Salt Hydrates vs Paraffins: PCM Selection Guide for High-Temperature Industrial Use

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Evolution and Goals

Phase Change Materials (PCMs) have undergone significant evolution since their initial discovery and application. The journey of PCMs began with simple ice-based systems and has progressed to sophisticated engineered materials capable of precise temperature control in various industrial settings. Early PCMs were primarily focused on low-temperature applications, but as industrial needs expanded, so did the range of PCM operating temperatures.

The development of salt hydrates and paraffins as high-temperature PCMs marks a crucial milestone in this evolution. Salt hydrates, known for their high latent heat and thermal conductivity, emerged as promising candidates for industrial applications requiring temperatures above 100°C. Concurrently, paraffins gained attention due to their chemical stability and wide range of melting temperatures, making them suitable for diverse high-temperature scenarios.

The goals driving PCM evolution for high-temperature industrial use are multifaceted. Primarily, there is a push for materials with higher energy storage density, allowing for more compact and efficient thermal management systems. This is particularly crucial in space-constrained industrial environments where every cubic meter counts. Additionally, researchers aim to develop PCMs with improved thermal conductivity to enhance heat transfer rates, a critical factor in rapid thermal cycling applications.

Another key objective is to increase the operational temperature range of PCMs. While current high-temperature PCMs like certain salt hydrates can operate effectively up to 120°C, there is a growing demand for materials that can function reliably at even higher temperatures, potentially up to 200°C or beyond. This expansion would open up new possibilities in sectors such as concentrated solar power, high-temperature process industries, and advanced manufacturing.

Longevity and cycling stability represent another frontier in PCM development. The goal is to create materials that can withstand thousands of phase change cycles without significant degradation in performance. This is especially important in industrial settings where continuous operation and minimal maintenance are paramount.

Safety and environmental compatibility are also at the forefront of PCM evolution. There is a concerted effort to develop non-toxic, non-corrosive PCMs that pose minimal risk in case of leakage or system failure. This goal aligns with broader industrial trends towards sustainable and environmentally friendly technologies.

As the field progresses, there is an increasing focus on tailoring PCMs for specific industrial applications. This involves not just optimizing thermal properties but also considering factors like chemical compatibility with containment materials, ease of integration into existing systems, and cost-effectiveness at scale. The ultimate goal is to create a diverse palette of high-temperature PCMs that can be precisely matched to the unique requirements of different industrial processes, enhancing energy efficiency and process control across a wide range of sectors.

The development of salt hydrates and paraffins as high-temperature PCMs marks a crucial milestone in this evolution. Salt hydrates, known for their high latent heat and thermal conductivity, emerged as promising candidates for industrial applications requiring temperatures above 100°C. Concurrently, paraffins gained attention due to their chemical stability and wide range of melting temperatures, making them suitable for diverse high-temperature scenarios.

The goals driving PCM evolution for high-temperature industrial use are multifaceted. Primarily, there is a push for materials with higher energy storage density, allowing for more compact and efficient thermal management systems. This is particularly crucial in space-constrained industrial environments where every cubic meter counts. Additionally, researchers aim to develop PCMs with improved thermal conductivity to enhance heat transfer rates, a critical factor in rapid thermal cycling applications.

Another key objective is to increase the operational temperature range of PCMs. While current high-temperature PCMs like certain salt hydrates can operate effectively up to 120°C, there is a growing demand for materials that can function reliably at even higher temperatures, potentially up to 200°C or beyond. This expansion would open up new possibilities in sectors such as concentrated solar power, high-temperature process industries, and advanced manufacturing.

Longevity and cycling stability represent another frontier in PCM development. The goal is to create materials that can withstand thousands of phase change cycles without significant degradation in performance. This is especially important in industrial settings where continuous operation and minimal maintenance are paramount.

Safety and environmental compatibility are also at the forefront of PCM evolution. There is a concerted effort to develop non-toxic, non-corrosive PCMs that pose minimal risk in case of leakage or system failure. This goal aligns with broader industrial trends towards sustainable and environmentally friendly technologies.

As the field progresses, there is an increasing focus on tailoring PCMs for specific industrial applications. This involves not just optimizing thermal properties but also considering factors like chemical compatibility with containment materials, ease of integration into existing systems, and cost-effectiveness at scale. The ultimate goal is to create a diverse palette of high-temperature PCMs that can be precisely matched to the unique requirements of different industrial processes, enhancing energy efficiency and process control across a wide range of sectors.

