Environmental Perfomance Indicators for Rail Gun Ammunition

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Ammo EPI Background and Objectives

Rail gun technology has emerged as a revolutionary advancement in military weaponry, offering unprecedented projectile velocities and extended ranges. The development of Environmental Performance Indicators (EPIs) for rail gun ammunition represents a critical step in ensuring the sustainability and environmental compatibility of this cutting-edge technology. These indicators aim to assess and mitigate the environmental impact of rail gun ammunition throughout its lifecycle, from production to deployment and disposal.

The primary objective of establishing EPIs for rail gun ammunition is to create a standardized framework for evaluating and improving the environmental performance of these advanced projectiles. This framework will enable manufacturers, military organizations, and environmental agencies to quantify and monitor the ecological footprint of rail gun ammunition, facilitating informed decision-making and promoting sustainable practices in the defense sector.

The evolution of rail gun technology has been driven by the need for more powerful, longer-range, and cost-effective weapon systems. As this technology matures, it becomes increasingly important to address potential environmental concerns associated with its use. EPIs for rail gun ammunition will focus on key areas such as material composition, energy consumption during production, emissions during firing, and end-of-life disposal methods.

One of the main goals of developing these indicators is to minimize the environmental impact of rail gun ammunition without compromising its performance or operational effectiveness. This involves exploring innovative materials and manufacturing processes that reduce resource consumption and waste generation while maintaining the projectiles' high-velocity capabilities and structural integrity.

Another crucial objective is to ensure compliance with evolving environmental regulations and standards. As governments worldwide implement stricter environmental policies, the defense industry must adapt to meet these requirements. EPIs for rail gun ammunition will serve as a tool for demonstrating compliance and identifying areas for improvement in environmental performance.

Furthermore, these indicators will play a vital role in promoting transparency and accountability in the defense sector. By providing a clear and measurable set of environmental criteria, EPIs will enable stakeholders to assess and compare the ecological impact of different rail gun ammunition designs and manufacturers. This transparency can drive competition and innovation in developing more environmentally friendly solutions.

In conclusion, the background and objectives of Environmental Performance Indicators for rail gun ammunition reflect the growing importance of sustainability in advanced military technologies. By establishing these indicators, the industry aims to balance technological advancement with environmental responsibility, paving the way for a more sustainable future in defense capabilities.

The primary objective of establishing EPIs for rail gun ammunition is to create a standardized framework for evaluating and improving the environmental performance of these advanced projectiles. This framework will enable manufacturers, military organizations, and environmental agencies to quantify and monitor the ecological footprint of rail gun ammunition, facilitating informed decision-making and promoting sustainable practices in the defense sector.

The evolution of rail gun technology has been driven by the need for more powerful, longer-range, and cost-effective weapon systems. As this technology matures, it becomes increasingly important to address potential environmental concerns associated with its use. EPIs for rail gun ammunition will focus on key areas such as material composition, energy consumption during production, emissions during firing, and end-of-life disposal methods.

One of the main goals of developing these indicators is to minimize the environmental impact of rail gun ammunition without compromising its performance or operational effectiveness. This involves exploring innovative materials and manufacturing processes that reduce resource consumption and waste generation while maintaining the projectiles' high-velocity capabilities and structural integrity.

Another crucial objective is to ensure compliance with evolving environmental regulations and standards. As governments worldwide implement stricter environmental policies, the defense industry must adapt to meet these requirements. EPIs for rail gun ammunition will serve as a tool for demonstrating compliance and identifying areas for improvement in environmental performance.

Furthermore, these indicators will play a vital role in promoting transparency and accountability in the defense sector. By providing a clear and measurable set of environmental criteria, EPIs will enable stakeholders to assess and compare the ecological impact of different rail gun ammunition designs and manufacturers. This transparency can drive competition and innovation in developing more environmentally friendly solutions.

