Energy Conversion Efficacy in Rail Gun Systems

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Evolution

The evolution of rail gun technology has been marked by significant advancements in energy conversion efficacy over the past several decades. Initially conceived in the early 20th century, rail guns remained largely theoretical until the 1970s when practical experimentation began in earnest. The primary challenge has always been the efficient conversion of electrical energy into kinetic energy for projectile acceleration.

In the 1980s, early prototypes struggled with energy conversion rates below 10%, primarily due to limitations in power supply technology and materials science. The majority of input energy was lost as heat, causing rapid degradation of rail components. This period saw the development of improved power storage systems, including capacitor banks and pulsed power supplies, which allowed for higher current delivery.

The 1990s brought about a shift towards more advanced materials for rail construction. The introduction of composite materials and advanced alloys helped mitigate rail erosion and improved energy transfer efficiency. During this decade, energy conversion rates improved to the 20-30% range, marking a significant leap forward in rail gun viability.

The turn of the millennium saw the integration of sophisticated computer modeling and simulation techniques. These tools allowed engineers to optimize rail geometry, projectile design, and power delivery systems. As a result, by the mid-2000s, some experimental systems were achieving energy conversion efficiencies of up to 40%.

In the 2010s, the focus shifted towards scalability and repeatability. Researchers worked on developing rail guns capable of sustained fire without significant degradation in performance. This period also saw advancements in superconducting materials, which promised to reduce energy losses in the power delivery system.

Recent years have witnessed the exploration of novel energy storage technologies, such as supercapacitors and advanced battery systems, to provide the high-power, rapid discharge capabilities required for rail guns. Additionally, there has been growing interest in hybrid systems that combine electromagnetic acceleration with conventional propellants to achieve higher muzzle velocities and improved overall efficiency.

As of 2023, state-of-the-art rail gun systems are reported to achieve energy conversion efficiencies of up to 50-60% under optimal conditions. However, challenges remain in maintaining this level of performance over extended periods and in scaling the technology for various applications beyond experimental settings.

Looking forward, the rail gun technology evolution is likely to focus on further improvements in materials science, particularly in the development of more durable rail materials and advanced conductors. Additionally, research into novel energy storage and power delivery systems will continue to play a crucial role in pushing the boundaries of energy conversion efficacy in rail gun systems.

In the 1980s, early prototypes struggled with energy conversion rates below 10%, primarily due to limitations in power supply technology and materials science. The majority of input energy was lost as heat, causing rapid degradation of rail components. This period saw the development of improved power storage systems, including capacitor banks and pulsed power supplies, which allowed for higher current delivery.

The 1990s brought about a shift towards more advanced materials for rail construction. The introduction of composite materials and advanced alloys helped mitigate rail erosion and improved energy transfer efficiency. During this decade, energy conversion rates improved to the 20-30% range, marking a significant leap forward in rail gun viability.

The turn of the millennium saw the integration of sophisticated computer modeling and simulation techniques. These tools allowed engineers to optimize rail geometry, projectile design, and power delivery systems. As a result, by the mid-2000s, some experimental systems were achieving energy conversion efficiencies of up to 40%.

In the 2010s, the focus shifted towards scalability and repeatability. Researchers worked on developing rail guns capable of sustained fire without significant degradation in performance. This period also saw advancements in superconducting materials, which promised to reduce energy losses in the power delivery system.

Recent years have witnessed the exploration of novel energy storage technologies, such as supercapacitors and advanced battery systems, to provide the high-power, rapid discharge capabilities required for rail guns. Additionally, there has been growing interest in hybrid systems that combine electromagnetic acceleration with conventional propellants to achieve higher muzzle velocities and improved overall efficiency.

As of 2023, state-of-the-art rail gun systems are reported to achieve energy conversion efficiencies of up to 50-60% under optimal conditions. However, challenges remain in maintaining this level of performance over extended periods and in scaling the technology for various applications beyond experimental settings.

Looking forward, the rail gun technology evolution is likely to focus on further improvements in materials science, particularly in the development of more durable rail materials and advanced conductors. Additionally, research into novel energy storage and power delivery systems will continue to play a crucial role in pushing the boundaries of energy conversion efficacy in rail gun systems.

Military Demand Analysis

The military demand for rail gun systems has been steadily increasing due to their potential to revolutionize long-range artillery and naval warfare. These electromagnetic projectile launchers offer significant advantages over traditional chemical propellant-based weapons, including higher muzzle velocities, extended range, and reduced logistics requirements. The U.S. Navy, in particular, has shown keen interest in rail gun technology for its future surface combatants, viewing it as a game-changing capability for both offensive and defensive operations.

The primary drivers of military demand for rail gun systems are their ability to deliver kinetic energy projectiles at hypersonic speeds and their potential for cost-effective area denial and anti-access operations. Naval forces see rail guns as a means to engage targets at distances exceeding 100 nautical miles, far surpassing the range of conventional naval guns. This extended reach could significantly alter naval tactics and strategies, providing ships with enhanced offensive capabilities and improved defensive measures against incoming threats.