Industrial Demand Analysis

The industrial demand for high-temperature Phase Change Materials (PCMs) has been steadily increasing across various sectors, driven by the need for efficient thermal energy storage and management solutions. Industries such as concentrated solar power, waste heat recovery, and high-temperature process industries are particularly interested in PCMs that can operate at temperatures above 100°C.

Salt hydrates and paraffins are two prominent categories of PCMs that have garnered significant attention for high-temperature industrial applications. The market for these materials is expected to grow substantially in the coming years, with projections indicating a compound annual growth rate (CAGR) of over 20% for the PCM market as a whole.

In the concentrated solar power sector, there is a pressing demand for PCMs that can store thermal energy at temperatures ranging from 300°C to 400°C. This requirement stems from the industry's push towards higher efficiency and lower costs in solar thermal energy storage systems. Salt hydrates, particularly those based on nitrates and chlorides, are being extensively researched for this purpose due to their high energy density and relatively low cost.

The waste heat recovery industry is another significant driver of demand for high-temperature PCMs. With increasing focus on energy efficiency and sustainability, industries are looking to capture and reuse waste heat from various processes. PCMs that can operate in the range of 100°C to 300°C are particularly sought after for applications in steel, cement, and glass manufacturing.

Paraffins, while traditionally used for lower temperature applications, are also seeing increased demand for high-temperature use. This is due to their chemical stability and non-corrosive nature, which makes them attractive for certain industrial processes where material compatibility is a critical concern.

The automotive industry is emerging as a new frontier for high-temperature PCMs, particularly in electric vehicle battery thermal management systems. As battery technologies evolve and charging speeds increase, there is a growing need for PCMs that can effectively manage the high temperatures generated during rapid charging cycles.

Geographically, the demand for high-temperature PCMs is most pronounced in regions with a strong industrial base and a focus on renewable energy. Europe and North America are leading in terms of research and development, while Asia-Pacific is showing rapid growth in adoption, particularly in countries like China and India where industrial expansion and renewable energy projects are booming.

Salt hydrates and paraffins are two prominent categories of PCMs that have garnered significant attention for high-temperature industrial applications. The market for these materials is expected to grow substantially in the coming years, with projections indicating a compound annual growth rate (CAGR) of over 20% for the PCM market as a whole.

In the concentrated solar power sector, there is a pressing demand for PCMs that can store thermal energy at temperatures ranging from 300°C to 400°C. This requirement stems from the industry's push towards higher efficiency and lower costs in solar thermal energy storage systems. Salt hydrates, particularly those based on nitrates and chlorides, are being extensively researched for this purpose due to their high energy density and relatively low cost.

The waste heat recovery industry is another significant driver of demand for high-temperature PCMs. With increasing focus on energy efficiency and sustainability, industries are looking to capture and reuse waste heat from various processes. PCMs that can operate in the range of 100°C to 300°C are particularly sought after for applications in steel, cement, and glass manufacturing.

Paraffins, while traditionally used for lower temperature applications, are also seeing increased demand for high-temperature use. This is due to their chemical stability and non-corrosive nature, which makes them attractive for certain industrial processes where material compatibility is a critical concern.

The automotive industry is emerging as a new frontier for high-temperature PCMs, particularly in electric vehicle battery thermal management systems. As battery technologies evolve and charging speeds increase, there is a growing need for PCMs that can effectively manage the high temperatures generated during rapid charging cycles.

Geographically, the demand for high-temperature PCMs is most pronounced in regions with a strong industrial base and a focus on renewable energy. Europe and North America are leading in terms of research and development, while Asia-Pacific is showing rapid growth in adoption, particularly in countries like China and India where industrial expansion and renewable energy projects are booming.

PCM Challenges in Industry

Phase Change Materials (PCMs) have gained significant attention in industrial applications due to their ability to store and release large amounts of thermal energy. However, their implementation in high-temperature industrial settings faces several challenges that need to be addressed for widespread adoption.

