between different studies and enhances the reproducibility of experiments.

Interlaboratory comparison studies have played a vital role in refining and validating standardized testing procedures. These studies involve multiple laboratories performing identical tests on the same PCM samples, allowing for the identification and resolution of discrepancies in measurement techniques or data interpretation.

The development of international standards for PCM testing has been an ongoing collaborative effort involving academic institutions, industry partners, and standardization bodies. Organizations such as the International Energy Agency (IEA) and the American Society for Testing and Materials (ASTM) have been at the forefront of these efforts, publishing guidelines and standards that are continually updated to reflect advancements in PCM technology and measurement techniques.

PCM Environmental Impact Assessment

The environmental impact of Phase Change Materials (PCMs) is a critical consideration in their development and application. PCMs, while offering significant potential for energy storage and thermal management, may pose various environmental challenges throughout their lifecycle. The production of PCMs often involves the use of chemicals and energy-intensive processes, which can contribute to greenhouse gas emissions and resource depletion. Additionally, the raw materials used in PCM manufacturing may be sourced from non-renewable resources, raising concerns about long-term sustainability.

During their operational phase, PCMs can have both positive and negative environmental impacts. On the positive side, PCMs can significantly enhance energy efficiency in buildings and thermal management systems, potentially reducing overall energy consumption and associated carbon emissions. However, the long-term stability and potential leakage of PCMs into the environment must be carefully assessed. Some PCMs may contain substances that could be harmful if released into ecosystems or water sources.

The end-of-life disposal of PCMs presents another environmental challenge. Many PCMs are not easily biodegradable and may require specialized recycling or disposal methods to prevent environmental contamination. The potential for PCMs to accumulate in the environment over time, particularly if not properly managed, could lead to unforeseen ecological consequences.

To mitigate these environmental concerns, researchers and manufacturers are exploring more sustainable PCM options. This includes the development of bio-based PCMs derived from renewable resources, which may offer a lower environmental footprint compared to traditional petroleum-based alternatives. Additionally, efforts are being made to improve the recyclability and biodegradability of PCMs, aiming to create closed-loop systems that minimize waste and environmental impact.

The environmental impact assessment of PCMs also extends to their manufacturing processes. Innovations in green chemistry and sustainable production techniques are being pursued to reduce the environmental burden of PCM production. This includes optimizing energy use in manufacturing, minimizing waste generation, and exploring cleaner synthesis routes for PCM compounds.

As the adoption of PCMs continues to grow across various industries, it becomes increasingly important to conduct comprehensive life cycle assessments (LCAs) for different PCM types and applications. These assessments can provide valuable insights into the overall environmental impact of PCMs, from raw material extraction to end-of-life disposal, enabling more informed decision-making in their development and deployment.

During their operational phase, PCMs can have both positive and negative environmental impacts. On the positive side, PCMs can significantly enhance energy efficiency in buildings and thermal management systems, potentially reducing overall energy consumption and associated carbon emissions. However, the long-term stability and potential leakage of PCMs into the environment must be carefully assessed. Some PCMs may contain substances that could be harmful if released into ecosystems or water sources.

The end-of-life disposal of PCMs presents another environmental challenge. Many PCMs are not easily biodegradable and may require specialized recycling or disposal methods to prevent environmental contamination. The potential for PCMs to accumulate in the environment over time, particularly if not properly managed, could lead to unforeseen ecological consequences.

To mitigate these environmental concerns, researchers and manufacturers are exploring more sustainable PCM options. This includes the development of bio-based PCMs derived from renewable resources, which may offer a lower environmental footprint compared to traditional petroleum-based alternatives. Additionally, efforts are being made to improve the recyclability and biodegradability of PCMs, aiming to create closed-loop systems that minimize waste and environmental impact.

The environmental impact assessment of PCMs also extends to their manufacturing processes. Innovations in green chemistry and sustainable production techniques are being pursued to reduce the environmental burden of PCM production. This includes optimizing energy use in manufacturing, minimizing waste generation, and exploring cleaner synthesis routes for PCM compounds.

As the adoption of PCMs continues to grow across various industries, it becomes increasingly important to conduct comprehensive life cycle assessments (LCAs) for different PCM types and applications. These assessments can provide valuable insights into the overall environmental impact of PCMs, from raw material extraction to end-of-life disposal, enabling more informed decision-making in their development and deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!