Land-based military applications are also generating demand for rail gun systems. Army strategists envision using rail guns for long-range precision strikes, potentially replacing some missile systems with more cost-effective kinetic energy projectiles. The ability to rapidly fire multiple rounds without the need for explosive propellants also appeals to military planners concerned with ammunition storage safety and logistics.

However, the military demand for rail gun systems is tempered by several challenges. The high energy requirements and the need for robust power generation and storage systems pose significant integration hurdles, especially for mobile platforms. Additionally, the wear and tear on rail gun barrels due to extreme temperatures and electromagnetic forces during firing raise concerns about system longevity and maintenance requirements.

Despite these challenges, the potential benefits continue to drive military interest and investment in rail gun technology. The promise of increased lethality, extended range, and reduced per-shot costs compared to missile systems makes rail guns an attractive option for future weapon systems. Military strategists also value the multi-mission capabilities of rail guns, which could potentially be used for ballistic missile defense, anti-ship warfare, and land attack missions.

As global military powers compete for technological superiority, the demand for advanced weapon systems like rail guns is likely to grow. Countries such as China and Russia are reportedly developing their own rail gun technologies, further intensifying the interest in and perceived need for these systems among Western militaries. This international competition is spurring increased research and development efforts, with a focus on overcoming the energy conversion efficacy challenges that currently limit the full realization of rail gun potential in operational military systems.

The primary drivers of military demand for rail gun systems are their ability to deliver kinetic energy projectiles at hypersonic speeds and their potential for cost-effective area denial and anti-access operations. Naval forces see rail guns as a means to engage targets at distances exceeding 100 nautical miles, far surpassing the range of conventional naval guns. This extended reach could significantly alter naval tactics and strategies, providing ships with enhanced offensive capabilities and improved defensive measures against incoming threats.

Land-based military applications are also generating demand for rail gun systems. Army strategists envision using rail guns for long-range precision strikes, potentially replacing some missile systems with more cost-effective kinetic energy projectiles. The ability to rapidly fire multiple rounds without the need for explosive propellants also appeals to military planners concerned with ammunition storage safety and logistics.

However, the military demand for rail gun systems is tempered by several challenges. The high energy requirements and the need for robust power generation and storage systems pose significant integration hurdles, especially for mobile platforms. Additionally, the wear and tear on rail gun barrels due to extreme temperatures and electromagnetic forces during firing raise concerns about system longevity and maintenance requirements.

Despite these challenges, the potential benefits continue to drive military interest and investment in rail gun technology. The promise of increased lethality, extended range, and reduced per-shot costs compared to missile systems makes rail guns an attractive option for future weapon systems. Military strategists also value the multi-mission capabilities of rail guns, which could potentially be used for ballistic missile defense, anti-ship warfare, and land attack missions.

As global military powers compete for technological superiority, the demand for advanced weapon systems like rail guns is likely to grow. Countries such as China and Russia are reportedly developing their own rail gun technologies, further intensifying the interest in and perceived need for these systems among Western militaries. This international competition is spurring increased research and development efforts, with a focus on overcoming the energy conversion efficacy challenges that currently limit the full realization of rail gun potential in operational military systems.

Energy Conversion Challenges

Rail gun systems face significant challenges in energy conversion efficiency, primarily due to the complex interplay of electromagnetic, thermal, and mechanical processes involved in their operation. One of the foremost issues is the substantial energy loss during the conversion of electrical energy to kinetic energy. This inefficiency stems from various factors, including resistive heating in the rails and armature, as well as electromagnetic losses in the surrounding structure.

The rapid discharge of electrical energy in rail gun systems generates intense heat, which can lead to thermal management problems. The high temperatures achieved during operation can cause material degradation, affecting the structural integrity of the rails and other components. This thermal stress not only reduces the system's efficiency but also limits its operational lifespan and reliability.

Another critical challenge is the management of electromagnetic forces during projectile acceleration. The intense magnetic fields created during discharge can cause rail deformation and separation, leading to decreased performance and potential system failure. Mitigating these forces while maintaining high acceleration rates remains a significant engineering hurdle.

The power supply and pulsed power systems present additional conversion challenges. Efficiently storing and rapidly releasing the enormous amounts of energy required for rail gun operation demands advanced capacitor technologies and sophisticated power management systems. The transition from stored electrical energy to the high-current pulse needed for projectile acceleration often incurs substantial losses, reducing overall system efficiency.

Projectile design and its interaction with the electromagnetic field also play a crucial role in energy conversion efficacy. Optimizing the projectile's shape, material composition, and contact interface with the rails is essential for maximizing energy transfer and minimizing losses due to friction and plasma formation.

