Structural Integrity Analyses of High-Force Rail Gun Components

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Evolution

The evolution of rail guns represents a significant advancement in electromagnetic launch technology, tracing its roots back to the early 20th century. Initially conceived as a theoretical concept, rail guns have undergone substantial development over the past century, with major milestones marking their progression from experimental prototypes to potentially deployable weapons systems.

In the 1970s and 1980s, renewed interest in rail gun technology led to increased research and development efforts. This period saw the first successful demonstrations of small-scale rail guns, proving the feasibility of electromagnetic launch for projectiles. The 1990s marked a turning point, with advancements in power supply technology and materials science enabling the construction of more powerful and efficient rail gun systems.

The early 2000s witnessed a surge in rail gun development programs, particularly in the United States. The U.S. Navy's electromagnetic railgun program, initiated in 2005, aimed to develop a weapon capable of launching projectiles at hypersonic speeds over long distances. This program achieved several breakthroughs, including the demonstration of multi-shot capability and increased muzzle energy outputs.

Parallel to military applications, civilian research has explored the potential of rail guns for space launch systems and industrial applications. These efforts have contributed to advancements in high-strength materials, pulsed power systems, and projectile design, all critical components in addressing the structural integrity challenges of high-force rail gun components.

Recent years have seen a focus on overcoming key technical hurdles, particularly in the areas of rail life, power supply miniaturization, and thermal management. Innovations in composite materials and advanced cooling systems have significantly improved the durability of rail components, addressing one of the primary limitations of earlier designs.

The evolution of rail gun technology has also been marked by international competition, with several countries investing in research and development programs. This global interest has accelerated progress in addressing structural integrity issues, as diverse approaches and solutions are explored and shared within the scientific community.

Looking forward, the trajectory of rail gun evolution points towards further improvements in energy efficiency, projectile design, and system integration. Emerging technologies such as superconducting materials and advanced energy storage solutions promise to overcome current limitations, potentially leading to more compact and powerful rail gun systems capable of withstanding the extreme forces involved in electromagnetic launch.

In the 1970s and 1980s, renewed interest in rail gun technology led to increased research and development efforts. This period saw the first successful demonstrations of small-scale rail guns, proving the feasibility of electromagnetic launch for projectiles. The 1990s marked a turning point, with advancements in power supply technology and materials science enabling the construction of more powerful and efficient rail gun systems.

The early 2000s witnessed a surge in rail gun development programs, particularly in the United States. The U.S. Navy's electromagnetic railgun program, initiated in 2005, aimed to develop a weapon capable of launching projectiles at hypersonic speeds over long distances. This program achieved several breakthroughs, including the demonstration of multi-shot capability and increased muzzle energy outputs.

Parallel to military applications, civilian research has explored the potential of rail guns for space launch systems and industrial applications. These efforts have contributed to advancements in high-strength materials, pulsed power systems, and projectile design, all critical components in addressing the structural integrity challenges of high-force rail gun components.

Recent years have seen a focus on overcoming key technical hurdles, particularly in the areas of rail life, power supply miniaturization, and thermal management. Innovations in composite materials and advanced cooling systems have significantly improved the durability of rail components, addressing one of the primary limitations of earlier designs.

The evolution of rail gun technology has also been marked by international competition, with several countries investing in research and development programs. This global interest has accelerated progress in addressing structural integrity issues, as diverse approaches and solutions are explored and shared within the scientific community.

Looking forward, the trajectory of rail gun evolution points towards further improvements in energy efficiency, projectile design, and system integration. Emerging technologies such as superconducting materials and advanced energy storage solutions promise to overcome current limitations, potentially leading to more compact and powerful rail gun systems capable of withstanding the extreme forces involved in electromagnetic launch.

Military Demand Analysis

The demand for advanced rail gun technology in military applications has been steadily increasing over the past decade. This surge in interest is primarily driven by the need for long-range, high-velocity projectile systems that can provide superior firepower and strategic advantages in modern warfare scenarios. Rail guns offer significant benefits over traditional artillery, including extended range, higher muzzle velocities, and reduced logistical footprint due to the absence of propellant charges.

The U.S. Department of Defense has been at the forefront of rail gun research and development, allocating substantial resources to overcome technical challenges and bring this technology to operational readiness. The Navy, in particular, has shown keen interest in integrating rail guns into naval vessels for both offensive and defensive capabilities. This interest stems from the potential of rail guns to revolutionize naval warfare by providing cost-effective, long-range strike options and the ability to intercept incoming threats at high speeds.

