Heat Dissipation Solutions in Advanced Rail Gun Equipment

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Thermal Management Background and Objectives

Rail guns have emerged as a revolutionary technology in advanced weaponry, offering the potential for unprecedented projectile velocities and extended range. However, the immense energy requirements and extreme conditions during operation present significant thermal management challenges. The background of rail gun thermal management can be traced back to the early development of electromagnetic launch systems in the mid-20th century. As rail gun technology progressed, the need for effective heat dissipation solutions became increasingly apparent.

The primary objective of thermal management in rail gun systems is to maintain operational efficiency and extend the lifespan of critical components. This involves addressing the intense heat generated by electrical resistance, friction, and the rapid acceleration of projectiles. Without proper thermal management, rail guns risk rapid degradation of rails, insulation breakdown, and compromised structural integrity, ultimately leading to reduced performance and potential system failure.

Over the years, thermal management in rail guns has evolved from rudimentary cooling methods to sophisticated, multi-faceted approaches. Early solutions focused on passive cooling techniques and basic heat-resistant materials. As rail gun technology advanced, so did the complexity and effectiveness of thermal management strategies. Current objectives in this field include developing advanced materials capable of withstanding extreme temperatures, implementing active cooling systems, and optimizing rail gun design to minimize heat generation.

The goals of modern rail gun thermal management extend beyond mere heat dissipation. They encompass enhancing overall system efficiency, increasing firing rates, and enabling sustained operations. Researchers and engineers aim to develop integrated thermal solutions that not only manage heat but also contribute to the overall performance and durability of rail gun systems. This includes exploring novel cooling technologies, such as phase-change materials and advanced liquid cooling systems, as well as investigating the potential of nanotechnology in heat management.

Another critical objective is to address the scalability of thermal management solutions. As rail guns continue to evolve and potentially transition from experimental platforms to field-deployed systems, thermal management strategies must be adaptable to various operational environments and power scales. This necessitates a comprehensive approach that considers not only the immediate thermal challenges but also long-term sustainability and integration with other subsystems.

In conclusion, the background and objectives of rail gun thermal management reflect a dynamic and critical aspect of advanced weapons technology. The ongoing pursuit of effective heat dissipation solutions is fundamental to realizing the full potential of rail guns in modern warfare and defense systems. As research progresses, the focus remains on developing innovative, efficient, and robust thermal management strategies that can keep pace with the ever-increasing power and performance demands of advanced rail gun equipment.

The primary objective of thermal management in rail gun systems is to maintain operational efficiency and extend the lifespan of critical components. This involves addressing the intense heat generated by electrical resistance, friction, and the rapid acceleration of projectiles. Without proper thermal management, rail guns risk rapid degradation of rails, insulation breakdown, and compromised structural integrity, ultimately leading to reduced performance and potential system failure.

Over the years, thermal management in rail guns has evolved from rudimentary cooling methods to sophisticated, multi-faceted approaches. Early solutions focused on passive cooling techniques and basic heat-resistant materials. As rail gun technology advanced, so did the complexity and effectiveness of thermal management strategies. Current objectives in this field include developing advanced materials capable of withstanding extreme temperatures, implementing active cooling systems, and optimizing rail gun design to minimize heat generation.

The goals of modern rail gun thermal management extend beyond mere heat dissipation. They encompass enhancing overall system efficiency, increasing firing rates, and enabling sustained operations. Researchers and engineers aim to develop integrated thermal solutions that not only manage heat but also contribute to the overall performance and durability of rail gun systems. This includes exploring novel cooling technologies, such as phase-change materials and advanced liquid cooling systems, as well as investigating the potential of nanotechnology in heat management.

Another critical objective is to address the scalability of thermal management solutions. As rail guns continue to evolve and potentially transition from experimental platforms to field-deployed systems, thermal management strategies must be adaptable to various operational environments and power scales. This necessitates a comprehensive approach that considers not only the immediate thermal challenges but also long-term sustainability and integration with other subsystems.

