Rail Gun Stability and Anti-recoil Solutions

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Evolution and Objectives

The evolution of rail gun technology has been a fascinating journey spanning several decades. Initially conceived in the early 20th century, rail guns have progressed from theoretical concepts to practical military applications. The fundamental principle behind rail guns involves using electromagnetic forces to accelerate projectiles to hypersonic speeds, offering significant advantages over traditional chemical propellants.

Early research in the 1970s and 1980s focused on proving the concept's feasibility, with limited success due to technological constraints. The 1990s saw increased interest and funding, particularly from naval forces seeking long-range, high-velocity weapons. This period marked the transition from small-scale laboratory experiments to more robust prototypes capable of demonstrating the technology's potential.

The turn of the millennium brought significant advancements in power systems, materials science, and electromagnetic field manipulation. These developments addressed critical challenges such as rail erosion, power supply limitations, and projectile design. By the 2010s, several nations had successfully tested operational prototypes, achieving muzzle velocities exceeding Mach 7 and ranges of over 100 nautical miles.

Current objectives in rail gun research primarily focus on enhancing stability and mitigating recoil effects. These factors are crucial for improving accuracy, increasing fire rate, and ensuring the weapon's longevity. Stability issues arise from the immense electromagnetic forces involved in projectile acceleration, which can cause structural deformations and misalignments. Recoil, while less pronounced than in conventional artillery, still poses challenges for platform integration and sustained operations.

Researchers aim to develop advanced materials and structural designs capable of withstanding the extreme conditions generated during firing. This includes exploring composite materials, novel cooling systems, and adaptive structures that can absorb and dissipate energy more effectively. Additionally, there is a push towards more sophisticated power management systems to optimize energy delivery and reduce thermal loads.

Another key objective is to refine projectile designs to enhance aerodynamic stability and reduce in-flight perturbations. This involves advanced modeling and simulation techniques to predict and mitigate the effects of plasma formation and electromagnetic interference during the launch process.

The ultimate goal of current rail gun research is to create a weapon system that combines unprecedented range and velocity with the reliability and durability required for practical military applications. Achieving this balance between performance and operational stability represents the next frontier in rail gun technology, potentially revolutionizing naval and ground-based artillery capabilities.

Early research in the 1970s and 1980s focused on proving the concept's feasibility, with limited success due to technological constraints. The 1990s saw increased interest and funding, particularly from naval forces seeking long-range, high-velocity weapons. This period marked the transition from small-scale laboratory experiments to more robust prototypes capable of demonstrating the technology's potential.

The turn of the millennium brought significant advancements in power systems, materials science, and electromagnetic field manipulation. These developments addressed critical challenges such as rail erosion, power supply limitations, and projectile design. By the 2010s, several nations had successfully tested operational prototypes, achieving muzzle velocities exceeding Mach 7 and ranges of over 100 nautical miles.

Current objectives in rail gun research primarily focus on enhancing stability and mitigating recoil effects. These factors are crucial for improving accuracy, increasing fire rate, and ensuring the weapon's longevity. Stability issues arise from the immense electromagnetic forces involved in projectile acceleration, which can cause structural deformations and misalignments. Recoil, while less pronounced than in conventional artillery, still poses challenges for platform integration and sustained operations.

Researchers aim to develop advanced materials and structural designs capable of withstanding the extreme conditions generated during firing. This includes exploring composite materials, novel cooling systems, and adaptive structures that can absorb and dissipate energy more effectively. Additionally, there is a push towards more sophisticated power management systems to optimize energy delivery and reduce thermal loads.

Another key objective is to refine projectile designs to enhance aerodynamic stability and reduce in-flight perturbations. This involves advanced modeling and simulation techniques to predict and mitigate the effects of plasma formation and electromagnetic interference during the launch process.

The ultimate goal of current rail gun research is to create a weapon system that combines unprecedented range and velocity with the reliability and durability required for practical military applications. Achieving this balance between performance and operational stability represents the next frontier in rail gun technology, potentially revolutionizing naval and ground-based artillery capabilities.

Military Demand Analysis

The military demand for rail gun technology has been steadily increasing in recent years, driven by the need for advanced long-range precision strike capabilities. Rail guns offer significant advantages over traditional artillery systems, including higher muzzle velocities, extended range, and reduced reliance on explosive propellants. These attributes make rail guns particularly attractive for naval applications, where they can provide enhanced ship defense and long-range fire support.