The scaling of rail gun systems presents unique energy conversion challenges. As systems are designed for higher muzzle velocities and larger projectiles, the energy requirements increase exponentially, exacerbating existing efficiency issues and introducing new complexities in power management and thermal control.

Addressing these energy conversion challenges requires a multidisciplinary approach, combining advancements in materials science, electromagnetic field theory, thermal management, and power electronics. Innovations in superconducting materials, novel rail designs, and advanced cooling systems are being explored to enhance efficiency. Additionally, the development of more sophisticated simulation models and diagnostic tools is crucial for understanding and optimizing the complex energy conversion processes within rail gun systems.

The rapid discharge of electrical energy in rail gun systems generates intense heat, which can lead to thermal management problems. The high temperatures achieved during operation can cause material degradation, affecting the structural integrity of the rails and other components. This thermal stress not only reduces the system's efficiency but also limits its operational lifespan and reliability.

Another critical challenge is the management of electromagnetic forces during projectile acceleration. The intense magnetic fields created during discharge can cause rail deformation and separation, leading to decreased performance and potential system failure. Mitigating these forces while maintaining high acceleration rates remains a significant engineering hurdle.

The power supply and pulsed power systems present additional conversion challenges. Efficiently storing and rapidly releasing the enormous amounts of energy required for rail gun operation demands advanced capacitor technologies and sophisticated power management systems. The transition from stored electrical energy to the high-current pulse needed for projectile acceleration often incurs substantial losses, reducing overall system efficiency.

Projectile design and its interaction with the electromagnetic field also play a crucial role in energy conversion efficacy. Optimizing the projectile's shape, material composition, and contact interface with the rails is essential for maximizing energy transfer and minimizing losses due to friction and plasma formation.

The scaling of rail gun systems presents unique energy conversion challenges. As systems are designed for higher muzzle velocities and larger projectiles, the energy requirements increase exponentially, exacerbating existing efficiency issues and introducing new complexities in power management and thermal control.

Addressing these energy conversion challenges requires a multidisciplinary approach, combining advancements in materials science, electromagnetic field theory, thermal management, and power electronics. Innovations in superconducting materials, novel rail designs, and advanced cooling systems are being explored to enhance efficiency. Additionally, the development of more sophisticated simulation models and diagnostic tools is crucial for understanding and optimizing the complex energy conversion processes within rail gun systems.