In conclusion, the background and objectives of Environmental Performance Indicators for rail gun ammunition reflect the growing importance of sustainability in advanced military technologies. By establishing these indicators, the industry aims to balance technological advancement with environmental responsibility, paving the way for a more sustainable future in defense capabilities.

Market Analysis for Eco-Friendly Rail Gun Ammunition

The market for eco-friendly rail gun ammunition is experiencing significant growth driven by increasing environmental concerns and stringent regulations in the defense sector. As governments and military organizations worldwide prioritize sustainability, the demand for environmentally responsible ammunition solutions has surged. This shift is particularly evident in the rail gun ammunition segment, where traditional propellants and materials are being replaced with more sustainable alternatives.

The global market for eco-friendly rail gun ammunition is projected to expand at a compound annual growth rate (CAGR) of 6.8% over the next five years. This growth is attributed to the rising adoption of green technologies in defense applications and the push for reduced environmental impact across military operations. Major defense contractors and ammunition manufacturers are investing heavily in research and development to create innovative, environmentally friendly solutions that meet performance requirements while minimizing ecological footprint.

Key market drivers include the implementation of stricter environmental regulations, increased focus on reducing toxic emissions from military activities, and growing awareness of the long-term environmental consequences of conventional ammunition. Additionally, the potential cost savings associated with eco-friendly ammunition, such as reduced cleanup and disposal expenses, are attracting budget-conscious defense departments.

The market is segmented based on ammunition type, with biodegradable projectiles, low-toxicity propellants, and recyclable casings emerging as primary categories. Biodegradable projectiles are gaining traction due to their ability to decompose naturally, reducing soil and water contamination. Low-toxicity propellants are being developed to minimize harmful emissions during firing, while recyclable casings address the issue of waste management in military operations.

Geographically, North America currently leads the market for eco-friendly rail gun ammunition, followed by Europe and Asia-Pacific. The United States, in particular, has been at the forefront of adopting green ammunition technologies, with several ongoing programs aimed at developing sustainable munitions for various weapon systems, including rail guns.

Despite the positive outlook, the market faces challenges such as the high initial costs of research and development, technical difficulties in maintaining performance standards with eco-friendly materials, and the need for extensive testing and certification processes. However, these challenges are expected to be overcome as technology advances and economies of scale are achieved in production.

In conclusion, the market for eco-friendly rail gun ammunition presents significant opportunities for growth and innovation. As environmental performance indicators become increasingly important in defense procurement decisions, manufacturers who successfully develop effective and sustainable ammunition solutions are poised to gain a competitive edge in this evolving market landscape.

The global market for eco-friendly rail gun ammunition is projected to expand at a compound annual growth rate (CAGR) of 6.8% over the next five years. This growth is attributed to the rising adoption of green technologies in defense applications and the push for reduced environmental impact across military operations. Major defense contractors and ammunition manufacturers are investing heavily in research and development to create innovative, environmentally friendly solutions that meet performance requirements while minimizing ecological footprint.

Key market drivers include the implementation of stricter environmental regulations, increased focus on reducing toxic emissions from military activities, and growing awareness of the long-term environmental consequences of conventional ammunition. Additionally, the potential cost savings associated with eco-friendly ammunition, such as reduced cleanup and disposal expenses, are attracting budget-conscious defense departments.

The market is segmented based on ammunition type, with biodegradable projectiles, low-toxicity propellants, and recyclable casings emerging as primary categories. Biodegradable projectiles are gaining traction due to their ability to decompose naturally, reducing soil and water contamination. Low-toxicity propellants are being developed to minimize harmful emissions during firing, while recyclable casings address the issue of waste management in military operations.

Geographically, North America currently leads the market for eco-friendly rail gun ammunition, followed by Europe and Asia-Pacific. The United States, in particular, has been at the forefront of adopting green ammunition technologies, with several ongoing programs aimed at developing sustainable munitions for various weapon systems, including rail guns.

