Simulating Rail Gun Launch Dynamics for Enhanced Control

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Evolution

The evolution of rail gun technology has been marked by significant advancements in electromagnetic propulsion systems, materials science, and power management. Initially conceived in the early 20th century, rail guns remained largely theoretical until the late 1970s when practical experiments began in earnest. The fundamental principle of rail guns, utilizing electromagnetic forces to accelerate projectiles, has remained constant, but the implementation and efficiency have dramatically improved over time.

In the 1980s and 1990s, research focused on overcoming basic technological hurdles such as rail erosion, power supply limitations, and projectile design. This period saw the development of more robust rail materials and the exploration of various projectile configurations to enhance stability and reduce energy loss during launch. The turn of the millennium brought about a shift towards more sophisticated power systems, with the introduction of pulse-forming networks and capacitor banks capable of delivering the massive current required for effective rail gun operation.

The 2000s witnessed a surge in rail gun research, particularly in military applications. This era saw the integration of advanced computer modeling and simulation techniques, allowing for more precise predictions of rail gun performance and launch dynamics. These simulations became crucial in optimizing rail gun designs, reducing the need for costly physical prototypes and accelerating the development cycle.

By the 2010s, rail gun technology had progressed to the point where field testing of prototype weapons became feasible. Notable milestones included the U.S. Navy's successful demonstrations of rail guns capable of launching projectiles at speeds exceeding Mach 7. This period also saw increased focus on miniaturization and power efficiency, aiming to make rail guns more practical for various applications beyond large naval platforms.

Recent years have seen a shift towards enhancing control and precision in rail gun systems. The simulation of launch dynamics has become a critical area of research, with efforts directed at understanding and mitigating the complex interactions between the projectile, rails, and electromagnetic fields during launch. Advanced sensors and real-time data processing techniques are being incorporated to provide feedback and adjust launch parameters on the fly, potentially improving accuracy and consistency.

Looking forward, the evolution of rail gun technology is likely to continue along several key trajectories. These include the development of more energy-efficient power systems, further improvements in materials to withstand the extreme conditions of launch, and the integration of artificial intelligence for enhanced targeting and control. Additionally, there is growing interest in adapting rail gun technology for non-military applications, such as space launch systems and hypersonic research platforms, potentially opening new avenues for technological advancement in this field.

In the 1980s and 1990s, research focused on overcoming basic technological hurdles such as rail erosion, power supply limitations, and projectile design. This period saw the development of more robust rail materials and the exploration of various projectile configurations to enhance stability and reduce energy loss during launch. The turn of the millennium brought about a shift towards more sophisticated power systems, with the introduction of pulse-forming networks and capacitor banks capable of delivering the massive current required for effective rail gun operation.

The 2000s witnessed a surge in rail gun research, particularly in military applications. This era saw the integration of advanced computer modeling and simulation techniques, allowing for more precise predictions of rail gun performance and launch dynamics. These simulations became crucial in optimizing rail gun designs, reducing the need for costly physical prototypes and accelerating the development cycle.

By the 2010s, rail gun technology had progressed to the point where field testing of prototype weapons became feasible. Notable milestones included the U.S. Navy's successful demonstrations of rail guns capable of launching projectiles at speeds exceeding Mach 7. This period also saw increased focus on miniaturization and power efficiency, aiming to make rail guns more practical for various applications beyond large naval platforms.

Recent years have seen a shift towards enhancing control and precision in rail gun systems. The simulation of launch dynamics has become a critical area of research, with efforts directed at understanding and mitigating the complex interactions between the projectile, rails, and electromagnetic fields during launch. Advanced sensors and real-time data processing techniques are being incorporated to provide feedback and adjust launch parameters on the fly, potentially improving accuracy and consistency.

Looking forward, the evolution of rail gun technology is likely to continue along several key trajectories. These include the development of more energy-efficient power systems, further improvements in materials to withstand the extreme conditions of launch, and the integration of artificial intelligence for enhanced targeting and control. Additionally, there is growing interest in adapting rail gun technology for non-military applications, such as space launch systems and hypersonic research platforms, potentially opening new avenues for technological advancement in this field.

Military Demand Analysis

The military demand for advanced rail gun technology has been steadily increasing in recent years, driven by the need for more powerful and precise long-range artillery systems. Rail guns offer significant advantages over traditional artillery, including higher muzzle velocities, extended range, and reduced reliance on explosive propellants. These characteristics make rail guns particularly attractive for naval applications, where they can provide enhanced ship defense and long-range strike capabilities.

The United States Navy has been at the forefront of rail gun development, investing substantial resources in research and development programs. The Office of Naval Research (ONR) has been leading these efforts, with the goal of developing a rail gun system capable of launching projectiles at speeds exceeding Mach 7 and achieving ranges of up to 100 nautical miles. This represents a significant improvement over conventional naval guns, which typically have ranges limited to about 20-30 nautical miles.