In conclusion, the background and objectives of rail gun thermal management reflect a dynamic and critical aspect of advanced weapons technology. The ongoing pursuit of effective heat dissipation solutions is fundamental to realizing the full potential of rail guns in modern warfare and defense systems. As research progresses, the focus remains on developing innovative, efficient, and robust thermal management strategies that can keep pace with the ever-increasing power and performance demands of advanced rail gun equipment.

Market Analysis for Advanced Rail Gun Systems

The market for advanced rail gun systems is experiencing significant growth, driven by increasing defense budgets and the need for long-range precision strike capabilities. As nations seek to modernize their military arsenals, rail guns are emerging as a promising technology with potential applications in naval, land, and air defense systems.

The global market for electromagnetic weapons, including rail guns, is projected to expand at a compound annual growth rate of over 20% in the coming years. This growth is primarily fueled by investments from major military powers such as the United States, China, and Russia, who are actively developing and testing rail gun prototypes.

Naval applications currently dominate the market, with several countries exploring the integration of rail guns into their next-generation warships. The ability of rail guns to launch projectiles at hypersonic speeds over extended ranges makes them particularly attractive for naval warfare scenarios. Land-based systems are also gaining traction, especially for coastal defense and strategic deterrence roles.

The market landscape is characterized by a mix of established defense contractors and emerging technology companies. Key players include BAE Systems, Northrop Grumman, and Lockheed Martin, who are investing heavily in research and development to overcome technical challenges associated with rail gun technology.

One of the primary drivers of market growth is the potential cost-effectiveness of rail gun systems compared to traditional missile-based solutions. The relatively low cost per shot of rail gun projectiles, combined with their extended range and precision, offers a compelling value proposition for military planners.

However, the market faces several challenges that could impact its growth trajectory. The most significant hurdle is the immense power requirements of rail gun systems, which necessitate advanced energy storage and management solutions. Additionally, the issue of barrel wear due to extreme temperatures and electromagnetic forces remains a technical obstacle that needs to be addressed for widespread adoption.

Despite these challenges, the market outlook remains positive, with increasing interest from both developed and developing nations. The potential dual-use applications of rail gun technology in civilian sectors, such as space launch systems, could further expand the market in the long term.

As the technology matures and becomes more reliable, we can expect to see a gradual shift from research and development to procurement and deployment phases. This transition will likely lead to increased competition among suppliers and potentially drive down costs, making rail gun systems more accessible to a broader range of military customers.

The global market for electromagnetic weapons, including rail guns, is projected to expand at a compound annual growth rate of over 20% in the coming years. This growth is primarily fueled by investments from major military powers such as the United States, China, and Russia, who are actively developing and testing rail gun prototypes.

Naval applications currently dominate the market, with several countries exploring the integration of rail guns into their next-generation warships. The ability of rail guns to launch projectiles at hypersonic speeds over extended ranges makes them particularly attractive for naval warfare scenarios. Land-based systems are also gaining traction, especially for coastal defense and strategic deterrence roles.

The market landscape is characterized by a mix of established defense contractors and emerging technology companies. Key players include BAE Systems, Northrop Grumman, and Lockheed Martin, who are investing heavily in research and development to overcome technical challenges associated with rail gun technology.

One of the primary drivers of market growth is the potential cost-effectiveness of rail gun systems compared to traditional missile-based solutions. The relatively low cost per shot of rail gun projectiles, combined with their extended range and precision, offers a compelling value proposition for military planners.

However, the market faces several challenges that could impact its growth trajectory. The most significant hurdle is the immense power requirements of rail gun systems, which necessitate advanced energy storage and management solutions. Additionally, the issue of barrel wear due to extreme temperatures and electromagnetic forces remains a technical obstacle that needs to be addressed for widespread adoption.

Despite these challenges, the market outlook remains positive, with increasing interest from both developed and developing nations. The potential dual-use applications of rail gun technology in civilian sectors, such as space launch systems, could further expand the market in the long term.

As the technology matures and becomes more reliable, we can expect to see a gradual shift from research and development to procurement and deployment phases. This transition will likely lead to increased competition among suppliers and potentially drive down costs, making rail gun systems more accessible to a broader range of military customers.

