Standardized Testing Protocols for Advanced Rail Gun Systems

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Evolution and Objectives

Rail guns have evolved significantly since their inception in the early 20th century. Initially conceived as a theoretical concept, these electromagnetic projectile launchers have progressed from laboratory experiments to advanced weapon systems. The evolution of rail guns has been marked by continuous improvements in power supply, materials science, and projectile design.

In the 1970s and 1980s, research into rail gun technology gained momentum, driven by the potential for high-velocity projectile launches without the use of chemical propellants. The 1990s saw increased funding and interest from military organizations, leading to more sophisticated prototypes and testing facilities. By the early 2000s, rail gun systems had achieved muzzle velocities exceeding 2 km/s, demonstrating their potential as long-range, high-impact weapons.

The primary objectives of advanced rail gun systems focus on enhancing their operational capabilities and addressing key technical challenges. One crucial goal is to increase the muzzle velocity, aiming to achieve speeds of 7-8 km/s or higher. This would significantly extend the range and impact of rail gun projectiles, making them viable alternatives to conventional artillery and missile systems.

Another critical objective is to improve the durability and longevity of rail gun components. The intense electromagnetic forces and heat generated during firing can rapidly degrade the rail system, limiting operational lifespan. Developing materials and designs that can withstand these extreme conditions is essential for practical deployment.

Power management represents a significant challenge and objective in rail gun development. Current systems require massive amounts of electrical energy delivered in milliseconds. Advancing energy storage and pulsed power technologies to create more compact, efficient, and reliable power sources is crucial for the integration of rail guns into various platforms, including naval vessels and land-based systems.

Projectile design is another area of focus, with objectives centered on creating aerodynamic, high-strength projectiles capable of maintaining stability at hypersonic velocities. This includes research into advanced materials and geometries that can withstand the extreme acceleration forces and temperatures encountered during launch and flight.

The development of standardized testing protocols for advanced rail gun systems aims to address these evolutionary goals and technical objectives. By establishing consistent methods for evaluating performance, durability, and reliability, these protocols will facilitate the comparison of different rail gun designs and accelerate the overall development process. Standardization will also help in identifying key performance indicators and benchmarks, guiding future research and development efforts in this rapidly evolving field of electromagnetic launch technology.

In the 1970s and 1980s, research into rail gun technology gained momentum, driven by the potential for high-velocity projectile launches without the use of chemical propellants. The 1990s saw increased funding and interest from military organizations, leading to more sophisticated prototypes and testing facilities. By the early 2000s, rail gun systems had achieved muzzle velocities exceeding 2 km/s, demonstrating their potential as long-range, high-impact weapons.

The primary objectives of advanced rail gun systems focus on enhancing their operational capabilities and addressing key technical challenges. One crucial goal is to increase the muzzle velocity, aiming to achieve speeds of 7-8 km/s or higher. This would significantly extend the range and impact of rail gun projectiles, making them viable alternatives to conventional artillery and missile systems.

Another critical objective is to improve the durability and longevity of rail gun components. The intense electromagnetic forces and heat generated during firing can rapidly degrade the rail system, limiting operational lifespan. Developing materials and designs that can withstand these extreme conditions is essential for practical deployment.

Power management represents a significant challenge and objective in rail gun development. Current systems require massive amounts of electrical energy delivered in milliseconds. Advancing energy storage and pulsed power technologies to create more compact, efficient, and reliable power sources is crucial for the integration of rail guns into various platforms, including naval vessels and land-based systems.

Projectile design is another area of focus, with objectives centered on creating aerodynamic, high-strength projectiles capable of maintaining stability at hypersonic velocities. This includes research into advanced materials and geometries that can withstand the extreme acceleration forces and temperatures encountered during launch and flight.

The development of standardized testing protocols for advanced rail gun systems aims to address these evolutionary goals and technical objectives. By establishing consistent methods for evaluating performance, durability, and reliability, these protocols will facilitate the comparison of different rail gun designs and accelerate the overall development process. Standardization will also help in identifying key performance indicators and benchmarks, guiding future research and development efforts in this rapidly evolving field of electromagnetic launch technology.

Military Demand Analysis

The military demand for advanced rail gun systems has been steadily increasing in recent years, driven by the need for long-range precision strike capabilities and the desire to reduce reliance on conventional explosive propellants. Rail guns offer significant advantages over traditional artillery systems, including higher muzzle velocities, extended range, and reduced logistics footprint.

The United States Navy has been at the forefront of rail gun development, with ongoing research and development programs aimed at integrating these systems into future warships. The potential for rail guns to provide naval surface fire support and anti-ship capabilities has generated considerable interest within the maritime domain. Other major military powers, including China and Russia, have also invested in rail gun technology, recognizing its potential to reshape modern warfare.

