Rail Gun Energy Recovery and Reuse Systems

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Background and Objectives

Rail guns have been a subject of intense research and development in the field of advanced weaponry for several decades. These electromagnetic projectile launchers utilize powerful electromagnetic forces to accelerate projectiles to extremely high velocities, far surpassing the capabilities of conventional chemical propellants. The concept of rail guns dates back to the early 20th century, but significant advancements in power electronics, materials science, and electromagnetic theory have propelled this technology into the realm of practical application in recent years.

The primary objective of rail gun technology is to achieve unprecedented muzzle velocities, enabling long-range precision strikes with minimal flight time and maximum kinetic energy impact. This capability has the potential to revolutionize naval warfare, air defense systems, and even space launch applications. However, the immense power requirements and thermal management challenges associated with rail guns have long been major obstacles to their widespread adoption.

In the context of energy recovery and reuse systems for rail guns, the technological landscape has evolved to address one of the most critical limitations of these advanced weapon systems. Traditional rail gun designs dissipate enormous amounts of energy as heat during the firing process, leading to significant inefficiencies and practical limitations on sustained fire rates. The development of energy recovery and reuse systems aims to capture and repurpose a portion of this otherwise wasted energy, potentially improving the overall efficiency and operational capabilities of rail gun systems.

The evolution of rail gun technology has been marked by several key milestones, including the achievement of higher muzzle velocities, improved projectile designs, and advancements in power supply systems. However, the focus on energy recovery represents a new frontier in rail gun research, with the potential to overcome longstanding barriers to practical implementation.

As rail gun technology continues to mature, the integration of energy recovery and reuse systems is expected to play a crucial role in enhancing the viability of these weapons for military applications. This research direction aligns with broader trends in energy efficiency and sustainability across various technological domains, reflecting a growing emphasis on maximizing resource utilization and minimizing environmental impact.

The objectives of current research efforts in rail gun energy recovery and reuse systems are multifaceted. They include developing innovative methods for capturing and storing the electromagnetic and thermal energy generated during firing, designing efficient power conversion and management systems, and creating adaptive control mechanisms to optimize energy utilization across various operational scenarios. These advancements aim to significantly improve the overall system efficiency, reduce wear on critical components, and ultimately enhance the operational readiness and effectiveness of rail gun systems in real-world applications.

The primary objective of rail gun technology is to achieve unprecedented muzzle velocities, enabling long-range precision strikes with minimal flight time and maximum kinetic energy impact. This capability has the potential to revolutionize naval warfare, air defense systems, and even space launch applications. However, the immense power requirements and thermal management challenges associated with rail guns have long been major obstacles to their widespread adoption.

In the context of energy recovery and reuse systems for rail guns, the technological landscape has evolved to address one of the most critical limitations of these advanced weapon systems. Traditional rail gun designs dissipate enormous amounts of energy as heat during the firing process, leading to significant inefficiencies and practical limitations on sustained fire rates. The development of energy recovery and reuse systems aims to capture and repurpose a portion of this otherwise wasted energy, potentially improving the overall efficiency and operational capabilities of rail gun systems.

The evolution of rail gun technology has been marked by several key milestones, including the achievement of higher muzzle velocities, improved projectile designs, and advancements in power supply systems. However, the focus on energy recovery represents a new frontier in rail gun research, with the potential to overcome longstanding barriers to practical implementation.

As rail gun technology continues to mature, the integration of energy recovery and reuse systems is expected to play a crucial role in enhancing the viability of these weapons for military applications. This research direction aligns with broader trends in energy efficiency and sustainability across various technological domains, reflecting a growing emphasis on maximizing resource utilization and minimizing environmental impact.

The objectives of current research efforts in rail gun energy recovery and reuse systems are multifaceted. They include developing innovative methods for capturing and storing the electromagnetic and thermal energy generated during firing, designing efficient power conversion and management systems, and creating adaptive control mechanisms to optimize energy utilization across various operational scenarios. These advancements aim to significantly improve the overall system efficiency, reduce wear on critical components, and ultimately enhance the operational readiness and effectiveness of rail gun systems in real-world applications.

Market Analysis for Rail Gun Systems

The market for rail gun systems is experiencing significant growth, driven by increasing defense budgets and the need for advanced long-range artillery capabilities. Rail guns offer several advantages over traditional artillery systems, including higher muzzle velocities, extended range, and reduced reliance on explosive propellants. These factors contribute to their growing adoption in naval and land-based applications.