Current Heat Dissipation Challenges in Rail Guns

Rail guns, as advanced electromagnetic projectile launchers, face significant heat dissipation challenges that currently limit their operational capabilities and potential for widespread adoption. The primary source of heat generation in rail guns stems from the enormous electrical currents required to create the electromagnetic fields necessary for projectile acceleration. These currents, often in the range of millions of amperes, generate substantial Joule heating in the conductive rails and other components.

One of the most pressing challenges is the rapid temperature rise in the rails during firing. The intense heat can cause thermal expansion, leading to rail deformation and misalignment. This not only affects the accuracy of subsequent shots but also accelerates wear and erosion of the rail surfaces. The heat-induced wear is particularly problematic as it reduces the lifespan of the rails, necessitating frequent replacements and increasing maintenance costs.

Another critical issue is the thermal management of the power supply and energy storage systems. The capacitors and pulse-forming networks used to deliver the high-current pulses generate significant heat during discharge cycles. Inefficient cooling of these components can lead to reduced performance, shortened lifespan, and in extreme cases, catastrophic failure of the power systems.

The projectile-rail interface also presents unique heat dissipation challenges. As the projectile travels along the rails at hypersonic speeds, friction and electrical arcing create localized hot spots. These extreme temperature gradients can cause material ablation and plasma formation, further complicating the heat management problem and potentially damaging the projectile or altering its trajectory.

Moreover, the repetitive firing capability of rail guns is severely limited by heat accumulation. Without adequate cooling between shots, the residual heat from previous firings compounds, leading to a rapid degradation of performance and potential system failure. This challenge is particularly acute in scenarios requiring sustained fire rates, such as in naval defense applications.

The compact nature of modern rail gun designs exacerbates these heat dissipation issues. The need for portability and integration into existing platforms constrains the size and weight of cooling systems, making it difficult to implement traditional cooling solutions effectively. This size limitation forces engineers to explore novel materials and cooling technologies that can operate efficiently within the confined spaces of rail gun systems.

Addressing these heat dissipation challenges is crucial for advancing rail gun technology. Innovative cooling strategies, thermally resilient materials, and improved power management systems are all areas of active research and development. Overcoming these thermal barriers will be key to realizing the full potential of rail guns as next-generation weapon systems.

One of the most pressing challenges is the rapid temperature rise in the rails during firing. The intense heat can cause thermal expansion, leading to rail deformation and misalignment. This not only affects the accuracy of subsequent shots but also accelerates wear and erosion of the rail surfaces. The heat-induced wear is particularly problematic as it reduces the lifespan of the rails, necessitating frequent replacements and increasing maintenance costs.

Another critical issue is the thermal management of the power supply and energy storage systems. The capacitors and pulse-forming networks used to deliver the high-current pulses generate significant heat during discharge cycles. Inefficient cooling of these components can lead to reduced performance, shortened lifespan, and in extreme cases, catastrophic failure of the power systems.

The projectile-rail interface also presents unique heat dissipation challenges. As the projectile travels along the rails at hypersonic speeds, friction and electrical arcing create localized hot spots. These extreme temperature gradients can cause material ablation and plasma formation, further complicating the heat management problem and potentially damaging the projectile or altering its trajectory.

Moreover, the repetitive firing capability of rail guns is severely limited by heat accumulation. Without adequate cooling between shots, the residual heat from previous firings compounds, leading to a rapid degradation of performance and potential system failure. This challenge is particularly acute in scenarios requiring sustained fire rates, such as in naval defense applications.

The compact nature of modern rail gun designs exacerbates these heat dissipation issues. The need for portability and integration into existing platforms constrains the size and weight of cooling systems, making it difficult to implement traditional cooling solutions effectively. This size limitation forces engineers to explore novel materials and cooling technologies that can operate efficiently within the confined spaces of rail gun systems.

Addressing these heat dissipation challenges is crucial for advancing rail gun technology. Innovative cooling strategies, thermally resilient materials, and improved power management systems are all areas of active research and development. Overcoming these thermal barriers will be key to realizing the full potential of rail guns as next-generation weapon systems.