Land-based applications of rail gun systems are also being explored, with potential uses in air defense and long-range artillery roles. The ability to engage targets at extended ranges with high-velocity projectiles makes rail guns an attractive option for countering advanced aerial threats and providing responsive fire support to ground forces.

The development of standardized testing protocols for advanced rail gun systems is crucial for several reasons. First, it allows for consistent evaluation of system performance across different platforms and configurations. This standardization enables meaningful comparisons between various rail gun designs and helps identify areas for improvement. Second, it facilitates the establishment of benchmarks for key performance parameters such as muzzle velocity, accuracy, and rate of fire.

Furthermore, standardized testing protocols are essential for ensuring the safety and reliability of rail gun systems. Given the high energies involved in rail gun operation, rigorous testing procedures are necessary to validate system integrity and minimize the risk of catastrophic failures during operational use. These protocols also play a critical role in the certification process for new rail gun systems, providing a framework for assessing their readiness for field deployment.

The military demand for standardized testing protocols extends beyond individual weapon systems to encompass the entire rail gun ecosystem. This includes power supply systems, projectile designs, and fire control systems. Comprehensive testing protocols enable the evaluation of system integration and interoperability, ensuring that all components work together seamlessly in operational environments.

As rail gun technology continues to mature, the demand for standardized testing protocols is expected to grow. These protocols will be essential for guiding future research and development efforts, informing procurement decisions, and supporting the eventual fielding of operational rail gun systems across various military platforms.

The United States Navy has been at the forefront of rail gun development, with ongoing research and development programs aimed at integrating these systems into future warships. The potential for rail guns to provide naval surface fire support and anti-ship capabilities has generated considerable interest within the maritime domain. Other major military powers, including China and Russia, have also invested in rail gun technology, recognizing its potential to reshape modern warfare.

Land-based applications of rail gun systems are also being explored, with potential uses in air defense and long-range artillery roles. The ability to engage targets at extended ranges with high-velocity projectiles makes rail guns an attractive option for countering advanced aerial threats and providing responsive fire support to ground forces.

The development of standardized testing protocols for advanced rail gun systems is crucial for several reasons. First, it allows for consistent evaluation of system performance across different platforms and configurations. This standardization enables meaningful comparisons between various rail gun designs and helps identify areas for improvement. Second, it facilitates the establishment of benchmarks for key performance parameters such as muzzle velocity, accuracy, and rate of fire.

Furthermore, standardized testing protocols are essential for ensuring the safety and reliability of rail gun systems. Given the high energies involved in rail gun operation, rigorous testing procedures are necessary to validate system integrity and minimize the risk of catastrophic failures during operational use. These protocols also play a critical role in the certification process for new rail gun systems, providing a framework for assessing their readiness for field deployment.

The military demand for standardized testing protocols extends beyond individual weapon systems to encompass the entire rail gun ecosystem. This includes power supply systems, projectile designs, and fire control systems. Comprehensive testing protocols enable the evaluation of system integration and interoperability, ensuring that all components work together seamlessly in operational environments.

As rail gun technology continues to mature, the demand for standardized testing protocols is expected to grow. These protocols will be essential for guiding future research and development efforts, informing procurement decisions, and supporting the eventual fielding of operational rail gun systems across various military platforms.

Technical Challenges in Rail Gun Testing

Rail gun testing presents a unique set of technical challenges due to the extreme conditions and high-energy nature of these advanced weapon systems. One of the primary difficulties lies in accurately measuring and controlling the electromagnetic forces involved in rail gun operation. The intense electromagnetic fields generated during firing can interfere with sensitive measurement equipment, necessitating the development of specialized sensors and shielding techniques.

Another significant challenge is the management of thermal loads. The rapid acceleration of projectiles generates enormous amounts of heat, which can cause material degradation and affect the system's performance. Developing materials and cooling systems capable of withstanding these extreme temperatures while maintaining structural integrity is crucial for reliable testing protocols.

The high-speed nature of rail gun projectiles also poses challenges in tracking and measuring their trajectory. Traditional radar and optical tracking systems may struggle to accurately capture data on projectiles traveling at hypersonic velocities. This necessitates the development of advanced tracking technologies and data processing algorithms to provide precise measurements of projectile speed, accuracy, and impact characteristics.

Repeatability and consistency in testing are further complicated by the wear and erosion of rail gun components. The high currents and friction involved in firing can rapidly degrade rails, armatures, and other critical parts. Establishing standardized protocols for assessing and accounting for this wear is essential for ensuring comparable results across multiple test firings and between different rail gun systems.

Safety considerations add another layer of complexity to rail gun testing. The high energies involved and the potential for catastrophic failures require robust safety protocols and containment measures. Designing test facilities that can safely manage the risks associated with rail gun operation while still allowing for comprehensive data collection is a significant engineering challenge.

