How to Design a PCM Heat Exchanger: Key Parameters, Foams & Encapsulation Options

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Heat Exchanger Background and Objectives

Phase Change Material (PCM) heat exchangers represent a significant advancement in thermal management systems, offering enhanced energy efficiency and temperature control capabilities. The development of PCM heat exchangers has been driven by the growing demand for more effective and sustainable thermal solutions across various industries, including building construction, electronics cooling, and renewable energy systems.

The evolution of PCM heat exchanger technology can be traced back to the early 1980s when researchers began exploring the potential of latent heat storage materials for thermal management applications. Over the past four decades, significant progress has been made in understanding the behavior of PCMs, improving their thermal properties, and developing more efficient heat exchanger designs.

The primary objective of PCM heat exchanger design is to maximize the heat transfer rate between the PCM and the working fluid while ensuring reliable and consistent performance over numerous charge-discharge cycles. This involves optimizing several key parameters, including the selection of appropriate PCM materials, the design of the heat exchanger geometry, and the integration of heat transfer enhancement techniques.

One of the critical challenges in PCM heat exchanger design is addressing the inherently low thermal conductivity of most PCMs. This limitation has led to the exploration of various heat transfer enhancement methods, such as the incorporation of high-conductivity foams, the use of extended surfaces (fins), and the development of novel encapsulation techniques.

The selection of PCM materials is another crucial aspect of heat exchanger design. Factors such as melting temperature, latent heat of fusion, thermal stability, and compatibility with containment materials must be carefully considered to ensure optimal performance and longevity of the system. Recent research has focused on developing new PCM formulations with improved thermal properties and stability, including the use of nanoparticle additives and eutectic mixtures.

The design of PCM heat exchangers also involves careful consideration of the system's overall configuration, including the arrangement of PCM modules, the flow pattern of the heat transfer fluid, and the integration of auxiliary components such as pumps and valves. Advanced modeling and simulation techniques have become increasingly important in optimizing these design parameters and predicting system performance under various operating conditions.

As the technology continues to evolve, researchers and engineers are exploring innovative approaches to further enhance the performance and applicability of PCM heat exchangers. This includes the development of hybrid systems that combine PCMs with other thermal management technologies, such as thermoelectric devices or heat pipes, to achieve even greater efficiency and flexibility in thermal control applications.

The evolution of PCM heat exchanger technology can be traced back to the early 1980s when researchers began exploring the potential of latent heat storage materials for thermal management applications. Over the past four decades, significant progress has been made in understanding the behavior of PCMs, improving their thermal properties, and developing more efficient heat exchanger designs.

The primary objective of PCM heat exchanger design is to maximize the heat transfer rate between the PCM and the working fluid while ensuring reliable and consistent performance over numerous charge-discharge cycles. This involves optimizing several key parameters, including the selection of appropriate PCM materials, the design of the heat exchanger geometry, and the integration of heat transfer enhancement techniques.

One of the critical challenges in PCM heat exchanger design is addressing the inherently low thermal conductivity of most PCMs. This limitation has led to the exploration of various heat transfer enhancement methods, such as the incorporation of high-conductivity foams, the use of extended surfaces (fins), and the development of novel encapsulation techniques.

The selection of PCM materials is another crucial aspect of heat exchanger design. Factors such as melting temperature, latent heat of fusion, thermal stability, and compatibility with containment materials must be carefully considered to ensure optimal performance and longevity of the system. Recent research has focused on developing new PCM formulations with improved thermal properties and stability, including the use of nanoparticle additives and eutectic mixtures.

The design of PCM heat exchangers also involves careful consideration of the system's overall configuration, including the arrangement of PCM modules, the flow pattern of the heat transfer fluid, and the integration of auxiliary components such as pumps and valves. Advanced modeling and simulation techniques have become increasingly important in optimizing these design parameters and predicting system performance under various operating conditions.

As the technology continues to evolve, researchers and engineers are exploring innovative approaches to further enhance the performance and applicability of PCM heat exchangers. This includes the development of hybrid systems that combine PCMs with other thermal management technologies, such as thermoelectric devices or heat pipes, to achieve even greater efficiency and flexibility in thermal control applications.

Market Analysis for PCM Heat Exchanger Applications

The market for PCM heat exchangers is experiencing significant growth, driven by increasing demand for energy-efficient thermal management solutions across various industries. The global PCM heat exchanger market is expected to expand at a compound annual growth rate (CAGR) of 12.5% from 2021 to 2026, reaching a market value of $2.1 billion by the end of the forecast period.

