In-Field Maintenance Techniques for Deployed Rail Gun Systems

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Evolution

The evolution of rail gun technology has been marked by significant advancements and milestones over the past century. Initially conceptualized in the early 1900s, rail guns remained largely theoretical until the latter half of the 20th century when practical experimentation began in earnest.

The 1970s and 1980s saw a surge in rail gun research, primarily driven by military interests. During this period, the focus was on overcoming fundamental challenges such as power supply limitations, rail erosion, and projectile design. Early prototypes demonstrated the potential for hypervelocity launches but were plagued by reliability issues and short operational lifespans.

The 1990s brought about a shift towards more sophisticated power systems and materials science. Advances in capacitor technology and pulsed power systems allowed for more efficient energy storage and delivery, addressing one of the primary bottlenecks in rail gun development. Concurrently, progress in materials engineering led to the development of more durable rails and projectiles capable of withstanding the extreme conditions of electromagnetic launch.

The turn of the millennium marked the beginning of a new era for rail gun technology. Increased computational power enabled more accurate modeling and simulation of rail gun physics, leading to optimized designs and improved performance. This period also saw the integration of advanced diagnostics and control systems, enhancing the precision and repeatability of rail gun operations.

In the 2010s, rail gun technology transitioned from laboratory experiments to field demonstrations. Notable achievements include the U.S. Navy's successful tests of ship-mounted rail guns, capable of launching projectiles at speeds exceeding Mach 7. These demonstrations proved the viability of rail guns as long-range weapon systems and sparked renewed interest in their potential applications.

Recent years have witnessed a focus on addressing the challenges of in-field maintenance and operational reliability. Innovations in thermal management, rail wear reduction, and modular design have significantly improved the durability and serviceability of rail gun systems. Additionally, advancements in power electronics and energy storage have led to more compact and efficient power supply units, making rail guns more feasible for mobile platforms.

The evolution of rail gun technology continues to be driven by the pursuit of higher muzzle velocities, increased firing rates, and enhanced system longevity. Current research efforts are exploring novel rail materials, advanced projectile designs, and innovative cooling techniques to push the boundaries of electromagnetic launch capabilities.

The 1970s and 1980s saw a surge in rail gun research, primarily driven by military interests. During this period, the focus was on overcoming fundamental challenges such as power supply limitations, rail erosion, and projectile design. Early prototypes demonstrated the potential for hypervelocity launches but were plagued by reliability issues and short operational lifespans.

The 1990s brought about a shift towards more sophisticated power systems and materials science. Advances in capacitor technology and pulsed power systems allowed for more efficient energy storage and delivery, addressing one of the primary bottlenecks in rail gun development. Concurrently, progress in materials engineering led to the development of more durable rails and projectiles capable of withstanding the extreme conditions of electromagnetic launch.

The turn of the millennium marked the beginning of a new era for rail gun technology. Increased computational power enabled more accurate modeling and simulation of rail gun physics, leading to optimized designs and improved performance. This period also saw the integration of advanced diagnostics and control systems, enhancing the precision and repeatability of rail gun operations.

In the 2010s, rail gun technology transitioned from laboratory experiments to field demonstrations. Notable achievements include the U.S. Navy's successful tests of ship-mounted rail guns, capable of launching projectiles at speeds exceeding Mach 7. These demonstrations proved the viability of rail guns as long-range weapon systems and sparked renewed interest in their potential applications.

Recent years have witnessed a focus on addressing the challenges of in-field maintenance and operational reliability. Innovations in thermal management, rail wear reduction, and modular design have significantly improved the durability and serviceability of rail gun systems. Additionally, advancements in power electronics and energy storage have led to more compact and efficient power supply units, making rail guns more feasible for mobile platforms.

The evolution of rail gun technology continues to be driven by the pursuit of higher muzzle velocities, increased firing rates, and enhanced system longevity. Current research efforts are exploring novel rail materials, advanced projectile designs, and innovative cooling techniques to push the boundaries of electromagnetic launch capabilities.

Operational Demands

Rail gun systems deployed in the field face unique operational demands that significantly impact their maintenance requirements. These advanced weapon systems, characterized by their electromagnetic propulsion mechanism, operate under extreme conditions that push the boundaries of materials science and engineering. The primary operational demand is the ability to maintain consistent high-performance output over extended periods, often in harsh environmental conditions ranging from desert heat to arctic cold.

The electromagnetic nature of rail guns necessitates a robust power supply system capable of delivering massive electrical currents in short bursts. This places enormous stress on the power generation and storage components, requiring frequent checks and potential replacements to ensure optimal functionality. The rails themselves, subjected to extreme temperatures and pressures during firing, experience rapid wear and erosion. This wear pattern is a critical factor in determining maintenance schedules and techniques.