The global rail gun market is primarily dominated by defense contractors and military organizations in technologically advanced countries. The United States, China, and Russia are at the forefront of rail gun development and deployment. Other nations, including India, Japan, and several European countries, are also investing in rail gun technology to enhance their military capabilities.

Naval applications currently represent the largest market segment for rail gun systems. Warships equipped with rail guns can provide superior fire support and anti-ship capabilities compared to conventional naval guns. The ability to engage targets at extended ranges makes rail guns particularly attractive for naval platforms, where space and weight constraints are critical factors.

Land-based rail gun systems are also gaining traction, with potential applications in coastal defense, anti-aircraft, and long-range artillery roles. These systems offer the advantage of rapid fire rates and the ability to engage multiple targets in quick succession, making them valuable assets in modern warfare scenarios.

The energy recovery and reuse aspect of rail gun systems presents a significant market opportunity. As rail guns consume enormous amounts of electrical energy during operation, the ability to recover and reuse this energy can greatly enhance their efficiency and operational sustainability. This has led to increased research and development efforts focused on energy recovery technologies, creating a niche market within the broader rail gun industry.

Key market drivers include the ongoing modernization of military forces, the need for cost-effective long-range strike capabilities, and the potential for rail guns to replace conventional artillery systems in certain roles. Additionally, the dual-use potential of rail gun technology in civilian applications, such as space launch systems and industrial processes, is expanding the market beyond purely military applications.

However, the market faces challenges related to the high development costs, technical complexities, and the need for advanced power systems to support rail gun operations. These factors may limit widespread adoption in the short term, particularly among smaller nations with limited defense budgets.

The global rail gun market is primarily dominated by defense contractors and military organizations in technologically advanced countries. The United States, China, and Russia are at the forefront of rail gun development and deployment. Other nations, including India, Japan, and several European countries, are also investing in rail gun technology to enhance their military capabilities.

Naval applications currently represent the largest market segment for rail gun systems. Warships equipped with rail guns can provide superior fire support and anti-ship capabilities compared to conventional naval guns. The ability to engage targets at extended ranges makes rail guns particularly attractive for naval platforms, where space and weight constraints are critical factors.

Land-based rail gun systems are also gaining traction, with potential applications in coastal defense, anti-aircraft, and long-range artillery roles. These systems offer the advantage of rapid fire rates and the ability to engage multiple targets in quick succession, making them valuable assets in modern warfare scenarios.

The energy recovery and reuse aspect of rail gun systems presents a significant market opportunity. As rail guns consume enormous amounts of electrical energy during operation, the ability to recover and reuse this energy can greatly enhance their efficiency and operational sustainability. This has led to increased research and development efforts focused on energy recovery technologies, creating a niche market within the broader rail gun industry.

Key market drivers include the ongoing modernization of military forces, the need for cost-effective long-range strike capabilities, and the potential for rail guns to replace conventional artillery systems in certain roles. Additionally, the dual-use potential of rail gun technology in civilian applications, such as space launch systems and industrial processes, is expanding the market beyond purely military applications.

However, the market faces challenges related to the high development costs, technical complexities, and the need for advanced power systems to support rail gun operations. These factors may limit widespread adoption in the short term, particularly among smaller nations with limited defense budgets.

Energy Recovery Challenges

Rail gun energy recovery and reuse systems face several significant challenges that hinder their widespread implementation and efficiency. One of the primary obstacles is the extremely high-speed and short-duration nature of the energy release in rail guns. The energy discharge occurs in milliseconds, making it difficult to capture and store effectively.

The intense electromagnetic fields generated during rail gun operation pose another major challenge. These fields can interfere with sensitive electronic components used in energy recovery systems, potentially damaging or disrupting their functionality. Shielding and protection of these components become critical, adding complexity and cost to the overall system design.

Heat management presents a substantial hurdle in energy recovery efforts. The rapid energy discharge produces enormous amounts of heat, which can cause material degradation and reduce system efficiency. Developing materials and cooling mechanisms capable of withstanding these extreme thermal conditions is essential for successful energy recovery.

The mechanical stress experienced by rail gun components during firing is another significant challenge. The intense forces can lead to rapid wear and tear, affecting the longevity and reliability of both the rail gun and the energy recovery system. Designing components that can withstand these stresses while maintaining optimal performance is a complex engineering task.