Key factors contributing to this market growth include the rising adoption of renewable energy systems, stringent energy efficiency regulations, and the growing need for temperature-sensitive product storage and transportation. The building and construction sector represents the largest application segment for PCM heat exchangers, accounting for approximately 35% of the market share. This is primarily due to the increasing focus on green building practices and the integration of passive cooling systems in both residential and commercial structures.

The HVAC industry is another significant market for PCM heat exchangers, with a growing emphasis on energy-efficient cooling solutions. The automotive sector is also emerging as a promising application area, particularly in electric vehicles where thermal management is crucial for battery performance and longevity.

Geographically, North America and Europe are the leading markets for PCM heat exchangers, collectively accounting for over 60% of the global market share. This dominance is attributed to stringent energy efficiency regulations, high adoption rates of green technologies, and substantial investments in research and development. However, the Asia-Pacific region is expected to witness the fastest growth during the forecast period, driven by rapid industrialization, urbanization, and increasing awareness of energy conservation.

The market landscape is characterized by a mix of established players and innovative start-ups. Key market players include Climator Sweden AB, Rubitherm Technologies GmbH, and Phase Change Energy Solutions. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

Despite the positive growth outlook, the PCM heat exchanger market faces certain challenges. These include the high initial costs associated with PCM technologies, limited awareness among end-users, and the need for further research to improve the long-term stability and performance of PCM materials. Addressing these challenges will be crucial for sustaining the market's growth trajectory and realizing the full potential of PCM heat exchanger applications across various industries.

Key factors contributing to this market growth include the rising adoption of renewable energy systems, stringent energy efficiency regulations, and the growing need for temperature-sensitive product storage and transportation. The building and construction sector represents the largest application segment for PCM heat exchangers, accounting for approximately 35% of the market share. This is primarily due to the increasing focus on green building practices and the integration of passive cooling systems in both residential and commercial structures.

The HVAC industry is another significant market for PCM heat exchangers, with a growing emphasis on energy-efficient cooling solutions. The automotive sector is also emerging as a promising application area, particularly in electric vehicles where thermal management is crucial for battery performance and longevity.

Geographically, North America and Europe are the leading markets for PCM heat exchangers, collectively accounting for over 60% of the global market share. This dominance is attributed to stringent energy efficiency regulations, high adoption rates of green technologies, and substantial investments in research and development. However, the Asia-Pacific region is expected to witness the fastest growth during the forecast period, driven by rapid industrialization, urbanization, and increasing awareness of energy conservation.

The market landscape is characterized by a mix of established players and innovative start-ups. Key market players include Climator Sweden AB, Rubitherm Technologies GmbH, and Phase Change Energy Solutions. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

Despite the positive growth outlook, the PCM heat exchanger market faces certain challenges. These include the high initial costs associated with PCM technologies, limited awareness among end-users, and the need for further research to improve the long-term stability and performance of PCM materials. Addressing these challenges will be crucial for sustaining the market's growth trajectory and realizing the full potential of PCM heat exchanger applications across various industries.

Current Challenges in PCM Heat Exchanger Design

The design of Phase Change Material (PCM) heat exchangers faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the low thermal conductivity of most PCMs, which limits heat transfer rates and overall system efficiency. This inherent property of PCMs can lead to slow charging and discharging cycles, reducing the effectiveness of thermal energy storage systems.

Another critical challenge is the containment and encapsulation of PCMs. As these materials transition between solid and liquid states, they often experience volume changes that can lead to leakage or damage to the heat exchanger structure. Developing robust and cost-effective encapsulation methods that can withstand repeated phase transitions while maintaining thermal performance is an ongoing area of research.

The selection of appropriate PCM for specific applications presents another hurdle. Different PCMs have varying melting temperatures, latent heat capacities, and chemical properties. Matching these characteristics to the requirements of a particular thermal management system is crucial but complex, often requiring extensive testing and optimization.

Heat exchanger geometry and design also pose significant challenges. Optimizing the surface area for heat transfer while managing pressure drop and flow distribution is a delicate balance. Traditional heat exchanger designs may not be suitable for PCM applications, necessitating innovative approaches to maximize thermal contact between the PCM and the heat transfer fluid.

