Low-Cost Manufacturing Options for Rail Gun Components

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Background

Rail guns have been a subject of military research and development for several decades, representing a significant leap in projectile technology. These electromagnetic weapons utilize powerful electromagnetic fields to accelerate conductive projectiles to extremely high velocities, far surpassing the capabilities of traditional chemical propellants.

The concept of rail guns dates back to the early 20th century, with the first patents filed in the 1910s. However, it wasn't until the late 1970s and early 1980s that serious research and development efforts began, primarily driven by military interests in the United States and other technologically advanced nations.

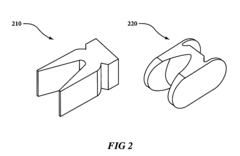

The fundamental principle behind rail guns involves the use of two parallel conducting rails connected to a power supply. When a conductive projectile is inserted between these rails and a large electric current is applied, it creates a powerful electromagnetic field that propels the projectile forward at incredible speeds.

Over the years, rail gun technology has progressed significantly, overcoming numerous technical challenges. Early prototypes faced issues such as rail erosion, power supply limitations, and projectile design constraints. Advancements in materials science, power electronics, and electromagnetic field modeling have contributed to substantial improvements in rail gun performance and reliability.

The potential advantages of rail guns over conventional artillery are numerous. They offer higher muzzle velocities, extended range, and the ability to use kinetic energy projectiles without the need for explosive warheads. This not only increases the weapon's effectiveness but also reduces the logistical burden associated with storing and transporting explosive ammunition.

Despite these advantages, rail guns have yet to see widespread deployment due to several persistent challenges. These include the need for enormous power supplies, rail durability issues, and the complexities of integrating such advanced systems into existing military platforms.

Recent years have seen renewed interest in rail gun technology, with several countries investing in research and development programs. The focus has shifted towards developing more compact and energy-efficient designs, as well as exploring potential non-military applications in areas such as space launch systems and hypersonic testing facilities.

As rail gun technology continues to mature, the emphasis on cost-effective manufacturing solutions for components has become increasingly important. This focus on low-cost manufacturing options aims to bridge the gap between the promising potential of rail guns and their practical implementation in real-world scenarios.

The concept of rail guns dates back to the early 20th century, with the first patents filed in the 1910s. However, it wasn't until the late 1970s and early 1980s that serious research and development efforts began, primarily driven by military interests in the United States and other technologically advanced nations.

The fundamental principle behind rail guns involves the use of two parallel conducting rails connected to a power supply. When a conductive projectile is inserted between these rails and a large electric current is applied, it creates a powerful electromagnetic field that propels the projectile forward at incredible speeds.

Over the years, rail gun technology has progressed significantly, overcoming numerous technical challenges. Early prototypes faced issues such as rail erosion, power supply limitations, and projectile design constraints. Advancements in materials science, power electronics, and electromagnetic field modeling have contributed to substantial improvements in rail gun performance and reliability.

The potential advantages of rail guns over conventional artillery are numerous. They offer higher muzzle velocities, extended range, and the ability to use kinetic energy projectiles without the need for explosive warheads. This not only increases the weapon's effectiveness but also reduces the logistical burden associated with storing and transporting explosive ammunition.

Despite these advantages, rail guns have yet to see widespread deployment due to several persistent challenges. These include the need for enormous power supplies, rail durability issues, and the complexities of integrating such advanced systems into existing military platforms.

Recent years have seen renewed interest in rail gun technology, with several countries investing in research and development programs. The focus has shifted towards developing more compact and energy-efficient designs, as well as exploring potential non-military applications in areas such as space launch systems and hypersonic testing facilities.

As rail gun technology continues to mature, the emphasis on cost-effective manufacturing solutions for components has become increasingly important. This focus on low-cost manufacturing options aims to bridge the gap between the promising potential of rail guns and their practical implementation in real-world scenarios.

Market Demand Analysis

The market demand for low-cost manufacturing options for rail gun components has been steadily increasing in recent years, driven by both military and civilian applications. The defense sector remains the primary driver, with several nations investing heavily in electromagnetic weapon systems. The United States Navy, for instance, has shown significant interest in rail gun technology for its potential to revolutionize naval warfare.

In the military market, the demand is primarily fueled by the need for long-range, high-velocity projectile systems that can outperform traditional artillery. Rail guns offer the advantage of extended range, increased accuracy, and reduced reliance on explosive propellants. This has led to a growing interest from various branches of the armed forces, including naval, ground, and potentially air-based applications.