Another significant operational demand is the need for rapid fire capability. This requirement puts additional strain on cooling systems and barrel integrity, as the intense heat generated during firing must be quickly dissipated to prevent damage and maintain accuracy. The precision components, including advanced targeting systems and electromagnetic coils, must remain calibrated and functional under these demanding conditions.

Mobility is a key operational requirement for many deployed rail gun systems. This necessitates a balance between system robustness and weight considerations, impacting the design of maintenance procedures and the selection of repair materials. Maintenance techniques must be adaptable to various field conditions, often with limited access to specialized equipment or facilities.

The operational environment also plays a crucial role in shaping maintenance demands. Exposure to salt spray in coastal deployments, sand and dust in desert operations, or extreme cold in arctic settings each present unique challenges for maintaining the intricate components of a rail gun system. Corrosion prevention, seal integrity, and lubricant performance become critical factors in these diverse environments.

Reliability and readiness are paramount operational demands. Given the strategic importance of rail gun systems, downtime must be minimized, and maintenance procedures must be efficient and effective. This necessitates a comprehensive predictive maintenance strategy, leveraging advanced diagnostics and potentially incorporating AI-driven prognostics to anticipate failures before they occur.

Lastly, the operational demand for increased range and projectile velocity continues to push the technological envelope. As rail gun systems evolve to meet these demands, maintenance techniques must adapt to address new materials, more powerful electromagnetic systems, and increasingly complex electronic components. This ongoing evolution underscores the need for flexible, adaptable maintenance strategies that can keep pace with rapid technological advancements in the field of electromagnetic weapon systems.

The electromagnetic nature of rail guns necessitates a robust power supply system capable of delivering massive electrical currents in short bursts. This places enormous stress on the power generation and storage components, requiring frequent checks and potential replacements to ensure optimal functionality. The rails themselves, subjected to extreme temperatures and pressures during firing, experience rapid wear and erosion. This wear pattern is a critical factor in determining maintenance schedules and techniques.

Another significant operational demand is the need for rapid fire capability. This requirement puts additional strain on cooling systems and barrel integrity, as the intense heat generated during firing must be quickly dissipated to prevent damage and maintain accuracy. The precision components, including advanced targeting systems and electromagnetic coils, must remain calibrated and functional under these demanding conditions.

Mobility is a key operational requirement for many deployed rail gun systems. This necessitates a balance between system robustness and weight considerations, impacting the design of maintenance procedures and the selection of repair materials. Maintenance techniques must be adaptable to various field conditions, often with limited access to specialized equipment or facilities.

The operational environment also plays a crucial role in shaping maintenance demands. Exposure to salt spray in coastal deployments, sand and dust in desert operations, or extreme cold in arctic settings each present unique challenges for maintaining the intricate components of a rail gun system. Corrosion prevention, seal integrity, and lubricant performance become critical factors in these diverse environments.

Reliability and readiness are paramount operational demands. Given the strategic importance of rail gun systems, downtime must be minimized, and maintenance procedures must be efficient and effective. This necessitates a comprehensive predictive maintenance strategy, leveraging advanced diagnostics and potentially incorporating AI-driven prognostics to anticipate failures before they occur.

Lastly, the operational demand for increased range and projectile velocity continues to push the technological envelope. As rail gun systems evolve to meet these demands, maintenance techniques must adapt to address new materials, more powerful electromagnetic systems, and increasingly complex electronic components. This ongoing evolution underscores the need for flexible, adaptable maintenance strategies that can keep pace with rapid technological advancements in the field of electromagnetic weapon systems.

Maintenance Challenges

Maintaining deployed rail gun systems in the field presents unique challenges due to the complex nature of these advanced weapons. The high-energy electromagnetic propulsion mechanism and associated components require specialized care and expertise to ensure optimal performance and longevity.

One of the primary maintenance challenges is managing the wear and tear on the rail gun's conductive rails. The extreme forces and temperatures generated during firing can cause rapid degradation of these critical components. Regular inspection and replacement of worn rails are essential, but conducting these operations in field conditions can be logistically complex and time-consuming.

Another significant challenge is maintaining the integrity of the power supply and energy storage systems. Rail guns require massive amounts of electrical energy delivered in short bursts, necessitating robust capacitor banks and power distribution networks. These systems are susceptible to environmental factors such as humidity, temperature fluctuations, and dust, which can lead to performance degradation or failure if not properly maintained.

The precision guidance and control systems of rail guns also demand meticulous maintenance. Calibration of targeting systems, sensors, and fire control computers must be performed regularly to ensure accuracy. However, the sensitive nature of these electronic components makes them vulnerable to electromagnetic interference and physical shock, complicating maintenance procedures in combat zones.

