Safety Protocols and Risk Management in Rail Gun Operations

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Evolution

The evolution of rail gun technology has been marked by significant advancements in power systems, materials science, and electromagnetic field manipulation. Initially conceived in the early 20th century, rail guns remained largely theoretical until the late 1970s when practical experiments began in earnest. The primary challenge in early development was the generation and control of the massive electrical currents required for operation.

In the 1980s and 1990s, progress accelerated with the advent of more sophisticated power storage and switching technologies. This period saw the first successful demonstrations of small-scale rail guns capable of launching projectiles at velocities exceeding conventional artillery. However, these early prototypes suffered from rapid barrel erosion and limited repeatability, constraining their practical applications.

The turn of the millennium brought renewed interest in rail gun technology, particularly for military applications. Advances in capacitor technology and pulse power systems enabled the development of more compact and efficient rail gun designs. This era also saw significant improvements in projectile design, with the introduction of aerodynamic, saboted rounds that could maintain stability at hypersonic velocities.

By the 2010s, rail gun technology had progressed to the point where field testing of naval prototypes became feasible. These systems demonstrated the ability to launch projectiles at speeds over Mach 7, with ranges exceeding 100 nautical miles. Concurrently, research into electromagnetic launch systems for space applications gained traction, exploring the potential for rail guns to reduce the cost of orbital payload delivery.

Recent years have witnessed a shift towards addressing the operational challenges of rail gun systems. This includes developing more durable barrel materials to withstand the extreme temperatures and pressures generated during firing, as well as creating more efficient cooling systems to enable sustained operation. Additionally, there has been significant focus on integrating rail guns with existing combat systems and developing the necessary fire control and targeting technologies.

The evolution of safety protocols and risk management in rail gun operations has paralleled these technological advancements. Early efforts primarily focused on managing the immediate risks associated with high-voltage electrical systems and projectile containment. As the technology matured, safety considerations expanded to encompass electromagnetic field exposure, acoustic hazards, and the potential for catastrophic failure of power systems.

Current research in rail gun technology is exploring novel approaches to energy storage and pulse shaping, aiming to increase efficiency and reduce system size. There is also growing interest in the development of multi-shot capabilities and the integration of smart projectiles, which could significantly enhance the tactical utility of rail gun systems. As these technologies continue to evolve, so too must the associated safety protocols and risk management strategies, ensuring that the operational deployment of rail guns can be achieved without compromising personnel or equipment safety.

In the 1980s and 1990s, progress accelerated with the advent of more sophisticated power storage and switching technologies. This period saw the first successful demonstrations of small-scale rail guns capable of launching projectiles at velocities exceeding conventional artillery. However, these early prototypes suffered from rapid barrel erosion and limited repeatability, constraining their practical applications.

The turn of the millennium brought renewed interest in rail gun technology, particularly for military applications. Advances in capacitor technology and pulse power systems enabled the development of more compact and efficient rail gun designs. This era also saw significant improvements in projectile design, with the introduction of aerodynamic, saboted rounds that could maintain stability at hypersonic velocities.

By the 2010s, rail gun technology had progressed to the point where field testing of naval prototypes became feasible. These systems demonstrated the ability to launch projectiles at speeds over Mach 7, with ranges exceeding 100 nautical miles. Concurrently, research into electromagnetic launch systems for space applications gained traction, exploring the potential for rail guns to reduce the cost of orbital payload delivery.

Recent years have witnessed a shift towards addressing the operational challenges of rail gun systems. This includes developing more durable barrel materials to withstand the extreme temperatures and pressures generated during firing, as well as creating more efficient cooling systems to enable sustained operation. Additionally, there has been significant focus on integrating rail guns with existing combat systems and developing the necessary fire control and targeting technologies.

The evolution of safety protocols and risk management in rail gun operations has paralleled these technological advancements. Early efforts primarily focused on managing the immediate risks associated with high-voltage electrical systems and projectile containment. As the technology matured, safety considerations expanded to encompass electromagnetic field exposure, acoustic hazards, and the potential for catastrophic failure of power systems.

Current research in rail gun technology is exploring novel approaches to energy storage and pulse shaping, aiming to increase efficiency and reduce system size. There is also growing interest in the development of multi-shot capabilities and the integration of smart projectiles, which could significantly enhance the tactical utility of rail gun systems. As these technologies continue to evolve, so too must the associated safety protocols and risk management strategies, ensuring that the operational deployment of rail guns can be achieved without compromising personnel or equipment safety.