Despite the positive outlook, the market faces challenges such as the high initial costs of research and development, technical difficulties in maintaining performance standards with eco-friendly materials, and the need for extensive testing and certification processes. However, these challenges are expected to be overcome as technology advances and economies of scale are achieved in production.

In conclusion, the market for eco-friendly rail gun ammunition presents significant opportunities for growth and innovation. As environmental performance indicators become increasingly important in defense procurement decisions, manufacturers who successfully develop effective and sustainable ammunition solutions are poised to gain a competitive edge in this evolving market landscape.

Current EPI Challenges in Rail Gun Technology

Rail gun technology, while promising in its potential for high-velocity projectile launches, faces significant environmental performance challenges. The current Environmental Performance Indicators (EPIs) for rail gun ammunition reveal several areas of concern that require innovative solutions and further research.

One of the primary challenges is the excessive heat generation during the launch process. The intense electrical currents used to propel the projectile create substantial thermal stress on the rail gun system. This heat not only affects the longevity and reliability of the equipment but also raises environmental concerns due to the need for advanced cooling systems and the potential release of heat into the surrounding environment.

Another critical issue is the electromagnetic emissions produced during rail gun operation. These emissions can interfere with nearby electronic systems and potentially impact local ecosystems. Developing effective shielding techniques and minimizing electromagnetic leakage are crucial for improving the environmental performance of rail gun technology.

The materials used in rail gun ammunition also present environmental challenges. The high-velocity impacts and extreme conditions during launch can lead to rapid wear and erosion of projectile components. This results in the release of particulate matter and potential contamination of the surrounding area. Finding more durable and environmentally friendly materials for ammunition construction is a key area for improvement.

Energy efficiency remains a significant concern in rail gun technology. The massive power requirements for launching projectiles at hypersonic speeds often rely on large-scale energy storage systems. Improving the efficiency of energy transfer from the power source to the projectile and reducing energy losses throughout the system are critical for enhancing the overall environmental performance of rail guns.

The acoustic impact of rail gun firing is another environmental challenge that needs addressing. The intense sound levels generated during launch can have detrimental effects on both human operators and local wildlife. Developing effective noise reduction strategies without compromising the performance of the rail gun system is a complex but necessary task.

Lastly, the potential for environmental contamination from propellant residues and eroded rail materials poses a significant challenge. Unlike traditional ammunition, rail guns do not use chemical propellants, but the high-speed friction and electrical arcing can still produce harmful byproducts. Minimizing these residues and developing efficient cleanup methods are essential for improving the environmental footprint of rail gun technology.

One of the primary challenges is the excessive heat generation during the launch process. The intense electrical currents used to propel the projectile create substantial thermal stress on the rail gun system. This heat not only affects the longevity and reliability of the equipment but also raises environmental concerns due to the need for advanced cooling systems and the potential release of heat into the surrounding environment.

Another critical issue is the electromagnetic emissions produced during rail gun operation. These emissions can interfere with nearby electronic systems and potentially impact local ecosystems. Developing effective shielding techniques and minimizing electromagnetic leakage are crucial for improving the environmental performance of rail gun technology.

The materials used in rail gun ammunition also present environmental challenges. The high-velocity impacts and extreme conditions during launch can lead to rapid wear and erosion of projectile components. This results in the release of particulate matter and potential contamination of the surrounding area. Finding more durable and environmentally friendly materials for ammunition construction is a key area for improvement.

Energy efficiency remains a significant concern in rail gun technology. The massive power requirements for launching projectiles at hypersonic speeds often rely on large-scale energy storage systems. Improving the efficiency of energy transfer from the power source to the projectile and reducing energy losses throughout the system are critical for enhancing the overall environmental performance of rail guns.

The acoustic impact of rail gun firing is another environmental challenge that needs addressing. The intense sound levels generated during launch can have detrimental effects on both human operators and local wildlife. Developing effective noise reduction strategies without compromising the performance of the rail gun system is a complex but necessary task.