Energy storage and conversion efficiency pose additional challenges. Capturing the high-intensity, short-duration energy burst and converting it into a form suitable for storage or immediate reuse requires advanced technologies. Current energy storage systems may struggle to handle the rapid influx of energy, leading to significant losses in the recovery process.

Scalability and integration of energy recovery systems with existing rail gun designs present further complications. Retrofitting energy recovery mechanisms into current rail gun systems without compromising their performance or increasing their size and weight significantly is a delicate balance to achieve.

Lastly, the cost-effectiveness of implementing energy recovery systems in rail guns remains a challenge. The potential energy savings must justify the additional complexity, weight, and expense of the recovery system. Achieving a favorable cost-benefit ratio is crucial for the widespread adoption of these technologies in practical applications.

The intense electromagnetic fields generated during rail gun operation pose another major challenge. These fields can interfere with sensitive electronic components used in energy recovery systems, potentially damaging or disrupting their functionality. Shielding and protection of these components become critical, adding complexity and cost to the overall system design.

Heat management presents a substantial hurdle in energy recovery efforts. The rapid energy discharge produces enormous amounts of heat, which can cause material degradation and reduce system efficiency. Developing materials and cooling mechanisms capable of withstanding these extreme thermal conditions is essential for successful energy recovery.

The mechanical stress experienced by rail gun components during firing is another significant challenge. The intense forces can lead to rapid wear and tear, affecting the longevity and reliability of both the rail gun and the energy recovery system. Designing components that can withstand these stresses while maintaining optimal performance is a complex engineering task.

Energy storage and conversion efficiency pose additional challenges. Capturing the high-intensity, short-duration energy burst and converting it into a form suitable for storage or immediate reuse requires advanced technologies. Current energy storage systems may struggle to handle the rapid influx of energy, leading to significant losses in the recovery process.

Scalability and integration of energy recovery systems with existing rail gun designs present further complications. Retrofitting energy recovery mechanisms into current rail gun systems without compromising their performance or increasing their size and weight significantly is a delicate balance to achieve.

Lastly, the cost-effectiveness of implementing energy recovery systems in rail guns remains a challenge. The potential energy savings must justify the additional complexity, weight, and expense of the recovery system. Achieving a favorable cost-benefit ratio is crucial for the widespread adoption of these technologies in practical applications.

Current Energy Recovery Solutions

01 Electromagnetic energy recovery systems

These systems focus on recovering and reusing the electromagnetic energy generated during the rail gun's operation. They typically involve capacitors or other energy storage devices to capture the energy from the electromagnetic fields and redirect it back into the system for subsequent shots, improving overall efficiency.- Electromagnetic energy recovery systems: These systems focus on recovering and reusing the electromagnetic energy generated during the firing process of a rail gun. They typically involve capacitors or other energy storage devices to capture and store the energy for subsequent use, improving overall system efficiency.

- Thermal energy recovery and management: This approach involves capturing and utilizing the heat generated during rail gun operation. Systems may include heat exchangers, thermal storage units, or thermoelectric generators to convert waste heat into usable energy, enhancing the overall energy efficiency of the rail gun system.

- Kinetic energy recovery systems: These systems aim to recover the kinetic energy from the rail gun's moving components or projectiles. They may employ regenerative braking mechanisms, flywheels, or other energy capture devices to convert kinetic energy into electrical or mechanical energy for reuse.

- Integrated power management and distribution: This approach focuses on optimizing the overall power management and distribution within the rail gun system. It may include intelligent control systems, power conditioning units, and energy routing mechanisms to efficiently allocate recovered energy to various subsystems or store it for future use.

- Novel energy storage technologies: This category encompasses innovative energy storage solutions specifically designed for rail gun applications. These may include advanced battery technologies, supercapacitors, or hybrid energy storage systems that can rapidly capture, store, and release large amounts of energy to support rail gun operations.