Existing Heat Dissipation Techniques for Rail Guns

01 Cooling systems for rail gun components

Various cooling systems are employed to dissipate heat generated in rail gun components. These may include liquid cooling circuits, heat exchangers, or coolant channels integrated into the rail gun structure. Such systems help maintain optimal operating temperatures and prevent overheating of critical parts.- Cooling systems for rail gun components: Various cooling systems are employed to dissipate heat generated during rail gun operation. These may include liquid cooling circuits, heat exchangers, or coolant channels integrated into critical components such as rails, capacitors, or power supplies. The cooling systems help maintain optimal operating temperatures and prevent overheating of sensitive equipment.

- Heat-resistant materials and coatings: Specialized heat-resistant materials and coatings are used in rail gun construction to withstand high temperatures generated during firing. These materials may include advanced ceramics, refractory metals, or composite materials with high thermal conductivity. Protective coatings can be applied to surfaces exposed to extreme heat to enhance durability and heat dissipation.

- Thermal management in power supply systems: Efficient thermal management strategies are implemented in rail gun power supply systems to handle the high currents and voltages involved. This may include advanced cooling techniques for capacitors, pulse-forming networks, and switching components. Heat sinks, forced air cooling, or liquid cooling systems are often integrated into power supply units to maintain stable operation.

- Active cooling for projectile launchers: Active cooling mechanisms are employed in rail gun projectile launchers to dissipate heat generated by friction and electromagnetic forces. These may include forced air circulation, cryogenic cooling systems, or specialized coolant circulation within the launcher assembly. Efficient heat removal from the launch rails and surrounding structures helps maintain accuracy and extend operational lifespan.

- Thermal sensors and monitoring systems: Advanced thermal sensors and monitoring systems are integrated into rail gun equipment to provide real-time temperature data. These systems help detect potential overheating issues and allow for adaptive cooling control. Temperature monitoring may be coupled with automated safety mechanisms to prevent damage from excessive heat buildup during extended operations.

02 Heat-resistant materials and coatings

The use of advanced heat-resistant materials and coatings in rail gun construction helps to manage thermal stress and improve heat dissipation. These materials may include ceramics, composites, or specially engineered alloys that can withstand high temperatures and thermal cycling.Expand Specific Solutions03 Thermal management through design optimization

Optimizing the design of rail gun components and overall structure can significantly improve heat dissipation. This may involve creating heat sinks, improving airflow, or incorporating thermal barriers to manage heat distribution and prevent localized hot spots.Expand Specific Solutions04 Active cooling technologies

Implementation of active cooling technologies such as thermoelectric coolers, forced air systems, or pulsed cooling mechanisms can enhance heat dissipation in rail gun equipment. These systems actively remove heat from critical components during operation.Expand Specific Solutions05 Thermal monitoring and control systems

Integration of advanced thermal monitoring and control systems helps manage heat dissipation in rail guns. These systems may include temperature sensors, real-time monitoring, and adaptive cooling mechanisms that adjust based on operational conditions to maintain optimal performance and prevent thermal damage.Expand Specific Solutions

Key Players in Rail Gun Thermal Solution Development

The heat dissipation solutions market for advanced rail gun equipment is in an early growth stage, with significant potential for expansion as military modernization efforts increase globally. The market size is estimated to be relatively small but growing rapidly, driven by increasing defense budgets and technological advancements. The technology is still evolving, with varying levels of maturity across different companies. Key players like CRRC Zhuzhou Locomotive, Mitsubishi Electric, and Siemens Mobility are leveraging their expertise in rail systems and thermal management to develop innovative solutions. Research institutions such as the University of Science & Technology of China and Huazhong University of Science & Technology are contributing to technological advancements. Companies like Intel and Hitachi Industrial Equipment Systems are bringing their thermal management expertise from other sectors to this specialized field.