Furthermore, the integration of power supply systems capable of delivering the massive electrical currents required for rail gun operation presents its own set of technical hurdles. Developing and testing power storage and delivery systems that can provide the necessary energy while maintaining stability and efficiency is crucial for advancing rail gun technology.

Lastly, the development of standardized testing protocols is complicated by the diverse range of rail gun designs and applications. Creating a unified set of testing standards that can accurately assess and compare different rail gun systems, while accounting for variations in design philosophy and intended use, requires careful consideration and collaboration across the field.

Another significant challenge is the management of thermal loads. The rapid acceleration of projectiles generates enormous amounts of heat, which can cause material degradation and affect the system's performance. Developing materials and cooling systems capable of withstanding these extreme temperatures while maintaining structural integrity is crucial for reliable testing protocols.

The high-speed nature of rail gun projectiles also poses challenges in tracking and measuring their trajectory. Traditional radar and optical tracking systems may struggle to accurately capture data on projectiles traveling at hypersonic velocities. This necessitates the development of advanced tracking technologies and data processing algorithms to provide precise measurements of projectile speed, accuracy, and impact characteristics.

Repeatability and consistency in testing are further complicated by the wear and erosion of rail gun components. The high currents and friction involved in firing can rapidly degrade rails, armatures, and other critical parts. Establishing standardized protocols for assessing and accounting for this wear is essential for ensuring comparable results across multiple test firings and between different rail gun systems.

Safety considerations add another layer of complexity to rail gun testing. The high energies involved and the potential for catastrophic failures require robust safety protocols and containment measures. Designing test facilities that can safely manage the risks associated with rail gun operation while still allowing for comprehensive data collection is a significant engineering challenge.

Furthermore, the integration of power supply systems capable of delivering the massive electrical currents required for rail gun operation presents its own set of technical hurdles. Developing and testing power storage and delivery systems that can provide the necessary energy while maintaining stability and efficiency is crucial for advancing rail gun technology.

Lastly, the development of standardized testing protocols is complicated by the diverse range of rail gun designs and applications. Creating a unified set of testing standards that can accurately assess and compare different rail gun systems, while accounting for variations in design philosophy and intended use, requires careful consideration and collaboration across the field.

Current Rail Gun Testing Methods

01 Testing protocols for rail gun systems

Comprehensive testing protocols are essential for evaluating rail gun systems. These protocols involve various aspects such as performance measurement, safety checks, and system diagnostics. Testing procedures may include assessing projectile velocity, energy efficiency, and overall system reliability under different operational conditions.- Testing protocols for rail gun systems: Various testing protocols are developed for rail gun systems to evaluate their performance, safety, and reliability. These protocols may include measurements of projectile velocity, electromagnetic field strength, and thermal management. Advanced sensors and data acquisition systems are often employed to capture and analyze test results.

- Simulation and modeling techniques: Simulation and modeling techniques are utilized to predict and optimize rail gun system performance before physical testing. These methods may involve computational fluid dynamics, electromagnetic simulations, and structural analysis to assess various aspects of the rail gun design and operation.

- Diagnostic and monitoring systems: Specialized diagnostic and monitoring systems are developed to assess rail gun performance during testing. These systems may include high-speed cameras, pressure sensors, and electromagnetic field sensors to capture real-time data on projectile acceleration, rail wear, and system efficiency.

- Safety and containment measures: Testing protocols for rail gun systems incorporate safety and containment measures to protect personnel and equipment. These may include reinforced test chambers, remote operation capabilities, and fail-safe mechanisms to prevent unintended discharge or system failures during testing.

- Data analysis and performance evaluation: Comprehensive data analysis and performance evaluation methods are employed to interpret test results and assess rail gun system capabilities. These may involve statistical analysis, machine learning algorithms, and comparative studies to optimize system parameters and identify areas for improvement.

02 Data acquisition and analysis in rail gun testing

Advanced data acquisition systems are crucial for collecting and analyzing information during rail gun tests. These systems capture real-time data on various parameters such as current flow, electromagnetic field strength, and projectile trajectory. Sophisticated analysis tools are employed to process this data, enabling researchers to evaluate system performance and identify areas for improvement.Expand Specific Solutions03 Simulation and modeling for rail gun development

Simulation and modeling techniques play a vital role in rail gun system development and testing. These methods allow researchers to predict system behavior, optimize design parameters, and evaluate performance under various conditions before conducting physical tests. Advanced computational models incorporate factors such as electromagnetic interactions, thermal effects, and material properties to provide accurate simulations.Expand Specific Solutions04 Safety measures and monitoring in rail gun testing

Implementing robust safety measures and monitoring systems is critical during rail gun testing. This includes establishing safety protocols, using protective equipment, and employing real-time monitoring systems to detect potential hazards. Continuous monitoring of system parameters helps prevent accidents and ensures the safety of personnel and equipment during high-energy experiments.Expand Specific Solutions05 Performance evaluation and optimization techniques