The civilian market, while smaller, is also showing potential growth. Research institutions and private companies are exploring rail gun technology for space launch applications, where the ability to accelerate payloads to high velocities without chemical propellants could significantly reduce launch costs. Additionally, there is emerging interest in using rail gun technology for industrial applications, such as high-speed material testing and advanced manufacturing processes.

Market analysis indicates that the global rail gun market is expected to grow substantially over the next decade. This growth is attributed to increased defense spending in several countries, ongoing research and development efforts, and the potential for cost reduction through improved manufacturing techniques.

However, the market faces challenges related to the high costs associated with current manufacturing methods for rail gun components. The complex nature of rail gun systems, which require precision-engineered parts capable of withstanding extreme electromagnetic forces and temperatures, has traditionally resulted in high production costs. This has limited widespread adoption and slowed market expansion.

The demand for low-cost manufacturing options is therefore critical to the future growth of the rail gun market. Innovations in materials science, advanced manufacturing techniques such as 3D printing, and improved design methodologies are seen as key factors that could significantly reduce production costs. Market analysts predict that if manufacturing costs can be substantially reduced, it could lead to a rapid expansion of the rail gun market, potentially opening up new applications and increasing adoption rates across various sectors.

In conclusion, the market demand for low-cost manufacturing options for rail gun components is strong and growing. The potential for rail gun technology to disrupt traditional weapon systems and open new civilian applications is driving investment and research. However, the realization of this market potential is heavily dependent on the development of cost-effective manufacturing solutions that can make rail gun technology more accessible and economically viable for a broader range of applications.

In the military market, the demand is primarily fueled by the need for long-range, high-velocity projectile systems that can outperform traditional artillery. Rail guns offer the advantage of extended range, increased accuracy, and reduced reliance on explosive propellants. This has led to a growing interest from various branches of the armed forces, including naval, ground, and potentially air-based applications.

The civilian market, while smaller, is also showing potential growth. Research institutions and private companies are exploring rail gun technology for space launch applications, where the ability to accelerate payloads to high velocities without chemical propellants could significantly reduce launch costs. Additionally, there is emerging interest in using rail gun technology for industrial applications, such as high-speed material testing and advanced manufacturing processes.

Market analysis indicates that the global rail gun market is expected to grow substantially over the next decade. This growth is attributed to increased defense spending in several countries, ongoing research and development efforts, and the potential for cost reduction through improved manufacturing techniques.

However, the market faces challenges related to the high costs associated with current manufacturing methods for rail gun components. The complex nature of rail gun systems, which require precision-engineered parts capable of withstanding extreme electromagnetic forces and temperatures, has traditionally resulted in high production costs. This has limited widespread adoption and slowed market expansion.

The demand for low-cost manufacturing options is therefore critical to the future growth of the rail gun market. Innovations in materials science, advanced manufacturing techniques such as 3D printing, and improved design methodologies are seen as key factors that could significantly reduce production costs. Market analysts predict that if manufacturing costs can be substantially reduced, it could lead to a rapid expansion of the rail gun market, potentially opening up new applications and increasing adoption rates across various sectors.

In conclusion, the market demand for low-cost manufacturing options for rail gun components is strong and growing. The potential for rail gun technology to disrupt traditional weapon systems and open new civilian applications is driving investment and research. However, the realization of this market potential is heavily dependent on the development of cost-effective manufacturing solutions that can make rail gun technology more accessible and economically viable for a broader range of applications.

Manufacturing Challenges

The manufacturing of rail gun components presents several significant challenges, primarily due to the extreme conditions these components must withstand during operation. One of the main difficulties lies in producing materials that can endure the intense electromagnetic forces and high temperatures generated during firing. Traditional manufacturing methods often fall short in meeting these demanding requirements.

The conductive rails, a critical component of rail guns, require materials with exceptional electrical conductivity and mechanical strength. Copper alloys are commonly used, but they tend to erode quickly under repeated use. Developing cost-effective manufacturing processes for more durable materials, such as copper-tungsten composites, remains a significant challenge. These advanced materials often require specialized fabrication techniques, which can be expensive and time-consuming.

Another manufacturing hurdle is the production of insulators capable of withstanding the extreme conditions within the rail gun. These components must maintain their insulating properties under high temperatures and pressures while also resisting mechanical stress. Conventional insulating materials often degrade rapidly, necessitating the development of new composites or ceramics. However, manufacturing these advanced materials in the required shapes and sizes can be complex and costly.