Current Energy Solutions

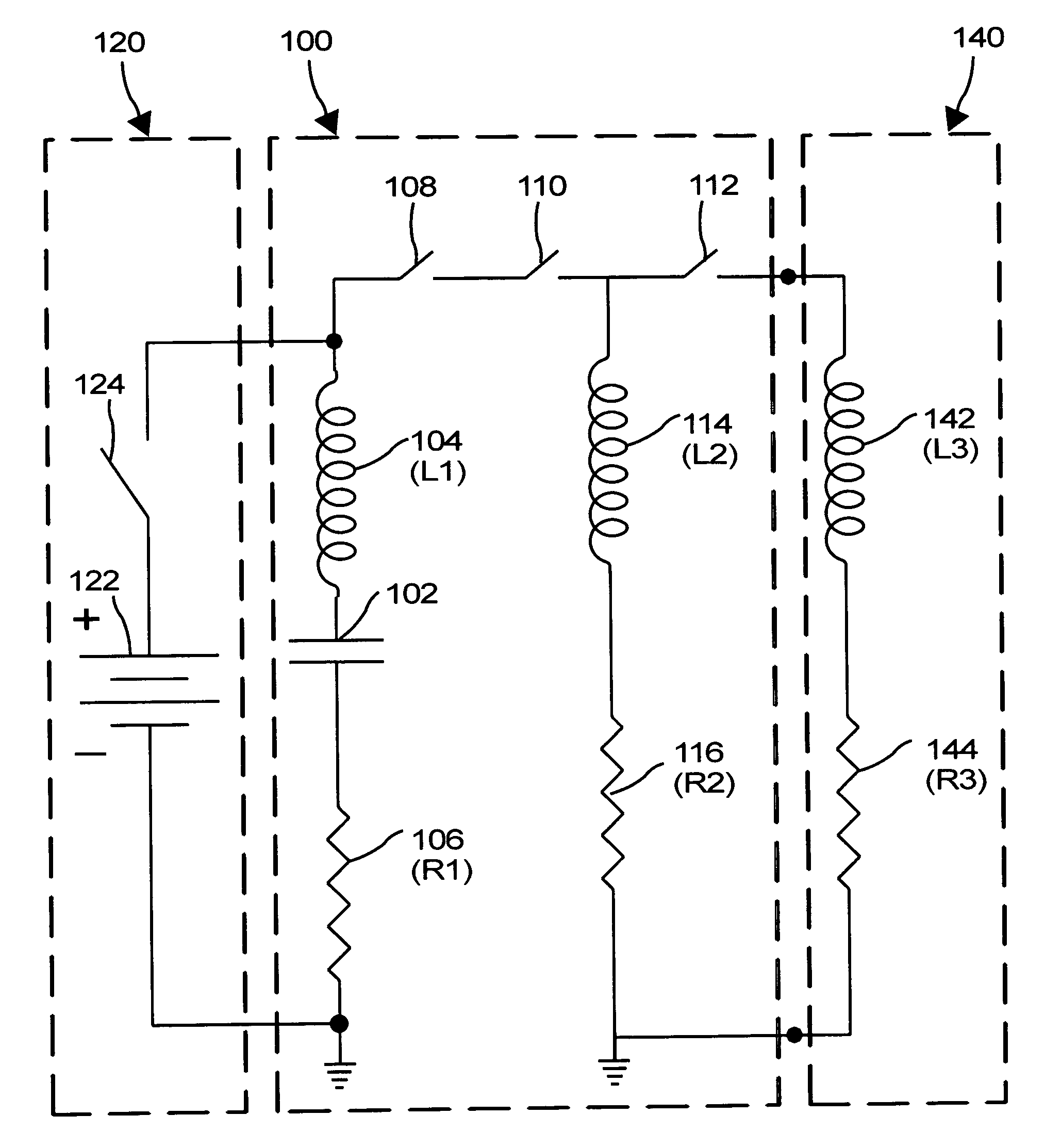

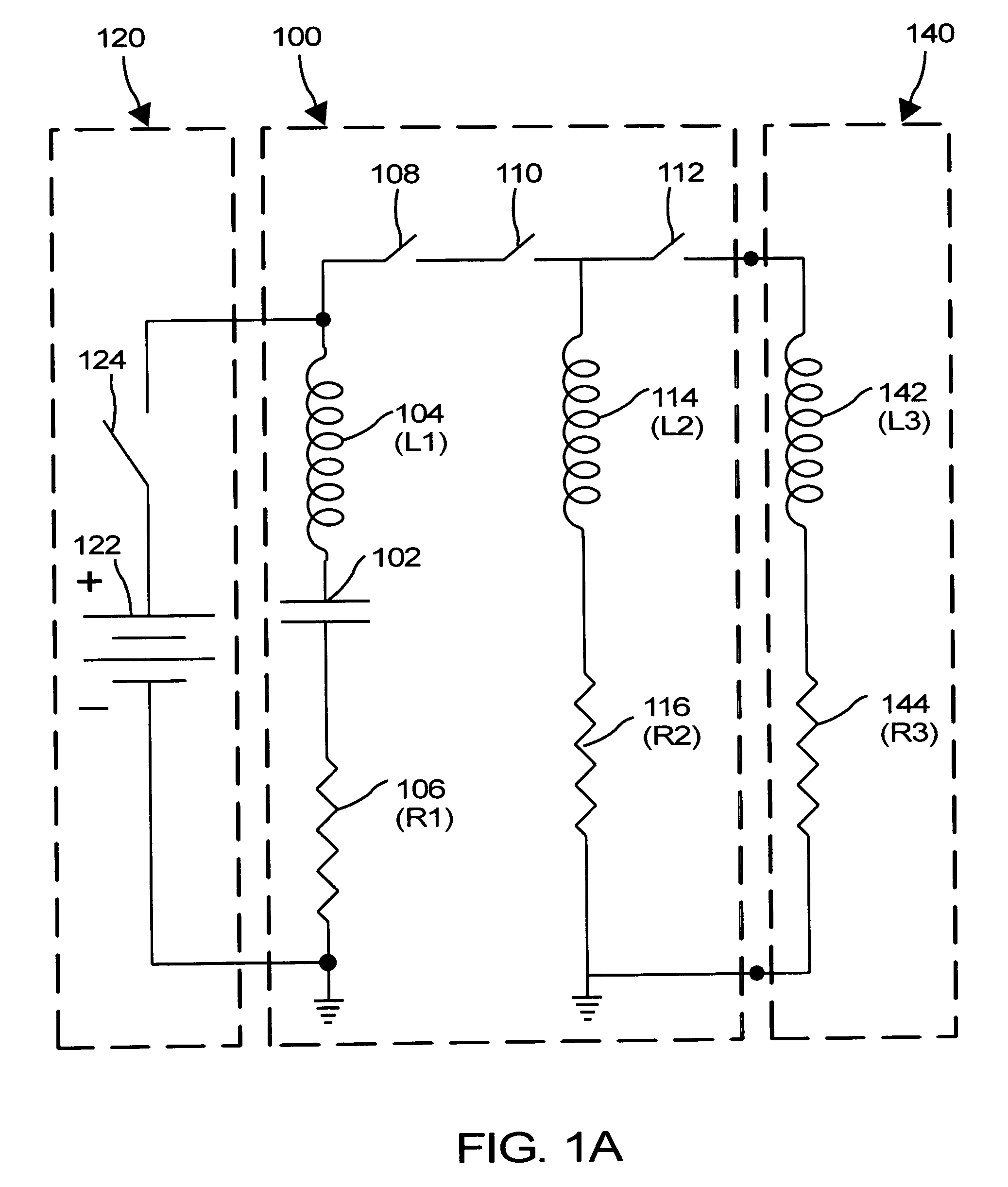

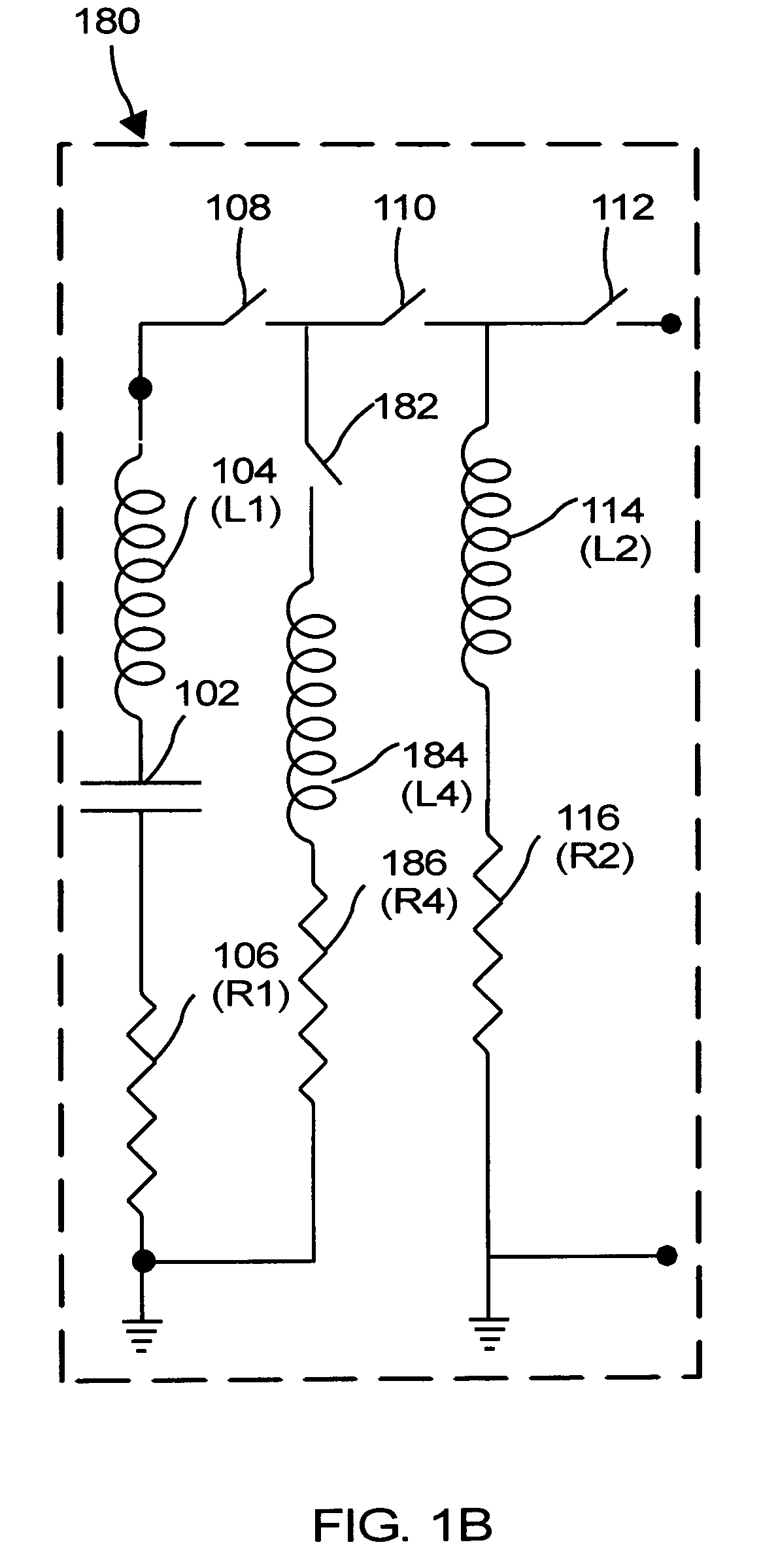

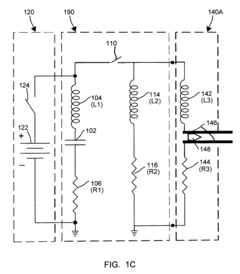

01 Energy storage and conversion systems

Rail gun systems utilize advanced energy storage and conversion technologies to rapidly release large amounts of electrical energy. These systems often incorporate capacitors, pulse forming networks, or other high-power electrical components to efficiently convert stored energy into the electromagnetic force needed to accelerate projectiles.- Energy storage and conversion systems: Rail gun systems utilize advanced energy storage and conversion technologies to rapidly release large amounts of electrical energy. These systems often incorporate capacitors, pulse forming networks, or other high-power electrical components to efficiently convert stored energy into the electromagnetic force needed to accelerate projectiles.