Developing effective methods for evaluating and optimizing rail gun performance is crucial for advancing the technology. This involves creating standardized metrics for assessing system efficiency, accuracy, and reliability. Researchers employ various techniques such as statistical analysis, machine learning algorithms, and iterative testing to identify optimal operating parameters and improve overall system performance.Expand Specific Solutions

Key Players in Rail Gun Development

The standardized testing protocols for advanced rail gun systems are in an early development stage, with a growing market as military and research institutions invest in this technology. The technical maturity is still evolving, with key players like China Academy of Railway Sciences, Beijing Jiaotong University, and Zhuzhou CRRC Times Electric Co. leading research efforts. These organizations are focusing on improving precision, reliability, and power efficiency of rail gun systems. As the technology progresses, we can expect increased collaboration between academic institutions and industry partners to refine testing protocols and accelerate development in this emerging field.

China Academy of Railway Sciences Group Co. Ltd.

Technical Solution: China Academy of Railway Sciences Group Co. Ltd. has developed a comprehensive standardized testing protocol for advanced rail gun systems. Their approach includes multi-stage performance evaluation, focusing on power supply efficiency, projectile velocity measurement, and electromagnetic interference assessment. The protocol utilizes high-speed cameras and advanced sensors to capture real-time data during firing tests. They have also implemented a sophisticated data analysis system that processes test results to optimize rail gun design and performance[1][3]. The academy has established a dedicated testing facility equipped with state-of-the-art instruments to simulate various operational conditions, ensuring thorough evaluation of rail gun systems under different scenarios[5].

Strengths: Comprehensive testing methodology, advanced data analysis capabilities, and dedicated testing facilities. Weaknesses: Potential limitations in testing ultra-high-power systems due to facility constraints.

Beijing Jiaotong University

Technical Solution: Beijing Jiaotong University has developed a novel standardized testing protocol for advanced rail gun systems, focusing on the integration of electromagnetic and thermal analysis. Their approach utilizes a combination of finite element modeling and experimental validation to assess rail gun performance. The university has created a unique test bed that allows for the simultaneous measurement of electromagnetic field distribution and thermal effects during rail gun operation[2]. This integrated approach enables more accurate prediction of rail gun behavior under various operational conditions. Additionally, they have developed specialized sensors capable of withstanding the extreme conditions present during rail gun firing, providing high-fidelity data for analysis[4].

Strengths: Innovative integration of electromagnetic and thermal analysis, advanced sensor technology. Weaknesses: May require further validation for large-scale, high-power rail gun systems.

Innovative Rail Gun Test Protocols

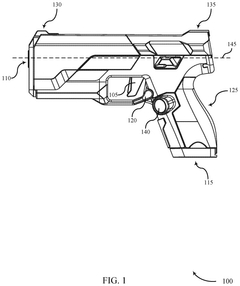

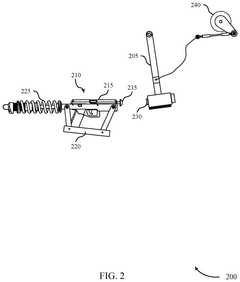

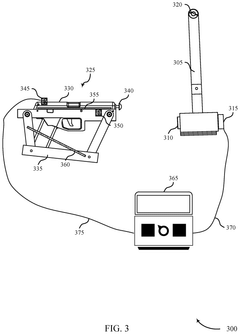

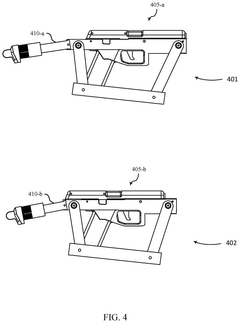

Systems and techniques for testing a gun

PatentActiveUS12372320B1

Innovation

- A system is developed to simulate the firing of live ammunition using a striking mechanism with compressible rods to apply a force profile that mimics live ammunition, coupled with an attachment and backstop mechanism to replicate the grip of a shooter, allowing for efficient and repeatable testing of guns and their components.

Closed loop defined profile current controller for electromagnetic rail gun applications