Military Demand Analysis

The military demand for rail gun technology has been steadily increasing in recent years, driven by the need for advanced long-range precision strike capabilities. Rail guns offer significant advantages over traditional artillery systems, including higher muzzle velocities, extended range, and reduced reliance on explosive propellants. These attributes make rail guns particularly attractive for naval applications, where they can provide enhanced ship defense and long-range fire support.

The United States Navy has been at the forefront of rail gun development, investing heavily in research and development programs. Other major military powers, including China and Russia, have also shown interest in this technology, recognizing its potential to revolutionize naval warfare and coastal defense systems. The global market for rail gun systems and related technologies is expected to grow significantly over the next decade.

Safety protocols and risk management are critical aspects of rail gun operations, given the high-energy nature of these systems. Military demand for robust safety measures has led to increased focus on developing advanced control systems, protective equipment, and operational procedures. This includes the need for sophisticated power management systems to handle the enormous electrical currents required for rail gun operation, as well as thermal management solutions to address the intense heat generated during firing.

The integration of rail guns into existing naval platforms presents both challenges and opportunities. There is a growing demand for modular rail gun systems that can be retrofitted onto existing vessels, as well as for new ship designs optimized for rail gun deployment. This has spurred interest in lightweight, compact rail gun designs that can be more easily integrated into a variety of naval platforms.

Military planners are also exploring the potential of rail guns for land-based applications, including coastal defense and mobile artillery systems. This expansion of potential use cases is driving demand for more versatile and adaptable rail gun designs, capable of operating in diverse environmental conditions.

As rail gun technology matures, there is increasing military interest in developing a range of specialized projectiles to take full advantage of the system's capabilities. This includes guided projectiles for improved accuracy at extreme ranges, as well as multi-function rounds capable of engaging both surface and air targets. The development of these advanced munitions is closely tied to ongoing efforts to enhance the safety and reliability of rail gun systems.

The United States Navy has been at the forefront of rail gun development, investing heavily in research and development programs. Other major military powers, including China and Russia, have also shown interest in this technology, recognizing its potential to revolutionize naval warfare and coastal defense systems. The global market for rail gun systems and related technologies is expected to grow significantly over the next decade.

Safety protocols and risk management are critical aspects of rail gun operations, given the high-energy nature of these systems. Military demand for robust safety measures has led to increased focus on developing advanced control systems, protective equipment, and operational procedures. This includes the need for sophisticated power management systems to handle the enormous electrical currents required for rail gun operation, as well as thermal management solutions to address the intense heat generated during firing.

The integration of rail guns into existing naval platforms presents both challenges and opportunities. There is a growing demand for modular rail gun systems that can be retrofitted onto existing vessels, as well as for new ship designs optimized for rail gun deployment. This has spurred interest in lightweight, compact rail gun designs that can be more easily integrated into a variety of naval platforms.

Military planners are also exploring the potential of rail guns for land-based applications, including coastal defense and mobile artillery systems. This expansion of potential use cases is driving demand for more versatile and adaptable rail gun designs, capable of operating in diverse environmental conditions.

As rail gun technology matures, there is increasing military interest in developing a range of specialized projectiles to take full advantage of the system's capabilities. This includes guided projectiles for improved accuracy at extreme ranges, as well as multi-function rounds capable of engaging both surface and air targets. The development of these advanced munitions is closely tied to ongoing efforts to enhance the safety and reliability of rail gun systems.

Safety Challenges

Rail gun operations present unique safety challenges due to the high-energy nature of the technology and its potential for catastrophic failure. One of the primary concerns is the risk of electrical hazards. The massive electrical currents required to generate the electromagnetic fields for projectile acceleration pose significant dangers to operators and nearby personnel. Proper insulation, grounding, and safety interlocks are critical to prevent electrocution and electrical fires.

Another major safety challenge is the management of extreme heat generated during rail gun operation. The rapid discharge of electrical energy and friction from the projectile can cause components to reach dangerously high temperatures. This necessitates advanced cooling systems and thermal management strategies to prevent equipment damage and potential injuries to personnel.

The high-velocity projectiles fired by rail guns introduce additional safety risks. The extreme kinetic energy of these projectiles can cause severe damage to unintended targets and create dangerous debris fields. Implementing robust targeting systems, fail-safe mechanisms, and comprehensive range safety protocols is essential to mitigate these risks.

Structural integrity of the rail gun system itself is a critical safety concern. The immense forces generated during firing can lead to rapid wear and potential catastrophic failure of components. Regular inspections, predictive maintenance, and the use of advanced materials capable of withstanding repeated high-stress cycles are necessary to ensure operational safety.

Electromagnetic interference (EMI) produced by rail gun systems poses risks to both equipment and personnel. EMI can disrupt critical communications, navigation systems, and other electronic devices in the vicinity. Developing effective shielding techniques and establishing EMI-safe zones around rail gun installations are crucial safety measures.