Other major military powers, including China and Russia, have also recognized the strategic importance of rail gun technology and are actively pursuing their own research programs. This global competition has further intensified the demand for advanced rail gun systems and associated technologies, including high-strength materials and power management solutions.

The aerospace and missile defense sectors have also expressed growing interest in rail gun technology. The ability to launch payloads or intercept incoming threats at hypersonic speeds makes rail guns an attractive option for future space launch systems and missile defense platforms. This cross-domain applicability has expanded the potential market for rail gun technology beyond traditional artillery systems.

However, the demand for rail gun technology is not without challenges. The high-force components of rail guns are subject to extreme stresses and wear, necessitating advanced materials and sophisticated structural integrity analyses. Military planners and engineers are particularly focused on developing rail gun systems that can maintain consistent performance over extended periods, withstand repeated firings, and operate reliably in various environmental conditions.

The increasing emphasis on directed energy weapons and electromagnetic systems in military modernization programs has further bolstered the demand for rail gun technology. As armed forces worldwide seek to reduce their reliance on conventional munitions and explore more versatile and cost-effective weapon systems, rail guns have emerged as a promising solution that aligns with these strategic objectives.

The U.S. Department of Defense has been at the forefront of rail gun research and development, allocating substantial resources to overcome technical challenges and bring this technology to operational readiness. The Navy, in particular, has shown keen interest in integrating rail guns into naval vessels for both offensive and defensive capabilities. This interest stems from the potential of rail guns to revolutionize naval warfare by providing cost-effective, long-range strike options and the ability to intercept incoming threats at high speeds.

Other major military powers, including China and Russia, have also recognized the strategic importance of rail gun technology and are actively pursuing their own research programs. This global competition has further intensified the demand for advanced rail gun systems and associated technologies, including high-strength materials and power management solutions.

The aerospace and missile defense sectors have also expressed growing interest in rail gun technology. The ability to launch payloads or intercept incoming threats at hypersonic speeds makes rail guns an attractive option for future space launch systems and missile defense platforms. This cross-domain applicability has expanded the potential market for rail gun technology beyond traditional artillery systems.

However, the demand for rail gun technology is not without challenges. The high-force components of rail guns are subject to extreme stresses and wear, necessitating advanced materials and sophisticated structural integrity analyses. Military planners and engineers are particularly focused on developing rail gun systems that can maintain consistent performance over extended periods, withstand repeated firings, and operate reliably in various environmental conditions.

The increasing emphasis on directed energy weapons and electromagnetic systems in military modernization programs has further bolstered the demand for rail gun technology. As armed forces worldwide seek to reduce their reliance on conventional munitions and explore more versatile and cost-effective weapon systems, rail guns have emerged as a promising solution that aligns with these strategic objectives.

Structural Challenges

Rail gun technology presents significant structural challenges due to the extreme forces involved in accelerating projectiles to hypersonic velocities. The primary concern is the structural integrity of key components under high-stress conditions. The electromagnetic forces generated during firing can cause severe mechanical stress on the rails, barrel, and supporting structures.

One of the most critical issues is rail erosion and deformation. The intense electrical current passing through the rails creates localized heating and material ablation, leading to surface degradation and potential structural failure over time. This erosion not only affects the performance of the rail gun but also raises concerns about the longevity and reliability of the system.

The projectile launch package also faces substantial structural challenges. The rapid acceleration subjects the projectile to extreme g-forces, which can cause deformation or disintegration if not properly designed. Ensuring the structural integrity of the projectile while maintaining its aerodynamic properties is a delicate balance that engineers must strike.

Containment of the electromagnetic forces within the rail gun system is another significant challenge. The strong magnetic fields generated during firing can induce eddy currents in nearby metallic structures, leading to unwanted heating and potential structural weakening. Proper shielding and material selection are crucial to mitigate these effects and maintain the overall structural integrity of the system.

The power supply and energy storage components of rail guns also face unique structural challenges. The rapid discharge of enormous amounts of electrical energy places severe stress on capacitors, switches, and conductors. Ensuring these components can withstand repeated high-energy pulses without degradation or failure is essential for the system's reliability and safety.