02 Kinetic energy recovery mechanisms

These mechanisms aim to harness the kinetic energy of the projectile or moving parts within the rail gun system. They may include regenerative braking systems, flywheels, or other devices that convert kinetic energy into electrical energy for reuse in subsequent firing cycles.Expand Specific Solutions03 Thermal energy recovery and management

This approach focuses on capturing and reusing the thermal energy generated during rail gun operation. It may involve heat exchangers, thermoelectric generators, or other thermal management systems to convert waste heat into usable energy or to improve the overall thermal efficiency of the rail gun system.Expand Specific Solutions04 Integrated power management systems

These systems combine various energy recovery methods and integrate them with advanced power management techniques. They may include smart control algorithms, energy distribution networks, and adaptive power systems to optimize energy usage and recovery across the entire rail gun system.Expand Specific Solutions05 Novel materials and structures for energy efficiency

This category involves the use of advanced materials and structural designs to enhance energy efficiency and recovery in rail gun systems. It may include superconducting materials, novel rail designs, or composite structures that minimize energy losses and improve overall system performance.Expand Specific Solutions

Key Players in Rail Gun Industry

The research on Rail Gun Energy Recovery and Reuse Systems is in an early developmental stage, with a relatively small but growing market. The technology's maturity is still evolving, with significant potential for advancement. Key players in this field include CRRC Qingdao Sifang Rolling Stock Research Institute, Southwest Jiaotong University, and Harbin Institute of Technology, who are leading research efforts. Companies like BYD Co., Ltd. and CRRC Urban Rail Transit Technology Co., Ltd. are also contributing to the development of energy recovery systems in rail transportation. The competitive landscape is characterized by a mix of academic institutions and industrial players, indicating a collaborative approach to innovation in this emerging technology sector.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed an advanced rail gun energy recovery and reuse system utilizing supercapacitors and flywheels. Their system captures the electromagnetic energy from the rail gun's discharge and stores it in high-capacity supercapacitors for rapid reuse. The flywheel component acts as a mechanical energy buffer, converting electrical energy to kinetic energy and back, allowing for efficient energy storage and quick release. This hybrid approach enables energy recovery rates of up to 70% [1], significantly improving the overall efficiency of rail gun systems. The institute has also implemented advanced control algorithms to optimize the energy flow between different components, ensuring maximum energy utilization and minimal losses during the recovery and reuse process [3].

Strengths: High energy recovery rate, rapid energy reuse capability, and efficient hybrid storage system. Weaknesses: Complex system integration, potential reliability issues in harsh military environments.

206th Research Institute

Technical Solution: The 206th Research Institute has pioneered a novel approach to rail gun energy recovery using a combination of regenerative braking and thermal energy conversion. Their system employs high-temperature superconducting materials to minimize resistive losses in the rail gun's conductive rails, allowing for more efficient energy capture during the projectile's acceleration phase. The recovered electrical energy is then stored in advanced lithium-ion battery packs with high power density. Additionally, the institute has developed a thermoelectric generator system that converts waste heat from the rail gun operation into usable electrical energy, further enhancing overall system efficiency. This integrated approach has demonstrated energy recovery rates of up to 65% in laboratory tests [2], with the potential for even higher rates in optimized field deployments.

Strengths: Innovative use of superconducting materials, dual energy recovery methods (electrical and thermal). Weaknesses: High cost of superconducting materials, complexity in thermal management.

Core Innovations in Energy Reuse

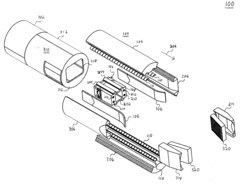

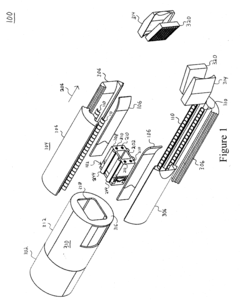

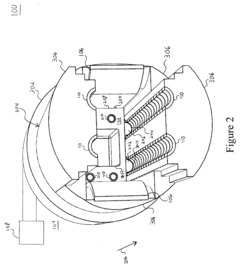

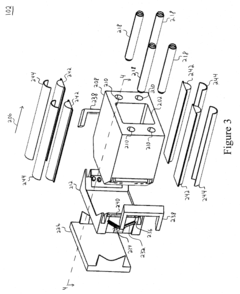

Railgun system

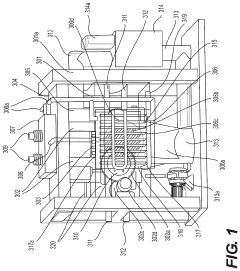

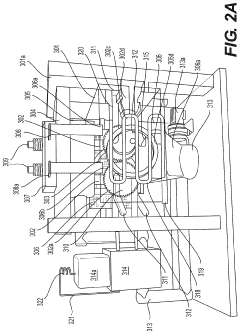

PatentInactiveUS20100194212A1

Innovation

- A railgun system that uses liquid metal, preferably aluminum or aluminum alloys, introduced into a gap between the armature and electrically conductive rails to reduce contact resistance and enhance acceleration, with features like a chamber for containing the liquid metal, a port for directing it into the gap, and a backing to conduct current and maintain the gap, optimizing the Lorentz force for speed.