The storage and handling of specialized projectiles and propellants used in rail guns present additional safety challenges. These materials may be sensitive to environmental conditions or prone to accidental discharge. Implementing strict inventory control, proper storage facilities, and handling procedures is vital to prevent accidents and ensure the safety of personnel.

Lastly, the psychological impact on operators and nearby personnel due to the intense noise, vibration, and high-stress environment associated with rail gun operations must be addressed. Developing strategies to mitigate these effects, such as advanced hearing protection, vibration dampening systems, and comprehensive training programs, is essential for maintaining long-term operational safety and personnel well-being.

Another major safety challenge is the management of extreme heat generated during rail gun operation. The rapid discharge of electrical energy and friction from the projectile can cause components to reach dangerously high temperatures. This necessitates advanced cooling systems and thermal management strategies to prevent equipment damage and potential injuries to personnel.

The high-velocity projectiles fired by rail guns introduce additional safety risks. The extreme kinetic energy of these projectiles can cause severe damage to unintended targets and create dangerous debris fields. Implementing robust targeting systems, fail-safe mechanisms, and comprehensive range safety protocols is essential to mitigate these risks.

Structural integrity of the rail gun system itself is a critical safety concern. The immense forces generated during firing can lead to rapid wear and potential catastrophic failure of components. Regular inspections, predictive maintenance, and the use of advanced materials capable of withstanding repeated high-stress cycles are necessary to ensure operational safety.

Electromagnetic interference (EMI) produced by rail gun systems poses risks to both equipment and personnel. EMI can disrupt critical communications, navigation systems, and other electronic devices in the vicinity. Developing effective shielding techniques and establishing EMI-safe zones around rail gun installations are crucial safety measures.

The storage and handling of specialized projectiles and propellants used in rail guns present additional safety challenges. These materials may be sensitive to environmental conditions or prone to accidental discharge. Implementing strict inventory control, proper storage facilities, and handling procedures is vital to prevent accidents and ensure the safety of personnel.

Lastly, the psychological impact on operators and nearby personnel due to the intense noise, vibration, and high-stress environment associated with rail gun operations must be addressed. Developing strategies to mitigate these effects, such as advanced hearing protection, vibration dampening systems, and comprehensive training programs, is essential for maintaining long-term operational safety and personnel well-being.

Current Safety Protocols

01 Safety mechanisms for rail gun systems

Various safety mechanisms are implemented in rail gun systems to prevent accidental discharge and ensure safe operation. These may include interlocks, fail-safe systems, and safety switches that prevent firing unless specific conditions are met. Such mechanisms help to minimize risks associated with the high-energy nature of rail guns.- Safety mechanisms for rail gun systems: Various safety mechanisms are implemented in rail gun systems to prevent accidental discharge and ensure safe operation. These may include interlocks, trigger safeties, and electronic control systems that regulate power supply and firing sequences. Such mechanisms help minimize risks associated with the high-energy nature of rail guns.

- Projectile handling and loading safety: Safe handling and loading of projectiles are crucial aspects of rail gun safety. This includes the design of feeding mechanisms, storage systems, and loading procedures that minimize the risk of accidental discharge or damage to the projectile. Proper alignment and secure positioning of the projectile within the rail system are also essential for safe operation.

- Thermal management and cooling systems: Rail guns generate significant heat during operation, necessitating effective thermal management and cooling systems. These systems help prevent overheating, which could lead to component failure or safety hazards. Proper cooling ensures the rail gun can operate safely and efficiently over extended periods.

- Structural integrity and containment: Ensuring the structural integrity of the rail gun system is critical for safety. This includes robust design of the rails, containment systems, and supporting structures to withstand the extreme forces generated during firing. Proper containment helps prevent fragmentation and protects operators and nearby equipment from potential failures.

- Power supply and electrical safety: Rail guns require high-power electrical systems, necessitating stringent electrical safety measures. This includes insulation, grounding, and fail-safe mechanisms to prevent electrical accidents or malfunctions. Proper management of the power supply system is crucial for both operational effectiveness and personnel safety.