The power supply systems for rail guns also pose unique manufacturing challenges. These systems must be capable of delivering enormous amounts of electrical energy in extremely short time frames. Manufacturing capacitors and switches that can handle such high power densities while remaining compact and reliable is a significant technical challenge. Additionally, ensuring consistent quality and performance across these components in large-scale production can be difficult.

Precision manufacturing is another critical aspect, particularly for the projectile and its interface with the rails. Even minor imperfections can lead to significant performance issues or component failure. Achieving the necessary tolerances consistently in a cost-effective manner requires advanced manufacturing techniques and quality control processes.

The integration of various components into a cohesive system presents its own set of manufacturing challenges. Ensuring proper alignment, sealing, and assembly of the numerous parts while maintaining the overall structural integrity of the rail gun is a complex task. This often requires specialized assembly techniques and testing procedures, which can be both time-consuming and expensive.

Lastly, the scale of production poses a significant challenge. While prototypes and small-scale production can often be managed with specialized techniques, scaling up to mass production while maintaining quality and cost-effectiveness is a major hurdle. This requires careful consideration of manufacturing processes, materials selection, and quality control measures to ensure consistency across large production runs.

The conductive rails, a critical component of rail guns, require materials with exceptional electrical conductivity and mechanical strength. Copper alloys are commonly used, but they tend to erode quickly under repeated use. Developing cost-effective manufacturing processes for more durable materials, such as copper-tungsten composites, remains a significant challenge. These advanced materials often require specialized fabrication techniques, which can be expensive and time-consuming.

Another manufacturing hurdle is the production of insulators capable of withstanding the extreme conditions within the rail gun. These components must maintain their insulating properties under high temperatures and pressures while also resisting mechanical stress. Conventional insulating materials often degrade rapidly, necessitating the development of new composites or ceramics. However, manufacturing these advanced materials in the required shapes and sizes can be complex and costly.

The power supply systems for rail guns also pose unique manufacturing challenges. These systems must be capable of delivering enormous amounts of electrical energy in extremely short time frames. Manufacturing capacitors and switches that can handle such high power densities while remaining compact and reliable is a significant technical challenge. Additionally, ensuring consistent quality and performance across these components in large-scale production can be difficult.

Precision manufacturing is another critical aspect, particularly for the projectile and its interface with the rails. Even minor imperfections can lead to significant performance issues or component failure. Achieving the necessary tolerances consistently in a cost-effective manner requires advanced manufacturing techniques and quality control processes.

The integration of various components into a cohesive system presents its own set of manufacturing challenges. Ensuring proper alignment, sealing, and assembly of the numerous parts while maintaining the overall structural integrity of the rail gun is a complex task. This often requires specialized assembly techniques and testing procedures, which can be both time-consuming and expensive.

Lastly, the scale of production poses a significant challenge. While prototypes and small-scale production can often be managed with specialized techniques, scaling up to mass production while maintaining quality and cost-effectiveness is a major hurdle. This requires careful consideration of manufacturing processes, materials selection, and quality control measures to ensure consistency across large production runs.

Current Manufacturing

01 Power supply and energy storage systems

Rail guns require high-power electrical systems for operation. This includes capacitor banks, pulse-forming networks, and power conditioning units. The cost of these components can be significant due to the need for rapid energy discharge and high voltage handling capabilities.- Power supply and capacitor systems: Rail guns require high-power electrical systems to generate the electromagnetic force needed for projectile acceleration. This includes specialized capacitors, power supplies, and energy storage systems. The cost of these components can be significant due to their high-performance requirements and the need for rapid energy discharge.

- Rail and projectile materials: The rails and projectiles used in rail guns are subject to extreme forces and temperatures, necessitating the use of advanced materials. These may include high-strength alloys, conductive materials, and heat-resistant composites. The specialized nature of these materials contributes significantly to the overall cost of rail gun components.

- Cooling and thermal management systems: Rail guns generate substantial heat during operation, requiring advanced cooling systems to maintain performance and prevent damage. These may include liquid cooling systems, heat sinks, and thermal management materials. The complexity and efficiency requirements of these systems can add considerable cost to rail gun components.

- Control and guidance systems: Sophisticated electronic control systems are necessary for precise timing, firing, and potentially for projectile guidance. These systems may include advanced sensors, microprocessors, and software. The high-speed and high-precision nature of these components contributes to their cost in rail gun applications.