One of the primary challenges is the selection of appropriate PCMs for specific industrial processes. Salt hydrates and paraffins, two common types of PCMs, each have their own set of advantages and limitations. Salt hydrates offer higher latent heat storage capacity and thermal conductivity, making them attractive for high-temperature applications. However, they often suffer from phase segregation and supercooling, which can reduce their long-term performance and reliability. Paraffins, on the other hand, exhibit excellent thermal stability and cycling behavior but have lower thermal conductivity and energy storage density compared to salt hydrates.

The containment of PCMs presents another significant challenge, particularly in high-temperature industrial environments. The corrosive nature of some salt hydrates can lead to degradation of containment materials over time, potentially causing leaks and reducing system efficiency. Paraffins, while less corrosive, may require specialized containment solutions to prevent leakage during the liquid phase. Developing cost-effective and durable containment systems that can withstand repeated thermal cycling and maintain their integrity over extended periods is crucial for the successful implementation of PCMs in industrial settings.

Thermal management and heat transfer optimization pose additional challenges in PCM applications. The relatively low thermal conductivity of many PCMs, especially paraffins, can limit the rate of heat absorption and release, potentially reducing the overall efficiency of thermal energy storage systems. Enhancing heat transfer through the use of extended surfaces, metal foams, or nanoparticle additives is an active area of research, but scaling these solutions for industrial use while maintaining cost-effectiveness remains a challenge.

The integration of PCM-based thermal energy storage systems into existing industrial processes also presents logistical and engineering challenges. Retrofitting existing facilities to incorporate PCM systems may require significant modifications to process equipment and control systems. Additionally, optimizing the sizing and placement of PCM units to maximize energy efficiency while minimizing disruption to existing operations requires careful analysis and design considerations.

Lastly, the long-term stability and performance of PCMs under industrial operating conditions remain areas of concern. Repeated thermal cycling, exposure to contaminants, and potential chemical degradation can affect the thermal properties and lifespan of PCMs. Developing robust prediction models and accelerated testing methodologies to assess the long-term performance of PCMs in industrial environments is essential for building confidence in their reliability and effectiveness.

One of the primary challenges is the selection of appropriate PCMs for specific industrial processes. Salt hydrates and paraffins, two common types of PCMs, each have their own set of advantages and limitations. Salt hydrates offer higher latent heat storage capacity and thermal conductivity, making them attractive for high-temperature applications. However, they often suffer from phase segregation and supercooling, which can reduce their long-term performance and reliability. Paraffins, on the other hand, exhibit excellent thermal stability and cycling behavior but have lower thermal conductivity and energy storage density compared to salt hydrates.

The containment of PCMs presents another significant challenge, particularly in high-temperature industrial environments. The corrosive nature of some salt hydrates can lead to degradation of containment materials over time, potentially causing leaks and reducing system efficiency. Paraffins, while less corrosive, may require specialized containment solutions to prevent leakage during the liquid phase. Developing cost-effective and durable containment systems that can withstand repeated thermal cycling and maintain their integrity over extended periods is crucial for the successful implementation of PCMs in industrial settings.

Thermal management and heat transfer optimization pose additional challenges in PCM applications. The relatively low thermal conductivity of many PCMs, especially paraffins, can limit the rate of heat absorption and release, potentially reducing the overall efficiency of thermal energy storage systems. Enhancing heat transfer through the use of extended surfaces, metal foams, or nanoparticle additives is an active area of research, but scaling these solutions for industrial use while maintaining cost-effectiveness remains a challenge.

The integration of PCM-based thermal energy storage systems into existing industrial processes also presents logistical and engineering challenges. Retrofitting existing facilities to incorporate PCM systems may require significant modifications to process equipment and control systems. Additionally, optimizing the sizing and placement of PCM units to maximize energy efficiency while minimizing disruption to existing operations requires careful analysis and design considerations.

Lastly, the long-term stability and performance of PCMs under industrial operating conditions remain areas of concern. Repeated thermal cycling, exposure to contaminants, and potential chemical degradation can affect the thermal properties and lifespan of PCMs. Developing robust prediction models and accelerated testing methodologies to assess the long-term performance of PCMs in industrial environments is essential for building confidence in their reliability and effectiveness.