Thermal management is a critical aspect of maintaining structural integrity in rail gun systems. The intense heat generated during firing can cause thermal expansion, warping, and material fatigue. Developing effective cooling systems and selecting materials with appropriate thermal properties are necessary to prevent structural failures due to heat-induced stress.

Addressing these structural challenges requires a multidisciplinary approach, combining expertise in materials science, electromagnetic theory, and mechanical engineering. Advanced simulation techniques, such as finite element analysis and computational fluid dynamics, play a crucial role in predicting and mitigating structural issues before physical prototyping. Ongoing research in novel materials, such as advanced composites and nanomaterials, offers promising solutions to enhance the structural integrity of rail gun components under extreme conditions.

One of the most critical issues is rail erosion and deformation. The intense electrical current passing through the rails creates localized heating and material ablation, leading to surface degradation and potential structural failure over time. This erosion not only affects the performance of the rail gun but also raises concerns about the longevity and reliability of the system.

The projectile launch package also faces substantial structural challenges. The rapid acceleration subjects the projectile to extreme g-forces, which can cause deformation or disintegration if not properly designed. Ensuring the structural integrity of the projectile while maintaining its aerodynamic properties is a delicate balance that engineers must strike.

Containment of the electromagnetic forces within the rail gun system is another significant challenge. The strong magnetic fields generated during firing can induce eddy currents in nearby metallic structures, leading to unwanted heating and potential structural weakening. Proper shielding and material selection are crucial to mitigate these effects and maintain the overall structural integrity of the system.

The power supply and energy storage components of rail guns also face unique structural challenges. The rapid discharge of enormous amounts of electrical energy places severe stress on capacitors, switches, and conductors. Ensuring these components can withstand repeated high-energy pulses without degradation or failure is essential for the system's reliability and safety.

Thermal management is a critical aspect of maintaining structural integrity in rail gun systems. The intense heat generated during firing can cause thermal expansion, warping, and material fatigue. Developing effective cooling systems and selecting materials with appropriate thermal properties are necessary to prevent structural failures due to heat-induced stress.

Addressing these structural challenges requires a multidisciplinary approach, combining expertise in materials science, electromagnetic theory, and mechanical engineering. Advanced simulation techniques, such as finite element analysis and computational fluid dynamics, play a crucial role in predicting and mitigating structural issues before physical prototyping. Ongoing research in novel materials, such as advanced composites and nanomaterials, offers promising solutions to enhance the structural integrity of rail gun components under extreme conditions.

Current Design Solutions

01 Structural design and materials for rail gun components

The structural integrity of rail gun components is crucial for their performance and longevity. This involves careful selection of materials that can withstand high electromagnetic forces and thermal stresses. Advanced composites and alloys are often used to enhance durability while maintaining the necessary conductivity. The design must account for the rapid acceleration and extreme conditions experienced during firing.- Structural design and materials for rail gun components: The structural integrity of rail gun components is crucial for their performance and longevity. This involves the use of advanced materials and design techniques to withstand the extreme forces and temperatures generated during operation. Key considerations include the selection of high-strength alloys, composite materials, and innovative structural designs that can handle the electromagnetic and thermal stresses.

- Monitoring and analysis of rail gun structural integrity: Implementing advanced monitoring and analysis systems is essential for maintaining the structural integrity of rail gun components. This includes the use of sensors, data acquisition systems, and analytical tools to detect and predict potential structural issues. Real-time monitoring and predictive maintenance strategies help ensure the reliability and safety of rail gun systems during operation.

- Thermal management for rail gun components: Effective thermal management is critical for maintaining the structural integrity of rail gun components. This involves the development of cooling systems, heat-resistant materials, and thermal insulation techniques to mitigate the extreme temperatures generated during firing. Proper thermal management helps prevent material degradation and ensures consistent performance of the rail gun system.

- Electromagnetic shielding and insulation: Protecting rail gun components from electromagnetic interference and managing the intense electromagnetic fields generated during operation is crucial for structural integrity. This includes the development of specialized shielding materials, insulation techniques, and design strategies to prevent electromagnetic-induced damage and ensure proper functioning of the rail gun system.

- Testing and validation methods for rail gun components: Rigorous testing and validation procedures are essential for ensuring the structural integrity of rail gun components. This involves the development of specialized testing equipment, simulation techniques, and experimental methodologies to assess the performance and durability of components under extreme conditions. These methods help identify potential weaknesses and validate the design and materials used in rail gun systems.