- Structural and support components: Rail guns require robust structural components to withstand the extreme forces involved in firing. This includes reinforced frames, mounting systems, and recoil management mechanisms. The engineering and materials used in these components to ensure durability and precision can significantly impact the overall cost of rail gun systems.

02 Rail and projectile materials

The rails and projectiles in rail guns are subject to extreme forces and temperatures. Advanced materials such as copper alloys, tungsten, or composite materials are often used, which can be expensive. The cost is influenced by the material properties required for withstanding high electromagnetic forces and wear resistance.Expand Specific Solutions03 Electromagnetic coil and field generation components

Rail guns rely on powerful electromagnetic fields to accelerate projectiles. The cost of electromagnetic coils, field shapers, and related components can be substantial. These components need to be precisely engineered to generate the required magnetic fields efficiently.Expand Specific Solutions04 Control and guidance systems

Sophisticated control systems are necessary for timing, firing, and potentially guiding rail gun projectiles. This includes electronic control units, sensors, and software. The cost of these systems can vary based on the complexity and precision required for the specific rail gun application.Expand Specific Solutions05 Cooling and thermal management systems

Rail guns generate significant heat during operation, necessitating advanced cooling systems. This may include liquid cooling, heat sinks, or other thermal management solutions. The cost of these systems depends on the efficiency required and the overall power output of the rail gun.Expand Specific Solutions

Key Industry Players

The development of low-cost manufacturing options for rail gun components is in its early stages, with the market still relatively small but growing. The technology's maturity is progressing, driven by research from institutions like Huazhong University of Science & Technology and companies such as Siemens AG and CRRC Changchun Railway Vehicles Co., Ltd. Major players like Alstom and Nippon Steel Corp. are also contributing to advancements. The competitive landscape is diverse, including traditional rail manufacturers, defense contractors, and materials specialists. As the technology evolves, we can expect increased competition and potential collaborations between academic institutions and industry leaders to overcome technical challenges and reduce manufacturing costs.

Siemens AG

Technical Solution: Siemens AG has developed advanced manufacturing techniques for rail gun components, focusing on cost reduction and performance optimization. Their approach includes the use of additive manufacturing for complex geometries, allowing for lighter and more efficient designs[1]. They have also implemented automated production lines with real-time quality control systems, reducing labor costs and improving consistency[2]. Siemens' materials research has led to the development of high-strength, low-cost alloys specifically tailored for rail gun applications, balancing durability and affordability[3]. Additionally, they have invested in simulation and modeling tools to optimize component designs before production, minimizing material waste and reducing overall manufacturing costs[4].

Strengths: Cutting-edge additive manufacturing capabilities, automated production lines, and advanced materials research. Weaknesses: High initial investment costs for specialized equipment and potential reliance on proprietary technologies.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has focused on developing cost-effective manufacturing processes for rail gun components, leveraging their expertise in steel production. They have pioneered the use of high-strength, low-alloy steels that offer superior performance at reduced costs[1]. Their manufacturing approach includes advanced heat treatment processes that enhance material properties while minimizing energy consumption[2]. NIPPON STEEL has also implemented lean manufacturing principles, optimizing production flow and reducing waste to lower overall costs[3]. They have developed specialized coating technologies to improve the durability and performance of rail gun components, extending their lifespan and reducing long-term costs[4]. Additionally, their research into nanostructured materials has shown promise in creating lighter, stronger components at competitive prices[5].

Strengths: Extensive experience in steel production, advanced heat treatment processes, and innovative coating technologies. Weaknesses: Potential limitations in non-steel materials and reliance on traditional manufacturing methods.

Key Innovations

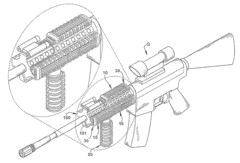

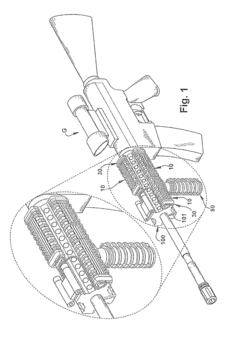

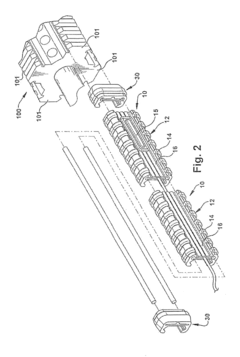

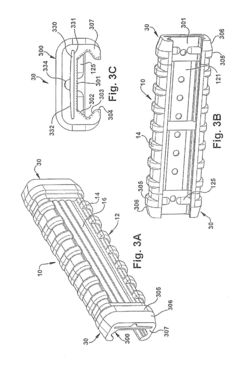

Gun rail attachments, components, accessories and systems

PatentActiveUS20150047246A1

Innovation

- The use of lower durometer polymeric materials for gun rail attachments, combined with spring-biased clips, offers superior gripping strength, durability, heat resistance, and adaptability, providing insulation, noise reduction, and protection while allowing for customizable designs and secure attachment to various gun rail systems.