- Electromagnetic launch mechanisms: The core of rail gun systems involves electromagnetic launch mechanisms that convert electrical energy into kinetic energy. These mechanisms typically use parallel conducting rails and a sliding armature to generate the Lorentz force necessary for projectile acceleration, with ongoing research focused on improving the efficiency of this energy conversion process.

- Power supply and pulsed power technologies: Efficient power supply and pulsed power technologies are crucial for rail gun systems. These include high-voltage power sources, switching systems, and pulse-shaping circuits designed to deliver the intense, short-duration electrical pulses required for optimal rail gun operation while maximizing energy conversion efficiency.

- Thermal management and energy recovery: Advanced thermal management systems and energy recovery techniques are employed in rail gun systems to improve overall energy conversion efficacy. These may include methods for dissipating waste heat, recapturing unused energy, and optimizing the system's thermodynamic efficiency to enhance performance and reduce energy losses.

- Materials and structural design for efficiency: The selection of advanced materials and innovative structural designs plays a crucial role in enhancing the energy conversion efficacy of rail gun systems. This includes the use of high-conductivity materials for rails, low-friction coatings, and optimized geometries to reduce energy losses and improve the overall system efficiency.

02 Electromagnetic launch mechanisms

The core of rail gun systems involves electromagnetic launch mechanisms that convert electrical energy into kinetic energy. These mechanisms typically use powerful electromagnetic fields generated by conducting rails to accelerate projectiles to extremely high velocities, significantly improving the efficiency of energy transfer compared to traditional propellant-based systems.Expand Specific Solutions03 Power supply and distribution optimization

Enhancing the efficacy of rail gun systems involves optimizing power supply and distribution networks. This includes developing high-voltage power sources, efficient switching systems, and advanced power conditioning units to ensure consistent and reliable energy delivery to the electromagnetic launch mechanism.Expand Specific Solutions04 Thermal management and energy recovery

Improving the overall energy conversion efficiency of rail gun systems requires effective thermal management strategies and energy recovery systems. This involves developing heat dissipation techniques, recycling waste heat, and implementing regenerative braking mechanisms to capture and reuse energy from the system's operation.Expand Specific Solutions05 Advanced materials and design optimization

The use of advanced materials and optimized designs plays a crucial role in enhancing the energy conversion efficacy of rail gun systems. This includes developing high-strength, low-resistance conductors for rails, advanced composite materials for projectiles, and innovative structural designs to minimize energy losses and improve overall system performance.Expand Specific Solutions

Key Rail Gun Developers

The energy conversion efficacy in rail gun systems is currently in an early development stage, with a growing market driven by military and research applications. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Southwest Jiaotong University and the Naval Research Laboratory. Major industrial players such as Hitachi Ltd., Siemens AG, and Mitsubishi Electric Corp. are investing in related technologies, indicating potential for commercial applications. The competitive landscape is diverse, with academic institutions, defense contractors, and multinational corporations all contributing to advancements in this field, suggesting a complex and dynamic market environment.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has focused on improving energy conversion efficacy in rail gun systems through innovative electromagnetic design and materials engineering. Their research includes the development of novel rail materials with high conductivity and wear resistance, as well as advanced projectile designs that minimize energy losses during launch. They have achieved projectile velocities of over 2 km/s in laboratory settings[6]. The institute has also made progress in pulse power technology, developing compact and efficient capacitor-based power supplies for rail gun systems[7].

Strengths: Strong focus on materials engineering, innovative electromagnetic design. Weaknesses: Limited full-scale testing capabilities, potential challenges in system integration.

Northwest Electromechanical Engineering Research Institute

Technical Solution: The Northwest Electromechanical Engineering Research Institute has made notable contributions to rail gun energy conversion efficacy. Their research focuses on optimizing the electromagnetic launch process through advanced control systems and rail designs. They have developed a multi-stage rail gun concept that aims to improve overall system efficiency by distributing the acceleration process across multiple sections[10]. The institute has also worked on enhancing the durability of rail materials to withstand repeated high-energy launches, which is crucial for maintaining consistent energy conversion efficacy over time.

Strengths: Innovative multi-stage rail gun concept, focus on system durability. Weaknesses: Complexity of multi-stage systems, potential challenges in synchronization and control.