Other major military powers, including China and Russia, have also shown interest in rail gun technology, recognizing its potential to revolutionize naval warfare and coastal defense systems. The Chinese People's Liberation Army (PLA) has reportedly made significant progress in rail gun development, with prototypes being tested on naval vessels.

The demand for rail gun technology extends beyond naval applications. Ground-based rail gun systems are being explored for use in air defense and as a potential replacement for traditional artillery in certain scenarios. The ability to launch projectiles at hypersonic speeds without the need for explosive propellants offers advantages in terms of logistics, safety, and operational flexibility.

Simulating rail gun launch dynamics is crucial for enhancing control and optimizing performance. Accurate simulations allow engineers to predict and mitigate issues such as rail erosion, projectile integrity, and electromagnetic interference. This, in turn, enables the development of more reliable and effective rail gun systems, addressing key challenges that have hindered widespread adoption of the technology.

The military demand for rail gun technology is also driving advancements in related fields, such as power storage and management, materials science, and electromagnetic shielding. These developments have potential spillover effects into civilian applications, further increasing the overall interest and investment in rail gun research.

As geopolitical tensions persist and the need for advanced military capabilities grows, the demand for rail gun technology is expected to remain strong. Military planners see rail guns as a potential game-changer in future conflicts, particularly in scenarios involving anti-access/area denial (A2/AD) strategies. The ability to strike targets at extended ranges with high precision and reduced time-to-target could provide a significant tactical advantage in various operational contexts.

The United States Navy has been at the forefront of rail gun development, investing substantial resources in research and development programs. The Office of Naval Research (ONR) has been leading these efforts, with the goal of developing a rail gun system capable of launching projectiles at speeds exceeding Mach 7 and achieving ranges of up to 100 nautical miles. This represents a significant improvement over conventional naval guns, which typically have ranges limited to about 20-30 nautical miles.

Other major military powers, including China and Russia, have also shown interest in rail gun technology, recognizing its potential to revolutionize naval warfare and coastal defense systems. The Chinese People's Liberation Army (PLA) has reportedly made significant progress in rail gun development, with prototypes being tested on naval vessels.

The demand for rail gun technology extends beyond naval applications. Ground-based rail gun systems are being explored for use in air defense and as a potential replacement for traditional artillery in certain scenarios. The ability to launch projectiles at hypersonic speeds without the need for explosive propellants offers advantages in terms of logistics, safety, and operational flexibility.

Simulating rail gun launch dynamics is crucial for enhancing control and optimizing performance. Accurate simulations allow engineers to predict and mitigate issues such as rail erosion, projectile integrity, and electromagnetic interference. This, in turn, enables the development of more reliable and effective rail gun systems, addressing key challenges that have hindered widespread adoption of the technology.

The military demand for rail gun technology is also driving advancements in related fields, such as power storage and management, materials science, and electromagnetic shielding. These developments have potential spillover effects into civilian applications, further increasing the overall interest and investment in rail gun research.

As geopolitical tensions persist and the need for advanced military capabilities grows, the demand for rail gun technology is expected to remain strong. Military planners see rail guns as a potential game-changer in future conflicts, particularly in scenarios involving anti-access/area denial (A2/AD) strategies. The ability to strike targets at extended ranges with high precision and reduced time-to-target could provide a significant tactical advantage in various operational contexts.

Current Challenges

The simulation of rail gun launch dynamics for enhanced control faces several significant challenges in the current technological landscape. One of the primary obstacles is the accurate modeling of the complex electromagnetic interactions within the rail gun system. The rapid acceleration of the projectile creates intense electromagnetic fields that are difficult to predict and simulate with high fidelity. This challenge is compounded by the need to account for the dynamic changes in the system's geometry and material properties during the launch process.

Another major hurdle is the integration of multi-physics simulations that can simultaneously account for electromagnetic, thermal, and mechanical phenomena. The extreme conditions during a rail gun launch involve rapid heating, structural deformation, and plasma formation, all of which interact in complex ways. Developing simulation models that can accurately capture these interdependent processes in real-time remains a significant technical challenge.

The high-speed nature of rail gun launches also presents difficulties in data acquisition and validation. Experimental measurements are challenging due to the short duration of the launch event and the extreme conditions involved. This lack of comprehensive experimental data makes it difficult to validate and refine simulation models, creating a gap between theoretical predictions and real-world performance.

Computational resources pose another limitation. The detailed simulations required for accurate rail gun dynamics often demand substantial computing power, especially when attempting to model the system at high temporal and spatial resolutions. Balancing computational efficiency with simulation accuracy is an ongoing challenge, particularly for real-time control applications.

Material science challenges also play a crucial role. The extreme conditions during launch can lead to rapid wear and degradation of rail gun components. Simulating these material behaviors accurately, including potential phase changes and structural failures, is essential for predicting system performance and longevity but remains difficult with current modeling techniques.