02 Monitoring and analysis of rail gun structural integrity

Sophisticated monitoring systems are employed to assess the structural integrity of rail gun components in real-time. These systems use sensors and data analysis techniques to detect potential failures or degradation. Advanced algorithms process the collected data to predict maintenance needs and optimize performance. This proactive approach helps maintain the operational readiness of the rail gun system.Expand Specific Solutions03 Innovative cooling systems for thermal management

Thermal management is critical for maintaining the structural integrity of rail gun components. Innovative cooling systems are designed to dissipate the enormous heat generated during firing. These may include advanced heat sinks, liquid cooling circuits, or novel materials with superior heat dissipation properties. Effective thermal management prevents warping, melting, or other heat-induced structural failures.Expand Specific Solutions04 Electromagnetic shielding and insulation techniques

To preserve structural integrity, rail gun components require effective electromagnetic shielding and insulation. This involves the use of specialized materials and designs to contain the intense electromagnetic fields generated during operation. Proper shielding prevents interference with other systems and protects sensitive components from electromagnetic damage, ensuring the overall structural stability of the rail gun.Expand Specific Solutions05 Testing and simulation methods for structural integrity

Advanced testing and simulation methods are employed to evaluate and predict the structural integrity of rail gun components. These include finite element analysis, high-speed imaging, and accelerated life testing. Virtual prototyping and computer simulations allow for the optimization of designs before physical testing. These methods help identify potential weak points and improve the overall robustness of the rail gun system.Expand Specific Solutions

Key Industry Players

The structural integrity analysis of high-force rail gun components is in a nascent stage of development, with a growing market driven by increasing defense investments. The technology's maturity is still evolving, with key players like NIPPON STEEL CORP., JFE Steel Corp., and Kobe Steel, Ltd. leading research efforts. These Japanese steel manufacturers are leveraging their expertise in high-strength materials to address the unique challenges of rail gun components. Universities such as Washington State University and Huazhong University of Science & Technology are contributing to fundamental research, while specialized institutes like the Institute of Mechanics, Chinese Academy of Sciences are focusing on advanced modeling and simulation techniques. The competitive landscape is characterized by a mix of established steel producers and emerging research institutions, indicating a dynamic and rapidly evolving field.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced high-strength steels specifically designed for high-force rail gun components. Their approach involves a combination of precise alloy composition control and innovative heat treatment processes. The company's proprietary steel grades exhibit exceptional tensile strength exceeding 2000 MPa, with improved ductility to withstand the extreme forces involved in rail gun operation[1]. They have also implemented advanced non-destructive testing techniques, including ultrasonic and eddy current methods, to ensure the structural integrity of critical components[3]. NIPPON STEEL's materials have demonstrated superior resistance to thermal fatigue and erosion, crucial for maintaining rail gun performance over extended firing cycles[5].

Strengths: Exceptional material strength and durability, advanced testing capabilities, and proven performance in high-stress environments. Weaknesses: Potentially higher production costs and longer lead times for specialized materials.

Institute of Mechanics, Chinese Academy of Sciences

Technical Solution: The Institute of Mechanics has developed a comprehensive structural integrity analysis framework for high-force rail gun components. Their approach combines multi-physics simulation models with experimental validation techniques. They utilize advanced finite element analysis (FEA) software to simulate the complex electromagnetic, thermal, and mechanical interactions within rail gun systems[2]. The institute has also pioneered the use of high-speed imaging and strain gauge measurements to capture real-time deformation and stress distributions during rail gun firing events[4]. Their research has led to the development of novel composite materials that offer improved thermal management and reduced wear in rail gun barrels[6].

Strengths: Cutting-edge simulation capabilities, integrated experimental validation, and innovative material solutions. Weaknesses: Potential gaps between theoretical models and practical implementation in full-scale systems.

