Rail Gun Ammunition Packaging and Material Requirements

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Background

The concept of rail guns dates back to the early 20th century, with the first patent for an electric gun filed in 1901. However, significant advancements in rail gun technology have only been realized in recent decades due to progress in materials science, power electronics, and energy storage systems.

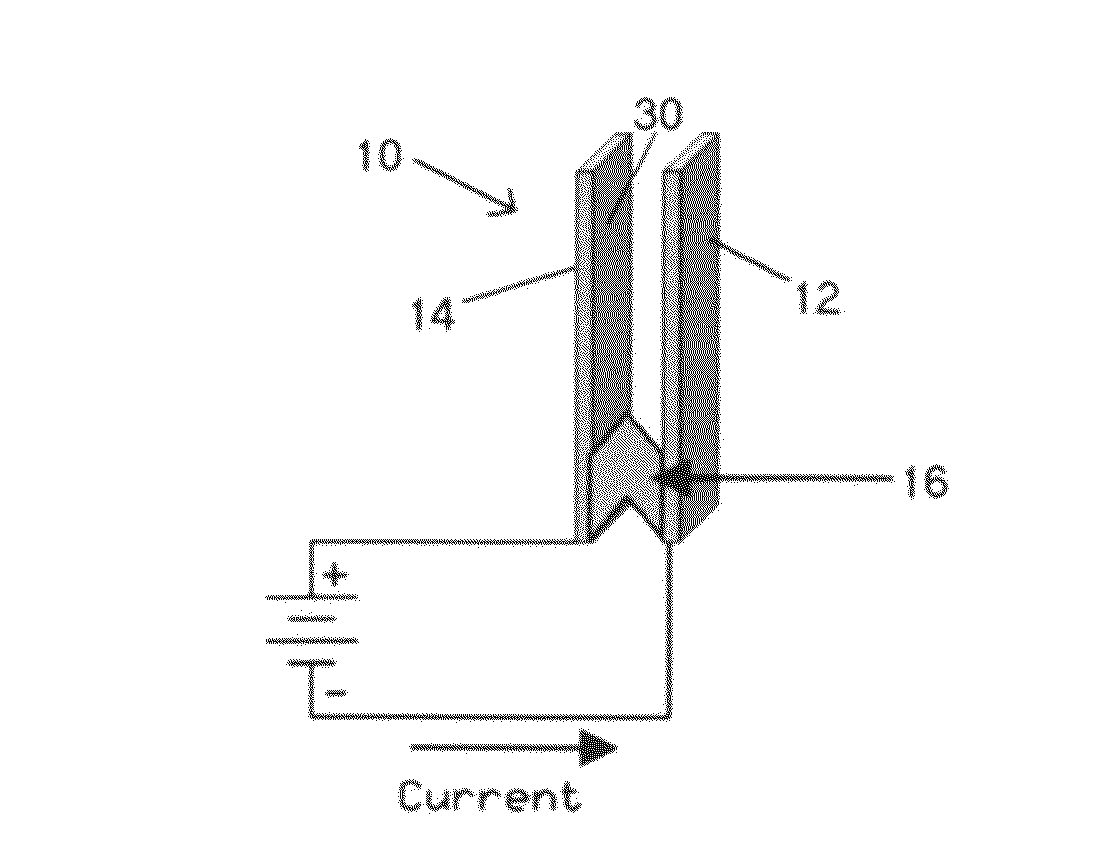

Rail guns operate on the principle of electromagnetic propulsion, using powerful electromagnetic forces to accelerate projectiles to extremely high velocities. Unlike conventional chemical propellant-based weapons, rail guns offer the potential for increased range, higher muzzle velocities, and reduced logistics requirements.

The development of rail gun technology has been primarily driven by military applications, with several nations investing in research and development programs. The United States Navy, in particular, has been at the forefront of rail gun research, aiming to develop ship-based systems for long-range precision strikes and air defense.

Key technological challenges in rail gun development include power supply and storage, rail durability, projectile design, and thermal management. The intense electrical currents and electromagnetic forces involved in rail gun operation place extreme stress on components, necessitating advanced materials and engineering solutions.