Control system integration presents yet another challenge. Developing control algorithms that can effectively utilize the simulation outputs in real-time to adjust launch parameters is a complex task. The need for rapid decision-making based on predictive simulations puts significant strain on both the simulation models and the control systems.

Lastly, the scalability of simulation models across different rail gun designs and operational parameters is a persistent issue. Creating flexible, adaptable simulation frameworks that can be easily modified for various rail gun configurations without sacrificing accuracy or computational efficiency is an ongoing area of research and development in the field.

Another major hurdle is the integration of multi-physics simulations that can simultaneously account for electromagnetic, thermal, and mechanical phenomena. The extreme conditions during a rail gun launch involve rapid heating, structural deformation, and plasma formation, all of which interact in complex ways. Developing simulation models that can accurately capture these interdependent processes in real-time remains a significant technical challenge.

The high-speed nature of rail gun launches also presents difficulties in data acquisition and validation. Experimental measurements are challenging due to the short duration of the launch event and the extreme conditions involved. This lack of comprehensive experimental data makes it difficult to validate and refine simulation models, creating a gap between theoretical predictions and real-world performance.

Computational resources pose another limitation. The detailed simulations required for accurate rail gun dynamics often demand substantial computing power, especially when attempting to model the system at high temporal and spatial resolutions. Balancing computational efficiency with simulation accuracy is an ongoing challenge, particularly for real-time control applications.

Material science challenges also play a crucial role. The extreme conditions during launch can lead to rapid wear and degradation of rail gun components. Simulating these material behaviors accurately, including potential phase changes and structural failures, is essential for predicting system performance and longevity but remains difficult with current modeling techniques.

Control system integration presents yet another challenge. Developing control algorithms that can effectively utilize the simulation outputs in real-time to adjust launch parameters is a complex task. The need for rapid decision-making based on predictive simulations puts significant strain on both the simulation models and the control systems.

Lastly, the scalability of simulation models across different rail gun designs and operational parameters is a persistent issue. Creating flexible, adaptable simulation frameworks that can be easily modified for various rail gun configurations without sacrificing accuracy or computational efficiency is an ongoing area of research and development in the field.