Lastly, the potential for environmental contamination from propellant residues and eroded rail materials poses a significant challenge. Unlike traditional ammunition, rail guns do not use chemical propellants, but the high-speed friction and electrical arcing can still produce harmful byproducts. Minimizing these residues and developing efficient cleanup methods are essential for improving the environmental footprint of rail gun technology.

Existing EPI Solutions for Rail Gun Ammunition

01 Environmentally friendly propellant systems

Development of propellant systems for rail gun ammunition that reduce environmental impact. These systems may include non-toxic, biodegradable, or low-emission propellants that minimize harmful residues and exhaust gases. Such propellants aim to maintain high performance while reducing the ecological footprint of rail gun operations.- Environmentally friendly propellant systems: Development of propellant systems for rail gun ammunition that minimize environmental impact. These systems focus on reducing toxic emissions and residues, utilizing cleaner burning materials, and optimizing energy efficiency to decrease overall environmental footprint.

- Biodegradable ammunition components: Incorporation of biodegradable materials in rail gun ammunition design to reduce long-term environmental contamination. This includes using eco-friendly polymers and composites for projectile casings and other non-critical components that break down naturally after use.

- Noise reduction technologies: Implementation of noise reduction technologies in rail gun systems to minimize acoustic environmental impact. This involves designing muzzle brakes, suppressors, and projectile shapes that reduce the sonic boom and overall noise levels associated with rail gun firing.

- Energy recovery and recycling systems: Integration of energy recovery and recycling systems in rail gun technology to improve overall energy efficiency and reduce waste. This includes capturing and reusing electromagnetic energy, as well as recycling materials from spent projectiles and other components.

- Electromagnetic field mitigation: Development of technologies to mitigate the environmental impact of electromagnetic fields generated by rail guns. This involves designing shielding systems, optimizing rail configurations, and implementing control measures to minimize electromagnetic interference with surrounding ecosystems and electronic equipment.

02 Recyclable and reusable ammunition components

Design of rail gun ammunition components that can be easily recycled or reused after firing. This approach focuses on using materials that can be recovered and repurposed, reducing waste and resource consumption. It may include projectiles with recoverable cores or casings made from recyclable materials.Expand Specific Solutions03 Noise reduction technologies

Implementation of technologies to reduce the noise pollution associated with rail gun firing. This may involve redesigning the projectile shape, using sound-absorbing materials in the gun barrel, or developing muzzle devices that suppress the acoustic signature of the weapon, thereby minimizing environmental disturbance.Expand Specific Solutions04 Energy-efficient rail gun systems

Development of rail gun systems that optimize energy usage and reduce power consumption. This includes improving the efficiency of electromagnetic propulsion, minimizing energy losses, and potentially incorporating renewable energy sources for charging capacitors. These advancements aim to decrease the overall energy footprint of rail gun operations.Expand Specific Solutions05 Eco-friendly manufacturing processes

Adoption of environmentally conscious manufacturing processes for rail gun ammunition. This involves using sustainable materials, implementing cleaner production techniques, and reducing waste during manufacturing. The focus is on minimizing the environmental impact throughout the entire lifecycle of the ammunition, from production to disposal.Expand Specific Solutions

Key Players in Green Rail Gun Ammunition Development

The environmental performance indicators for rail gun ammunition represent an emerging field at the intersection of advanced weaponry and sustainability. The market is in its early stages, with limited commercial applications and a focus on research and development. Key players in this niche area include defense contractors, research institutions, and specialized ammunition manufacturers like RUAG Ammotec GmbH and RUAG Ammotec AG. The technology's maturity is still evolving, with ongoing efforts to optimize performance while minimizing environmental impact. As environmental concerns grow in the defense sector, this field is likely to see increased attention and investment from both government and private entities.