Thermal cycling and long-term stability of PCMs in heat exchangers are additional concerns. Repeated phase changes can lead to material degradation, separation, or changes in thermal properties over time. Ensuring consistent performance throughout the operational life of the system is essential for practical applications.

The integration of PCM heat exchangers into existing systems and processes presents both technical and economic challenges. Retrofitting or redesigning thermal management systems to incorporate PCM technology often requires significant investment and may face resistance due to unfamiliarity or perceived risks.

Lastly, the scalability of PCM heat exchanger technology from laboratory prototypes to industrial-scale applications remains a significant challenge. Issues such as uniform PCM distribution, thermal response times, and system control become more complex at larger scales, requiring innovative solutions and extensive engineering efforts.

Addressing these challenges requires interdisciplinary research and development efforts, combining materials science, thermal engineering, and system design to create more efficient, reliable, and cost-effective PCM heat exchanger solutions.

Another critical challenge is the containment and encapsulation of PCMs. As these materials transition between solid and liquid states, they often experience volume changes that can lead to leakage or damage to the heat exchanger structure. Developing robust and cost-effective encapsulation methods that can withstand repeated phase transitions while maintaining thermal performance is an ongoing area of research.

The selection of appropriate PCM for specific applications presents another hurdle. Different PCMs have varying melting temperatures, latent heat capacities, and chemical properties. Matching these characteristics to the requirements of a particular thermal management system is crucial but complex, often requiring extensive testing and optimization.

Heat exchanger geometry and design also pose significant challenges. Optimizing the surface area for heat transfer while managing pressure drop and flow distribution is a delicate balance. Traditional heat exchanger designs may not be suitable for PCM applications, necessitating innovative approaches to maximize thermal contact between the PCM and the heat transfer fluid.

Thermal cycling and long-term stability of PCMs in heat exchangers are additional concerns. Repeated phase changes can lead to material degradation, separation, or changes in thermal properties over time. Ensuring consistent performance throughout the operational life of the system is essential for practical applications.

The integration of PCM heat exchangers into existing systems and processes presents both technical and economic challenges. Retrofitting or redesigning thermal management systems to incorporate PCM technology often requires significant investment and may face resistance due to unfamiliarity or perceived risks.

Lastly, the scalability of PCM heat exchanger technology from laboratory prototypes to industrial-scale applications remains a significant challenge. Issues such as uniform PCM distribution, thermal response times, and system control become more complex at larger scales, requiring innovative solutions and extensive engineering efforts.

Addressing these challenges requires interdisciplinary research and development efforts, combining materials science, thermal engineering, and system design to create more efficient, reliable, and cost-effective PCM heat exchanger solutions.

Existing PCM Heat Exchanger Design Solutions

01 PCM selection and properties

The choice of Phase Change Material (PCM) is crucial in heat exchanger design. Factors to consider include melting point, latent heat of fusion, thermal conductivity, and stability. The PCM should have a phase transition temperature suitable for the application and high latent heat to maximize energy storage capacity.- PCM selection and properties: The choice of Phase Change Material (PCM) is crucial in heat exchanger design. Key properties to consider include melting point, latent heat of fusion, thermal conductivity, and stability. The PCM should be selected based on the specific application temperature range and desired thermal storage capacity.

- Heat transfer enhancement techniques: Various methods can be employed to improve heat transfer in PCM heat exchangers. These include the use of fins, metal foams, encapsulation of PCM, and the incorporation of high thermal conductivity materials. Such techniques aim to overcome the inherently low thermal conductivity of most PCMs and enhance overall system efficiency.

- Geometric design considerations: The geometry of the heat exchanger plays a significant role in its performance. Factors such as the shape of the PCM container, arrangement of heat transfer tubes, and overall exchanger configuration affect the melting and solidification processes. Optimizing these parameters can lead to improved heat transfer rates and system efficiency.

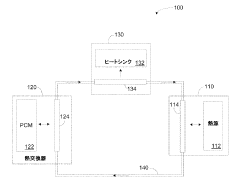

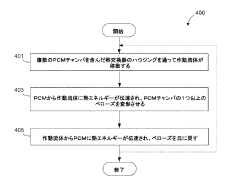

- System integration and control: Effective integration of PCM heat exchangers into larger systems requires careful consideration of control strategies, flow rates, and operating conditions. Proper system design ensures optimal utilization of the PCM's thermal storage capacity and efficient heat transfer to and from the working fluid.