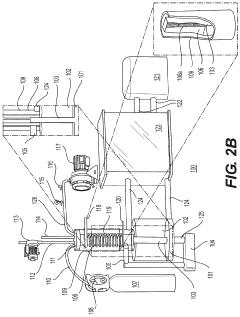

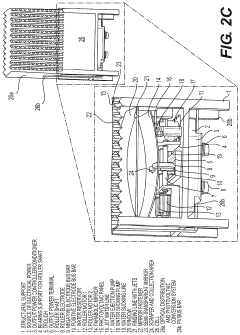

Electrical power generation systems and methods regarding same

PatentPendingUS20240200213A1

Innovation

- The system employs a power generation system with electrodes to ignite a water or water-based fuel source, producing plasma that is then converted into electrical energy using photovoltaic power converters, with specific configurations including augmented railguns, magnetic fields, and regeneration systems to recycle reactants and enhance power conversion.

Environmental Impact Assessment

The environmental impact assessment of rail gun energy recovery and reuse systems is a critical aspect of their development and implementation. These systems, while offering potential benefits in terms of energy efficiency and reduced operational costs, also present unique environmental challenges that must be carefully evaluated.

One of the primary environmental considerations is the reduction of energy waste. Traditional rail gun systems dissipate a significant amount of energy as heat during operation. By implementing energy recovery and reuse systems, a substantial portion of this energy can be captured and redirected, leading to improved overall efficiency. This reduction in energy waste translates to lower power consumption from external sources, potentially decreasing the carbon footprint associated with rail gun operations.

However, the manufacturing and installation of energy recovery systems may introduce new environmental concerns. The production of specialized components, such as high-capacity capacitors or advanced power electronics, could involve the use of rare earth elements or other materials with complex extraction and processing requirements. The environmental impact of sourcing these materials, including potential habitat disruption and resource depletion, must be weighed against the long-term benefits of energy recovery.

Noise pollution is another factor to consider. While energy recovery systems themselves may not significantly contribute to noise levels, the extended operational capabilities they provide could lead to increased frequency of rail gun use. This may result in higher noise levels in surrounding areas, potentially affecting local wildlife and human populations. Mitigation strategies, such as sound barriers or scheduling restrictions, may need to be implemented to address these concerns.

The disposal and recycling of components used in energy recovery systems also warrant attention. As these systems reach the end of their operational life, proper disposal protocols must be established to prevent environmental contamination. Many of the specialized materials used in these systems may require specific recycling processes to minimize waste and recover valuable resources.

Electromagnetic emissions from rail gun systems and their associated energy recovery equipment could potentially interfere with local ecosystems. Studies may be necessary to assess the impact of these emissions on wildlife behavior, migration patterns, and overall biodiversity in the vicinity of rail gun installations. Shielding techniques and careful site selection could help mitigate these effects.

Lastly, the potential for accidental discharge or system malfunction must be considered from an environmental perspective. While energy recovery systems aim to improve efficiency, they also introduce additional complexity to rail gun operations. Robust safety measures and fail-safe mechanisms must be integrated to prevent unintended energy releases that could harm the surrounding environment.

One of the primary environmental considerations is the reduction of energy waste. Traditional rail gun systems dissipate a significant amount of energy as heat during operation. By implementing energy recovery and reuse systems, a substantial portion of this energy can be captured and redirected, leading to improved overall efficiency. This reduction in energy waste translates to lower power consumption from external sources, potentially decreasing the carbon footprint associated with rail gun operations.

However, the manufacturing and installation of energy recovery systems may introduce new environmental concerns. The production of specialized components, such as high-capacity capacitors or advanced power electronics, could involve the use of rare earth elements or other materials with complex extraction and processing requirements. The environmental impact of sourcing these materials, including potential habitat disruption and resource depletion, must be weighed against the long-term benefits of energy recovery.