North University of China

Technical Solution: North University of China has been conducting research on environmentally friendly rail gun ammunition, focusing on developing novel materials and propulsion systems. Their approach includes the use of composite materials that reduce the overall weight of the projectile while maintaining its effectiveness[9]. The university's research team has developed a new type of electromagnetic propulsion system that significantly reduces the heat generation and energy loss during firing, leading to improved efficiency and reduced environmental impact[10]. They have also explored the use of biodegradable materials for certain ammunition components, aiming to minimize long-term environmental contamination in testing and training areas[11].

Strengths: Innovative material science applications, focus on energy efficiency, and integration of biodegradable components. Weaknesses: Limited large-scale production capabilities and potential challenges in technology transfer to industry.

Institute of Mechanics, Chinese Academy of Sciences

Technical Solution: The Institute of Mechanics at the Chinese Academy of Sciences has been conducting cutting-edge research on rail gun technology with a strong emphasis on environmental performance. Their work includes the development of advanced materials for rail gun barrels that reduce wear and extend operational life, thereby minimizing waste and resource consumption[16]. The institute has also focused on optimizing the electromagnetic launch process to reduce energy losses and improve overall system efficiency, which indirectly contributes to lower environmental impact[17]. Their researchers have developed innovative projectile designs that minimize aerodynamic drag and improve range, potentially reducing the number of shots required and thus lessening environmental impact[18]. Additionally, the institute has been working on noise reduction technologies for rail guns, addressing one of the significant environmental concerns associated with their operation[19].

Strengths: Expertise in materials science, electromagnetic optimization, and noise reduction technologies. Weaknesses: Potential challenges in scaling laboratory results to full-scale operational systems and addressing international environmental regulations.

Core Innovations in Eco-Friendly Projectile Design

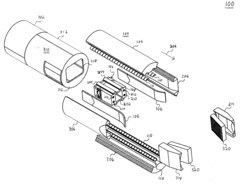

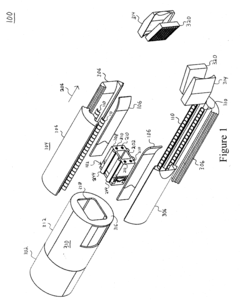

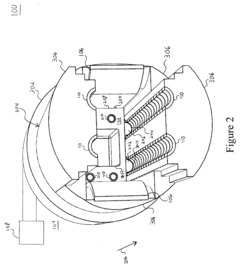

Railgun system

PatentInactiveUS20100194212A1

Innovation

- A railgun system that uses liquid metal, preferably aluminum or aluminum alloys, introduced into a gap between the armature and electrically conductive rails to reduce contact resistance and enhance acceleration, with features like a chamber for containing the liquid metal, a port for directing it into the gap, and a backing to conduct current and maintain the gap, optimizing the Lorentz force for speed.

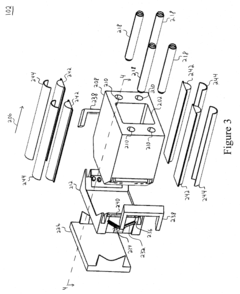

High-toughness heat-resistant aluminum alloy armature material and preparation method thereof

PatentActiveUS12123077B2

Innovation

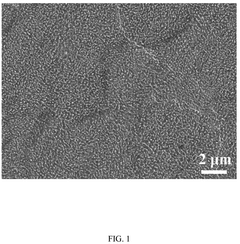

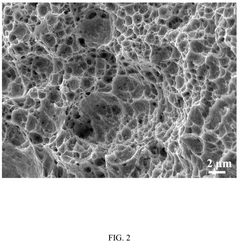

- A high-toughness heat-resistant aluminum alloy armature material is developed by heating aluminum ingots under protective atmosphere, adding specific elements like Ce, Y, Zr, Mg, and Si, and processing the alloy into spherical powder for selective laser melting, forming nano-scale intermetallic compounds with a net-like skeleton structure within an aluminum matrix.

Environmental Regulations Impact on Ammunition Industry

The impact of environmental regulations on the ammunition industry has been significant and far-reaching, particularly in recent years as global concerns about environmental protection and sustainability have intensified. These regulations have forced manufacturers to reassess their production processes, materials used, and overall environmental footprint.