Thermal management presents another critical maintenance challenge. The intense heat generated during firing can cause thermal expansion and warping of components, affecting the gun's accuracy and reliability. Implementing effective cooling systems and conducting thermal inspections are crucial but can be difficult to execute comprehensively in field conditions.

Maintaining the structural integrity of the rail gun system is also a significant concern. The immense recoil forces generated during firing can stress the mounting structures and support systems. Regular structural inspections and reinforcement are necessary but may require specialized equipment and expertise not readily available in forward operating areas.

Lastly, the maintenance of safety systems and protocols poses unique challenges in field operations. Ensuring proper functioning of interlocks, emergency shutdown mechanisms, and personnel protection equipment is critical but can be complicated by the harsh environments and operational pressures of deployed settings.

Addressing these maintenance challenges requires a combination of advanced diagnostic tools, specialized training for maintenance personnel, and innovative solutions for conducting complex repairs in austere conditions. Developing robust, modular designs that facilitate easier field maintenance and implementing predictive maintenance technologies could significantly enhance the operational readiness of deployed rail gun systems.

One of the primary maintenance challenges is managing the wear and tear on the rail gun's conductive rails. The extreme forces and temperatures generated during firing can cause rapid degradation of these critical components. Regular inspection and replacement of worn rails are essential, but conducting these operations in field conditions can be logistically complex and time-consuming.

Another significant challenge is maintaining the integrity of the power supply and energy storage systems. Rail guns require massive amounts of electrical energy delivered in short bursts, necessitating robust capacitor banks and power distribution networks. These systems are susceptible to environmental factors such as humidity, temperature fluctuations, and dust, which can lead to performance degradation or failure if not properly maintained.

The precision guidance and control systems of rail guns also demand meticulous maintenance. Calibration of targeting systems, sensors, and fire control computers must be performed regularly to ensure accuracy. However, the sensitive nature of these electronic components makes them vulnerable to electromagnetic interference and physical shock, complicating maintenance procedures in combat zones.

Thermal management presents another critical maintenance challenge. The intense heat generated during firing can cause thermal expansion and warping of components, affecting the gun's accuracy and reliability. Implementing effective cooling systems and conducting thermal inspections are crucial but can be difficult to execute comprehensively in field conditions.

Maintaining the structural integrity of the rail gun system is also a significant concern. The immense recoil forces generated during firing can stress the mounting structures and support systems. Regular structural inspections and reinforcement are necessary but may require specialized equipment and expertise not readily available in forward operating areas.

Lastly, the maintenance of safety systems and protocols poses unique challenges in field operations. Ensuring proper functioning of interlocks, emergency shutdown mechanisms, and personnel protection equipment is critical but can be complicated by the harsh environments and operational pressures of deployed settings.

Addressing these maintenance challenges requires a combination of advanced diagnostic tools, specialized training for maintenance personnel, and innovative solutions for conducting complex repairs in austere conditions. Developing robust, modular designs that facilitate easier field maintenance and implementing predictive maintenance technologies could significantly enhance the operational readiness of deployed rail gun systems.

Current Solutions

01 Electromagnetic rail gun systems

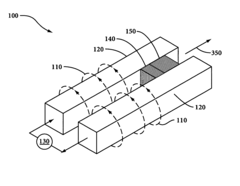

These systems use electromagnetic forces to accelerate projectiles to high velocities. They typically consist of parallel conducting rails connected to a power source, which creates a strong magnetic field to propel the projectile. This technology offers advantages in terms of projectile speed and range compared to traditional firearms.- Electromagnetic rail gun systems: These systems use electromagnetic forces to launch projectiles at high velocities. They typically consist of parallel conducting rails connected to a power source, with a conductive projectile or armature between them. When current flows through the system, it creates a powerful electromagnetic field that accelerates the projectile along the rails.

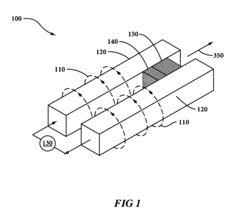

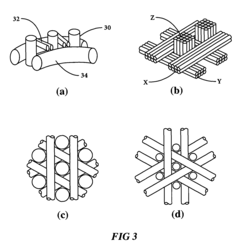

- Projectile and armature designs for rail guns: Various projectile and armature designs are utilized in rail gun systems to improve performance and efficiency. These may include specialized shapes, materials, and configurations to enhance conductivity, reduce friction, and withstand the extreme forces involved in electromagnetic launching.