Simulation Techniques

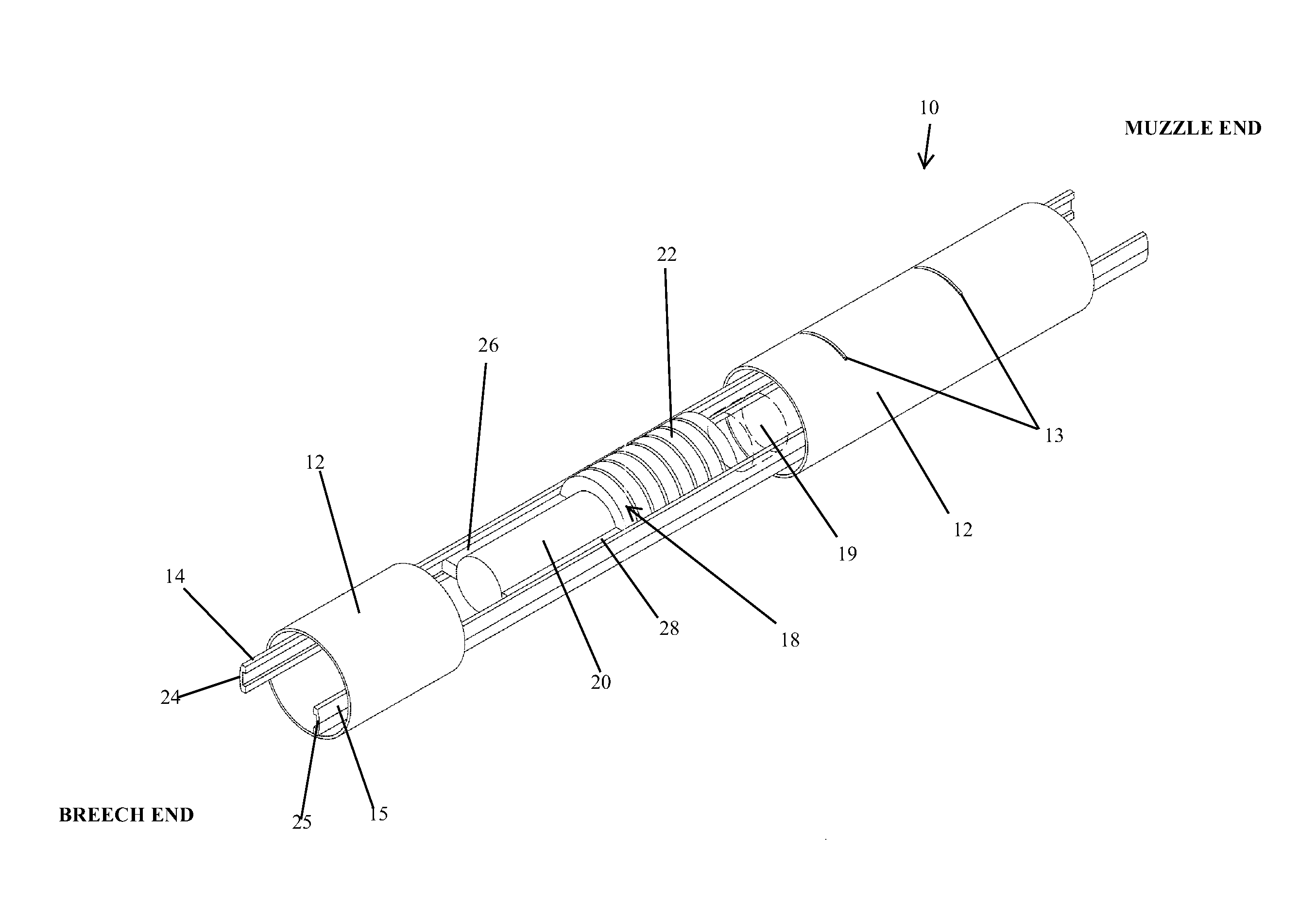

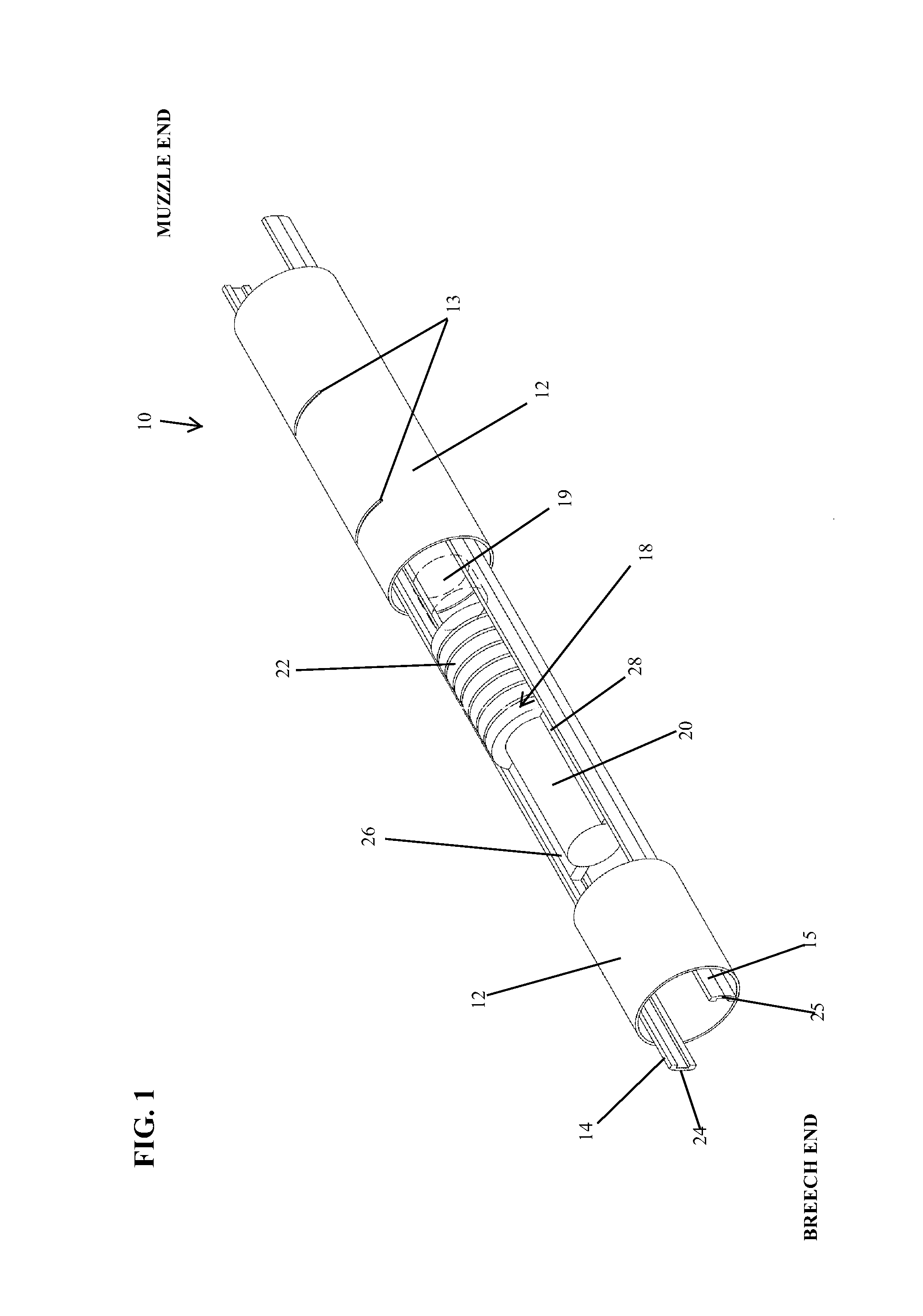

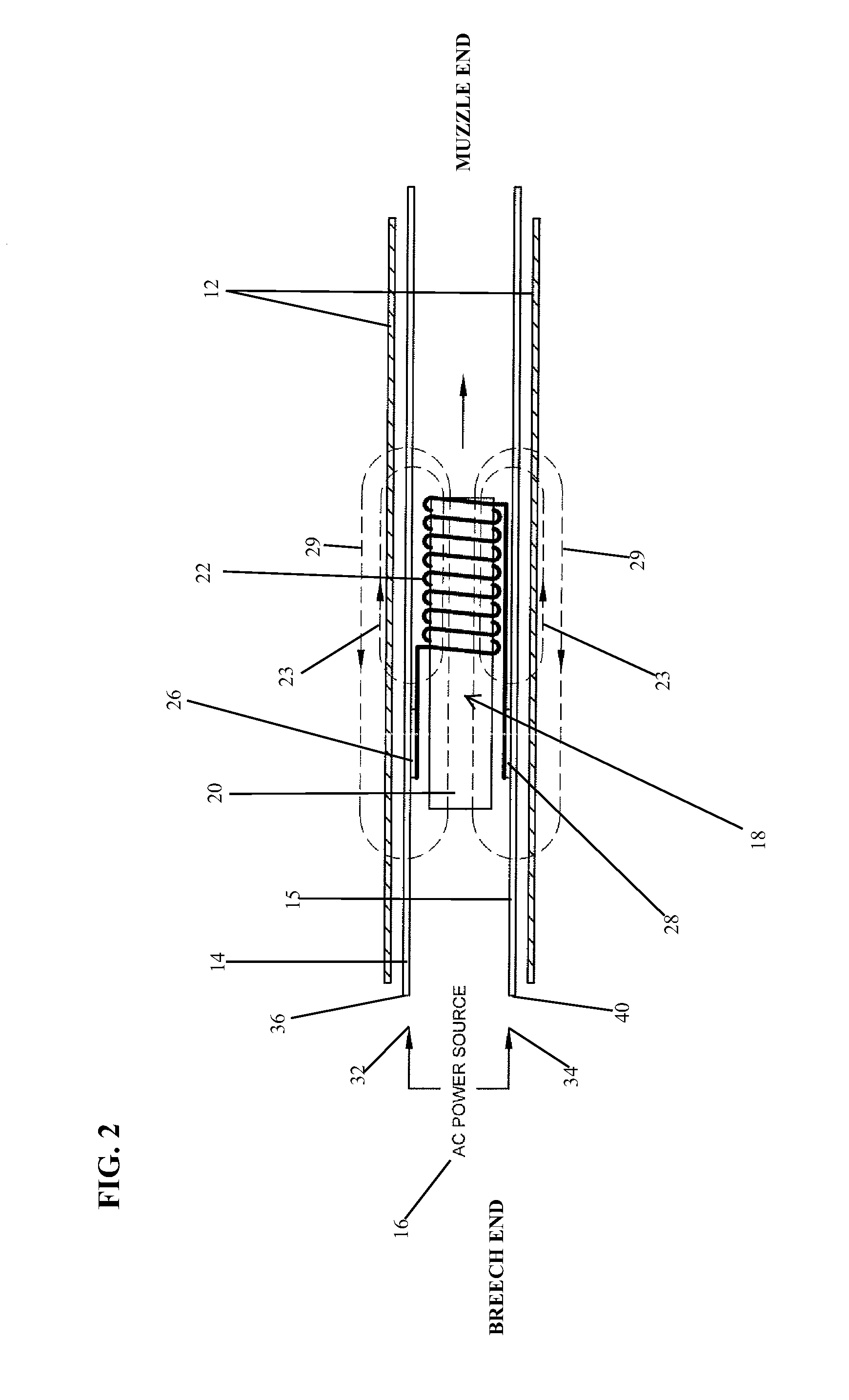

01 Electromagnetic rail gun design and operation

Rail guns use electromagnetic forces to accelerate projectiles to high velocities. The design includes conductive rails, a power supply, and a projectile. When current flows through the rails and projectile, it creates a magnetic field that propels the projectile forward. Key considerations include rail material, power source efficiency, and projectile design for optimal launch dynamics.- Electromagnetic rail gun design and operation: Rail guns use electromagnetic forces to accelerate projectiles to high velocities. The design includes conductive rails, a power source, and a projectile. When current flows through the rails and projectile, it creates a magnetic field that propels the projectile forward. Key considerations include rail material, power supply, and projectile design to optimize launch dynamics.