One of the primary areas affected by environmental regulations is the production of propellants and explosives. Traditional ammunition often contains toxic heavy metals and chemicals that can leach into soil and water systems. As a result, manufacturers have been compelled to develop "green" alternatives that reduce or eliminate these harmful substances. This has led to the emergence of lead-free primers and non-toxic propellants, which not only comply with stricter environmental standards but also improve the health and safety conditions for workers and end-users.

The disposal and recycling of spent ammunition have also come under scrutiny. Environmental regulations now mandate proper disposal methods to prevent contamination of ecosystems. This has spurred innovations in ammunition design, with some manufacturers developing biodegradable components that break down naturally over time, minimizing long-term environmental impact.

Furthermore, the regulations have influenced the testing and evaluation processes for ammunition. Environmental impact assessments are now a crucial part of product development, with manufacturers required to demonstrate that their products meet stringent environmental standards before they can be approved for use. This has led to the development of more sophisticated testing methodologies and the integration of environmental considerations into the early stages of ammunition design.

The shift towards more environmentally friendly ammunition has also had economic implications for the industry. While initial costs for research and development of compliant products have been high, many companies are finding that environmentally responsible practices can lead to long-term cost savings and improved market positioning. Consumers, particularly government and military clients, are increasingly prioritizing environmentally friendly options in their procurement decisions.

However, the transition to environmentally compliant ammunition production has not been without challenges. Some manufacturers have struggled to maintain performance standards while meeting new environmental requirements. This has necessitated significant investment in research and development to bridge the gap between environmental compliance and operational effectiveness.

In conclusion, environmental regulations have fundamentally altered the landscape of the ammunition industry, driving innovation, reshaping production processes, and influencing market dynamics. As regulations continue to evolve, the industry must remain adaptable, balancing environmental responsibility with performance and cost-effectiveness.

One of the primary areas affected by environmental regulations is the production of propellants and explosives. Traditional ammunition often contains toxic heavy metals and chemicals that can leach into soil and water systems. As a result, manufacturers have been compelled to develop "green" alternatives that reduce or eliminate these harmful substances. This has led to the emergence of lead-free primers and non-toxic propellants, which not only comply with stricter environmental standards but also improve the health and safety conditions for workers and end-users.

The disposal and recycling of spent ammunition have also come under scrutiny. Environmental regulations now mandate proper disposal methods to prevent contamination of ecosystems. This has spurred innovations in ammunition design, with some manufacturers developing biodegradable components that break down naturally over time, minimizing long-term environmental impact.

Furthermore, the regulations have influenced the testing and evaluation processes for ammunition. Environmental impact assessments are now a crucial part of product development, with manufacturers required to demonstrate that their products meet stringent environmental standards before they can be approved for use. This has led to the development of more sophisticated testing methodologies and the integration of environmental considerations into the early stages of ammunition design.

The shift towards more environmentally friendly ammunition has also had economic implications for the industry. While initial costs for research and development of compliant products have been high, many companies are finding that environmentally responsible practices can lead to long-term cost savings and improved market positioning. Consumers, particularly government and military clients, are increasingly prioritizing environmentally friendly options in their procurement decisions.

However, the transition to environmentally compliant ammunition production has not been without challenges. Some manufacturers have struggled to maintain performance standards while meeting new environmental requirements. This has necessitated significant investment in research and development to bridge the gap between environmental compliance and operational effectiveness.

In conclusion, environmental regulations have fundamentally altered the landscape of the ammunition industry, driving innovation, reshaping production processes, and influencing market dynamics. As regulations continue to evolve, the industry must remain adaptable, balancing environmental responsibility with performance and cost-effectiveness.