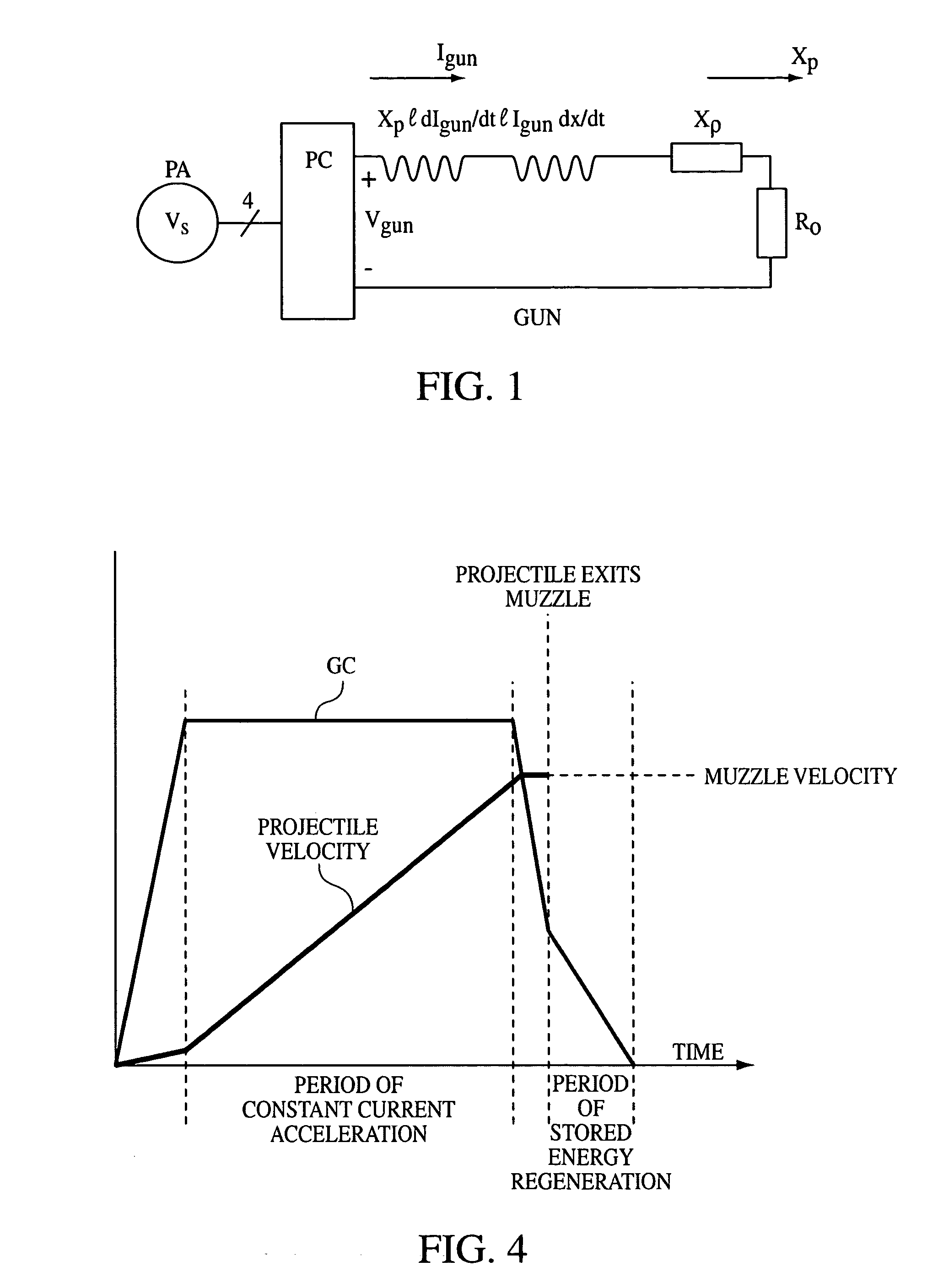

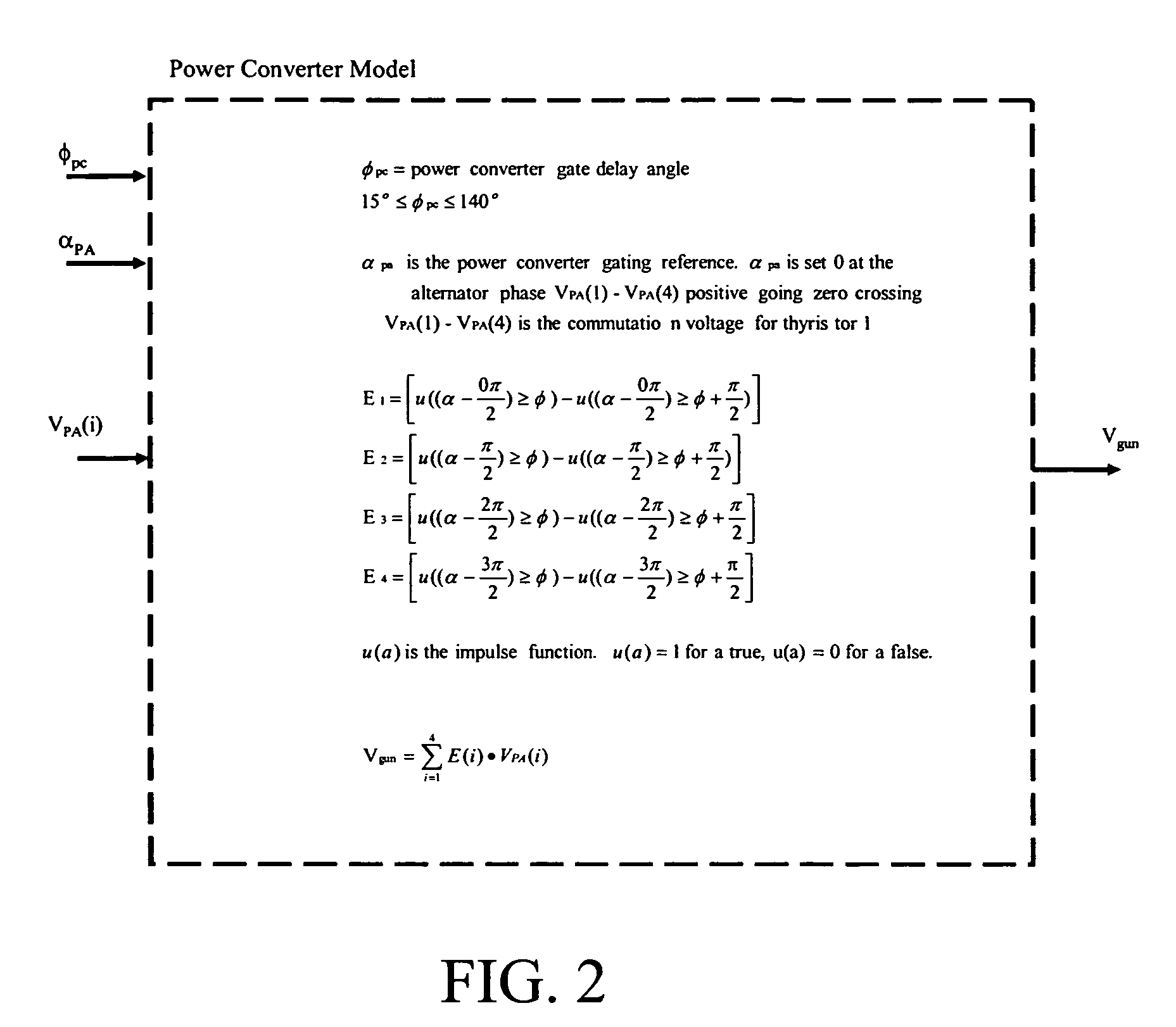

- Power supply and energy storage for rail guns: Rail gun systems require significant electrical power to operate effectively. Advanced power supply and energy storage solutions are developed to provide the necessary high-current pulses. These may include capacitor banks, pulsed alternators, or other specialized power systems designed to deliver large amounts of energy in short bursts.

- Rail gun barrel and launcher designs: The design of rail gun barrels and launchers is crucial for system performance. This includes considerations for rail material and configuration, insulation, cooling systems, and methods to reduce rail erosion and extend operational life. Advanced designs may incorporate features to manage plasma formation and improve projectile guidance.