Salt Hydrate vs Paraffin

01 Composition and properties of PCMs

Phase Change Materials (PCMs) are substances that absorb or release heat during phase transitions. They are characterized by their ability to store and release large amounts of latent heat at a nearly constant temperature. PCMs can be organic, inorganic, or eutectic mixtures, each with specific melting points and heat storage capacities. The selection of PCMs depends on the desired temperature range and application requirements.- Composition and properties of PCMs: Phase Change Materials (PCMs) are substances that absorb or release large amounts of latent heat during phase transitions. They are characterized by their ability to store and release thermal energy at specific temperature ranges. PCMs can be organic, inorganic, or eutectic mixtures, each with unique properties suitable for various applications in thermal management and energy storage.

- Applications of PCMs in energy storage: PCMs are widely used in energy storage systems due to their high energy density and isothermal behavior during phase transitions. They can be incorporated into building materials for passive temperature regulation, used in solar thermal systems for heat storage, and integrated into electronic devices for thermal management. PCMs also find applications in textiles, packaging, and transportation for temperature control.

- Encapsulation techniques for PCMs: Encapsulation of PCMs is crucial for their effective implementation in various applications. Microencapsulation and macroencapsulation techniques are used to contain PCMs within a protective shell, preventing leakage and improving thermal conductivity. These encapsulated PCMs can be easily integrated into different matrices and materials without compromising their phase change properties.

- Novel PCM composites and nanocomposites: Research in PCMs focuses on developing novel composites and nanocomposites to enhance their thermal properties and overcome limitations such as low thermal conductivity. Incorporation of nanoparticles, carbon-based materials, and metal foams into PCMs can significantly improve heat transfer rates and overall thermal performance. These advanced PCM composites offer improved energy storage capacity and faster charging/discharging rates.

- Integration of PCMs in smart thermal management systems: PCMs are being integrated into smart thermal management systems for dynamic temperature control in various applications. These systems combine PCMs with sensors, actuators, and control algorithms to optimize energy storage and release based on environmental conditions and user requirements. Smart PCM-based systems are being developed for applications in buildings, electronics cooling, and renewable energy integration.

02 Applications of PCMs in energy storage

PCMs are widely used in thermal energy storage systems for various applications. They can be incorporated into building materials for passive temperature regulation, used in solar thermal systems to store excess heat, and employed in electronic devices for thermal management. PCMs also find applications in textiles for temperature-regulating clothing and in transportation for maintaining cargo temperatures.Expand Specific Solutions03 Encapsulation techniques for PCMs

To improve the stability and handling of PCMs, various encapsulation techniques are employed. Microencapsulation involves enclosing PCM droplets within a shell material, while macroencapsulation uses larger containers. These methods prevent leakage, improve heat transfer, and allow for easier integration of PCMs into different systems. The choice of encapsulation method depends on the specific application and desired properties.Expand Specific Solutions04 PCM composites and enhanced materials

Research focuses on developing PCM composites and enhanced materials to improve their performance. This includes incorporating PCMs into polymers, ceramics, or other matrices to create form-stable composites. Additionally, the use of nanoparticles or carbon-based materials can enhance the thermal conductivity of PCMs, improving their heat transfer characteristics. These advancements aim to overcome limitations such as low thermal conductivity and phase segregation.Expand Specific Solutions05 Novel PCM synthesis and characterization

Ongoing research explores novel PCM synthesis methods and characterization techniques. This includes developing new PCM formulations with improved properties, such as supercooling suppression or enhanced cycling stability. Advanced characterization methods, such as differential scanning calorimetry and thermal conductivity measurements, are used to evaluate PCM performance. These efforts aim to expand the range of available PCMs and optimize their properties for specific applications.Expand Specific Solutions

Key PCM Manufacturers

The market for high-temperature phase change materials (PCMs) in industrial applications is in a growth phase, with increasing demand driven by energy efficiency and thermal management needs. The global PCM market size is projected to reach several billion dollars by 2025, with a compound annual growth rate of over 15%. Technological maturity varies between salt hydrates and paraffins, with companies like PureTemp.com, Sunamp Ltd., and Stepan Co. leading innovation in PCM formulations. Research institutions such as Nanyang Technological University and Colorado State University are advancing PCM science, while industrial players like Robert Bosch GmbH and IBM are exploring applications. The competitive landscape is diverse, with specialized PCM manufacturers, chemical companies, and technology integrators vying for market share in this rapidly evolving field.