- Projectile design and materials for rail guns: Projectile design is crucial for rail gun performance. Materials must withstand high electromagnetic forces and temperatures. Aerodynamic shapes reduce air resistance during flight. Some designs incorporate sabots to protect the projectile during launch. Advanced materials and composite structures are used to optimize weight, strength, and conductivity.

- Power supply and energy storage systems: Rail guns require high-power, pulsed energy sources. Capacitor banks, rotating machines, or advanced battery systems are used to store and rapidly discharge energy. Power management systems control the timing and magnitude of current flow. Efficient energy storage and delivery are critical for achieving high muzzle velocities and rapid fire rates.

- Rail gun launch control and guidance systems: Precise control of launch dynamics is essential for accuracy. Advanced control systems manage current flow, timing, and projectile release. Some designs incorporate guidance systems for in-flight trajectory correction. Sensors and feedback mechanisms monitor rail conditions and projectile position during launch.

- Thermal management and wear reduction: High currents and friction generate significant heat during launch. Cooling systems and heat-resistant materials are employed to manage thermal loads. Wear on rails and other components is a major concern. Advanced materials, surface treatments, and design optimizations aim to extend operational life and maintain consistent performance over multiple launches.

02 Projectile design and materials for rail guns

Projectile design is crucial for rail gun performance. Materials must withstand high temperatures and pressures while maintaining structural integrity during launch. Advanced composites and alloys are used to create lightweight yet durable projectiles. Aerodynamic shapes and sabot designs help optimize flight characteristics and reduce drag during the launch phase.Expand Specific Solutions03 Power supply and energy storage systems

Efficient power supply and energy storage are essential for rail gun operation. High-capacity capacitors or pulse-forming networks are used to deliver the intense current required for launch. Advanced power management systems ensure rapid charging and controlled discharge to maximize launch efficiency and minimize system wear.Expand Specific Solutions04 Rail gun launch control and timing systems

Precise control and timing are critical for successful rail gun launches. Advanced electronic systems manage current flow, projectile positioning, and launch sequence timing. Sensors and feedback mechanisms monitor rail conditions, projectile acceleration, and muzzle velocity to optimize launch parameters and ensure consistent performance.Expand Specific Solutions05 Thermal management and wear reduction in rail guns

The extreme conditions during rail gun launches necessitate effective thermal management and wear reduction strategies. Cooling systems, heat-resistant materials, and advanced lubricants are employed to mitigate rail erosion and extend operational life. Novel rail designs and surface treatments help distribute thermal loads and reduce wear from high-current arcing.Expand Specific Solutions

Key Rail Gun Developers

The simulation of rail gun launch dynamics for enhanced control is an emerging field in advanced weaponry and propulsion technology. The market is in its early growth stage, with increasing interest from military and research institutions. While the market size remains relatively small, it is expected to grow significantly in the coming years due to the potential applications in defense and space exploration. The technology is still in the development phase, with varying levels of maturity among key players. Universities like Beihang University, Nanjing University of Aeronautics & Astronautics, and Harbin Institute of Technology are conducting foundational research, while companies such as General Atomics and Raytheon Co. are advancing practical applications. Government entities like the Naval Research Laboratory are also heavily involved in pushing the boundaries of this technology.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics (NUAA) has developed a comprehensive simulation framework for rail gun launch dynamics, focusing on the integration of electromagnetic, thermal, and structural analyses. Their approach employs a novel co-simulation technique that allows for efficient coupling between different physical domains. NUAA has implemented advanced numerical methods for solving the coupled partial differential equations governing rail gun physics, including spectral element methods for improved accuracy[14]. Their simulations incorporate detailed models of rail and armature materials, accounting for nonlinear behavior under extreme conditions. NUAA has also developed innovative techniques for modeling plasma formation and its effects on launch dynamics. For enhanced control, they have implemented model predictive control algorithms that optimize launch parameters in real-time based on desired trajectory and accuracy requirements[15].

Strengths: Strong theoretical foundation, innovative numerical methods. Weaknesses: Potential limitations in access to experimental data for validation, may lack practical implementation experience compared to industry players.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has developed advanced simulation models for rail gun launch dynamics. Their approach integrates electromagnetic field analysis with structural dynamics and thermal effects. NRL utilizes high-fidelity 3D finite element models to simulate the complex interactions between the projectile, rails, and electromagnetic fields during launch[1]. They have also implemented adaptive mesh refinement techniques to capture localized phenomena such as rail gouging and plasma formation[3]. NRL's simulations incorporate sophisticated material models that account for strain-rate effects and phase transitions under extreme launch conditions[5]. To enhance control, they have developed closed-loop feedback algorithms that adjust power input based on real-time projectile velocity measurements[2].