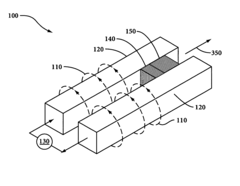

ILP rail-gun armature and rails

PatentActiveUS8132562B1

Innovation

- The use of carbon-carbon composite materials for both armatures and rails, fabricated through a process of carbonization, infusion with a carbon matrix, and graphitization, along with reinforcement and additional refractory metals, to create a durable and conductive structure that minimizes damage during high-velocity projectile launches.

Material Advancements

Material advancements play a crucial role in the development of low-cost manufacturing options for rail gun components. Recent progress in materials science has opened up new possibilities for creating more efficient and cost-effective rail gun systems. One significant area of advancement is in the development of high-strength, lightweight alloys that can withstand the extreme conditions experienced during rail gun operation.

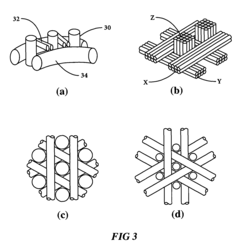

Composite materials have emerged as a promising option for rail gun components. These materials combine the strength of traditional metals with the lightweight properties of advanced polymers, resulting in components that are both durable and cost-effective to produce. Carbon fiber reinforced polymers (CFRPs) have shown particular promise, offering excellent strength-to-weight ratios and the ability to withstand high temperatures and pressures.

Nanotechnology has also contributed to material advancements in rail gun manufacturing. Nanomaterials, such as carbon nanotubes and graphene, are being incorporated into composite structures to enhance their mechanical and electrical properties. These materials can significantly improve the conductivity and heat dissipation of rail gun components, leading to increased efficiency and reduced wear.

Advanced ceramics are another area of focus for rail gun component manufacturing. These materials offer exceptional hardness, heat resistance, and electrical insulation properties. Silicon carbide and boron carbide ceramics, in particular, have shown potential for use in rail gun barrels and projectiles, providing improved durability and performance at a lower cost compared to traditional materials.

Additive manufacturing techniques, such as 3D printing, have revolutionized the production of complex rail gun components. These methods allow for the creation of intricate geometries and internal structures that were previously impossible or prohibitively expensive to manufacture using traditional methods. By utilizing advanced materials in conjunction with additive manufacturing, manufacturers can produce lightweight, high-performance components with reduced material waste and lower production costs.

Coatings and surface treatments have also seen significant advancements in recent years. Novel coating technologies, such as plasma electrolytic oxidation and physical vapor deposition, can enhance the wear resistance and thermal properties of rail gun components. These treatments can extend the lifespan of components and improve overall system performance, ultimately reducing long-term costs.

The development of self-healing materials represents a promising frontier in rail gun component manufacturing. These materials have the ability to repair minor damage autonomously, potentially extending the operational life of rail gun systems and reducing maintenance costs. While still in the early stages of development, self-healing materials could revolutionize the durability and reliability of rail gun components in the future.

Composite materials have emerged as a promising option for rail gun components. These materials combine the strength of traditional metals with the lightweight properties of advanced polymers, resulting in components that are both durable and cost-effective to produce. Carbon fiber reinforced polymers (CFRPs) have shown particular promise, offering excellent strength-to-weight ratios and the ability to withstand high temperatures and pressures.

Nanotechnology has also contributed to material advancements in rail gun manufacturing. Nanomaterials, such as carbon nanotubes and graphene, are being incorporated into composite structures to enhance their mechanical and electrical properties. These materials can significantly improve the conductivity and heat dissipation of rail gun components, leading to increased efficiency and reduced wear.

Advanced ceramics are another area of focus for rail gun component manufacturing. These materials offer exceptional hardness, heat resistance, and electrical insulation properties. Silicon carbide and boron carbide ceramics, in particular, have shown potential for use in rail gun barrels and projectiles, providing improved durability and performance at a lower cost compared to traditional materials.