206th Research Institute

Technical Solution: The 206th Research Institute, part of China's defense research establishment, has developed innovative heat dissipation solutions for advanced rail gun equipment. Their approach focuses on a combination of advanced materials and novel cooling techniques. They have pioneered the use of nanofluid coolants, which contain suspended nanoparticles to enhance thermal conductivity and heat transfer efficiency[6]. The institute has also developed a pulsed cooling system that synchronizes with the rail gun's firing cycle, providing intense cooling during peak heat generation periods[7]. Additionally, they have implemented a multi-layer thermal management system that incorporates phase change materials (PCMs) to absorb and store excess heat, which is then gradually released during cooling cycles[8].

Strengths: Cutting-edge research in nanofluids and pulsed cooling, direct experience with rail gun systems, integration of advanced materials. Weaknesses: Solutions may be at early stages of development, potential challenges in scaling up for large-scale production.

University of Science & Technology of China

Technical Solution: The University of Science & Technology of China has conducted extensive research on heat dissipation solutions for advanced rail gun equipment. Their approach combines theoretical modeling with experimental validation. The university has developed a novel heat pipe system specifically designed for the unique thermal challenges of rail guns. This system utilizes a network of ultra-thin heat pipes with advanced working fluids to rapidly transport heat away from critical components[9]. They have also explored the use of metamaterials with engineered thermal properties to create highly efficient heat spreaders and thermal insulators[10]. Furthermore, the university has developed advanced algorithms for real-time thermal management, which dynamically adjust cooling parameters based on the rail gun's operational conditions[11].

Strengths: Strong theoretical foundation, innovative use of metamaterials, advanced modeling capabilities. Weaknesses: May lack practical experience in implementing solutions in real-world rail gun systems, potential challenges in technology transfer to industry.

Innovative Thermal Management Technologies for Rail Guns

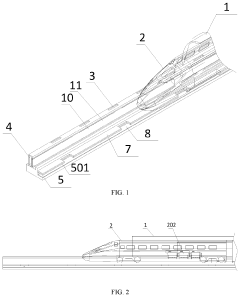

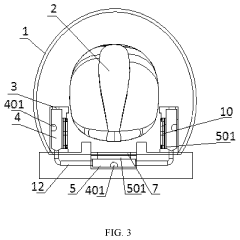

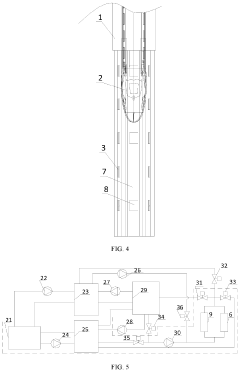

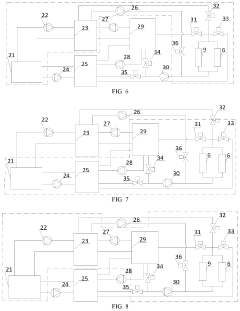

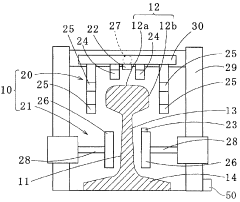

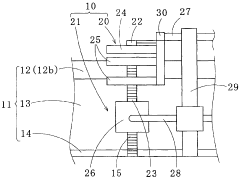

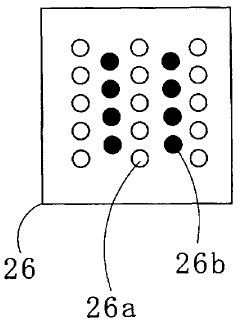

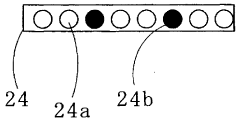

Heat dissipation system for high-speed train running in low-vacuum tube

PatentActiveUS11999387B2

Innovation

- A heat dissipation system is implemented, featuring component groups with cooling assemblies, including cooling-type heat exchangers and nozzle assemblies, along with cavities and air vents to facilitate air circulation and heat exchange, ensuring effective heat removal from the train components.

Device and method for cooling welded rail section

PatentWO2010109837A1

Innovation

- A cooling device and method that separately control the cooling of the rail head and column using temperature-detecting units and fluid ejection systems to adjust cooling fluid types, flow rates, and velocities, focusing on specific cooling widths and temperature ranges to reduce residual stress and improve fatigue strength.