- Performance evaluation and modeling: Accurate modeling and performance evaluation are essential for optimizing PCM heat exchanger designs. This includes computational fluid dynamics (CFD) simulations, experimental validation, and the development of predictive models. These tools help in understanding the complex heat transfer processes and guide the design of more efficient systems.

02 Heat transfer enhancement techniques

Various methods can be employed to improve heat transfer in PCM heat exchangers. These include using fins, metal foams, or encapsulation to increase surface area, incorporating high thermal conductivity materials, and optimizing flow patterns to enhance convection.Expand Specific Solutions03 Geometric design considerations

The geometry of the heat exchanger significantly impacts its performance. Key parameters include the shape and size of PCM containers, arrangement of heat transfer tubes or plates, and overall exchanger configuration. Optimizing these factors can lead to improved heat transfer rates and system efficiency.Expand Specific Solutions04 System integration and control

Effective integration of PCM heat exchangers into larger systems requires careful consideration of operational parameters. This includes designing appropriate control strategies, managing flow rates, and optimizing charging and discharging cycles to maximize energy storage and retrieval efficiency.Expand Specific Solutions05 Thermal cycling and long-term performance

Design parameters must account for the effects of repeated thermal cycling on PCM and heat exchanger components. Considerations include material degradation, potential leakage, and maintaining consistent performance over time. Strategies to mitigate these issues and ensure long-term reliability are essential in the design process.Expand Specific Solutions

Key Players in PCM Heat Exchanger Industry

The development of PCM heat exchangers is in a growth phase, with increasing market demand driven by energy efficiency needs. The global market for thermal energy storage, including PCM technologies, is projected to reach significant size in the coming years. Technologically, PCM heat exchangers are advancing but still face challenges in optimizing performance and long-term stability. Companies like Sunamp, SABIC, and Celanese are at the forefront, developing innovative PCM materials and encapsulation techniques. Academic institutions such as MIT, IIT Bombay, and Xi'an Jiaotong University are contributing fundamental research. Collaboration between industry and academia is accelerating progress in key areas like foam-based designs and novel encapsulation methods to enhance heat transfer and system integration.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced PCM heat exchanger designs utilizing nanostructured materials. Their approach focuses on enhancing thermal conductivity and heat transfer rates through the incorporation of carbon nanotubes and graphene into PCM matrices[1]. This nanocomposite PCM system significantly improves thermal management efficiency, with reported heat transfer rate increases of up to 200% compared to conventional PCMs[3]. MIT researchers have also explored novel encapsulation techniques, including microencapsulation with polymer shells, which allows for better thermal cycling stability and prevents leakage during phase transitions[5]. Additionally, they have investigated the use of metal foams as supporting structures for PCMs, optimizing pore size and distribution to maximize heat transfer while maintaining structural integrity[2].

Strengths: Cutting-edge nanostructured materials, superior thermal conductivity, improved heat transfer rates, and innovative encapsulation techniques. Weaknesses: Potentially high production costs and scalability challenges for nanocomposite materials.

Sunamp Ltd.

Technical Solution: Sunamp has pioneered the development of compact, high-density PCM heat exchangers for residential and commercial applications. Their proprietary PCM formulations, known as "heat batteries," utilize salt-based eutectics that offer high energy storage density and excellent thermal cycling stability[4]. Sunamp's heat exchangers incorporate advanced heat transfer surfaces, such as finned tube designs and plate heat exchangers, to optimize thermal conductivity and energy transfer rates. The company has also developed innovative encapsulation methods that allow for modular, scalable PCM units that can be easily integrated into existing HVAC systems[6]. Sunamp's PCM heat exchangers have demonstrated energy savings of up to 50% in domestic hot water applications and have a lifespan of over 40,000 thermal cycles without degradation[7].

Strengths: High energy storage density, excellent thermal cycling stability, modular design for easy integration, and proven energy savings. Weaknesses: Limited to specific temperature ranges based on PCM formulations, potentially higher initial costs compared to traditional systems.