Recent advancements in rail gun technology have focused on improving power efficiency, extending barrel life, and developing more robust projectiles. Researchers are exploring novel rail materials, such as copper-chromium-zirconium alloys, to enhance conductivity and durability. Additionally, progress in capacitor technology and pulsed power systems has enabled more compact and efficient power supplies for rail guns.

The evolution of rail gun technology has significant implications for ammunition design and packaging. Traditional ammunition packaging methods are inadequate for rail gun projectiles due to the unique stresses and requirements associated with electromagnetic launch. This has led to a growing focus on developing specialized packaging and materials tailored to rail gun ammunition.

As rail gun technology continues to mature, there is an increasing emphasis on integrating these systems into existing military platforms and developing tactics for their operational use. This includes addressing challenges related to targeting, fire control, and battlefield integration.

The ongoing research in rail gun technology is expected to yield advancements in related fields, such as high-power electronics, advanced materials, and energy storage. These developments may have broader applications beyond military use, potentially impacting industries such as space launch systems and high-speed transportation.

Rail guns operate on the principle of electromagnetic propulsion, using powerful electromagnetic forces to accelerate projectiles to extremely high velocities. Unlike conventional chemical propellant-based weapons, rail guns offer the potential for increased range, higher muzzle velocities, and reduced logistics requirements.

The development of rail gun technology has been primarily driven by military applications, with several nations investing in research and development programs. The United States Navy, in particular, has been at the forefront of rail gun research, aiming to develop ship-based systems for long-range precision strikes and air defense.

Key technological challenges in rail gun development include power supply and storage, rail durability, projectile design, and thermal management. The intense electrical currents and electromagnetic forces involved in rail gun operation place extreme stress on components, necessitating advanced materials and engineering solutions.

Recent advancements in rail gun technology have focused on improving power efficiency, extending barrel life, and developing more robust projectiles. Researchers are exploring novel rail materials, such as copper-chromium-zirconium alloys, to enhance conductivity and durability. Additionally, progress in capacitor technology and pulsed power systems has enabled more compact and efficient power supplies for rail guns.

The evolution of rail gun technology has significant implications for ammunition design and packaging. Traditional ammunition packaging methods are inadequate for rail gun projectiles due to the unique stresses and requirements associated with electromagnetic launch. This has led to a growing focus on developing specialized packaging and materials tailored to rail gun ammunition.

As rail gun technology continues to mature, there is an increasing emphasis on integrating these systems into existing military platforms and developing tactics for their operational use. This includes addressing challenges related to targeting, fire control, and battlefield integration.

The ongoing research in rail gun technology is expected to yield advancements in related fields, such as high-power electronics, advanced materials, and energy storage. These developments may have broader applications beyond military use, potentially impacting industries such as space launch systems and high-speed transportation.

Market Demand Analysis

The market demand for rail gun ammunition packaging and material requirements is driven by the increasing adoption of electromagnetic railgun technology in military applications. As conventional artillery systems are gradually being replaced by more advanced electromagnetic propulsion systems, there is a growing need for specialized ammunition packaging and materials that can withstand the unique challenges posed by railguns.

The global railgun market is expected to experience significant growth in the coming years, with a compound annual growth rate (CAGR) projected to be in the double digits. This growth is primarily fueled by increased defense spending in major economies, particularly in the United States, China, and Russia. These countries are investing heavily in research and development of railgun technology, which in turn drives the demand for advanced ammunition packaging and materials.

One of the key factors driving market demand is the need for ammunition packaging that can withstand the extreme conditions generated by railguns. Traditional ammunition packaging materials are often inadequate for use in railgun systems due to the intense electromagnetic fields, high temperatures, and extreme acceleration forces involved. This has created a niche market for specialized packaging materials that can protect the projectiles and ensure their integrity during storage, transport, and firing.

The naval sector represents a significant portion of the market demand for railgun ammunition packaging. Navies around the world are exploring the potential of railguns as long-range, high-velocity weapons for ship-based defense systems. This application requires ammunition packaging that is not only resistant to electromagnetic interference but also capable of withstanding the corrosive marine environment and the dynamic conditions aboard naval vessels.

Another important factor driving market demand is the push for increased range and accuracy in military operations. Railguns offer the potential for extended range compared to conventional artillery, which necessitates the development of ammunition packaging that can maintain the projectile's aerodynamic properties and structural integrity over longer distances. This has led to a focus on lightweight, yet durable materials that can withstand the stresses of high-velocity launches while minimizing the overall weight of the ammunition.