Core Energy Innovations

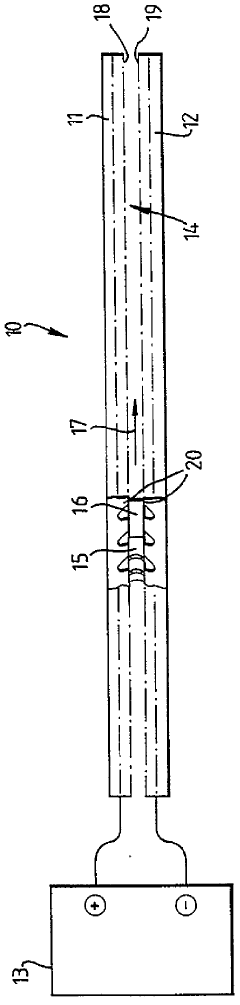

Inductive pulse forming network for high-current, high-power applications

PatentInactiveUS7675198B1

Innovation

- An inductive PFN design that stores electrical energy in a low-voltage, high-energy density network capacitor and converts it into a magnetic field to supply high-current pulses, using a network inductor and switches to manage energy transfer, allowing for smaller, lighter, and safer power delivery systems.

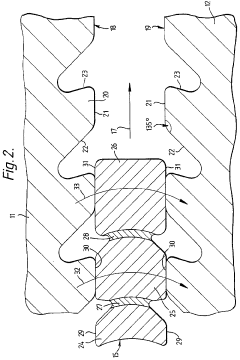

Improvements in or relating to rail gun assemblies

PatentInactiveGB2236835B

Innovation

- The rail gun assembly features elongate co-extensive rail electrodes with regular toothed cross-sections and an armature composed of three electrically conductive portions, which makes and breaks contact with sequential pairs of tooth faces, distributing the current path and reducing overheating by ensuring each portion is only exposed to maximum current for a short period.

Materials Science Impact

The impact of materials science on energy conversion efficacy in rail gun systems is profound and multifaceted. Advanced materials play a crucial role in enhancing the performance, durability, and overall efficiency of these electromagnetic launch systems. The development of high-strength, low-resistance conductors has significantly improved the energy transfer from the power source to the projectile, reducing energy losses and increasing muzzle velocities.

Composite materials have revolutionized rail design, offering superior mechanical properties and thermal management capabilities. These materials can withstand the extreme conditions generated during rail gun operation, including high temperatures, pressures, and electromagnetic forces. By minimizing rail erosion and deformation, composite materials extend the operational lifespan of rail gun systems and maintain consistent performance over multiple firings.

Nanotechnology has enabled the creation of novel materials with enhanced electrical and thermal properties. Nanostructured conductors and supercapacitors have improved energy storage and rapid discharge capabilities, critical for the high-power requirements of rail guns. These advancements have led to more compact and efficient power supply systems, reducing the overall size and weight of rail gun installations.

The development of advanced projectile materials has also contributed significantly to energy conversion efficacy. Ultra-high-strength alloys and ceramics capable of withstanding extreme acceleration forces and temperatures have been engineered. These materials allow for higher muzzle velocities and improved aerodynamic performance, translating to greater range and accuracy.

Thermal management materials have addressed one of the key challenges in rail gun systems: heat dissipation. Innovative heat-resistant coatings and thermally conductive materials help manage the intense heat generated during firing, preventing system degradation and maintaining optimal performance. This has led to increased firing rates and extended operational periods.

Advancements in superconducting materials hold promise for future rail gun designs. While still in the experimental stage, superconducting rails could dramatically reduce resistive losses, potentially revolutionizing energy conversion efficiency in these systems. Research in high-temperature superconductors is ongoing, with the goal of creating practical, field-deployable superconducting rail gun systems.

The integration of smart materials and sensors into rail gun components has enabled real-time monitoring and adaptive control of the launch process. These technologies allow for precise energy management, optimizing performance based on environmental conditions and specific mission requirements. This level of control contributes to improved energy conversion efficacy and overall system reliability.

Composite materials have revolutionized rail design, offering superior mechanical properties and thermal management capabilities. These materials can withstand the extreme conditions generated during rail gun operation, including high temperatures, pressures, and electromagnetic forces. By minimizing rail erosion and deformation, composite materials extend the operational lifespan of rail gun systems and maintain consistent performance over multiple firings.

Nanotechnology has enabled the creation of novel materials with enhanced electrical and thermal properties. Nanostructured conductors and supercapacitors have improved energy storage and rapid discharge capabilities, critical for the high-power requirements of rail guns. These advancements have led to more compact and efficient power supply systems, reducing the overall size and weight of rail gun installations.

The development of advanced projectile materials has also contributed significantly to energy conversion efficacy. Ultra-high-strength alloys and ceramics capable of withstanding extreme acceleration forces and temperatures have been engineered. These materials allow for higher muzzle velocities and improved aerodynamic performance, translating to greater range and accuracy.

Thermal management materials have addressed one of the key challenges in rail gun systems: heat dissipation. Innovative heat-resistant coatings and thermally conductive materials help manage the intense heat generated during firing, preventing system degradation and maintaining optimal performance. This has led to increased firing rates and extended operational periods.