Environmental Impact of Rail Gun Thermal Solutions

The environmental impact of rail gun thermal solutions is a critical consideration in the development and deployment of advanced rail gun equipment. As these high-energy weapons generate significant heat during operation, the methods used to dissipate this thermal energy can have substantial environmental consequences.

One of the primary environmental concerns is the potential release of coolants or other heat transfer fluids into the surrounding ecosystem. Many traditional cooling systems rely on liquid coolants, which may contain chemicals harmful to soil, water sources, and local flora and fauna if leaked or improperly disposed of. Advanced rail gun systems often require more sophisticated cooling solutions, potentially involving exotic materials or compounds that could pose even greater environmental risks.

The energy consumption associated with heat dissipation systems is another significant environmental factor. Powerful cooling systems may require substantial electricity to operate, potentially increasing the carbon footprint of rail gun installations if the energy source is not renewable. This indirect environmental impact must be carefully considered when designing and implementing thermal management solutions for rail guns.

Noise pollution is an often-overlooked environmental consequence of heat dissipation systems. Large-scale cooling units, such as industrial-grade air conditioning systems or liquid cooling pumps, can generate considerable noise. This acoustic pollution can disrupt local wildlife habitats and potentially affect nearby human populations, especially if rail gun installations are located near residential areas or sensitive ecosystems.

The physical footprint of heat dissipation infrastructure is another environmental consideration. Large cooling towers, radiators, or other heat exchange equipment may require significant land use, potentially leading to habitat destruction or alteration of local landscapes. This is particularly relevant for mobile or field-deployed rail gun systems, where the environmental impact may be spread across multiple locations.

Water usage is a critical environmental concern for certain types of cooling systems. If water-based cooling methods are employed, the sourcing and disposal of large volumes of water can strain local water resources and potentially impact aquatic ecosystems. In arid regions or areas with limited water supplies, this can be a particularly pressing issue.

Electromagnetic interference (EMI) from rail gun operations and associated cooling systems can also have environmental implications. While not directly related to heat dissipation, the interaction between high-power electromagnetic fields and cooling system components may create unintended electromagnetic emissions that could affect local wildlife or interfere with sensitive electronic equipment in the surrounding area.

One of the primary environmental concerns is the potential release of coolants or other heat transfer fluids into the surrounding ecosystem. Many traditional cooling systems rely on liquid coolants, which may contain chemicals harmful to soil, water sources, and local flora and fauna if leaked or improperly disposed of. Advanced rail gun systems often require more sophisticated cooling solutions, potentially involving exotic materials or compounds that could pose even greater environmental risks.

The energy consumption associated with heat dissipation systems is another significant environmental factor. Powerful cooling systems may require substantial electricity to operate, potentially increasing the carbon footprint of rail gun installations if the energy source is not renewable. This indirect environmental impact must be carefully considered when designing and implementing thermal management solutions for rail guns.

Noise pollution is an often-overlooked environmental consequence of heat dissipation systems. Large-scale cooling units, such as industrial-grade air conditioning systems or liquid cooling pumps, can generate considerable noise. This acoustic pollution can disrupt local wildlife habitats and potentially affect nearby human populations, especially if rail gun installations are located near residential areas or sensitive ecosystems.

The physical footprint of heat dissipation infrastructure is another environmental consideration. Large cooling towers, radiators, or other heat exchange equipment may require significant land use, potentially leading to habitat destruction or alteration of local landscapes. This is particularly relevant for mobile or field-deployed rail gun systems, where the environmental impact may be spread across multiple locations.

Water usage is a critical environmental concern for certain types of cooling systems. If water-based cooling methods are employed, the sourcing and disposal of large volumes of water can strain local water resources and potentially impact aquatic ecosystems. In arid regions or areas with limited water supplies, this can be a particularly pressing issue.

Electromagnetic interference (EMI) from rail gun operations and associated cooling systems can also have environmental implications. While not directly related to heat dissipation, the interaction between high-power electromagnetic fields and cooling system components may create unintended electromagnetic emissions that could affect local wildlife or interfere with sensitive electronic equipment in the surrounding area.