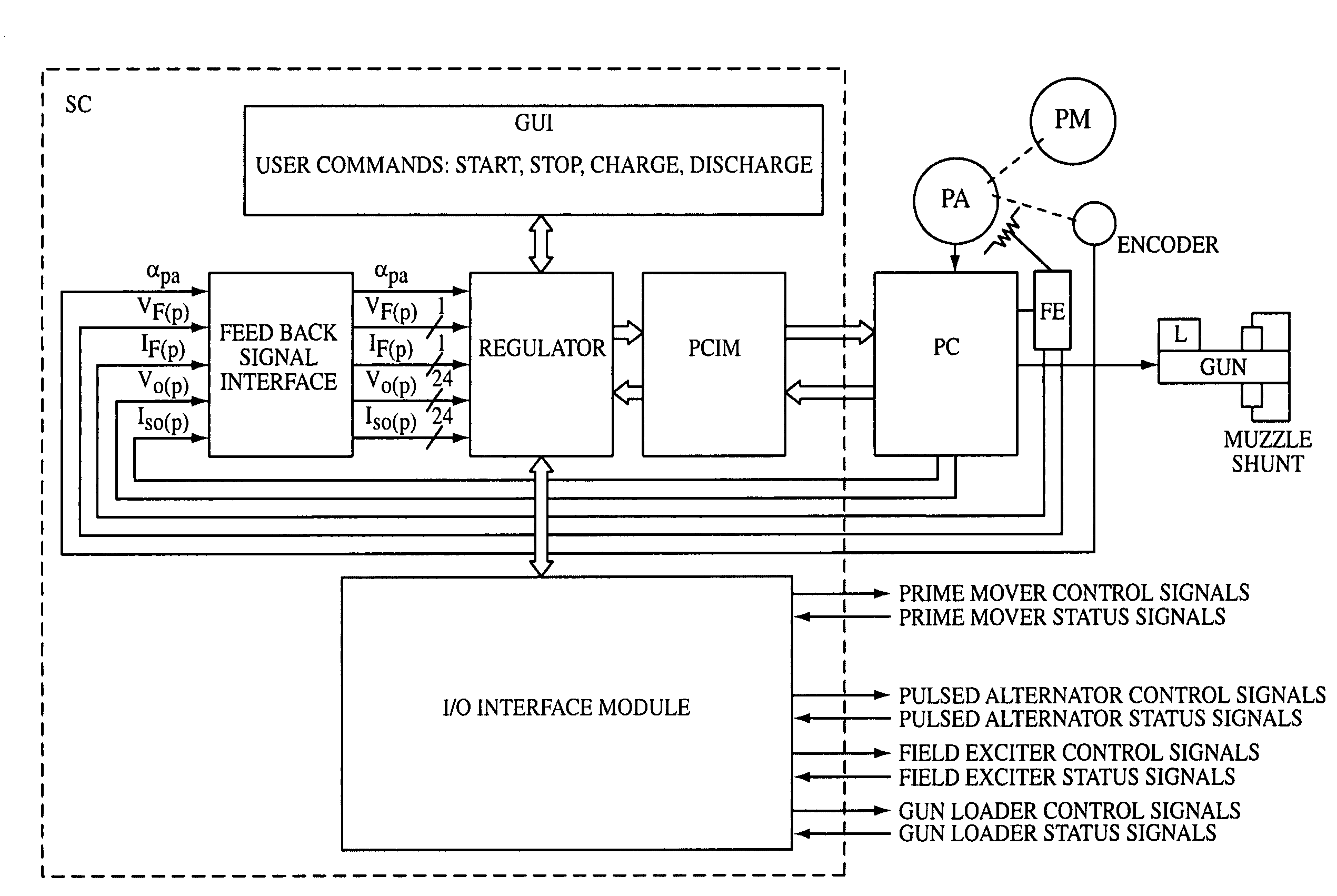

- Control and targeting systems for rail guns: Sophisticated control and targeting systems are developed to enhance the accuracy and effectiveness of rail guns. These may include advanced fire control computers, precision aiming mechanisms, and integrated sensors for tracking and adjusting projectile trajectories. Some systems also incorporate features for rapid firing and automatic reloading.

02 Rail gun power supply and capacitor systems

Specialized power supply and capacitor systems are crucial for rail guns to generate the high currents required for projectile acceleration. These systems often involve advanced energy storage and rapid discharge mechanisms to provide the necessary power for electromagnetic propulsion.Expand Specific Solutions03 Rail gun projectile design and guidance

Projectiles for rail guns require specific designs to withstand the high acceleration forces and maintain stability during flight. Some systems incorporate guidance mechanisms for improved accuracy. Advanced materials and aerodynamic profiles are often employed in projectile development.Expand Specific Solutions04 Rail gun cooling and thermal management

Effective cooling and thermal management systems are essential for rail guns due to the high heat generation during operation. These systems may include advanced heat dissipation techniques, coolant circulation, and materials with high thermal conductivity to maintain operational efficiency and prevent damage to the gun components.Expand Specific Solutions05 Integration of rail guns with existing weapon platforms

Efforts to integrate rail gun systems into existing military platforms, such as ships or ground vehicles, present unique engineering challenges. This involves adapting the rail gun technology to fit within space and power constraints while ensuring compatibility with existing targeting and fire control systems.Expand Specific Solutions

Industry Leaders

The in-field maintenance techniques for deployed rail gun systems are in an early development stage, with a relatively small but growing market. The technology's maturity is still evolving, as evidenced by ongoing research and development efforts from various players. Companies like BNSF Railway Co. and Robel Bahnbaumaschinen GmbH are likely contributing to advancements in rail-related technologies, while defense-oriented firms such as Hanwha Corp. and Cybernet Systems Corp. may be exploring applications specific to rail gun systems. The involvement of government entities like the U.S. Government and research institutions such as the PLA Army Engineering University suggests a strategic interest in developing this technology for both civilian and military applications.