The market for railgun ammunition packaging and materials is also influenced by the growing emphasis on sustainability and environmental considerations in military operations. There is an increasing demand for packaging materials that are recyclable or biodegradable, without compromising on performance or protective qualities. This trend is driving innovation in eco-friendly packaging solutions that meet the stringent requirements of railgun systems.

In conclusion, the market demand for rail gun ammunition packaging and material requirements is characterized by rapid growth, technological innovation, and a focus on performance under extreme conditions. As railgun technology continues to mature and find wider application in military systems, the demand for specialized packaging and materials is expected to increase, presenting significant opportunities for manufacturers and material scientists in this niche but expanding market.

The global railgun market is expected to experience significant growth in the coming years, with a compound annual growth rate (CAGR) projected to be in the double digits. This growth is primarily fueled by increased defense spending in major economies, particularly in the United States, China, and Russia. These countries are investing heavily in research and development of railgun technology, which in turn drives the demand for advanced ammunition packaging and materials.

One of the key factors driving market demand is the need for ammunition packaging that can withstand the extreme conditions generated by railguns. Traditional ammunition packaging materials are often inadequate for use in railgun systems due to the intense electromagnetic fields, high temperatures, and extreme acceleration forces involved. This has created a niche market for specialized packaging materials that can protect the projectiles and ensure their integrity during storage, transport, and firing.

The naval sector represents a significant portion of the market demand for railgun ammunition packaging. Navies around the world are exploring the potential of railguns as long-range, high-velocity weapons for ship-based defense systems. This application requires ammunition packaging that is not only resistant to electromagnetic interference but also capable of withstanding the corrosive marine environment and the dynamic conditions aboard naval vessels.

Another important factor driving market demand is the push for increased range and accuracy in military operations. Railguns offer the potential for extended range compared to conventional artillery, which necessitates the development of ammunition packaging that can maintain the projectile's aerodynamic properties and structural integrity over longer distances. This has led to a focus on lightweight, yet durable materials that can withstand the stresses of high-velocity launches while minimizing the overall weight of the ammunition.

The market for railgun ammunition packaging and materials is also influenced by the growing emphasis on sustainability and environmental considerations in military operations. There is an increasing demand for packaging materials that are recyclable or biodegradable, without compromising on performance or protective qualities. This trend is driving innovation in eco-friendly packaging solutions that meet the stringent requirements of railgun systems.

In conclusion, the market demand for rail gun ammunition packaging and material requirements is characterized by rapid growth, technological innovation, and a focus on performance under extreme conditions. As railgun technology continues to mature and find wider application in military systems, the demand for specialized packaging and materials is expected to increase, presenting significant opportunities for manufacturers and material scientists in this niche but expanding market.

Current Challenges

Rail gun ammunition packaging and material requirements face several significant challenges in the current technological landscape. One of the primary obstacles is the extreme environmental conditions that the ammunition must withstand during firing. The intense electromagnetic forces and high temperatures generated during launch place unprecedented stress on both the packaging and materials used in rail gun ammunition.

The packaging must be designed to maintain structural integrity under extreme acceleration forces, often exceeding 100,000 g's. This level of force can cause conventional packaging materials to fail, potentially leading to ammunition damage or misfires. Additionally, the packaging needs to protect the projectile from electromagnetic interference, which can affect its guidance systems and overall performance.

Material selection for rail gun ammunition is equally challenging. The projectiles must be capable of withstanding not only the immense launch forces but also the extreme temperatures generated by air friction during flight. Traditional materials often fall short in meeting these demanding requirements, necessitating the development of advanced composites and alloys.

Electrical conductivity is another critical factor in material selection. The ammunition must efficiently conduct electricity to create the electromagnetic field necessary for propulsion. However, this conductivity must be carefully balanced with the material's ability to resist melting or deformation under the intense currents involved in the firing process.

Weight considerations pose an additional challenge. The ammunition must be light enough to achieve the desired velocities and ranges, yet robust enough to maintain structural integrity throughout the launch and flight. This delicate balance often requires innovative material solutions and design approaches.