Strengths: Comprehensive multi-physics modeling, access to classified military data for validation. Weaknesses: High computational requirements, potential limitations in real-time simulation capabilities.

Core Launch Physics

Rail gun

PatentInactiveUS6622713B1

Innovation

- A rail gun system using magnetic forces to accelerate a caseless, magnetically sensitive round through a simple and robust design, powered by a rechargeable battery, with a toroid and solenoid magnet configuration and a loading mechanism that allows for efficient electrical use.

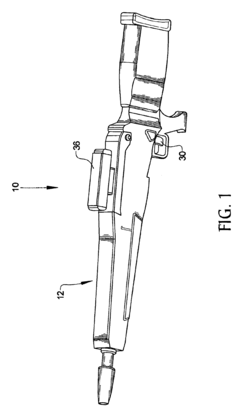

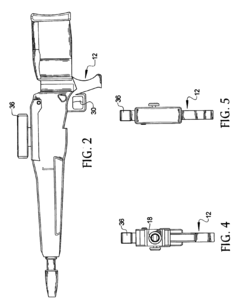

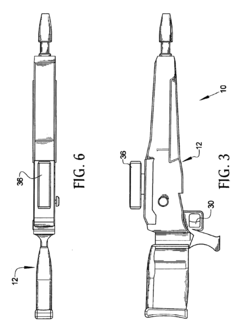

Rail gun launcher

PatentInactiveUS8302584B1

Innovation

- A rail gun launcher with a multi-turn armature and a non-magnetic, conductive barrel that uses induced magnetism to accelerate the armature without commutation or switching devices, allowing for continuous acceleration with a smaller power source and reduced heat generation, and utilizing AC power connected at multiple points along the rails to minimize resistance and heat loss.

Environmental Impact

The environmental impact of rail gun technology is a critical consideration in its development and deployment. While rail guns offer potential advantages in terms of reduced reliance on chemical propellants, their operation still carries significant environmental implications.

One of the primary environmental concerns associated with rail gun launch dynamics is the electromagnetic pulse (EMP) generated during firing. This intense burst of electromagnetic energy can potentially disrupt nearby electronic systems and communication networks. Mitigating these effects requires careful shielding and design considerations to minimize electromagnetic interference in surrounding areas.

Acoustic impact is another environmental factor to consider. The high-velocity projectile launch produces a substantial shockwave and acoustic signature. This noise pollution can have adverse effects on local wildlife and human populations, necessitating the implementation of sound dampening technologies and strategic placement of testing and operational facilities.

The high-energy nature of rail gun launches also raises thermal management concerns. The rapid discharge of electrical energy generates significant heat, which must be efficiently dissipated to prevent damage to the system and minimize thermal pollution in the surrounding environment. Advanced cooling systems and heat-resistant materials are essential for addressing this challenge.

Material erosion and wear present additional environmental considerations. The high-speed projectile launch and intense electromagnetic forces can cause rapid degradation of rail gun components, potentially releasing particulate matter and contaminants into the environment. Developing more durable materials and implementing effective containment and filtration systems are crucial for mitigating these effects.

The power requirements for rail gun systems also have indirect environmental implications. The need for large-scale energy storage and rapid discharge capabilities may necessitate the development of new power infrastructure, which could have its own environmental footprint. Exploring renewable energy integration and improving energy efficiency in rail gun systems could help offset these impacts.

Lastly, the potential for unintended environmental damage from rail gun projectiles must be addressed. The extended range and high velocity of these projectiles increase the risk of collateral damage and environmental contamination in target areas. Developing precision guidance systems and environmentally friendly projectile materials are essential steps in minimizing these risks and ensuring responsible use of rail gun technology.

One of the primary environmental concerns associated with rail gun launch dynamics is the electromagnetic pulse (EMP) generated during firing. This intense burst of electromagnetic energy can potentially disrupt nearby electronic systems and communication networks. Mitigating these effects requires careful shielding and design considerations to minimize electromagnetic interference in surrounding areas.

Acoustic impact is another environmental factor to consider. The high-velocity projectile launch produces a substantial shockwave and acoustic signature. This noise pollution can have adverse effects on local wildlife and human populations, necessitating the implementation of sound dampening technologies and strategic placement of testing and operational facilities.

The high-energy nature of rail gun launches also raises thermal management concerns. The rapid discharge of electrical energy generates significant heat, which must be efficiently dissipated to prevent damage to the system and minimize thermal pollution in the surrounding environment. Advanced cooling systems and heat-resistant materials are essential for addressing this challenge.

Material erosion and wear present additional environmental considerations. The high-speed projectile launch and intense electromagnetic forces can cause rapid degradation of rail gun components, potentially releasing particulate matter and contaminants into the environment. Developing more durable materials and implementing effective containment and filtration systems are crucial for mitigating these effects.