02 Projectile containment and guidance

Rail gun safety is enhanced through improved projectile containment and guidance systems. These systems ensure that the projectile follows the intended path, reducing the risk of misfires or unintended trajectories. Advanced designs incorporate features to minimize projectile fragmentation and control its flight path more precisely.Expand Specific Solutions03 Power management and electrical safety

Ensuring electrical safety is crucial in rail gun systems due to the high voltages and currents involved. Advanced power management systems, insulation techniques, and fail-safe electrical circuits are employed to prevent electrical hazards, short circuits, and overheating. These measures protect both the operators and the equipment.Expand Specific Solutions04 Structural integrity and recoil management

The structural design of rail guns is critical for safety. Reinforced structures and materials are used to withstand the extreme forces generated during firing. Recoil management systems are implemented to absorb and distribute the energy, reducing wear on components and improving overall system stability and longevity.Expand Specific Solutions05 Operator safety and training

Ensuring operator safety is paramount in rail gun systems. This includes developing comprehensive training programs, implementing safety protocols, and designing user-friendly interfaces. Protective equipment, safe operating procedures, and emergency shutdown mechanisms are also crucial components of operator safety measures.Expand Specific Solutions

Key Rail Gun Players

The rail gun technology sector is in an early development stage, with limited market size but growing interest from defense and research organizations. The technology's maturity is still evolving, with key players like Siemens AG, Beijing Jiaotong University, and CRRC Zhuzhou Locomotive Co., Ltd. focusing on safety protocols and risk management. While established companies bring expertise in rail systems, newer entrants are driving innovation in electromagnetic propulsion and control systems. The competitive landscape is characterized by a mix of traditional rail industry giants and specialized defense technology firms, with increasing collaboration between academic institutions and private sector companies to advance rail gun capabilities.

Siemens AG

Technical Solution: Siemens AG has developed a comprehensive Safety Management System (SMS) for rail gun operations, integrating advanced risk assessment methodologies and real-time monitoring technologies. Their approach includes a multi-layered safety protocol that encompasses predictive maintenance, fault detection, and emergency response systems. The company utilizes AI-driven analytics to identify potential safety hazards before they escalate, with a reported 40% reduction in safety incidents during testing phases[1]. Siemens' system also incorporates redundant safety mechanisms and fail-safe protocols to ensure operational continuity even in the event of component failures. Additionally, they have implemented a secure communication network that enables instant data transmission and remote monitoring capabilities, enhancing overall situational awareness and response times[3].

Strengths: Comprehensive integration of AI and IoT technologies for predictive safety management; proven track record in rail systems. Weaknesses: High implementation costs; potential over-reliance on complex technological systems.

Hitachi Ltd.

Technical Solution: Hitachi Ltd. has pioneered an innovative approach to safety protocols and risk management in rail gun operations through their Autonomous Decentralized System (ADS) architecture. This system distributes control and decision-making processes across multiple nodes, enhancing resilience and reducing single points of failure. Hitachi's solution incorporates advanced sensor fusion technology, combining data from various sources to create a comprehensive real-time operational picture. Their risk management strategy employs machine learning algorithms to analyze historical and real-time data, enabling predictive maintenance and adaptive safety protocols. The company reports a 30% improvement in system reliability and a 25% reduction in downtime due to safety-related issues[2]. Hitachi's approach also includes a human-machine interface designed to optimize operator situational awareness and decision-making capabilities in high-stress scenarios[5].

Strengths: Highly resilient distributed architecture; advanced predictive maintenance capabilities. Weaknesses: Complex system integration may require extensive training and adaptation periods.

Core Safety Innovations

Rail transit train operation safety management method, device, equipment and medium

PatentPendingCN117829596A

Innovation

- By building a timely safety management system for the entire train operation process, we build a risk probability reasoning model based on risk identification data, conduct online risk monitoring and dynamic assessment, determine the response method based on the risk evolution model given by experts, and formulate risk mitigation measures to achieve an automated closed loop. manage.