Core Innovations in PCM Heat Exchanger Technology

Thermal storage heat exchanger structures employing phase change materials

PatentActiveJP2021036195A

Innovation

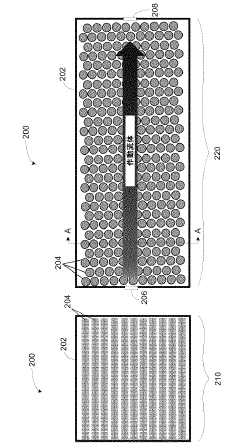

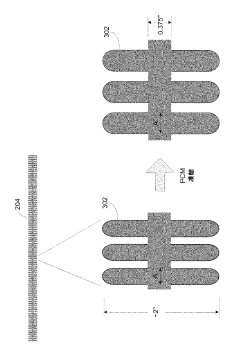

- The use of ice/water as a PCM in heat exchangers with expandable bellows in the chamber walls to accommodate expansion, enhancing thermal conductivity and energy density, and incorporating flexible corrugated metal bellows to maintain effective heat transfer.

Phase change materials, heat exchangers and associated thermal batteries

PatentWO2024243609A1

Innovation

- A PCM formulation comprising 35% to 60% inorganic salt, 1% to 9% nucleating agent, 1% to 4% thickening agent, and 30% to 66% water, with a phase change temperature between 3°C and 26°C, and a HEX design with offset fluid flow paths to induce turbulence, enhancing heat transfer efficiency in thermal batteries.

Thermal Performance Optimization Strategies

Optimizing the thermal performance of PCM heat exchangers is crucial for maximizing their efficiency and effectiveness. One key strategy involves enhancing heat transfer rates through the use of extended surfaces or fins. These structures increase the contact area between the PCM and the heat transfer fluid, facilitating more rapid and efficient energy exchange. The design and arrangement of fins can be tailored to specific applications, considering factors such as fin spacing, thickness, and material conductivity.

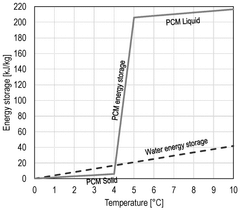

Another important approach is the incorporation of high thermal conductivity materials or additives within the PCM itself. This can be achieved through the use of metal foams, graphite matrices, or nanoparticles dispersed throughout the phase change material. These additions create thermal networks that significantly improve heat distribution and reduce thermal resistance within the PCM, leading to faster charging and discharging cycles.

Encapsulation techniques also play a vital role in thermal performance optimization. By encapsulating the PCM in small capsules or containers, the surface area-to-volume ratio is increased, promoting faster heat transfer. Additionally, encapsulation can help maintain the structural integrity of the PCM and prevent leakage during phase transitions. The selection of appropriate encapsulation materials and methods is critical, as they must be compatible with the PCM and able to withstand repeated thermal cycling.

The design of the heat exchanger geometry is another crucial factor in optimizing thermal performance. Innovative configurations such as shell-and-tube, plate, or compact heat exchangers can be employed to maximize heat transfer efficiency while minimizing pressure drop and pumping power requirements. The arrangement of PCM modules within the heat exchanger can also be optimized to ensure uniform temperature distribution and prevent localized overheating or subcooling.

Furthermore, the implementation of advanced control strategies can significantly enhance the overall thermal performance of PCM heat exchangers. This may include the use of variable flow rates, adaptive temperature setpoints, or predictive algorithms that anticipate thermal loads and adjust system parameters accordingly. Such intelligent control systems can optimize the charging and discharging cycles, ensuring that the PCM is utilized to its full potential while minimizing energy waste.

Another important approach is the incorporation of high thermal conductivity materials or additives within the PCM itself. This can be achieved through the use of metal foams, graphite matrices, or nanoparticles dispersed throughout the phase change material. These additions create thermal networks that significantly improve heat distribution and reduce thermal resistance within the PCM, leading to faster charging and discharging cycles.

Encapsulation techniques also play a vital role in thermal performance optimization. By encapsulating the PCM in small capsules or containers, the surface area-to-volume ratio is increased, promoting faster heat transfer. Additionally, encapsulation can help maintain the structural integrity of the PCM and prevent leakage during phase transitions. The selection of appropriate encapsulation materials and methods is critical, as they must be compatible with the PCM and able to withstand repeated thermal cycling.

The design of the heat exchanger geometry is another crucial factor in optimizing thermal performance. Innovative configurations such as shell-and-tube, plate, or compact heat exchangers can be employed to maximize heat transfer efficiency while minimizing pressure drop and pumping power requirements. The arrangement of PCM modules within the heat exchanger can also be optimized to ensure uniform temperature distribution and prevent localized overheating or subcooling.