Scalability and cost-effectiveness present further obstacles. As rail gun technology moves towards practical military applications, there is a growing need for ammunition that can be mass-produced efficiently and at a reasonable cost. This requirement often conflicts with the use of exotic materials and complex manufacturing processes necessary to meet performance standards.

Environmental concerns also play a role in current challenges. The materials used in rail gun ammunition must not only perform well but also comply with increasingly stringent environmental regulations. This includes considerations for disposal and potential environmental impact of spent ammunition.

Lastly, the integration of smart technologies into rail gun ammunition presents new packaging and material challenges. As projectiles become more sophisticated, incorporating guidance systems and other electronic components, the packaging and materials must provide adequate protection for these sensitive elements while maintaining overall performance characteristics.

The packaging must be designed to maintain structural integrity under extreme acceleration forces, often exceeding 100,000 g's. This level of force can cause conventional packaging materials to fail, potentially leading to ammunition damage or misfires. Additionally, the packaging needs to protect the projectile from electromagnetic interference, which can affect its guidance systems and overall performance.

Material selection for rail gun ammunition is equally challenging. The projectiles must be capable of withstanding not only the immense launch forces but also the extreme temperatures generated by air friction during flight. Traditional materials often fall short in meeting these demanding requirements, necessitating the development of advanced composites and alloys.

Electrical conductivity is another critical factor in material selection. The ammunition must efficiently conduct electricity to create the electromagnetic field necessary for propulsion. However, this conductivity must be carefully balanced with the material's ability to resist melting or deformation under the intense currents involved in the firing process.

Weight considerations pose an additional challenge. The ammunition must be light enough to achieve the desired velocities and ranges, yet robust enough to maintain structural integrity throughout the launch and flight. This delicate balance often requires innovative material solutions and design approaches.

Scalability and cost-effectiveness present further obstacles. As rail gun technology moves towards practical military applications, there is a growing need for ammunition that can be mass-produced efficiently and at a reasonable cost. This requirement often conflicts with the use of exotic materials and complex manufacturing processes necessary to meet performance standards.

Environmental concerns also play a role in current challenges. The materials used in rail gun ammunition must not only perform well but also comply with increasingly stringent environmental regulations. This includes considerations for disposal and potential environmental impact of spent ammunition.

Lastly, the integration of smart technologies into rail gun ammunition presents new packaging and material challenges. As projectiles become more sophisticated, incorporating guidance systems and other electronic components, the packaging and materials must provide adequate protection for these sensitive elements while maintaining overall performance characteristics.