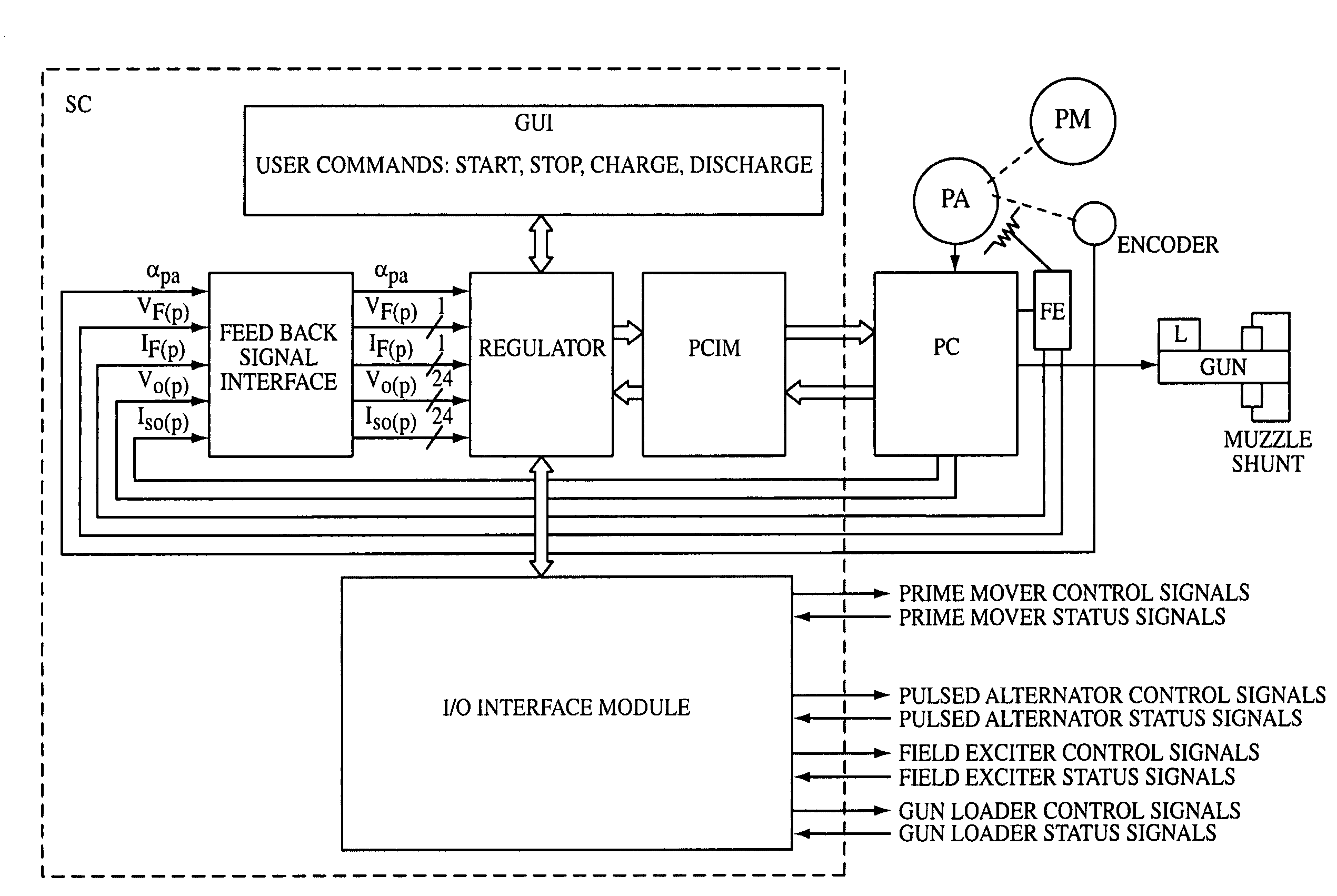

Closed loop defined profile current controller for electromagnetic rail gun applications