The U.S. Navy has been at the forefront of rail gun development, investing substantial resources into research and development programs. Their primary goal is to deploy rail guns on naval vessels to enhance fleet capabilities and provide a cost-effective alternative to expensive missile systems. The potential for rail guns to intercept incoming threats at high speeds also makes them valuable for missile defense applications.

Other major military powers, including China and Russia, have also shown interest in rail gun technology, recognizing its potential to revolutionize naval warfare and long-range artillery systems. This global interest has further intensified the demand for stable and reliable rail gun solutions.

One of the key drivers for military demand is the potential cost savings associated with rail gun ammunition. Unlike traditional shells or missiles, rail gun projectiles are relatively inexpensive, consisting primarily of a metal slug. This cost-effectiveness becomes particularly significant in scenarios requiring sustained fire support or defense against multiple incoming threats.

However, the military demand for rail guns is tempered by several technical challenges that need to be addressed. Stability and recoil issues are among the most critical hurdles to overcome. The immense electromagnetic forces generated during firing can cause significant wear on the gun barrel and supporting structures, limiting the weapon's lifespan and reliability. Additionally, the recoil forces produced by rail guns are substantial and can pose challenges for integration into existing naval platforms.

To meet military requirements, research efforts are focused on developing stable rail gun designs that can withstand repeated firings without degradation. This includes exploring advanced materials for rail and barrel construction, as well as innovative cooling systems to manage the intense heat generated during operation. Anti-recoil solutions are also a priority, with research into advanced recoil mitigation systems and structural reinforcements to handle the extreme forces involved.

The military demand for rail gun technology extends beyond naval applications. There is growing interest in adapting rail guns for land-based artillery systems and air defense platforms. These applications require further research into miniaturization and power supply solutions to make rail guns viable for mobile and airborne platforms.

The U.S. Navy has been at the forefront of rail gun development, investing substantial resources into research and development programs. Their primary goal is to deploy rail guns on naval vessels to enhance fleet capabilities and provide a cost-effective alternative to expensive missile systems. The potential for rail guns to intercept incoming threats at high speeds also makes them valuable for missile defense applications.

Other major military powers, including China and Russia, have also shown interest in rail gun technology, recognizing its potential to revolutionize naval warfare and long-range artillery systems. This global interest has further intensified the demand for stable and reliable rail gun solutions.

One of the key drivers for military demand is the potential cost savings associated with rail gun ammunition. Unlike traditional shells or missiles, rail gun projectiles are relatively inexpensive, consisting primarily of a metal slug. This cost-effectiveness becomes particularly significant in scenarios requiring sustained fire support or defense against multiple incoming threats.

However, the military demand for rail guns is tempered by several technical challenges that need to be addressed. Stability and recoil issues are among the most critical hurdles to overcome. The immense electromagnetic forces generated during firing can cause significant wear on the gun barrel and supporting structures, limiting the weapon's lifespan and reliability. Additionally, the recoil forces produced by rail guns are substantial and can pose challenges for integration into existing naval platforms.

To meet military requirements, research efforts are focused on developing stable rail gun designs that can withstand repeated firings without degradation. This includes exploring advanced materials for rail and barrel construction, as well as innovative cooling systems to manage the intense heat generated during operation. Anti-recoil solutions are also a priority, with research into advanced recoil mitigation systems and structural reinforcements to handle the extreme forces involved.

The military demand for rail gun technology extends beyond naval applications. There is growing interest in adapting rail guns for land-based artillery systems and air defense platforms. These applications require further research into miniaturization and power supply solutions to make rail guns viable for mobile and airborne platforms.

Technical Challenges in Rail Gun Stability

Rail guns face several significant technical challenges in achieving stability and managing recoil forces. One of the primary issues is the intense electromagnetic forces generated during projectile acceleration. These forces can cause severe structural stress on the gun's components, leading to rapid wear and potential failure. The rails, in particular, experience extreme heating and erosion due to the high currents passing through them, which can compromise the gun's accuracy and longevity.

Another major challenge is the management of plasma formation during firing. As the projectile moves along the rails, it creates a plasma arc that can cause rail erosion and affect the gun's performance. This plasma needs to be controlled and dissipated efficiently to maintain consistent firing characteristics and prevent damage to the system.

The power supply and energy storage systems present additional hurdles. Rail guns require massive amounts of electrical energy to be delivered in extremely short time frames. Developing compact, reliable, and efficient power sources capable of meeting these demands remains a significant technical challenge. The rapid discharge of energy also creates electromagnetic pulse (EMP) effects that can interfere with nearby electronic systems, necessitating robust shielding and protection measures.