Government of the United States of America

Technical Solution: The U.S. Government, particularly through the Navy and Defense Advanced Research Projects Agency (DARPA), has developed advanced in-field maintenance techniques for deployed rail gun systems. Their approach includes modular design for easy component replacement, advanced diagnostics using AI and machine learning for predictive maintenance, and the use of additive manufacturing for on-site part production[1][3]. They have also implemented remote monitoring systems that allow for real-time performance analysis and troubleshooting, reducing downtime and improving operational readiness[2]. Additionally, the U.S. has developed specialized tools and training programs for field technicians to perform complex maintenance tasks in challenging environments[4].

Strengths: Extensive research and development resources, access to cutting-edge technologies, and real-world deployment experience. Weaknesses: High costs associated with development and implementation, potential security concerns with remote monitoring systems.

Hanwha Corp.

Technical Solution: Hanwha Corporation has developed a comprehensive in-field maintenance system for rail gun systems, focusing on durability and efficiency. Their approach includes the use of advanced materials for critical components to extend operational life[5], and the implementation of a modular power supply system that allows for quick replacement of faulty units without extensive disassembly[6]. Hanwha has also integrated an automated diagnostic system that uses sensor data to identify potential issues before they lead to system failure, enabling proactive maintenance[7]. Furthermore, they have developed a portable, ruggedized maintenance kit specifically designed for field operations, containing specialized tools and spare parts optimized for rapid repairs in challenging environments[8].

Strengths: Focus on practical, field-ready solutions; integration of automated diagnostics for proactive maintenance. Weaknesses: Limited experience with large-scale deployment compared to some competitors; potential for higher initial costs due to specialized equipment.

Key Innovations

Closed loop defined profile current controller for electromagnetic rail gun applications

PatentInactiveUS7357128B1

Innovation

- A closed loop control system using state space control concepts, with a pulsed alternator observer, gun observer, and current compensator to regulate energy transfer and control muzzle velocity by transitioning the system through defined state transitions, enabling precise control of the rail gun current and projectile acceleration.

ILP rail-gun armature and rails

PatentActiveUS8132562B1

Innovation

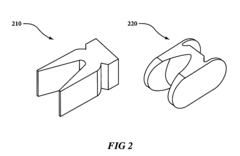

- The use of carbon-carbon composite materials for both armatures and rails, fabricated through a process of carbonization, infusion with a carbon matrix, and graphitization, along with reinforcement and additional refractory metals, to create a durable and conductive structure that minimizes damage during high-velocity projectile launches.

Logistical Concerns

The logistical concerns surrounding in-field maintenance of deployed rail gun systems present significant challenges that require careful consideration and planning. One of the primary issues is the transportation and storage of specialized equipment and spare parts necessary for maintenance operations. Rail gun systems comprise complex components that may require unique tools and replacement parts, which must be readily available in the field. This necessitates the development of robust supply chains and inventory management systems to ensure that critical components are accessible when needed.

Another crucial aspect is the deployment of skilled technicians capable of performing intricate maintenance procedures in potentially harsh or remote environments. These personnel must be trained not only in the technical aspects of rail gun maintenance but also in operating effectively under field conditions. This may involve establishing mobile maintenance units or developing modular rail gun designs that facilitate easier field repairs.

The power requirements for rail gun systems pose additional logistical challenges. Maintenance operations may require substantial energy sources, which can be difficult to provide in remote locations. This necessitates the development of portable power solutions or the integration of maintenance capabilities with existing power infrastructure in the field.

Environmental factors also play a significant role in logistical planning for rail gun maintenance. Extreme temperatures, humidity, dust, and other environmental conditions can affect both the performance of the rail gun systems and the effectiveness of maintenance procedures. Protective measures and specialized equipment may be required to ensure that maintenance can be carried out efficiently in various operational environments.

Time constraints are another critical factor to consider. The operational readiness of rail gun systems is paramount, and extended downtime for maintenance can significantly impact military capabilities. This drives the need for rapid diagnostic tools, efficient repair procedures, and potentially the development of predictive maintenance technologies to minimize unexpected failures and optimize maintenance schedules.

Lastly, the security and confidentiality of rail gun technology must be maintained during field maintenance operations. This requires implementing strict protocols for handling sensitive components and information, as well as ensuring that maintenance activities do not compromise the operational security of deployed units.

Another crucial aspect is the deployment of skilled technicians capable of performing intricate maintenance procedures in potentially harsh or remote environments. These personnel must be trained not only in the technical aspects of rail gun maintenance but also in operating effectively under field conditions. This may involve establishing mobile maintenance units or developing modular rail gun designs that facilitate easier field repairs.

The power requirements for rail gun systems pose additional logistical challenges. Maintenance operations may require substantial energy sources, which can be difficult to provide in remote locations. This necessitates the development of portable power solutions or the integration of maintenance capabilities with existing power infrastructure in the field.