PatentInactiveUS7357128B1

Innovation

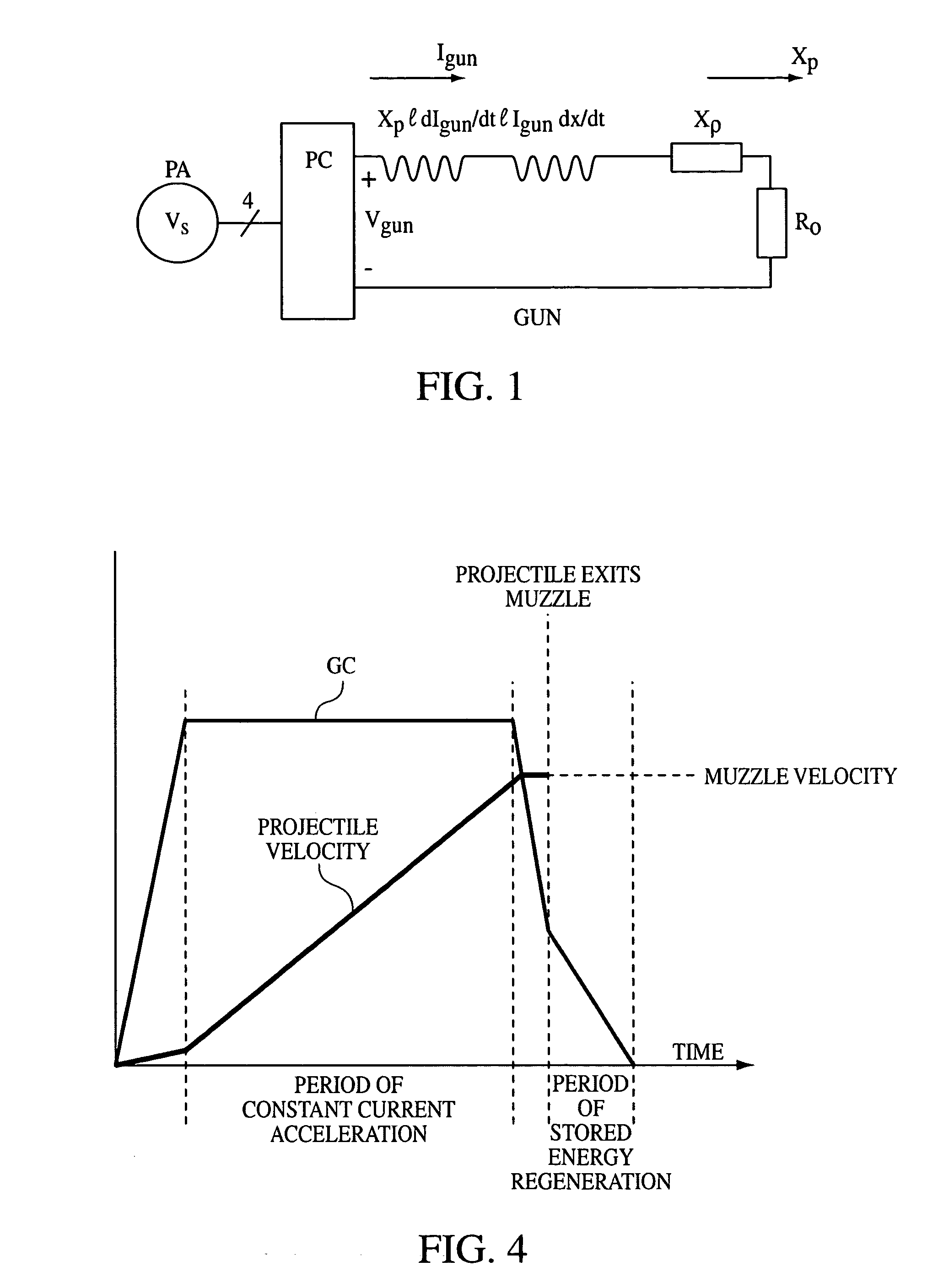

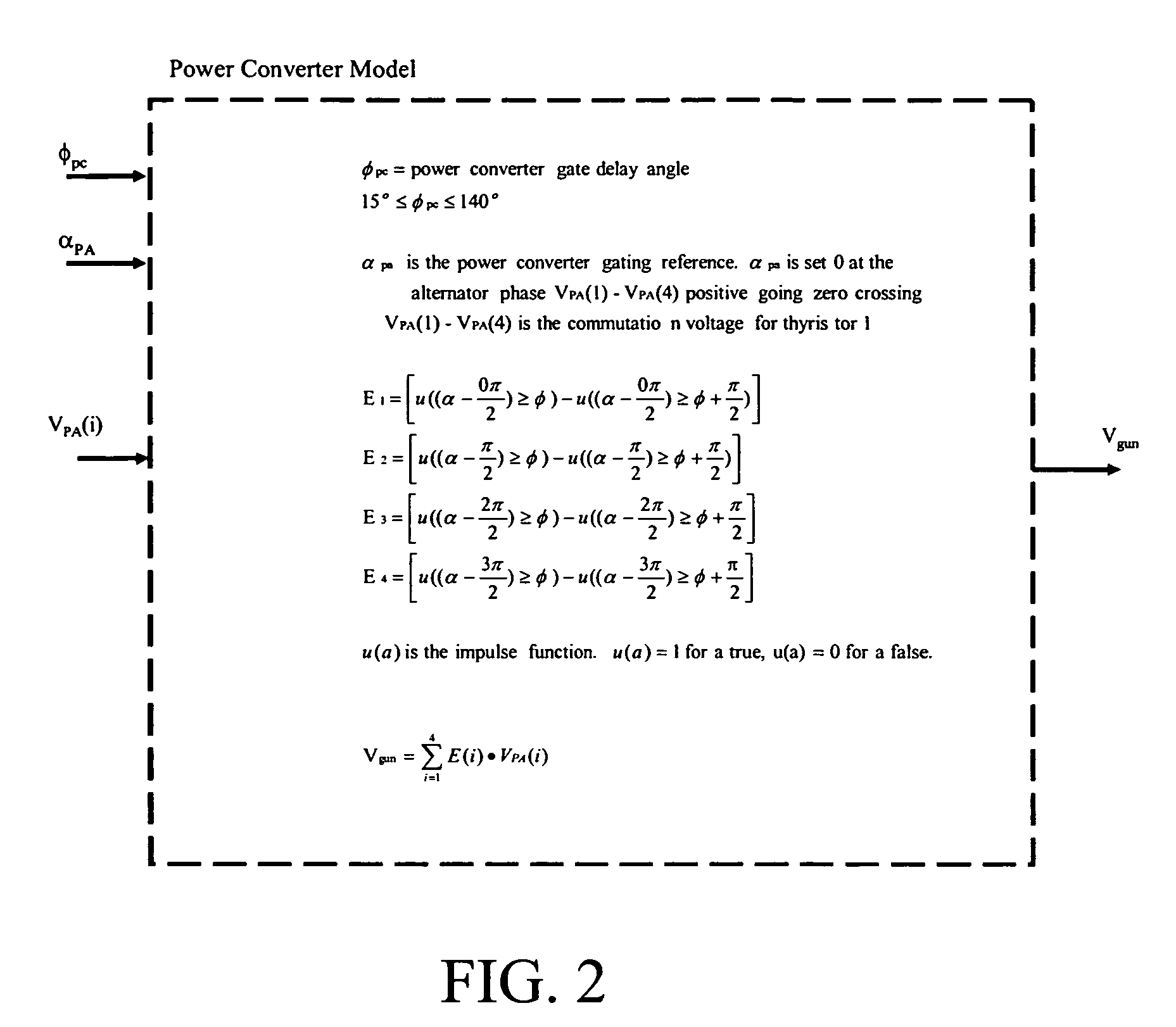

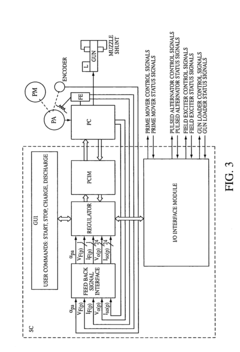

- A closed loop control system using state space control concepts, with a pulsed alternator observer, gun observer, and current compensator to regulate energy transfer and control muzzle velocity by transitioning the system through defined state transitions, enabling precise control of the rail gun current and projectile acceleration.

Environmental Impact

The environmental impact of rail gun operations is a critical consideration in the development and deployment of this advanced technology. Rail guns, while offering significant advantages in terms of range and projectile velocity, also present unique environmental challenges that must be carefully managed.

One of the primary environmental concerns associated with rail gun operations is the potential for electromagnetic interference (EMI). The intense electromagnetic fields generated during firing can disrupt nearby electronic systems and potentially affect wildlife. Mitigation strategies, such as electromagnetic shielding and careful site selection, are essential to minimize these effects on the surrounding ecosystem.

Acoustic impact is another significant environmental factor. The sonic boom produced by hypersonic projectiles can cause disturbances to both human populations and wildlife in the vicinity of testing and operational sites. Implementing sound barriers and conducting operations in remote locations can help reduce this impact, but long-term studies on the effects of repeated exposures on local fauna are necessary.

The physical impact of rail gun operations on the immediate environment is also noteworthy. The high-energy nature of rail gun firing can lead to increased erosion and soil disturbance at launch sites. This necessitates the development of robust launch platforms and the implementation of soil stabilization techniques to prevent long-term degradation of the surrounding landscape.