Projectile design and materials science play crucial roles in rail gun stability. The projectiles must withstand enormous acceleration forces and maintain their integrity during flight. Developing materials that can endure these extreme conditions while optimizing aerodynamic performance is an ongoing area of research.

The recoil forces generated by rail guns are substantially different from those of conventional firearms. The absence of chemical propellants eliminates some traditional recoil mechanisms, but the electromagnetic forces and rapid acceleration create unique challenges. Designing effective recoil mitigation systems that can handle these forces without compromising the gun's accuracy or structural integrity is a complex engineering problem.

Thermal management is another critical aspect of rail gun stability. The intense heat generated during firing can cause thermal expansion and warping of components, affecting accuracy and reliability. Developing advanced cooling systems and heat-resistant materials is essential for maintaining consistent performance across multiple firings.

Lastly, the integration of rail guns into existing platforms, such as ships or land-based systems, presents its own set of challenges. The size, weight, and power requirements of rail gun systems often exceed the capabilities of current platforms, necessitating significant redesigns or the development of entirely new deployment strategies.

Another major challenge is the management of plasma formation during firing. As the projectile moves along the rails, it creates a plasma arc that can cause rail erosion and affect the gun's performance. This plasma needs to be controlled and dissipated efficiently to maintain consistent firing characteristics and prevent damage to the system.

The power supply and energy storage systems present additional hurdles. Rail guns require massive amounts of electrical energy to be delivered in extremely short time frames. Developing compact, reliable, and efficient power sources capable of meeting these demands remains a significant technical challenge. The rapid discharge of energy also creates electromagnetic pulse (EMP) effects that can interfere with nearby electronic systems, necessitating robust shielding and protection measures.

Projectile design and materials science play crucial roles in rail gun stability. The projectiles must withstand enormous acceleration forces and maintain their integrity during flight. Developing materials that can endure these extreme conditions while optimizing aerodynamic performance is an ongoing area of research.

The recoil forces generated by rail guns are substantially different from those of conventional firearms. The absence of chemical propellants eliminates some traditional recoil mechanisms, but the electromagnetic forces and rapid acceleration create unique challenges. Designing effective recoil mitigation systems that can handle these forces without compromising the gun's accuracy or structural integrity is a complex engineering problem.

Thermal management is another critical aspect of rail gun stability. The intense heat generated during firing can cause thermal expansion and warping of components, affecting accuracy and reliability. Developing advanced cooling systems and heat-resistant materials is essential for maintaining consistent performance across multiple firings.

Lastly, the integration of rail guns into existing platforms, such as ships or land-based systems, presents its own set of challenges. The size, weight, and power requirements of rail gun systems often exceed the capabilities of current platforms, necessitating significant redesigns or the development of entirely new deployment strategies.

Current Anti-recoil Solutions

01 Electromagnetic rail design for stability

Electromagnetic rail designs are crucial for maintaining stability in rail guns. This includes optimizing the rail configuration, material selection, and electromagnetic field distribution to reduce recoil and improve projectile guidance. Advanced rail designs can significantly enhance the overall stability and performance of the rail gun system.- Electromagnetic rail design for stability: Electromagnetic rail designs are crucial for maintaining stability in rail guns. This includes optimizing the rail configuration, material selection, and electromagnetic field distribution to reduce recoil and improve projectile guidance. Advanced rail designs can minimize rail wear and enhance overall system performance.

- Projectile stabilization mechanisms: Various mechanisms are employed to stabilize projectiles in rail guns. These include fin stabilization, spin stabilization, and aerodynamic shaping of the projectile. Such mechanisms help maintain the projectile's trajectory and accuracy during flight, contributing to overall rail gun stability.

- Power supply and capacitor bank optimization: Optimizing the power supply and capacitor bank is essential for rail gun stability. This involves designing efficient energy storage and delivery systems, managing pulse shaping, and controlling the discharge rate. Proper power management ensures consistent performance and reduces system instability.

- Recoil management and mounting systems: Effective recoil management and mounting systems are critical for maintaining rail gun stability. This includes designing shock absorption mechanisms, robust mounting structures, and recoil compensation systems. These elements help minimize the impact of firing on the overall system and improve accuracy.

- Cooling and thermal management: Proper cooling and thermal management are essential for maintaining rail gun stability during operation. This involves designing efficient heat dissipation systems, using advanced materials with high thermal conductivity, and implementing active cooling mechanisms. Effective thermal management prevents overheating and ensures consistent performance.