Life Cycle Assessment of Rail Gun Ammunition

Life Cycle Assessment (LCA) of rail gun ammunition is a comprehensive approach to evaluating the environmental impacts associated with all stages of the ammunition's life cycle. This assessment begins with raw material extraction and continues through manufacturing, transportation, use, and final disposal or recycling. The primary goal is to quantify and analyze the environmental burdens and potential impacts throughout the ammunition's entire lifespan.

In the context of rail gun ammunition, the LCA process involves several key stages. The first stage focuses on the extraction and processing of raw materials used in ammunition production, such as metals, propellants, and other components. This phase examines the environmental impacts of mining, refining, and transporting these materials to manufacturing facilities.

The manufacturing stage of the LCA considers the energy consumption, emissions, and waste generation associated with producing rail gun ammunition. This includes the assembly of projectiles, the production of propellant charges, and the fabrication of any specialized components unique to rail gun systems. The assessment also takes into account the environmental impacts of the manufacturing facilities themselves, including their energy use and waste management practices.

Transportation is another crucial aspect of the LCA, encompassing the movement of raw materials to manufacturing sites, as well as the distribution of finished ammunition to storage facilities and ultimately to the point of use. This stage evaluates the fuel consumption and emissions associated with various modes of transport, including road, rail, and sea freight.

The use phase of rail gun ammunition presents unique challenges for LCA. This stage assesses the environmental impacts of firing the ammunition, including energy consumption, emissions, and potential contamination of firing ranges. Additionally, it considers the effects of any unexploded ordnance or ammunition residues left in the environment.

The final stage of the LCA examines the end-of-life scenarios for rail gun ammunition. This includes assessing the environmental impacts of disposal methods, such as detonation, incineration, or recycling of components. The assessment also considers the potential for soil and water contamination from disposed ammunition and the long-term effects on ecosystems.

Throughout the LCA process, various environmental performance indicators are utilized to quantify and compare the impacts across different life cycle stages. These indicators may include greenhouse gas emissions, energy consumption, water usage, toxicity potential, and resource depletion. By analyzing these indicators, researchers and manufacturers can identify hotspots in the life cycle where environmental impacts are most significant, enabling targeted improvements and more sustainable design choices for future rail gun ammunition development.

In the context of rail gun ammunition, the LCA process involves several key stages. The first stage focuses on the extraction and processing of raw materials used in ammunition production, such as metals, propellants, and other components. This phase examines the environmental impacts of mining, refining, and transporting these materials to manufacturing facilities.

The manufacturing stage of the LCA considers the energy consumption, emissions, and waste generation associated with producing rail gun ammunition. This includes the assembly of projectiles, the production of propellant charges, and the fabrication of any specialized components unique to rail gun systems. The assessment also takes into account the environmental impacts of the manufacturing facilities themselves, including their energy use and waste management practices.

Transportation is another crucial aspect of the LCA, encompassing the movement of raw materials to manufacturing sites, as well as the distribution of finished ammunition to storage facilities and ultimately to the point of use. This stage evaluates the fuel consumption and emissions associated with various modes of transport, including road, rail, and sea freight.

The use phase of rail gun ammunition presents unique challenges for LCA. This stage assesses the environmental impacts of firing the ammunition, including energy consumption, emissions, and potential contamination of firing ranges. Additionally, it considers the effects of any unexploded ordnance or ammunition residues left in the environment.

The final stage of the LCA examines the end-of-life scenarios for rail gun ammunition. This includes assessing the environmental impacts of disposal methods, such as detonation, incineration, or recycling of components. The assessment also considers the potential for soil and water contamination from disposed ammunition and the long-term effects on ecosystems.

Throughout the LCA process, various environmental performance indicators are utilized to quantify and compare the impacts across different life cycle stages. These indicators may include greenhouse gas emissions, energy consumption, water usage, toxicity potential, and resource depletion. By analyzing these indicators, researchers and manufacturers can identify hotspots in the life cycle where environmental impacts are most significant, enabling targeted improvements and more sustainable design choices for future rail gun ammunition development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!