Existing Solutions

01 Electromagnetic rail gun ammunition design

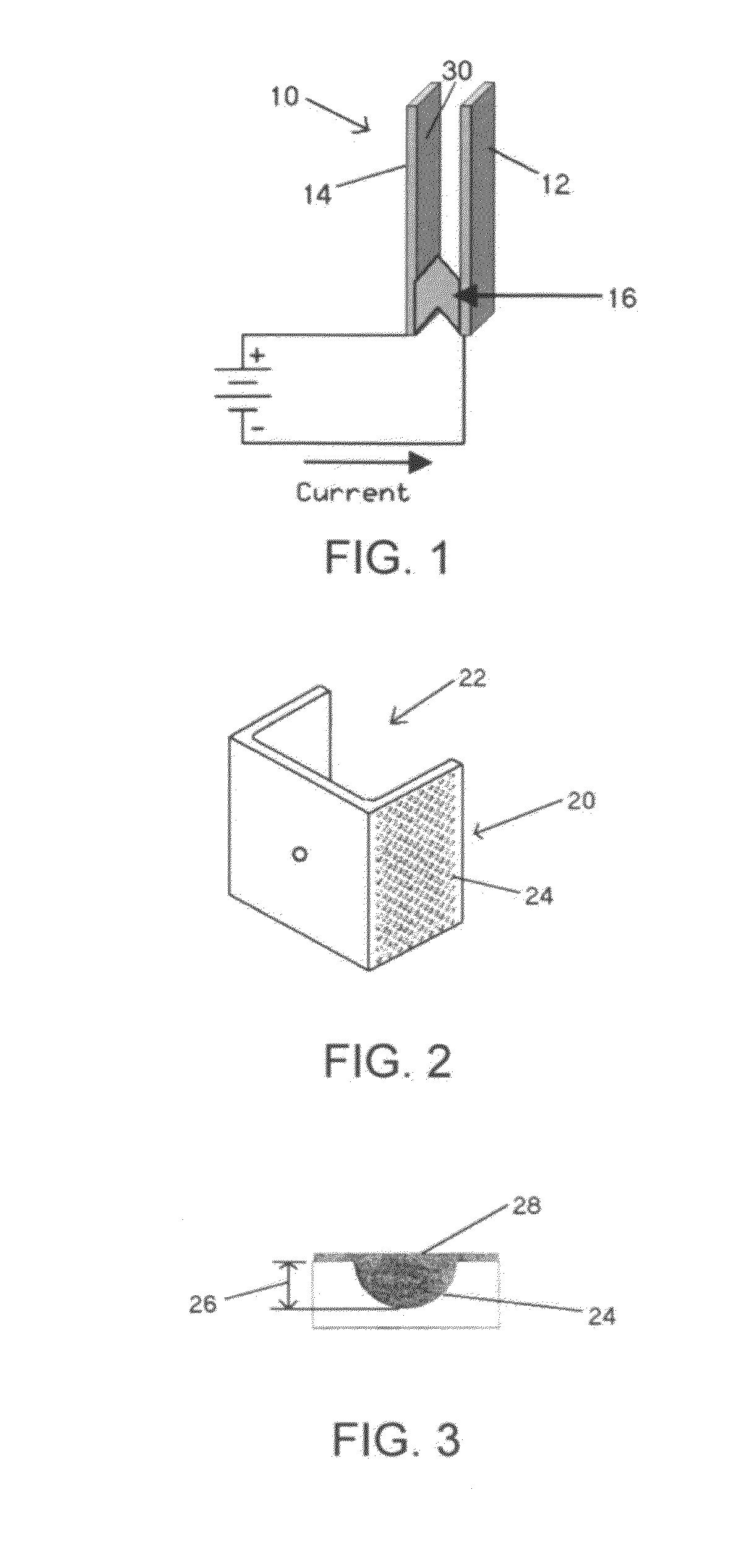

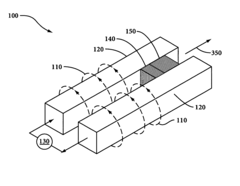

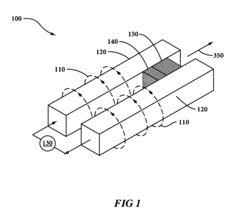

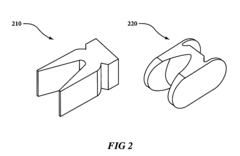

Specialized ammunition designs for electromagnetic rail guns, focusing on projectile shape, materials, and construction to optimize performance in high-velocity launches. These designs consider factors such as aerodynamics, structural integrity, and electromagnetic properties to enhance accuracy and effectiveness.- Electromagnetic rail gun ammunition design: Specialized ammunition designs for electromagnetic rail guns, including projectile shapes, materials, and configurations to optimize performance and withstand high acceleration forces. These designs may incorporate features like sabots, aerodynamic profiles, and reinforced structures to enhance stability and penetration capabilities.

- Packaging solutions for rail gun ammunition: Innovative packaging solutions designed to protect and transport rail gun ammunition. These may include shock-absorbing materials, moisture-resistant containers, and modular designs for easy loading and unloading. The packaging aims to maintain the integrity of the ammunition during storage and handling while ensuring quick access during operations.

- Advanced materials for rail gun projectiles: Development of advanced materials for rail gun projectiles to withstand extreme conditions. These materials may include high-strength alloys, composites, or ceramics that can maintain structural integrity under high temperatures and pressures. The focus is on maximizing penetration power while minimizing weight and optimizing aerodynamics.

- Rail gun ammunition loading and feeding systems: Specialized systems for loading and feeding rail gun ammunition, designed to handle the unique requirements of electromagnetic launchers. These systems may include automated loaders, magazine designs, and feed mechanisms that can rapidly and safely supply projectiles to the rail gun while withstanding the intense electromagnetic fields and mechanical stresses involved.

- Safety features for rail gun ammunition handling: Implementation of safety features in rail gun ammunition design and handling procedures. This includes fail-safe mechanisms, insulation materials to prevent accidental discharge, and specialized handling equipment. The focus is on minimizing risks associated with the high-energy nature of rail gun systems and ensuring safe storage, transport, and loading of ammunition.