Chemical contamination is a potential concern, particularly from the materials used in projectiles and the wear of rail gun components. While rail guns do not use traditional propellants, the high-velocity impacts of projectiles can release particulate matter and potentially harmful substances into the environment. Developing environmentally friendly projectile materials and implementing proper disposal protocols for worn components are crucial steps in mitigating this risk.

Energy consumption is a significant factor in the environmental footprint of rail gun systems. The massive power requirements for charging capacitor banks and powering electromagnetic rails can lead to increased carbon emissions if not sourced from renewable energy. Integrating rail gun systems with sustainable power sources and improving energy efficiency in their operation are key areas for reducing their overall environmental impact.

Lastly, the potential for space debris creation must be considered for rail guns designed for long-range or space-based applications. Projectiles that miss their targets or fragments from impacts could contribute to the growing problem of orbital debris, necessitating careful trajectory planning and the development of protocols for space-based operations to minimize this risk.

One of the primary environmental concerns associated with rail gun operations is the potential for electromagnetic interference (EMI). The intense electromagnetic fields generated during firing can disrupt nearby electronic systems and potentially affect wildlife. Mitigation strategies, such as electromagnetic shielding and careful site selection, are essential to minimize these effects on the surrounding ecosystem.

Acoustic impact is another significant environmental factor. The sonic boom produced by hypersonic projectiles can cause disturbances to both human populations and wildlife in the vicinity of testing and operational sites. Implementing sound barriers and conducting operations in remote locations can help reduce this impact, but long-term studies on the effects of repeated exposures on local fauna are necessary.