PatentInactiveUS7357128B1

Innovation

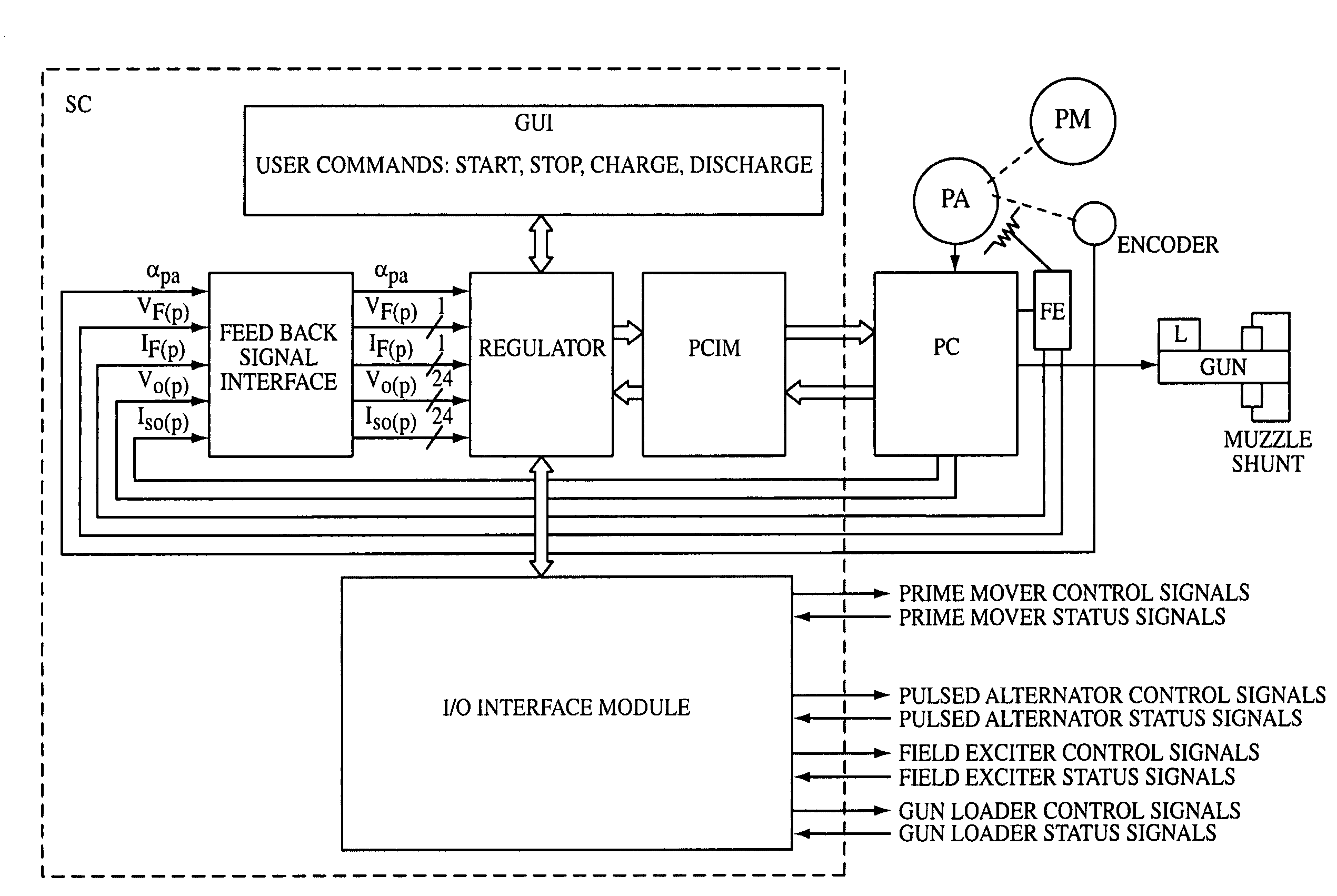

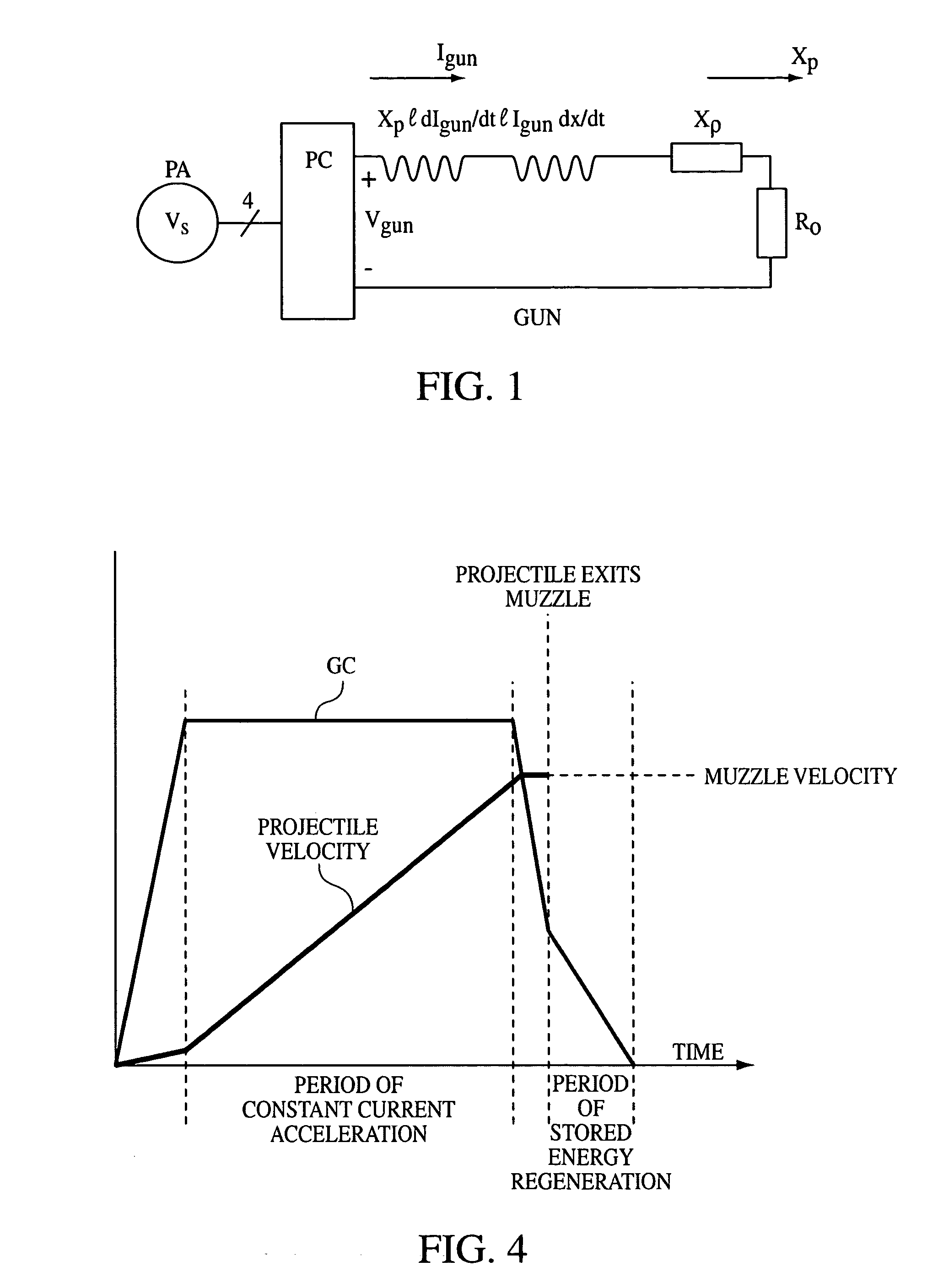

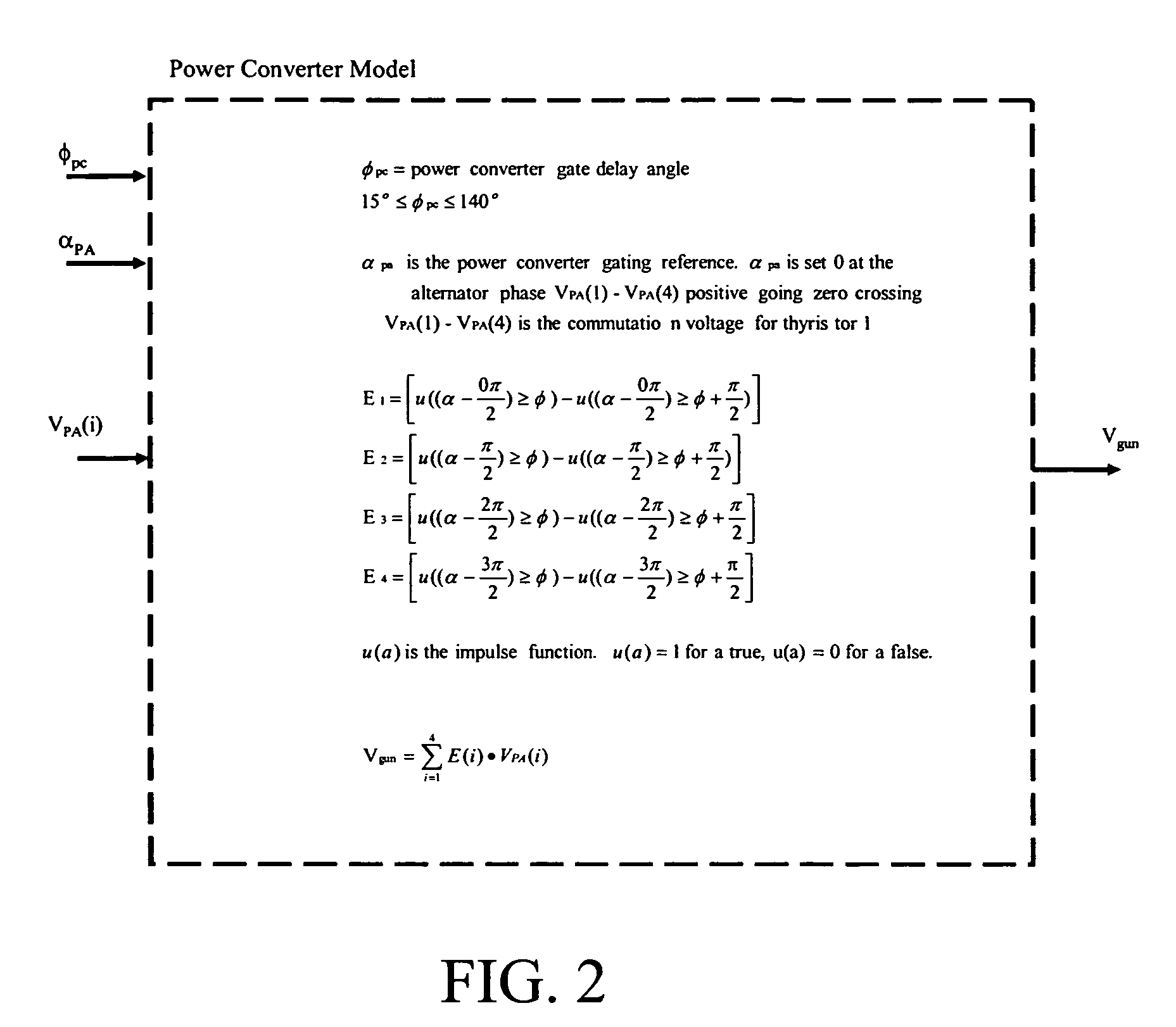

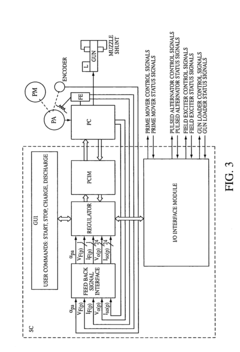

- A closed loop control system using state space control concepts, with a pulsed alternator observer, gun observer, and current compensator to regulate energy transfer and control muzzle velocity by transitioning the system through defined state transitions, enabling precise control of the rail gun current and projectile acceleration.

Safety Regulations for Rail Gun Testing

Safety regulations for rail gun testing are paramount to ensure the protection of personnel, equipment, and the environment during the development and evaluation of advanced rail gun systems. These regulations encompass a wide range of safety measures and protocols that must be strictly adhered to throughout the testing process.

One of the primary safety considerations is the establishment of a secure testing environment. This includes the designation of restricted access areas, implementation of robust perimeter security, and the installation of protective barriers to contain potential projectile impacts. Additionally, comprehensive risk assessments must be conducted prior to each test to identify and mitigate potential hazards.