02 Packaging solutions for rail gun ammunition

Innovative packaging solutions designed to protect and transport rail gun ammunition. These packaging systems consider the unique characteristics of rail gun projectiles, including their size, weight, and sensitivity to environmental factors. The packaging aims to ensure safe handling, storage, and transportation while maintaining the integrity of the ammunition.Expand Specific Solutions03 Advanced materials for rail gun projectiles

Development of advanced materials specifically tailored for use in rail gun projectiles. These materials are selected or engineered to withstand the extreme conditions of electromagnetic launch, including high temperatures, pressures, and electromagnetic forces. The focus is on improving durability, performance, and overall effectiveness of the ammunition.Expand Specific Solutions04 Rail gun ammunition loading and handling systems

Specialized systems and mechanisms for loading and handling rail gun ammunition. These systems are designed to efficiently and safely load projectiles into the rail gun, considering the unique requirements of electromagnetic launch systems. The focus is on improving loading speed, accuracy, and overall system performance.Expand Specific Solutions05 Protective coatings and treatments for rail gun ammunition

Development of protective coatings and surface treatments for rail gun ammunition. These coatings are designed to enhance the projectile's performance, protect against wear and environmental factors, and improve its electromagnetic properties. The treatments may also contribute to improved accuracy and range of the ammunition.Expand Specific Solutions

Key Industry Players

The research on rail gun ammunition packaging and material requirements is in an early developmental stage, with a growing market driven by increasing military modernization efforts. The technology's maturity is still evolving, with key players like Naval Research Laboratory and General Atomics leading in research and development. Universities such as Shanghai Jiao Tong University and Beijing Institute of Technology are contributing to academic advancements. Companies like Orano Nuclear Packages & Services and NIPPON STEEL CORP. are exploring materials and packaging solutions. The competitive landscape is diverse, involving defense contractors, research institutions, and materials manufacturers, indicating a multidisciplinary approach to addressing the complex challenges of rail gun ammunition technology.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology (BIT) has made significant contributions to railgun ammunition research, focusing on advanced materials and packaging solutions. Their research team has developed novel nano-structured alloys that exhibit exceptional strength-to-weight ratios, crucial for railgun projectiles[4]. BIT has also pioneered the use of metamaterials in projectile design, which can help control electromagnetic fields during launch and reduce wear on the railgun barrel[5]. In terms of packaging, BIT has introduced innovative multi-layer composite structures that provide both thermal insulation and structural support for the projectile's internal components[6]. Their work also extends to the development of smart materials that can adapt to the extreme conditions experienced during launch and flight.

Strengths: Strong focus on material science and nanotechnology, collaboration with China's defense industry. Weaknesses: Potential limitations in international collaboration due to geopolitical factors.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has been at the forefront of railgun ammunition packaging and material research. They have developed advanced composite materials for railgun projectiles that can withstand extreme acceleration forces and temperatures. NRL's research focuses on lightweight, high-strength materials such as carbon fiber reinforced polymers and ceramic matrix composites[1]. These materials are designed to maintain structural integrity under the intense electromagnetic forces experienced during launch. NRL has also pioneered the use of aerodynamic projectile designs that reduce in-bore friction and improve flight stability[2]. Their packaging solutions incorporate innovative shock absorption techniques to protect sensitive electronic components within the projectile[3].

Strengths: Access to cutting-edge materials and testing facilities, extensive experience in naval weapon systems. Weaknesses: Research may be limited by military classification, potential delays in technology transfer to commercial applications.

Core Innovations

Nontoxic low melting point fusible alloy lubrication of electromagnetic railgun armatures and rails

PatentActiveUS20130333678A1

Innovation

- A ternary alloy of bismuth, indium, and tin is used as a lubricant, applied via surface patterns on the rails and armature, reducing friction and electrical resistance by forming a low-temperature, renewable boundary lubricant film.