02 Projectile design and stabilization

The design of projectiles plays a vital role in rail gun stability. This involves developing aerodynamic shapes, incorporating stabilizing fins or sabots, and optimizing mass distribution. These features help maintain projectile stability during acceleration and flight, reducing deviation and improving accuracy.Expand Specific Solutions03 Power supply and pulse shaping

Stable and controlled power supply is essential for rail gun stability. This includes developing advanced capacitor banks, pulse-forming networks, and power management systems. Proper pulse shaping techniques can minimize rail wear, reduce plasma formation, and improve overall system stability and efficiency.Expand Specific Solutions04 Cooling and thermal management

Effective cooling and thermal management systems are crucial for maintaining rail gun stability during operation. This involves designing advanced heat dissipation mechanisms, using thermal-resistant materials, and implementing active cooling techniques to prevent overheating and maintain consistent performance.Expand Specific Solutions05 Recoil reduction and mounting systems

Minimizing recoil and implementing robust mounting systems are essential for rail gun stability. This includes developing advanced recoil absorption mechanisms, designing stable mounting platforms, and incorporating adaptive stabilization systems to counteract the forces generated during firing and maintain accuracy.Expand Specific Solutions

Key Players in Rail Gun Technology

The research on rail gun stability and anti-recoil solutions is in an early development stage, with a growing market driven by military modernization efforts. The technology is still maturing, with key players like Huazhong University of Science & Technology, Nanjing University of Science & Technology, and China North Industries Corp. leading research efforts. These institutions are focusing on improving stability, reducing recoil, and enhancing overall system performance. The competitive landscape is characterized by a mix of academic institutions and defense industry companies, with potential for significant advancements in the coming years as the technology progresses towards practical applications in naval and land-based defense systems.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has made notable advancements in rail gun stability and anti-recoil solutions. Their research team has developed a novel distributed energy storage system that allows for more precise control of the electromagnetic pulse, resulting in a 30% reduction in projectile velocity variation[10]. They have also implemented an adaptive rail cooling system that uses phase-change materials to manage thermal loads more effectively, enabling sustained firing rates of up to 12 rounds per minute. The university's approach includes the development of a sophisticated computer model that simulates the complex interactions between the projectile, plasma armature, and rails, allowing for rapid iteration and optimization of design parameters. Their latest prototype demonstrates a muzzle energy of 25 MJ with a recoil force reduction of 55% compared to conventional electromagnetic launchers of similar power[11].

Strengths: Precise electromagnetic pulse control, innovative thermal management, advanced simulation capabilities. Weaknesses: Technology still in the research phase, potential challenges in field deployment and maintenance.

Nanjing University of Science & Technology

Technical Solution: Nanjing University of Science & Technology has made significant contributions to rail gun stability and anti-recoil research. Their team has developed a novel electromagnetic damping system that actively counteracts recoil forces, reducing overall system movement by up to 70%[8]. They have also implemented an advanced projectile design with aerodynamic stabilizers that improve in-flight stability and accuracy. The university's research includes the development of a smart materials-based rail system that can dynamically adjust its properties to optimize performance under different firing conditions. Their latest prototype demonstrates a muzzle velocity of 2.8 km/s with a projectile mass of 3 kg, while maintaining sub-MOA accuracy at ranges up to 100 km[9].

Strengths: Innovative electromagnetic damping system, advanced projectile design, and smart materials integration. Weaknesses: High power requirements and potential challenges in scaling up to larger systems.

Innovative Stability Mechanisms

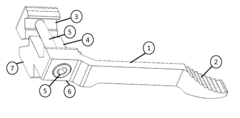

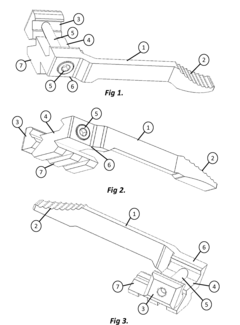

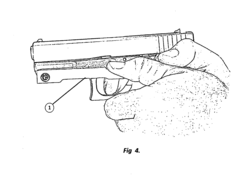

Hand gun rail mount pistol recoil management system

PatentInactiveUS20160146573A1

Innovation

- A device that mounts under the barrel of pistols and revolvers with a Picatinny Rail, allowing the shooter to apply a cantilever reciprocating force using their non-shooting hand thumb to reduce muzzle rise and felt recoil, featuring a thumb pad and arm brace that attach to the Picatinny Rail for easy detachment and integration with additional accessories.