Critical Innovations

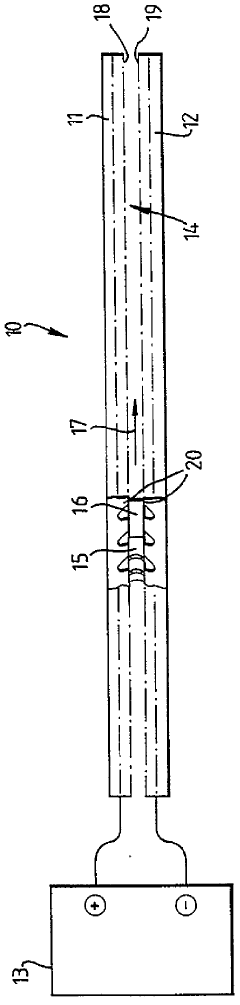

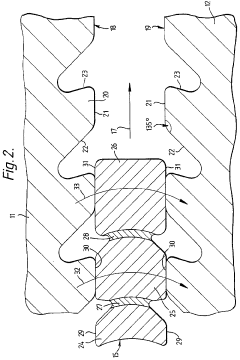

Improvements in or relating to rail gun assemblies

PatentInactiveGB2236835B

Innovation

- The rail gun assembly features elongate co-extensive rail electrodes with regular toothed cross-sections and an armature composed of three electrically conductive portions, which makes and breaks contact with sequential pairs of tooth faces, distributing the current path and reducing overheating by ensuring each portion is only exposed to maximum current for a short period.

Material Science Impact

The impact of material science on the structural integrity analyses of high-force rail gun components is profound and multifaceted. Advanced materials play a crucial role in enhancing the performance, durability, and reliability of rail gun systems. The extreme conditions experienced by rail gun components, including high temperatures, pressures, and electromagnetic forces, necessitate the use of cutting-edge materials that can withstand these harsh environments.

Composite materials have emerged as a promising solution for rail gun components. These materials offer a unique combination of high strength, low weight, and excellent thermal properties. Carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) are particularly noteworthy for their potential applications in rail gun systems. CFRPs provide exceptional strength-to-weight ratios, while CMCs offer superior heat resistance and thermal stability.

Nanomaterials have also shown significant potential in improving the structural integrity of rail gun components. Carbon nanotubes and graphene, when incorporated into composite materials, can dramatically enhance mechanical properties and electrical conductivity. These nanomaterials can help distribute electromagnetic forces more evenly, reducing localized stress concentrations and improving overall component longevity.

Advanced alloys, such as high-strength steels and titanium alloys, continue to play a vital role in rail gun design. These materials offer excellent mechanical properties and can be tailored to specific requirements through heat treatment and alloying processes. Recent developments in powder metallurgy and additive manufacturing have enabled the creation of complex alloy structures with optimized properties for rail gun applications.

Coatings and surface treatments have become increasingly important in protecting rail gun components from wear, erosion, and thermal damage. Thermal barrier coatings, for instance, can significantly extend the lifespan of components exposed to extreme temperatures. Similarly, advanced lubricants and solid lubricant coatings can reduce friction and wear in critical sliding interfaces, enhancing overall system efficiency and reliability.

The integration of smart materials and structures into rail gun systems represents an emerging frontier in material science impact. Piezoelectric materials and shape memory alloys can be used to create adaptive structures that respond to changing conditions during operation. These materials enable real-time monitoring and adjustment of component properties, potentially improving performance and extending operational lifetimes.

In conclusion, material science advancements are driving significant improvements in the structural integrity of high-force rail gun components. The development of novel materials, composites, and coatings is enabling the creation of more robust, efficient, and reliable rail gun systems. As research in this field continues, we can expect further breakthroughs that will push the boundaries of rail gun technology and performance.

Composite materials have emerged as a promising solution for rail gun components. These materials offer a unique combination of high strength, low weight, and excellent thermal properties. Carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) are particularly noteworthy for their potential applications in rail gun systems. CFRPs provide exceptional strength-to-weight ratios, while CMCs offer superior heat resistance and thermal stability.

Nanomaterials have also shown significant potential in improving the structural integrity of rail gun components. Carbon nanotubes and graphene, when incorporated into composite materials, can dramatically enhance mechanical properties and electrical conductivity. These nanomaterials can help distribute electromagnetic forces more evenly, reducing localized stress concentrations and improving overall component longevity.

Advanced alloys, such as high-strength steels and titanium alloys, continue to play a vital role in rail gun design. These materials offer excellent mechanical properties and can be tailored to specific requirements through heat treatment and alloying processes. Recent developments in powder metallurgy and additive manufacturing have enabled the creation of complex alloy structures with optimized properties for rail gun applications.

Coatings and surface treatments have become increasingly important in protecting rail gun components from wear, erosion, and thermal damage. Thermal barrier coatings, for instance, can significantly extend the lifespan of components exposed to extreme temperatures. Similarly, advanced lubricants and solid lubricant coatings can reduce friction and wear in critical sliding interfaces, enhancing overall system efficiency and reliability.