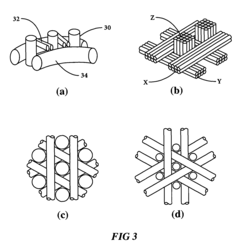

ILP rail-gun armature and rails

PatentActiveUS8132562B1

Innovation

- The use of carbon-carbon composite materials for both armatures and rails, fabricated through a process of carbonization, infusion with a carbon matrix, and graphitization, along with reinforcement and additional refractory metals, to create a durable and conductive structure that minimizes damage during high-velocity projectile launches.

Material Requirements

The material requirements for rail gun ammunition packaging are critical to ensure the integrity, performance, and safety of the projectiles during storage, transportation, and firing. These requirements are driven by the unique characteristics of rail gun technology and the extreme conditions the ammunition must withstand.

Firstly, the packaging materials must possess exceptional thermal resistance properties. Rail gun ammunition is subjected to intense heat generated during the firing process, with temperatures potentially reaching several thousand degrees Celsius. Materials such as advanced ceramics, high-temperature polymers, or composite materials with thermal barrier coatings are essential to protect the projectile from thermal degradation and maintain its structural integrity.

Electromagnetic shielding is another crucial requirement for rail gun ammunition packaging. The intense electromagnetic fields generated during firing can potentially interfere with sensitive electronic components within the projectile. Conductive materials like metal alloys or carbon-based composites are often employed to create a Faraday cage effect, shielding the internal components from electromagnetic interference.

The packaging materials must also exhibit extraordinary mechanical strength and durability. Rail gun projectiles experience extreme acceleration forces, often exceeding 100,000 g's. Materials with high tensile strength, impact resistance, and low deformation under stress are necessary to withstand these forces. Advanced alloys, carbon fiber reinforced polymers, or nanostructured materials are potential candidates for this application.

Corrosion resistance is another vital consideration, particularly for naval applications where exposure to saltwater and humid environments is common. Materials that can withstand prolonged exposure to corrosive elements without degradation are essential. This may include specialized coatings, passivated metals, or inherently corrosion-resistant materials like certain stainless steel alloys or titanium-based composites.

Weight optimization is a critical factor in rail gun ammunition packaging design. The materials used must provide the necessary protection and performance characteristics while minimizing the overall weight of the projectile. This often involves the use of lightweight yet strong materials such as advanced aluminum alloys, titanium-based composites, or engineered polymers.

Lastly, the packaging materials must be compatible with the rail gun's electromagnetic launch system. This includes considerations such as low electrical conductivity to prevent current leakage, minimal magnetic permeability to avoid interference with the rail gun's magnetic fields, and the ability to maintain structural integrity under the intense electromagnetic forces experienced during launch.

Firstly, the packaging materials must possess exceptional thermal resistance properties. Rail gun ammunition is subjected to intense heat generated during the firing process, with temperatures potentially reaching several thousand degrees Celsius. Materials such as advanced ceramics, high-temperature polymers, or composite materials with thermal barrier coatings are essential to protect the projectile from thermal degradation and maintain its structural integrity.

Electromagnetic shielding is another crucial requirement for rail gun ammunition packaging. The intense electromagnetic fields generated during firing can potentially interfere with sensitive electronic components within the projectile. Conductive materials like metal alloys or carbon-based composites are often employed to create a Faraday cage effect, shielding the internal components from electromagnetic interference.

The packaging materials must also exhibit extraordinary mechanical strength and durability. Rail gun projectiles experience extreme acceleration forces, often exceeding 100,000 g's. Materials with high tensile strength, impact resistance, and low deformation under stress are necessary to withstand these forces. Advanced alloys, carbon fiber reinforced polymers, or nanostructured materials are potential candidates for this application.

Corrosion resistance is another vital consideration, particularly for naval applications where exposure to saltwater and humid environments is common. Materials that can withstand prolonged exposure to corrosive elements without degradation are essential. This may include specialized coatings, passivated metals, or inherently corrosion-resistant materials like certain stainless steel alloys or titanium-based composites.

Weight optimization is a critical factor in rail gun ammunition packaging design. The materials used must provide the necessary protection and performance characteristics while minimizing the overall weight of the projectile. This often involves the use of lightweight yet strong materials such as advanced aluminum alloys, titanium-based composites, or engineered polymers.

Lastly, the packaging materials must be compatible with the rail gun's electromagnetic launch system. This includes considerations such as low electrical conductivity to prevent current leakage, minimal magnetic permeability to avoid interference with the rail gun's magnetic fields, and the ability to maintain structural integrity under the intense electromagnetic forces experienced during launch.