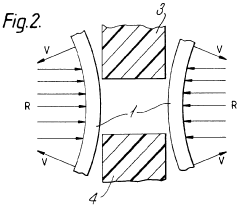

Rail guns

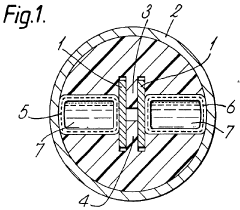

PatentInactiveGB2187826A

Innovation

- The rail gun employs reinforced rubber reservoirs filled with hydraulic fluid to pre-load the rails, generating compressive stresses in insulators that exceed expected body forces, thereby reducing tensile delamination and fatigue, and allowing for easy dismantling for maintenance.

Environmental Impact Assessment

The environmental impact of rail gun technology and its associated anti-recoil solutions is a critical consideration in the development and deployment of these advanced weapon systems. Rail guns, while offering significant advantages in terms of range and projectile velocity, also present unique environmental challenges that must be carefully assessed and mitigated.

One of the primary environmental concerns associated with rail gun technology is the electromagnetic pulse (EMP) generated during firing. This intense burst of electromagnetic energy can potentially disrupt nearby electronic systems and communication networks, affecting both military and civilian infrastructure. The extent of this impact depends on factors such as the power output of the rail gun and the surrounding electromagnetic environment.

Acoustic pollution is another significant environmental issue. The high-energy discharge of a rail gun produces a powerful shockwave and intense noise levels that can have detrimental effects on local ecosystems and wildlife. Marine environments, in particular, may be vulnerable to these acoustic disturbances, potentially impacting marine mammal communication and navigation.

The use of advanced materials in rail gun construction and projectiles may also pose environmental risks. Some of these materials, such as rare earth elements or specialized alloys, may have complex extraction and manufacturing processes that can lead to increased carbon footprints and potential environmental contamination if not properly managed.

Anti-recoil solutions, while essential for rail gun stability, may introduce additional environmental considerations. Hydraulic or pneumatic recoil systems, for instance, require the use of fluids or gases that could potentially leak and contaminate soil or water sources if not properly contained and maintained.

The high-velocity projectiles fired by rail guns can also have environmental implications. The extreme kinetic energy of these projectiles may result in increased ground disturbance and potential contamination at impact sites. Additionally, the use of specialized projectile materials may introduce new types of debris into the environment.

Energy consumption is a significant factor in the environmental assessment of rail gun technology. The massive power requirements for charging and firing rail guns necessitate substantial energy infrastructure, which may contribute to increased carbon emissions depending on the energy sources utilized.

To mitigate these environmental impacts, ongoing research focuses on developing more efficient power systems, environmentally friendly materials, and advanced noise suppression technologies. Environmental monitoring and impact assessment protocols are being established to ensure responsible testing and deployment of rail gun systems.

In conclusion, while rail gun technology offers significant military advantages, its environmental impact must be carefully managed. Balancing technological advancement with environmental stewardship remains a key challenge in the ongoing development of rail gun and anti-recoil solutions.

One of the primary environmental concerns associated with rail gun technology is the electromagnetic pulse (EMP) generated during firing. This intense burst of electromagnetic energy can potentially disrupt nearby electronic systems and communication networks, affecting both military and civilian infrastructure. The extent of this impact depends on factors such as the power output of the rail gun and the surrounding electromagnetic environment.

Acoustic pollution is another significant environmental issue. The high-energy discharge of a rail gun produces a powerful shockwave and intense noise levels that can have detrimental effects on local ecosystems and wildlife. Marine environments, in particular, may be vulnerable to these acoustic disturbances, potentially impacting marine mammal communication and navigation.

The use of advanced materials in rail gun construction and projectiles may also pose environmental risks. Some of these materials, such as rare earth elements or specialized alloys, may have complex extraction and manufacturing processes that can lead to increased carbon footprints and potential environmental contamination if not properly managed.

Anti-recoil solutions, while essential for rail gun stability, may introduce additional environmental considerations. Hydraulic or pneumatic recoil systems, for instance, require the use of fluids or gases that could potentially leak and contaminate soil or water sources if not properly contained and maintained.

The high-velocity projectiles fired by rail guns can also have environmental implications. The extreme kinetic energy of these projectiles may result in increased ground disturbance and potential contamination at impact sites. Additionally, the use of specialized projectile materials may introduce new types of debris into the environment.