Environmental factors also play a significant role in logistical planning for rail gun maintenance. Extreme temperatures, humidity, dust, and other environmental conditions can affect both the performance of the rail gun systems and the effectiveness of maintenance procedures. Protective measures and specialized equipment may be required to ensure that maintenance can be carried out efficiently in various operational environments.

Time constraints are another critical factor to consider. The operational readiness of rail gun systems is paramount, and extended downtime for maintenance can significantly impact military capabilities. This drives the need for rapid diagnostic tools, efficient repair procedures, and potentially the development of predictive maintenance technologies to minimize unexpected failures and optimize maintenance schedules.

Lastly, the security and confidentiality of rail gun technology must be maintained during field maintenance operations. This requires implementing strict protocols for handling sensitive components and information, as well as ensuring that maintenance activities do not compromise the operational security of deployed units.

Environmental Impact

The environmental impact of in-field maintenance techniques for deployed rail gun systems is a critical consideration that extends beyond operational efficiency. These advanced weapon systems, while offering significant military advantages, pose unique challenges in terms of their ecological footprint during maintenance operations.

Rail gun systems typically require substantial energy inputs and generate significant heat during operation. This thermal output can have localized effects on the immediate environment, potentially altering microclimates or affecting local flora and fauna. When conducting in-field maintenance, technicians must be aware of and mitigate these thermal impacts to minimize ecological disruption.

The use of specialized lubricants and coolants in rail gun systems presents another environmental concern. These substances, often synthetic and potentially harmful if released into the environment, require careful handling and disposal during maintenance procedures. Proper containment and recycling protocols are essential to prevent soil and water contamination in deployment areas.

Electromagnetic emissions from rail gun systems during testing and maintenance can interfere with local wildlife, particularly species that rely on electromagnetic fields for navigation or communication. Maintenance schedules and procedures should be designed to minimize such disruptions, potentially incorporating temporal restrictions to protect sensitive species during critical periods.

The acoustic impact of rail gun maintenance and testing is another significant factor. The high-energy discharges associated with these systems can produce intense sound waves that may disturb both human populations and wildlife in the vicinity. Implementing sound dampening techniques and conducting maintenance operations at appropriate times can help mitigate these acoustic disturbances.

Material wear and debris generated during rail gun operation and maintenance can introduce foreign particles into the local environment. These may include metal fragments, carbon residues, and other potentially harmful materials. Effective containment and cleanup procedures are crucial to prevent these materials from entering ecosystems and food chains.

Long-term environmental monitoring programs should be established in areas where rail gun systems are regularly maintained. These programs can track changes in soil composition, air quality, and biodiversity, providing valuable data to inform future maintenance practices and environmental protection strategies.

Lastly, the development of eco-friendly maintenance technologies and biodegradable materials for rail gun systems represents an important area for future research. Innovations in this field could significantly reduce the environmental footprint of these advanced weapon systems, aligning military capabilities with ecological stewardship.

Rail gun systems typically require substantial energy inputs and generate significant heat during operation. This thermal output can have localized effects on the immediate environment, potentially altering microclimates or affecting local flora and fauna. When conducting in-field maintenance, technicians must be aware of and mitigate these thermal impacts to minimize ecological disruption.

The use of specialized lubricants and coolants in rail gun systems presents another environmental concern. These substances, often synthetic and potentially harmful if released into the environment, require careful handling and disposal during maintenance procedures. Proper containment and recycling protocols are essential to prevent soil and water contamination in deployment areas.

Electromagnetic emissions from rail gun systems during testing and maintenance can interfere with local wildlife, particularly species that rely on electromagnetic fields for navigation or communication. Maintenance schedules and procedures should be designed to minimize such disruptions, potentially incorporating temporal restrictions to protect sensitive species during critical periods.

The acoustic impact of rail gun maintenance and testing is another significant factor. The high-energy discharges associated with these systems can produce intense sound waves that may disturb both human populations and wildlife in the vicinity. Implementing sound dampening techniques and conducting maintenance operations at appropriate times can help mitigate these acoustic disturbances.

Material wear and debris generated during rail gun operation and maintenance can introduce foreign particles into the local environment. These may include metal fragments, carbon residues, and other potentially harmful materials. Effective containment and cleanup procedures are crucial to prevent these materials from entering ecosystems and food chains.

Long-term environmental monitoring programs should be established in areas where rail gun systems are regularly maintained. These programs can track changes in soil composition, air quality, and biodiversity, providing valuable data to inform future maintenance practices and environmental protection strategies.

Lastly, the development of eco-friendly maintenance technologies and biodegradable materials for rail gun systems represents an important area for future research. Innovations in this field could significantly reduce the environmental footprint of these advanced weapon systems, aligning military capabilities with ecological stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!