PureTemp.com

Technical Solution: PureTemp.com specializes in bio-based phase change materials (PCMs) for thermal energy storage. Their technology focuses on developing salt hydrate PCMs for high-temperature industrial applications. These salt hydrates offer high latent heat storage capacity, typically ranging from 180-250 J/g[1]. PureTemp's salt hydrate PCMs are engineered to have melting points between 80°C and 120°C, making them suitable for industrial processes requiring high-temperature thermal management[2]. The company employs proprietary nucleating agents and thickeners to enhance the stability and cycling performance of their salt hydrate PCMs, addressing common issues such as phase separation and supercooling[3].

Strengths: High thermal storage density, non-flammable, relatively low cost. Weaknesses: Potential for corrosion, phase separation over multiple cycles, and supercooling effects.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed innovative PCM solutions for high-temperature industrial applications, focusing on both salt hydrates and paraffins. Their approach involves microencapsulation technology for paraffin-based PCMs, allowing for stable operation at temperatures up to 180°C[1]. For salt hydrates, Bosch has patented a composite PCM system that combines multiple salt hydrates with different melting points, creating a cascading thermal storage effect[2]. This system can operate efficiently between 80°C and 150°C, providing a more consistent heat release profile. Bosch's PCMs are integrated into their industrial heat recovery systems, improving energy efficiency in manufacturing processes by up to 30%[3].

Strengths: Wide temperature range coverage, enhanced thermal stability through composite systems, integration with existing industrial processes. Weaknesses: Complex system design, potentially higher implementation costs.

PCM Innovations Review

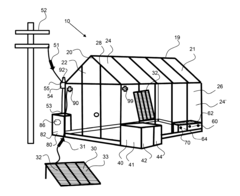

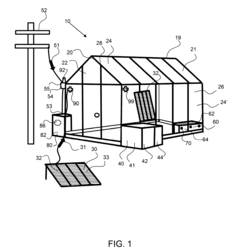

Enclosure Temperature Control System

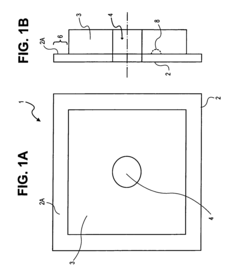

PatentActiveUS20170013789A1

Innovation

- A temperature control system utilizing renewable power sources, such as solar panels, combined with phase change materials to store and release heat, allowing for reduced or zero net power draw from the grid by using excess renewable energy generated during the day to power HVAC systems and storing heat for nighttime use.

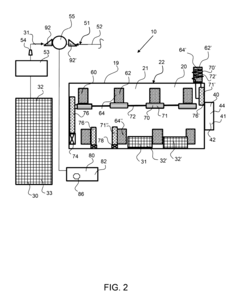

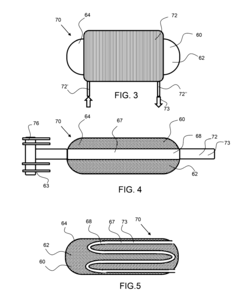

Latent heat storage devices

PatentInactiveUS8171984B2

Innovation

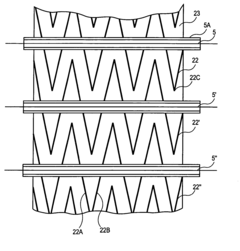

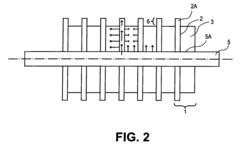

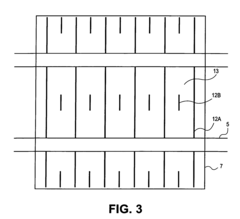

- Incorporating sheets of graphite foil within the phase change material to facilitate directional heat conduction, with a low volume fraction of graphite foil, allowing for efficient heat transfer while minimizing material usage and manufacturing complexity.

Environmental Impact

The environmental impact of Phase Change Materials (PCMs) is a critical consideration in their selection for high-temperature industrial applications. Salt hydrates and paraffins, two prominent types of PCMs, exhibit distinct environmental profiles that merit careful evaluation.