The integration of smart materials and structures into rail gun systems represents an emerging frontier in material science impact. Piezoelectric materials and shape memory alloys can be used to create adaptive structures that respond to changing conditions during operation. These materials enable real-time monitoring and adjustment of component properties, potentially improving performance and extending operational lifetimes.

In conclusion, material science advancements are driving significant improvements in the structural integrity of high-force rail gun components. The development of novel materials, composites, and coatings is enabling the creation of more robust, efficient, and reliable rail gun systems. As research in this field continues, we can expect further breakthroughs that will push the boundaries of rail gun technology and performance.

Safety and Regulations

Safety and regulations are paramount considerations in the development and deployment of high-force rail gun components. The extreme forces and energy levels involved in rail gun operations necessitate stringent safety protocols and regulatory frameworks to ensure the protection of personnel, equipment, and the environment.

Regulatory bodies, such as the Department of Defense and the Occupational Safety and Health Administration, have established guidelines specific to rail gun technology. These regulations cover various aspects, including structural integrity requirements, operational procedures, and safety measures. Compliance with these regulations is mandatory for all entities involved in rail gun research, development, and deployment.

One of the primary safety concerns in rail gun systems is the structural integrity of components under high-force conditions. Regulatory standards mandate comprehensive stress analysis and fatigue testing to ensure that components can withstand the extreme forces generated during operation. This includes requirements for materials selection, design specifications, and quality control measures throughout the manufacturing process.

Electromagnetic safety is another critical area addressed by regulations. The intense electromagnetic fields generated by rail guns pose potential health risks to personnel and can interfere with electronic systems. Regulatory guidelines specify shielding requirements, safe operating distances, and protocols for managing electromagnetic emissions to mitigate these risks.

Environmental impact considerations are also incorporated into rail gun safety regulations. This includes measures to control noise pollution, manage waste materials, and prevent potential contamination from propellants or other substances used in rail gun operations. Environmental impact assessments are typically required as part of the regulatory compliance process.

Operational safety protocols form a significant component of rail gun regulations. These include detailed procedures for system startup, operation, maintenance, and shutdown. Emergency response plans and fail-safe mechanisms are mandated to address potential malfunctions or accidents. Regular safety inspections and personnel training requirements are also specified to ensure ongoing compliance and risk mitigation.

As rail gun technology continues to evolve, regulatory frameworks are regularly updated to address new safety challenges and technological advancements. This dynamic regulatory environment requires ongoing collaboration between researchers, manufacturers, and regulatory bodies to ensure that safety standards keep pace with technological progress in the field of high-force rail gun components.

Regulatory bodies, such as the Department of Defense and the Occupational Safety and Health Administration, have established guidelines specific to rail gun technology. These regulations cover various aspects, including structural integrity requirements, operational procedures, and safety measures. Compliance with these regulations is mandatory for all entities involved in rail gun research, development, and deployment.

One of the primary safety concerns in rail gun systems is the structural integrity of components under high-force conditions. Regulatory standards mandate comprehensive stress analysis and fatigue testing to ensure that components can withstand the extreme forces generated during operation. This includes requirements for materials selection, design specifications, and quality control measures throughout the manufacturing process.

Electromagnetic safety is another critical area addressed by regulations. The intense electromagnetic fields generated by rail guns pose potential health risks to personnel and can interfere with electronic systems. Regulatory guidelines specify shielding requirements, safe operating distances, and protocols for managing electromagnetic emissions to mitigate these risks.

Environmental impact considerations are also incorporated into rail gun safety regulations. This includes measures to control noise pollution, manage waste materials, and prevent potential contamination from propellants or other substances used in rail gun operations. Environmental impact assessments are typically required as part of the regulatory compliance process.

Operational safety protocols form a significant component of rail gun regulations. These include detailed procedures for system startup, operation, maintenance, and shutdown. Emergency response plans and fail-safe mechanisms are mandated to address potential malfunctions or accidents. Regular safety inspections and personnel training requirements are also specified to ensure ongoing compliance and risk mitigation.

As rail gun technology continues to evolve, regulatory frameworks are regularly updated to address new safety challenges and technological advancements. This dynamic regulatory environment requires ongoing collaboration between researchers, manufacturers, and regulatory bodies to ensure that safety standards keep pace with technological progress in the field of high-force rail gun components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!