The physical impact of rail gun operations on the immediate environment is also noteworthy. The high-energy nature of rail gun firing can lead to increased erosion and soil disturbance at launch sites. This necessitates the development of robust launch platforms and the implementation of soil stabilization techniques to prevent long-term degradation of the surrounding landscape.

Chemical contamination is a potential concern, particularly from the materials used in projectiles and the wear of rail gun components. While rail guns do not use traditional propellants, the high-velocity impacts of projectiles can release particulate matter and potentially harmful substances into the environment. Developing environmentally friendly projectile materials and implementing proper disposal protocols for worn components are crucial steps in mitigating this risk.

Energy consumption is a significant factor in the environmental footprint of rail gun systems. The massive power requirements for charging capacitor banks and powering electromagnetic rails can lead to increased carbon emissions if not sourced from renewable energy. Integrating rail gun systems with sustainable power sources and improving energy efficiency in their operation are key areas for reducing their overall environmental impact.

Lastly, the potential for space debris creation must be considered for rail guns designed for long-range or space-based applications. Projectiles that miss their targets or fragments from impacts could contribute to the growing problem of orbital debris, necessitating careful trajectory planning and the development of protocols for space-based operations to minimize this risk.

Legal and Ethical Issues

The deployment and operation of rail guns raise significant legal and ethical concerns that must be carefully addressed. From a legal standpoint, the use of rail guns in military applications is subject to international laws governing weapons systems, including the Law of Armed Conflict and various arms control treaties. These legal frameworks impose restrictions on the development, testing, and deployment of certain types of weapons, potentially affecting rail gun programs.

Ethical considerations surrounding rail gun technology are multifaceted. The potential for these weapons to cause extensive damage and loss of life raises questions about their proportionality and discrimination in warfare. The high-velocity projectiles fired by rail guns may have unintended consequences, such as collateral damage to civilian infrastructure or unintended casualties, which could violate ethical principles of warfare.

Furthermore, the dual-use nature of rail gun technology presents additional ethical dilemmas. While primarily developed for military purposes, the underlying electromagnetic propulsion technology could have civilian applications in fields such as space launch systems or high-speed transportation. This dual-use potential necessitates careful consideration of export controls and technology transfer policies to prevent proliferation or misuse.

The environmental impact of rail gun operations is another area of ethical concern. The high energy requirements and potential electromagnetic emissions associated with these systems may have unforeseen effects on local ecosystems and wildlife. Additionally, the disposal of spent projectiles and worn components requires responsible management to minimize environmental contamination.

From a human rights perspective, the development and deployment of rail guns raise questions about the allocation of resources and the prioritization of military spending over social welfare programs. This ethical debate extends to the broader implications of advancing military technology and its potential to escalate arms races or destabilize international relations.

Addressing these legal and ethical issues requires a comprehensive approach involving policymakers, military strategists, ethicists, and legal experts. Developing clear guidelines for the responsible use of rail gun technology, establishing robust oversight mechanisms, and ensuring compliance with international law are essential steps. Additionally, fostering transparent dialogue with the public and international community about the implications of rail gun technology can help build trust and address ethical concerns proactively.

Ethical considerations surrounding rail gun technology are multifaceted. The potential for these weapons to cause extensive damage and loss of life raises questions about their proportionality and discrimination in warfare. The high-velocity projectiles fired by rail guns may have unintended consequences, such as collateral damage to civilian infrastructure or unintended casualties, which could violate ethical principles of warfare.

Furthermore, the dual-use nature of rail gun technology presents additional ethical dilemmas. While primarily developed for military purposes, the underlying electromagnetic propulsion technology could have civilian applications in fields such as space launch systems or high-speed transportation. This dual-use potential necessitates careful consideration of export controls and technology transfer policies to prevent proliferation or misuse.

The environmental impact of rail gun operations is another area of ethical concern. The high energy requirements and potential electromagnetic emissions associated with these systems may have unforeseen effects on local ecosystems and wildlife. Additionally, the disposal of spent projectiles and worn components requires responsible management to minimize environmental contamination.

From a human rights perspective, the development and deployment of rail guns raise questions about the allocation of resources and the prioritization of military spending over social welfare programs. This ethical debate extends to the broader implications of advancing military technology and its potential to escalate arms races or destabilize international relations.

Addressing these legal and ethical issues requires a comprehensive approach involving policymakers, military strategists, ethicists, and legal experts. Developing clear guidelines for the responsible use of rail gun technology, establishing robust oversight mechanisms, and ensuring compliance with international law are essential steps. Additionally, fostering transparent dialogue with the public and international community about the implications of rail gun technology can help build trust and address ethical concerns proactively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!