Salt hydrates, being inorganic compounds, generally have a lower environmental footprint in terms of production and disposal. They are often derived from naturally occurring minerals, which can be extracted with relatively low energy inputs. The production process for salt hydrates typically involves fewer synthetic steps compared to paraffins, potentially reducing the overall carbon emissions associated with their manufacture.

However, the environmental advantages of salt hydrates are not without caveats. Some salt hydrates may contain heavy metals or other potentially harmful elements, which could pose risks if released into the environment. Proper containment and disposal protocols are essential to mitigate these risks. Additionally, the corrosive nature of some salt hydrates may lead to increased wear on containment materials, potentially resulting in more frequent replacements and associated environmental costs.

Paraffins, on the other hand, are derived from petroleum, a non-renewable resource. Their production process is more energy-intensive and contributes to greenhouse gas emissions. The reliance on fossil fuels for paraffin production raises concerns about long-term sustainability and aligns less favorably with global efforts to reduce carbon footprints.

Nevertheless, paraffins offer certain environmental benefits in their application. They are generally non-toxic and do not pose significant risks to soil or water systems if accidentally released. This characteristic can be particularly advantageous in scenarios where containment failure is a possibility.

The end-of-life considerations for both materials also differ. Salt hydrates may be more readily recyclable or repurposed, potentially contributing to a more circular economy. Paraffins, while not as easily recycled, can often be incinerated for energy recovery, though this process does release carbon dioxide.

In high-temperature industrial applications, the longevity and stability of the PCM become crucial factors in assessing environmental impact. Materials that maintain their performance over extended periods reduce the need for frequent replacements, thereby minimizing waste generation and resource consumption. Both salt hydrates and paraffins can be engineered for long-term stability, but their performance in this regard can vary significantly based on specific formulations and application conditions.

Ultimately, the environmental impact assessment of salt hydrates versus paraffins in high-temperature industrial applications must consider the entire lifecycle of the materials, from production through application to disposal or recycling. This holistic approach ensures a comprehensive understanding of the environmental trade-offs associated with each option, enabling informed decision-making that aligns with both industrial needs and environmental stewardship goals.

Salt hydrates, being inorganic compounds, generally have a lower environmental footprint in terms of production and disposal. They are often derived from naturally occurring minerals, which can be extracted with relatively low energy inputs. The production process for salt hydrates typically involves fewer synthetic steps compared to paraffins, potentially reducing the overall carbon emissions associated with their manufacture.

However, the environmental advantages of salt hydrates are not without caveats. Some salt hydrates may contain heavy metals or other potentially harmful elements, which could pose risks if released into the environment. Proper containment and disposal protocols are essential to mitigate these risks. Additionally, the corrosive nature of some salt hydrates may lead to increased wear on containment materials, potentially resulting in more frequent replacements and associated environmental costs.

Paraffins, on the other hand, are derived from petroleum, a non-renewable resource. Their production process is more energy-intensive and contributes to greenhouse gas emissions. The reliance on fossil fuels for paraffin production raises concerns about long-term sustainability and aligns less favorably with global efforts to reduce carbon footprints.

Nevertheless, paraffins offer certain environmental benefits in their application. They are generally non-toxic and do not pose significant risks to soil or water systems if accidentally released. This characteristic can be particularly advantageous in scenarios where containment failure is a possibility.

The end-of-life considerations for both materials also differ. Salt hydrates may be more readily recyclable or repurposed, potentially contributing to a more circular economy. Paraffins, while not as easily recycled, can often be incinerated for energy recovery, though this process does release carbon dioxide.

In high-temperature industrial applications, the longevity and stability of the PCM become crucial factors in assessing environmental impact. Materials that maintain their performance over extended periods reduce the need for frequent replacements, thereby minimizing waste generation and resource consumption. Both salt hydrates and paraffins can be engineered for long-term stability, but their performance in this regard can vary significantly based on specific formulations and application conditions.

Ultimately, the environmental impact assessment of salt hydrates versus paraffins in high-temperature industrial applications must consider the entire lifecycle of the materials, from production through application to disposal or recycling. This holistic approach ensures a comprehensive understanding of the environmental trade-offs associated with each option, enabling informed decision-making that aligns with both industrial needs and environmental stewardship goals.

Safety and Regulations

When considering the use of Phase Change Materials (PCMs) such as salt hydrates and paraffins for high-temperature industrial applications, safety and regulatory compliance are paramount. The handling, storage, and implementation of these materials are subject to stringent regulations due to their potential hazards and environmental impacts.