Environmental Impact

The environmental impact of rail gun ammunition packaging and materials is a critical consideration in the development and deployment of this advanced technology. The high-energy nature of rail gun systems necessitates robust packaging solutions that can withstand extreme forces while minimizing ecological footprints.

One of the primary environmental concerns is the potential for material contamination during testing and operational use. Traditional ammunition packaging often contains heavy metals and synthetic compounds that can leach into soil and water systems. Rail gun ammunition packaging must be designed with environmentally friendly materials that maintain structural integrity under high-stress conditions while posing minimal risk to ecosystems.

Biodegradable polymers and composite materials are emerging as promising alternatives for rail gun ammunition packaging. These materials offer the required strength and durability while decomposing naturally over time, reducing long-term environmental impact. Research into bio-based plastics derived from renewable resources is ongoing, with the aim of creating packaging solutions that are both high-performance and ecologically responsible.

The manufacturing processes for rail gun ammunition packaging also warrant environmental scrutiny. Energy-intensive production methods contribute to carbon emissions and resource depletion. Innovations in low-energy manufacturing techniques, such as additive manufacturing and advanced molding processes, are being explored to reduce the overall environmental footprint of packaging production.

Recycling and waste management strategies play a crucial role in mitigating the environmental impact of rail gun ammunition packaging. Developing closed-loop systems for material recovery and reuse can significantly reduce the amount of waste generated. This approach not only minimizes environmental harm but also promotes resource efficiency and cost-effectiveness in the long term.

The acoustic impact of rail gun testing and operation is another environmental consideration. While not directly related to packaging, the design of ammunition and its containment systems can influence noise levels. Research into sound-dampening materials and structures for packaging may contribute to reducing the overall acoustic footprint of rail gun systems, particularly in sensitive ecological areas or populated regions.

As rail gun technology advances, the focus on environmentally conscious design extends beyond immediate operational concerns to the entire lifecycle of ammunition and packaging. This holistic approach encompasses raw material sourcing, manufacturing processes, operational use, and end-of-life disposal or recycling. By addressing environmental impacts at each stage, researchers and engineers can develop rail gun ammunition packaging solutions that meet stringent performance requirements while minimizing ecological harm.

One of the primary environmental concerns is the potential for material contamination during testing and operational use. Traditional ammunition packaging often contains heavy metals and synthetic compounds that can leach into soil and water systems. Rail gun ammunition packaging must be designed with environmentally friendly materials that maintain structural integrity under high-stress conditions while posing minimal risk to ecosystems.

Biodegradable polymers and composite materials are emerging as promising alternatives for rail gun ammunition packaging. These materials offer the required strength and durability while decomposing naturally over time, reducing long-term environmental impact. Research into bio-based plastics derived from renewable resources is ongoing, with the aim of creating packaging solutions that are both high-performance and ecologically responsible.

The manufacturing processes for rail gun ammunition packaging also warrant environmental scrutiny. Energy-intensive production methods contribute to carbon emissions and resource depletion. Innovations in low-energy manufacturing techniques, such as additive manufacturing and advanced molding processes, are being explored to reduce the overall environmental footprint of packaging production.

Recycling and waste management strategies play a crucial role in mitigating the environmental impact of rail gun ammunition packaging. Developing closed-loop systems for material recovery and reuse can significantly reduce the amount of waste generated. This approach not only minimizes environmental harm but also promotes resource efficiency and cost-effectiveness in the long term.

The acoustic impact of rail gun testing and operation is another environmental consideration. While not directly related to packaging, the design of ammunition and its containment systems can influence noise levels. Research into sound-dampening materials and structures for packaging may contribute to reducing the overall acoustic footprint of rail gun systems, particularly in sensitive ecological areas or populated regions.

As rail gun technology advances, the focus on environmentally conscious design extends beyond immediate operational concerns to the entire lifecycle of ammunition and packaging. This holistic approach encompasses raw material sourcing, manufacturing processes, operational use, and end-of-life disposal or recycling. By addressing environmental impacts at each stage, researchers and engineers can develop rail gun ammunition packaging solutions that meet stringent performance requirements while minimizing ecological harm.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!