Safety Regulations for High-Energy Weapon Systems

Safety regulations for high-energy weapon systems, such as advanced rail guns, are critical to ensure the protection of personnel, equipment, and the environment. These regulations encompass a wide range of considerations, including operational procedures, protective measures, and risk management strategies.

One of the primary safety concerns in rail gun systems is the management of extreme heat generated during operation. Strict protocols must be established for handling and maintaining cooling systems, as well as for monitoring temperature levels throughout the equipment. Personnel working with or near rail guns must be trained in recognizing signs of overheating and responding appropriately to prevent accidents or equipment damage.

Electrical safety is another crucial aspect of rail gun operation. Given the high voltages and currents involved, regulations must specify proper insulation requirements, grounding procedures, and safety interlocks to prevent electrical hazards. Regular inspections and maintenance of electrical components should be mandated to ensure system integrity and minimize the risk of electrical failures or arcing.

Projectile handling and storage regulations are essential for rail gun systems. These should cover proper storage conditions, handling procedures, and transportation protocols for the high-energy projectiles used in rail guns. Safety measures must be in place to prevent accidental discharge or detonation during loading and unloading processes.

Electromagnetic field exposure is a significant concern in rail gun operation. Safety regulations should establish limits on personnel exposure to electromagnetic fields and require appropriate shielding and protective equipment. Regular monitoring of electromagnetic radiation levels in and around the rail gun system should be mandated to ensure compliance with safety standards.

Operational safety procedures must be clearly defined and strictly enforced. These should include pre-operation checklists, emergency shutdown protocols, and post-operation safety checks. Clear communication protocols and chain of command structures should be established to ensure rapid and effective response to any safety incidents.

Environmental safety considerations are also crucial. Regulations should address potential environmental impacts of rail gun operation, including noise pollution, electromagnetic interference with nearby electronic systems, and the management of any hazardous materials used in the system's operation or maintenance.

Lastly, safety regulations must require comprehensive training programs for all personnel involved in rail gun operations. This training should cover not only operational procedures but also emergency response protocols, first aid, and the proper use of personal protective equipment. Regular safety drills and simulations should be conducted to maintain readiness and identify potential weaknesses in safety protocols.

One of the primary safety concerns in rail gun systems is the management of extreme heat generated during operation. Strict protocols must be established for handling and maintaining cooling systems, as well as for monitoring temperature levels throughout the equipment. Personnel working with or near rail guns must be trained in recognizing signs of overheating and responding appropriately to prevent accidents or equipment damage.

Electrical safety is another crucial aspect of rail gun operation. Given the high voltages and currents involved, regulations must specify proper insulation requirements, grounding procedures, and safety interlocks to prevent electrical hazards. Regular inspections and maintenance of electrical components should be mandated to ensure system integrity and minimize the risk of electrical failures or arcing.

Projectile handling and storage regulations are essential for rail gun systems. These should cover proper storage conditions, handling procedures, and transportation protocols for the high-energy projectiles used in rail guns. Safety measures must be in place to prevent accidental discharge or detonation during loading and unloading processes.

Electromagnetic field exposure is a significant concern in rail gun operation. Safety regulations should establish limits on personnel exposure to electromagnetic fields and require appropriate shielding and protective equipment. Regular monitoring of electromagnetic radiation levels in and around the rail gun system should be mandated to ensure compliance with safety standards.

Operational safety procedures must be clearly defined and strictly enforced. These should include pre-operation checklists, emergency shutdown protocols, and post-operation safety checks. Clear communication protocols and chain of command structures should be established to ensure rapid and effective response to any safety incidents.

Environmental safety considerations are also crucial. Regulations should address potential environmental impacts of rail gun operation, including noise pollution, electromagnetic interference with nearby electronic systems, and the management of any hazardous materials used in the system's operation or maintenance.

Lastly, safety regulations must require comprehensive training programs for all personnel involved in rail gun operations. This training should cover not only operational procedures but also emergency response protocols, first aid, and the proper use of personal protective equipment. Regular safety drills and simulations should be conducted to maintain readiness and identify potential weaknesses in safety protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!