Furthermore, the implementation of advanced control strategies can significantly enhance the overall thermal performance of PCM heat exchangers. This may include the use of variable flow rates, adaptive temperature setpoints, or predictive algorithms that anticipate thermal loads and adjust system parameters accordingly. Such intelligent control systems can optimize the charging and discharging cycles, ensuring that the PCM is utilized to its full potential while minimizing energy waste.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of PCM heat exchangers are crucial aspects that must be addressed in their design and implementation. These systems offer significant potential for energy efficiency and thermal management, but their environmental footprint must be carefully evaluated throughout their lifecycle.

PCM heat exchangers can contribute to sustainability by reducing energy consumption in various applications, such as building cooling and industrial processes. By storing and releasing thermal energy, they can help balance peak loads and minimize the need for additional energy generation. This can lead to reduced greenhouse gas emissions and a lower overall carbon footprint for the systems they support.

However, the production and disposal of PCM materials and heat exchanger components must be considered. Many PCMs are derived from petroleum-based products, which raises concerns about resource depletion and end-of-life disposal. To mitigate these issues, research into bio-based PCMs and recyclable encapsulation materials is ongoing. These alternatives could significantly reduce the environmental impact of PCM heat exchangers.

The choice of encapsulation materials and methods also plays a crucial role in the environmental profile of PCM heat exchangers. Metallic encapsulations, while durable, may have higher embodied energy and be more challenging to recycle. In contrast, polymeric encapsulations might offer easier recycling options but may have shorter lifespans. Balancing these factors is essential for optimizing the overall sustainability of the system.

Foam-based PCM heat exchangers present unique environmental considerations. While they can enhance heat transfer efficiency, the production of certain foams may involve environmentally harmful blowing agents. Selecting eco-friendly foam materials and manufacturing processes is vital to minimize negative environmental impacts.

The longevity and maintenance requirements of PCM heat exchangers are also important sustainability factors. Designs that prioritize durability and ease of maintenance can extend the operational life of these systems, reducing the need for frequent replacements and the associated resource consumption.

Water usage is another critical environmental consideration, particularly in applications where PCM heat exchangers interface with water-based cooling systems. Designs that minimize water consumption and incorporate water recycling features can significantly enhance the sustainability profile of these systems.

In conclusion, while PCM heat exchangers offer promising benefits for energy efficiency, their design must carefully balance performance with environmental impact. Ongoing research and innovation in materials, encapsulation techniques, and system integration are essential to maximize the sustainability potential of these technologies.

PCM heat exchangers can contribute to sustainability by reducing energy consumption in various applications, such as building cooling and industrial processes. By storing and releasing thermal energy, they can help balance peak loads and minimize the need for additional energy generation. This can lead to reduced greenhouse gas emissions and a lower overall carbon footprint for the systems they support.

However, the production and disposal of PCM materials and heat exchanger components must be considered. Many PCMs are derived from petroleum-based products, which raises concerns about resource depletion and end-of-life disposal. To mitigate these issues, research into bio-based PCMs and recyclable encapsulation materials is ongoing. These alternatives could significantly reduce the environmental impact of PCM heat exchangers.

The choice of encapsulation materials and methods also plays a crucial role in the environmental profile of PCM heat exchangers. Metallic encapsulations, while durable, may have higher embodied energy and be more challenging to recycle. In contrast, polymeric encapsulations might offer easier recycling options but may have shorter lifespans. Balancing these factors is essential for optimizing the overall sustainability of the system.

Foam-based PCM heat exchangers present unique environmental considerations. While they can enhance heat transfer efficiency, the production of certain foams may involve environmentally harmful blowing agents. Selecting eco-friendly foam materials and manufacturing processes is vital to minimize negative environmental impacts.

The longevity and maintenance requirements of PCM heat exchangers are also important sustainability factors. Designs that prioritize durability and ease of maintenance can extend the operational life of these systems, reducing the need for frequent replacements and the associated resource consumption.

Water usage is another critical environmental consideration, particularly in applications where PCM heat exchangers interface with water-based cooling systems. Designs that minimize water consumption and incorporate water recycling features can significantly enhance the sustainability profile of these systems.

In conclusion, while PCM heat exchangers offer promising benefits for energy efficiency, their design must carefully balance performance with environmental impact. Ongoing research and innovation in materials, encapsulation techniques, and system integration are essential to maximize the sustainability potential of these technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!