The power requirements for rail gun systems also have indirect environmental implications. The need for large-scale energy storage and rapid discharge capabilities may necessitate the development of new power infrastructure, which could have its own environmental footprint. Exploring renewable energy integration and improving energy efficiency in rail gun systems could help offset these impacts.

Lastly, the potential for unintended environmental damage from rail gun projectiles must be addressed. The extended range and high velocity of these projectiles increase the risk of collateral damage and environmental contamination in target areas. Developing precision guidance systems and environmentally friendly projectile materials are essential steps in minimizing these risks and ensuring responsible use of rail gun technology.

Safety Considerations

Safety considerations are paramount when simulating rail gun launch dynamics for enhanced control. The high-energy nature of rail gun systems presents significant risks that must be carefully addressed throughout the simulation and testing processes.

Electromagnetic safety is a primary concern due to the intense magnetic fields generated during rail gun operation. Simulations must account for potential electromagnetic interference with nearby electronic systems and personnel. Shielding requirements and safe distances for equipment and operators need to be accurately modeled to prevent malfunctions or health hazards.

Thermal management is another critical safety aspect. The rapid discharge of electrical energy in rail guns produces extreme heat that can lead to material degradation, component failure, or even fires. Simulations should incorporate detailed thermal models to predict temperature distributions and identify potential hotspots. This information is vital for designing adequate cooling systems and selecting appropriate materials for rail gun components.

Mechanical stress and structural integrity are key safety considerations. The immense forces involved in rail gun launches can cause severe wear and tear on the system. Simulations must accurately model the mechanical stresses on rails, projectiles, and supporting structures to prevent catastrophic failures. Fatigue analysis and lifetime predictions are essential for establishing safe operational limits and maintenance schedules.

Projectile behavior is a critical safety concern, both within the rail gun system and after launch. Simulations should model projectile stability, potential fragmentation, and trajectory deviations to minimize risks of unintended impacts or collateral damage. This includes analyzing the effects of various launch parameters on projectile integrity and accuracy.

Electrical safety is paramount given the high-voltage, high-current nature of rail gun systems. Simulations must account for potential arc formation, current leakage, and insulation breakdown. Modeling these phenomena helps in designing robust electrical systems and establishing safe operating procedures to prevent electrical accidents or system failures.

Environmental impact considerations should also be incorporated into rail gun simulations. This includes modeling acoustic emissions, electromagnetic radiation, and potential chemical byproducts from propellant or rail erosion. Understanding these factors is crucial for assessing and mitigating environmental risks associated with rail gun testing and operation.

By thoroughly addressing these safety considerations in rail gun launch dynamics simulations, researchers and engineers can significantly enhance the safety and reliability of rail gun systems. This comprehensive approach not only improves control and performance but also ensures the protection of personnel, equipment, and the environment during development and deployment of rail gun technology.

Electromagnetic safety is a primary concern due to the intense magnetic fields generated during rail gun operation. Simulations must account for potential electromagnetic interference with nearby electronic systems and personnel. Shielding requirements and safe distances for equipment and operators need to be accurately modeled to prevent malfunctions or health hazards.

Thermal management is another critical safety aspect. The rapid discharge of electrical energy in rail guns produces extreme heat that can lead to material degradation, component failure, or even fires. Simulations should incorporate detailed thermal models to predict temperature distributions and identify potential hotspots. This information is vital for designing adequate cooling systems and selecting appropriate materials for rail gun components.

Mechanical stress and structural integrity are key safety considerations. The immense forces involved in rail gun launches can cause severe wear and tear on the system. Simulations must accurately model the mechanical stresses on rails, projectiles, and supporting structures to prevent catastrophic failures. Fatigue analysis and lifetime predictions are essential for establishing safe operational limits and maintenance schedules.

Projectile behavior is a critical safety concern, both within the rail gun system and after launch. Simulations should model projectile stability, potential fragmentation, and trajectory deviations to minimize risks of unintended impacts or collateral damage. This includes analyzing the effects of various launch parameters on projectile integrity and accuracy.

Electrical safety is paramount given the high-voltage, high-current nature of rail gun systems. Simulations must account for potential arc formation, current leakage, and insulation breakdown. Modeling these phenomena helps in designing robust electrical systems and establishing safe operating procedures to prevent electrical accidents or system failures.

Environmental impact considerations should also be incorporated into rail gun simulations. This includes modeling acoustic emissions, electromagnetic radiation, and potential chemical byproducts from propellant or rail erosion. Understanding these factors is crucial for assessing and mitigating environmental risks associated with rail gun testing and operation.

By thoroughly addressing these safety considerations in rail gun launch dynamics simulations, researchers and engineers can significantly enhance the safety and reliability of rail gun systems. This comprehensive approach not only improves control and performance but also ensures the protection of personnel, equipment, and the environment during development and deployment of rail gun technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!