Personnel safety is a critical aspect of rail gun testing regulations. All individuals involved in the testing process must undergo thorough safety training and be equipped with appropriate personal protective equipment (PPE). This includes, but is not limited to, hearing protection, eye protection, and specialized clothing to guard against potential electrical and thermal hazards.

Electrical safety measures are of utmost importance due to the high-voltage and high-current nature of rail gun systems. Regulations mandate the implementation of robust electrical isolation systems, proper grounding procedures, and the use of insulated tools and equipment. Regular inspections and maintenance of electrical components are also required to prevent malfunctions and ensure safe operation.

Environmental protection is another key focus of safety regulations for rail gun testing. Measures must be in place to minimize noise pollution, control electromagnetic emissions, and manage the disposal of any hazardous materials used in the testing process. Environmental impact assessments may be required to ensure compliance with local and national environmental regulations.

Emergency response protocols form an integral part of safety regulations. These include the development of detailed emergency action plans, establishment of clear communication channels, and regular drills to ensure all personnel are prepared to respond effectively in case of accidents or incidents.

Data security and confidentiality measures are also addressed in safety regulations, given the sensitive nature of rail gun technology. Strict protocols must be in place to protect test data, design information, and other proprietary knowledge from unauthorized access or disclosure.

Compliance with these safety regulations is typically overseen by dedicated safety officers and regulatory bodies. Regular audits and inspections are conducted to ensure adherence to established safety standards and to identify areas for improvement in safety protocols.

One of the primary safety considerations is the establishment of a secure testing environment. This includes the designation of restricted access areas, implementation of robust perimeter security, and the installation of protective barriers to contain potential projectile impacts. Additionally, comprehensive risk assessments must be conducted prior to each test to identify and mitigate potential hazards.

Personnel safety is a critical aspect of rail gun testing regulations. All individuals involved in the testing process must undergo thorough safety training and be equipped with appropriate personal protective equipment (PPE). This includes, but is not limited to, hearing protection, eye protection, and specialized clothing to guard against potential electrical and thermal hazards.

Electrical safety measures are of utmost importance due to the high-voltage and high-current nature of rail gun systems. Regulations mandate the implementation of robust electrical isolation systems, proper grounding procedures, and the use of insulated tools and equipment. Regular inspections and maintenance of electrical components are also required to prevent malfunctions and ensure safe operation.