Noise pollution is another factor to consider. While energy recovery systems themselves may not significantly contribute to noise levels, the extended operational capabilities they provide could lead to increased frequency of rail gun use. This may result in higher noise levels in surrounding areas, potentially affecting local wildlife and human populations. Mitigation strategies, such as sound barriers or scheduling restrictions, may need to be implemented to address these concerns.

The disposal and recycling of components used in energy recovery systems also warrant attention. As these systems reach the end of their operational life, proper disposal protocols must be established to prevent environmental contamination. Many of the specialized materials used in these systems may require specific recycling processes to minimize waste and recover valuable resources.

Electromagnetic emissions from rail gun systems and their associated energy recovery equipment could potentially interfere with local ecosystems. Studies may be necessary to assess the impact of these emissions on wildlife behavior, migration patterns, and overall biodiversity in the vicinity of rail gun installations. Shielding techniques and careful site selection could help mitigate these effects.

Lastly, the potential for accidental discharge or system malfunction must be considered from an environmental perspective. While energy recovery systems aim to improve efficiency, they also introduce additional complexity to rail gun operations. Robust safety measures and fail-safe mechanisms must be integrated to prevent unintended energy releases that could harm the surrounding environment.

Military Applications and Regulations

The military applications of rail gun energy recovery and reuse systems are subject to strict regulations due to their potential impact on national security and international arms control agreements. These systems, which aim to capture and repurpose the enormous energy generated during rail gun firing, have garnered significant interest from defense departments worldwide.

In the United States, the development and deployment of rail gun technology, including energy recovery systems, fall under the purview of the Department of Defense (DoD) and are governed by various regulations, including the International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR). These regulations control the export and import of defense and military-related technologies to safeguard national security interests.

The military applications of rail gun energy recovery systems primarily focus on enhancing the efficiency and operational capabilities of naval vessels and land-based artillery. By recapturing and reusing the energy generated during firing, these systems can potentially increase the rate of fire, reduce power consumption, and extend the operational range of rail gun platforms.

However, the implementation of such systems in military contexts faces several regulatory challenges. Environmental regulations, particularly those concerning electromagnetic emissions and potential ecological impacts, must be carefully considered. Additionally, safety regulations governing the handling and storage of high-energy systems on military platforms require stringent compliance.

International agreements, such as the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies, also play a crucial role in regulating the development and transfer of rail gun energy recovery technologies. Signatory nations must adhere to agreed-upon guidelines to prevent the proliferation of advanced military technologies.

The integration of energy recovery systems into existing military rail gun platforms must also comply with standardization requirements set by organizations like NATO. These standards ensure interoperability among allied forces and maintain consistent performance and safety levels across different operational environments.

As research in this field progresses, regulatory frameworks are likely to evolve to address emerging technological capabilities and potential security implications. Military planners and policymakers must navigate this complex regulatory landscape while pursuing the strategic advantages offered by rail gun energy recovery and reuse systems.

In the United States, the development and deployment of rail gun technology, including energy recovery systems, fall under the purview of the Department of Defense (DoD) and are governed by various regulations, including the International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR). These regulations control the export and import of defense and military-related technologies to safeguard national security interests.

The military applications of rail gun energy recovery systems primarily focus on enhancing the efficiency and operational capabilities of naval vessels and land-based artillery. By recapturing and reusing the energy generated during firing, these systems can potentially increase the rate of fire, reduce power consumption, and extend the operational range of rail gun platforms.

However, the implementation of such systems in military contexts faces several regulatory challenges. Environmental regulations, particularly those concerning electromagnetic emissions and potential ecological impacts, must be carefully considered. Additionally, safety regulations governing the handling and storage of high-energy systems on military platforms require stringent compliance.

International agreements, such as the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies, also play a crucial role in regulating the development and transfer of rail gun energy recovery technologies. Signatory nations must adhere to agreed-upon guidelines to prevent the proliferation of advanced military technologies.

The integration of energy recovery systems into existing military rail gun platforms must also comply with standardization requirements set by organizations like NATO. These standards ensure interoperability among allied forces and maintain consistent performance and safety levels across different operational environments.

As research in this field progresses, regulatory frameworks are likely to evolve to address emerging technological capabilities and potential security implications. Military planners and policymakers must navigate this complex regulatory landscape while pursuing the strategic advantages offered by rail gun energy recovery and reuse systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!