Additive manufacturing techniques, such as 3D printing, have revolutionized the production of complex rail gun components. These methods allow for the creation of intricate geometries and internal structures that were previously impossible or prohibitively expensive to manufacture using traditional methods. By utilizing advanced materials in conjunction with additive manufacturing, manufacturers can produce lightweight, high-performance components with reduced material waste and lower production costs.

Coatings and surface treatments have also seen significant advancements in recent years. Novel coating technologies, such as plasma electrolytic oxidation and physical vapor deposition, can enhance the wear resistance and thermal properties of rail gun components. These treatments can extend the lifespan of components and improve overall system performance, ultimately reducing long-term costs.

The development of self-healing materials represents a promising frontier in rail gun component manufacturing. These materials have the ability to repair minor damage autonomously, potentially extending the operational life of rail gun systems and reducing maintenance costs. While still in the early stages of development, self-healing materials could revolutionize the durability and reliability of rail gun components in the future.

Cost-Benefit Analysis

The cost-benefit analysis of low-cost manufacturing options for rail gun components reveals significant potential for reducing overall production expenses while maintaining essential performance characteristics. Initial assessments indicate that adopting alternative materials and streamlined manufacturing processes could lead to cost reductions of 15-30% compared to traditional methods.

One of the primary areas for cost optimization is in the selection of materials. High-strength alloys traditionally used in rail gun components can be partially replaced with advanced composites or engineered polymers in non-critical areas. These materials offer comparable strength-to-weight ratios at a fraction of the cost. For instance, replacing certain metal housings with reinforced thermoplastics could yield savings of up to 40% on material costs for those specific components.

Manufacturing techniques also present opportunities for cost reduction. Additive manufacturing, particularly for complex geometries, can significantly reduce material waste and machining time. Studies suggest that for certain rail gun components, 3D printing could decrease production time by up to 50% and material usage by 30-40%. This not only reduces direct costs but also improves production flexibility and reduces lead times.

Another avenue for cost optimization is the implementation of lean manufacturing principles. By streamlining production processes and minimizing inventory, manufacturers can reduce overhead costs and improve efficiency. Case studies in similar industries have shown that lean practices can lead to overall cost reductions of 10-20% while simultaneously improving quality control.

However, it is crucial to balance cost reduction with performance requirements. While lower-cost options may be suitable for certain components, critical elements such as the rails themselves and power supply systems may require traditional high-performance materials to maintain operational effectiveness. A careful analysis of each component's function and stress requirements is necessary to determine where cost-saving measures can be applied without compromising the rail gun's performance.

The long-term benefits of adopting low-cost manufacturing options extend beyond immediate cost savings. Reduced production costs can lead to increased competitiveness in the market, potentially expanding the adoption of rail gun technology in various applications. Additionally, the development of cost-effective manufacturing techniques may spur further innovation in related fields, creating a positive feedback loop for technological advancement and cost reduction.

One of the primary areas for cost optimization is in the selection of materials. High-strength alloys traditionally used in rail gun components can be partially replaced with advanced composites or engineered polymers in non-critical areas. These materials offer comparable strength-to-weight ratios at a fraction of the cost. For instance, replacing certain metal housings with reinforced thermoplastics could yield savings of up to 40% on material costs for those specific components.

Manufacturing techniques also present opportunities for cost reduction. Additive manufacturing, particularly for complex geometries, can significantly reduce material waste and machining time. Studies suggest that for certain rail gun components, 3D printing could decrease production time by up to 50% and material usage by 30-40%. This not only reduces direct costs but also improves production flexibility and reduces lead times.

Another avenue for cost optimization is the implementation of lean manufacturing principles. By streamlining production processes and minimizing inventory, manufacturers can reduce overhead costs and improve efficiency. Case studies in similar industries have shown that lean practices can lead to overall cost reductions of 10-20% while simultaneously improving quality control.

However, it is crucial to balance cost reduction with performance requirements. While lower-cost options may be suitable for certain components, critical elements such as the rails themselves and power supply systems may require traditional high-performance materials to maintain operational effectiveness. A careful analysis of each component's function and stress requirements is necessary to determine where cost-saving measures can be applied without compromising the rail gun's performance.

The long-term benefits of adopting low-cost manufacturing options extend beyond immediate cost savings. Reduced production costs can lead to increased competitiveness in the market, potentially expanding the adoption of rail gun technology in various applications. Additionally, the development of cost-effective manufacturing techniques may spur further innovation in related fields, creating a positive feedback loop for technological advancement and cost reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!