Environmental protection is another key focus of safety regulations for rail gun testing. Measures must be in place to minimize noise pollution, control electromagnetic emissions, and manage the disposal of any hazardous materials used in the testing process. Environmental impact assessments may be required to ensure compliance with local and national environmental regulations.

Emergency response protocols form an integral part of safety regulations. These include the development of detailed emergency action plans, establishment of clear communication channels, and regular drills to ensure all personnel are prepared to respond effectively in case of accidents or incidents.

Data security and confidentiality measures are also addressed in safety regulations, given the sensitive nature of rail gun technology. Strict protocols must be in place to protect test data, design information, and other proprietary knowledge from unauthorized access or disclosure.

Compliance with these safety regulations is typically overseen by dedicated safety officers and regulatory bodies. Regular audits and inspections are conducted to ensure adherence to established safety standards and to identify areas for improvement in safety protocols.

Environmental Impact Assessment

The environmental impact assessment of standardized testing protocols for advanced rail gun systems is a critical aspect that requires thorough examination. These high-energy weapon systems, while offering significant military advantages, pose potential environmental concerns that must be addressed.

One of the primary environmental considerations is the acoustic impact of rail gun testing. The intense sound levels generated during firing can have detrimental effects on local wildlife and nearby human populations. Standardized protocols must include measures to mitigate noise pollution, such as strategic test site selection and the implementation of sound barriers.

Electromagnetic emissions from rail gun systems present another environmental challenge. The powerful electromagnetic fields generated during operation could potentially interfere with local ecosystems and wildlife behavior. Protocols should incorporate guidelines for monitoring and managing electromagnetic radiation to minimize ecological disruption.

The physical impact of projectiles on testing ranges is a significant concern. High-velocity projectiles can cause extensive damage to soil, vegetation, and potentially contaminate groundwater. Standardized protocols must outline procedures for range management, including regular environmental assessments and remediation efforts to maintain ecosystem integrity.

Air quality is another crucial factor to consider. The high-energy discharge of rail guns can produce various atmospheric pollutants, including particulate matter and potentially harmful gases. Testing protocols should include air quality monitoring systems and establish acceptable emission thresholds to ensure compliance with environmental regulations.

The use of advanced materials in rail gun systems introduces potential risks of environmental contamination. Protocols must address the proper handling, storage, and disposal of these materials to prevent soil and water pollution. This includes guidelines for managing any hazardous waste generated during testing and maintenance procedures.

Energy consumption is a significant environmental consideration for rail gun testing. The enormous power requirements of these systems can strain local energy grids and contribute to increased carbon emissions. Standardized protocols should promote energy efficiency measures and explore the integration of renewable energy sources for testing facilities.

Lastly, the long-term environmental impact of repeated testing must be assessed. Cumulative effects on local ecosystems, including changes in biodiversity and habitat degradation, should be monitored and addressed. Protocols should establish guidelines for periodic environmental impact studies and adaptive management strategies to ensure sustainable testing practices.

One of the primary environmental considerations is the acoustic impact of rail gun testing. The intense sound levels generated during firing can have detrimental effects on local wildlife and nearby human populations. Standardized protocols must include measures to mitigate noise pollution, such as strategic test site selection and the implementation of sound barriers.

Electromagnetic emissions from rail gun systems present another environmental challenge. The powerful electromagnetic fields generated during operation could potentially interfere with local ecosystems and wildlife behavior. Protocols should incorporate guidelines for monitoring and managing electromagnetic radiation to minimize ecological disruption.

The physical impact of projectiles on testing ranges is a significant concern. High-velocity projectiles can cause extensive damage to soil, vegetation, and potentially contaminate groundwater. Standardized protocols must outline procedures for range management, including regular environmental assessments and remediation efforts to maintain ecosystem integrity.

Air quality is another crucial factor to consider. The high-energy discharge of rail guns can produce various atmospheric pollutants, including particulate matter and potentially harmful gases. Testing protocols should include air quality monitoring systems and establish acceptable emission thresholds to ensure compliance with environmental regulations.

The use of advanced materials in rail gun systems introduces potential risks of environmental contamination. Protocols must address the proper handling, storage, and disposal of these materials to prevent soil and water pollution. This includes guidelines for managing any hazardous waste generated during testing and maintenance procedures.

Energy consumption is a significant environmental consideration for rail gun testing. The enormous power requirements of these systems can strain local energy grids and contribute to increased carbon emissions. Standardized protocols should promote energy efficiency measures and explore the integration of renewable energy sources for testing facilities.

Lastly, the long-term environmental impact of repeated testing must be assessed. Cumulative effects on local ecosystems, including changes in biodiversity and habitat degradation, should be monitored and addressed. Protocols should establish guidelines for periodic environmental impact studies and adaptive management strategies to ensure sustainable testing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!