Advancements in superconducting materials hold promise for future rail gun designs. While still in the experimental stage, superconducting rails could dramatically reduce resistive losses, potentially revolutionizing energy conversion efficiency in these systems. Research in high-temperature superconductors is ongoing, with the goal of creating practical, field-deployable superconducting rail gun systems.

The integration of smart materials and sensors into rail gun components has enabled real-time monitoring and adaptive control of the launch process. These technologies allow for precise energy management, optimizing performance based on environmental conditions and specific mission requirements. This level of control contributes to improved energy conversion efficacy and overall system reliability.

Environmental Considerations

The environmental considerations of rail gun systems, particularly in relation to energy conversion efficacy, are multifaceted and increasingly important in the context of sustainable military technology development. These systems, while offering significant advantages in terms of range and projectile velocity, also present unique environmental challenges that must be addressed.

One of the primary environmental concerns is the substantial electromagnetic emissions generated during rail gun operation. These emissions can potentially interfere with local ecosystems, affecting wildlife behavior and migration patterns. Additionally, the intense electromagnetic fields may have unforeseen long-term impacts on surrounding flora and fauna, necessitating comprehensive environmental impact assessments and ongoing monitoring programs.

The high-energy nature of rail gun systems also raises concerns about thermal pollution. The rapid conversion of electrical energy into kinetic energy produces significant heat, which, if not properly managed, can lead to localized temperature increases in the surrounding environment. This thermal output may affect local microclimates and potentially disrupt sensitive ecological balances in the immediate vicinity of testing and deployment sites.

Material degradation and waste generation are additional environmental considerations. The extreme conditions under which rail guns operate can lead to accelerated wear of components, resulting in the need for frequent replacements. The disposal of these worn components, which may contain specialized alloys and materials, requires careful consideration to minimize environmental impact and ensure proper recycling or safe disposal practices.

Noise pollution is another significant factor to consider. The acoustic signature of rail gun systems can be substantial, potentially causing disturbances to both human populations and wildlife in surrounding areas. Mitigation strategies, such as sound barriers and strategic positioning of testing facilities, may be necessary to minimize these impacts.

Energy consumption and its associated environmental footprint are critical aspects of rail gun system operation. The high power requirements for these systems often necessitate dedicated power generation facilities, which may contribute to increased carbon emissions if not sourced from renewable energy. Improving the energy conversion efficacy of rail gun systems is not only a matter of operational performance but also of environmental responsibility.

Lastly, the potential for environmental contamination from projectile materials and propellants must be addressed. While rail guns do not use traditional chemical propellants, the high-velocity impacts of projectiles can lead to the dispersal of materials over wide areas. Developing environmentally benign projectile materials and implementing rigorous clean-up protocols are essential steps in minimizing the long-term environmental impact of rail gun testing and deployment.

One of the primary environmental concerns is the substantial electromagnetic emissions generated during rail gun operation. These emissions can potentially interfere with local ecosystems, affecting wildlife behavior and migration patterns. Additionally, the intense electromagnetic fields may have unforeseen long-term impacts on surrounding flora and fauna, necessitating comprehensive environmental impact assessments and ongoing monitoring programs.

The high-energy nature of rail gun systems also raises concerns about thermal pollution. The rapid conversion of electrical energy into kinetic energy produces significant heat, which, if not properly managed, can lead to localized temperature increases in the surrounding environment. This thermal output may affect local microclimates and potentially disrupt sensitive ecological balances in the immediate vicinity of testing and deployment sites.

Material degradation and waste generation are additional environmental considerations. The extreme conditions under which rail guns operate can lead to accelerated wear of components, resulting in the need for frequent replacements. The disposal of these worn components, which may contain specialized alloys and materials, requires careful consideration to minimize environmental impact and ensure proper recycling or safe disposal practices.

Noise pollution is another significant factor to consider. The acoustic signature of rail gun systems can be substantial, potentially causing disturbances to both human populations and wildlife in surrounding areas. Mitigation strategies, such as sound barriers and strategic positioning of testing facilities, may be necessary to minimize these impacts.

Energy consumption and its associated environmental footprint are critical aspects of rail gun system operation. The high power requirements for these systems often necessitate dedicated power generation facilities, which may contribute to increased carbon emissions if not sourced from renewable energy. Improving the energy conversion efficacy of rail gun systems is not only a matter of operational performance but also of environmental responsibility.

Lastly, the potential for environmental contamination from projectile materials and propellants must be addressed. While rail guns do not use traditional chemical propellants, the high-velocity impacts of projectiles can lead to the dispersal of materials over wide areas. Developing environmentally benign projectile materials and implementing rigorous clean-up protocols are essential steps in minimizing the long-term environmental impact of rail gun testing and deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!