For salt hydrates, one of the primary safety concerns is their corrosive nature. Many salt hydrates can react with metals, leading to equipment degradation and potential leaks. This necessitates the use of corrosion-resistant materials in storage and handling systems. Additionally, some salt hydrates may release toxic fumes when heated, requiring proper ventilation and personal protective equipment for workers.

Paraffins, while generally less corrosive, present their own set of safety challenges. Their flammability is a significant concern, especially in high-temperature applications. Proper fire suppression systems and containment measures must be in place to mitigate the risk of fire spread. Furthermore, paraffins can produce harmful vapors when overheated, necessitating adequate ventilation and monitoring systems.

Regulatory bodies such as OSHA in the United States and the European Chemicals Agency (ECHA) have established guidelines for the safe handling and use of PCMs. These regulations often require comprehensive risk assessments, proper labeling, and the implementation of safety data sheets (SDS) for all PCM materials used in industrial settings.

Environmental regulations also play a crucial role in PCM selection and usage. The disposal of spent PCMs, particularly salt hydrates, may be subject to hazardous waste regulations due to their chemical composition. Companies must adhere to local and national environmental protection laws regarding the disposal and potential recycling of these materials.

In the context of high-temperature industrial use, thermal stability regulations are particularly relevant. PCMs must meet specific thermal cycling and long-term stability requirements to ensure safe and efficient operation over extended periods. This often involves rigorous testing and certification processes to verify the material's performance and safety under various temperature conditions.

Transportation of PCMs is another area heavily regulated, especially for international shipments. The International Maritime Dangerous Goods (IMDG) Code and air transport regulations set by the International Air Transport Association (IATA) dictate specific packaging, labeling, and documentation requirements for PCMs classified as hazardous materials.

Compliance with these safety regulations and standards is not only a legal requirement but also a critical factor in ensuring the long-term viability and acceptance of PCM technologies in industrial applications. As such, when selecting between salt hydrates and paraffins for high-temperature use, companies must carefully consider the regulatory landscape and implement robust safety management systems to address all potential risks associated with their chosen PCM.

For salt hydrates, one of the primary safety concerns is their corrosive nature. Many salt hydrates can react with metals, leading to equipment degradation and potential leaks. This necessitates the use of corrosion-resistant materials in storage and handling systems. Additionally, some salt hydrates may release toxic fumes when heated, requiring proper ventilation and personal protective equipment for workers.

Paraffins, while generally less corrosive, present their own set of safety challenges. Their flammability is a significant concern, especially in high-temperature applications. Proper fire suppression systems and containment measures must be in place to mitigate the risk of fire spread. Furthermore, paraffins can produce harmful vapors when overheated, necessitating adequate ventilation and monitoring systems.

Regulatory bodies such as OSHA in the United States and the European Chemicals Agency (ECHA) have established guidelines for the safe handling and use of PCMs. These regulations often require comprehensive risk assessments, proper labeling, and the implementation of safety data sheets (SDS) for all PCM materials used in industrial settings.

Environmental regulations also play a crucial role in PCM selection and usage. The disposal of spent PCMs, particularly salt hydrates, may be subject to hazardous waste regulations due to their chemical composition. Companies must adhere to local and national environmental protection laws regarding the disposal and potential recycling of these materials.

In the context of high-temperature industrial use, thermal stability regulations are particularly relevant. PCMs must meet specific thermal cycling and long-term stability requirements to ensure safe and efficient operation over extended periods. This often involves rigorous testing and certification processes to verify the material's performance and safety under various temperature conditions.

Transportation of PCMs is another area heavily regulated, especially for international shipments. The International Maritime Dangerous Goods (IMDG) Code and air transport regulations set by the International Air Transport Association (IATA) dictate specific packaging, labeling, and documentation requirements for PCMs classified as hazardous materials.

Compliance with these safety regulations and standards is not only a legal requirement but also a critical factor in ensuring the long-term viability and acceptance of PCM technologies in industrial applications. As such, when selecting between salt hydrates and paraffins for high-temperature use, companies must carefully consider the regulatory landscape and implement robust safety management systems to address all potential risks associated with their chosen PCM.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!