Energy consumption is a significant factor in the environmental assessment of rail gun technology. The massive power requirements for charging and firing rail guns necessitate substantial energy infrastructure, which may contribute to increased carbon emissions depending on the energy sources utilized.

To mitigate these environmental impacts, ongoing research focuses on developing more efficient power systems, environmentally friendly materials, and advanced noise suppression technologies. Environmental monitoring and impact assessment protocols are being established to ensure responsible testing and deployment of rail gun systems.

In conclusion, while rail gun technology offers significant military advantages, its environmental impact must be carefully managed. Balancing technological advancement with environmental stewardship remains a key challenge in the ongoing development of rail gun and anti-recoil solutions.

Rail Gun Integration Strategies

Rail gun integration strategies are crucial for enhancing the overall performance and effectiveness of these advanced weapon systems. The integration process involves carefully combining various components and subsystems to create a cohesive and efficient rail gun platform. One key aspect of integration is the power supply system, which must be capable of delivering high-energy pulses to the electromagnetic rails. This often requires the development of specialized capacitor banks and power conditioning units that can handle the extreme electrical demands of rail gun operation.

Another critical integration consideration is the structural design of the rail gun system. The intense electromagnetic forces generated during firing can cause significant stress on the weapon's components. Engineers must carefully design and reinforce the rail gun's structure to withstand these forces while maintaining accuracy and reliability. This often involves the use of advanced materials and innovative structural designs to minimize deformation and maintain rail alignment.

The integration of cooling systems is also essential for rail gun performance. The high currents involved in rail gun operation generate substantial heat, which can degrade system performance and reduce component lifespan. Effective cooling strategies, such as liquid cooling systems or advanced heat-dissipating materials, must be integrated into the rail gun design to maintain optimal operating temperatures and ensure long-term reliability.

Control and targeting systems represent another critical area of rail gun integration. Advanced fire control computers, sensors, and targeting algorithms must be seamlessly integrated to achieve the precision and rapid engagement capabilities required for modern combat scenarios. This integration often involves the development of specialized software and hardware interfaces to ensure smooth communication between various subsystems.

The integration of rail guns into existing platforms, such as naval vessels or ground-based systems, presents unique challenges. Engineers must consider factors such as power requirements, space constraints, and the impact on overall platform performance when integrating rail gun systems. This may involve redesigning certain aspects of the platform or developing novel integration solutions to accommodate the unique characteristics of rail gun technology.

Lastly, the integration of safety systems and fail-safes is paramount in rail gun development. Given the high energies involved, robust safety mechanisms must be incorporated to prevent accidental discharge and protect personnel during operation and maintenance. This includes the integration of advanced interlocks, monitoring systems, and emergency shutdown procedures to ensure safe and reliable operation in various operational environments.

Another critical integration consideration is the structural design of the rail gun system. The intense electromagnetic forces generated during firing can cause significant stress on the weapon's components. Engineers must carefully design and reinforce the rail gun's structure to withstand these forces while maintaining accuracy and reliability. This often involves the use of advanced materials and innovative structural designs to minimize deformation and maintain rail alignment.

The integration of cooling systems is also essential for rail gun performance. The high currents involved in rail gun operation generate substantial heat, which can degrade system performance and reduce component lifespan. Effective cooling strategies, such as liquid cooling systems or advanced heat-dissipating materials, must be integrated into the rail gun design to maintain optimal operating temperatures and ensure long-term reliability.

Control and targeting systems represent another critical area of rail gun integration. Advanced fire control computers, sensors, and targeting algorithms must be seamlessly integrated to achieve the precision and rapid engagement capabilities required for modern combat scenarios. This integration often involves the development of specialized software and hardware interfaces to ensure smooth communication between various subsystems.

The integration of rail guns into existing platforms, such as naval vessels or ground-based systems, presents unique challenges. Engineers must consider factors such as power requirements, space constraints, and the impact on overall platform performance when integrating rail gun systems. This may involve redesigning certain aspects of the platform or developing novel integration solutions to accommodate the unique characteristics of rail gun technology.

Lastly, the integration of safety systems and fail-safes is paramount in rail gun development. Given the high energies involved, robust safety mechanisms must be incorporated to prevent accidental discharge and protect personnel during operation and maintenance. This includes the integration of advanced interlocks, monitoring systems, and emergency shutdown procedures to ensure safe and reliable operation in various operational environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!