Energy Efficient QLED: Techniques and Developments

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Evolution and Efficiency Goals

Quantum Dot Light-Emitting Diodes (QLEDs) have emerged as a promising display technology, offering superior color performance and energy efficiency compared to traditional LED displays. The evolution of QLED technology has been marked by significant advancements in materials science, manufacturing processes, and device architectures.

The journey of QLED development began in the early 1990s with the discovery of quantum dots' unique optical properties. Initially, the focus was on understanding and controlling the synthesis of quantum dots to achieve precise emission wavelengths. As research progressed, the emphasis shifted towards integrating these nanocrystals into functional devices.

By the mid-2000s, the first QLED prototypes were demonstrated, showcasing the potential for high color purity and brightness. However, these early devices suffered from low efficiency and poor stability, limiting their practical applications. The subsequent decade saw intensive efforts to overcome these challenges, with researchers exploring various quantum dot compositions, device structures, and charge transport materials.

A major breakthrough came with the development of core-shell quantum dots, which significantly improved the stability and quantum yield of the emitters. This advancement, coupled with innovations in charge injection layers, led to a rapid increase in QLED efficiency and lifetime.

The current state-of-the-art QLEDs have achieved external quantum efficiencies (EQEs) exceeding 20% for red and green emitters, approaching the theoretical limits for conventional OLED architectures. Blue QLEDs, however, have lagged behind, with efficiencies typically below 10%, presenting a key area for improvement.

Looking forward, the primary efficiency goals for QLED technology include:

1. Achieving balanced RGB performance, with a particular focus on enhancing blue QLED efficiency to match that of red and green.

2. Increasing overall device efficiency to surpass 30% EQE across all colors, potentially through the implementation of advanced light outcoupling strategies.

3. Improving operational stability and lifetime, especially under high brightness conditions, to meet the demands of commercial display applications.

4. Reducing energy consumption in both active and standby modes, aligning with global energy efficiency standards for consumer electronics.

To reach these ambitious targets, researchers are exploring novel quantum dot compositions, such as perovskite nanocrystals, which offer promising efficiency and color purity. Additionally, advanced device architectures, including tandem structures and optical microcavities, are being investigated to maximize light extraction and reduce energy losses.

The pursuit of energy-efficient QLEDs is driven not only by the desire for improved display performance but also by the growing emphasis on sustainability in consumer electronics. As QLED technology continues to evolve, it holds the potential to revolutionize the display industry, offering unparalleled visual experiences while minimizing environmental impact through reduced energy consumption.

The journey of QLED development began in the early 1990s with the discovery of quantum dots' unique optical properties. Initially, the focus was on understanding and controlling the synthesis of quantum dots to achieve precise emission wavelengths. As research progressed, the emphasis shifted towards integrating these nanocrystals into functional devices.

By the mid-2000s, the first QLED prototypes were demonstrated, showcasing the potential for high color purity and brightness. However, these early devices suffered from low efficiency and poor stability, limiting their practical applications. The subsequent decade saw intensive efforts to overcome these challenges, with researchers exploring various quantum dot compositions, device structures, and charge transport materials.

A major breakthrough came with the development of core-shell quantum dots, which significantly improved the stability and quantum yield of the emitters. This advancement, coupled with innovations in charge injection layers, led to a rapid increase in QLED efficiency and lifetime.

The current state-of-the-art QLEDs have achieved external quantum efficiencies (EQEs) exceeding 20% for red and green emitters, approaching the theoretical limits for conventional OLED architectures. Blue QLEDs, however, have lagged behind, with efficiencies typically below 10%, presenting a key area for improvement.

Looking forward, the primary efficiency goals for QLED technology include:

1. Achieving balanced RGB performance, with a particular focus on enhancing blue QLED efficiency to match that of red and green.

2. Increasing overall device efficiency to surpass 30% EQE across all colors, potentially through the implementation of advanced light outcoupling strategies.

3. Improving operational stability and lifetime, especially under high brightness conditions, to meet the demands of commercial display applications.

4. Reducing energy consumption in both active and standby modes, aligning with global energy efficiency standards for consumer electronics.

To reach these ambitious targets, researchers are exploring novel quantum dot compositions, such as perovskite nanocrystals, which offer promising efficiency and color purity. Additionally, advanced device architectures, including tandem structures and optical microcavities, are being investigated to maximize light extraction and reduce energy losses.

The pursuit of energy-efficient QLEDs is driven not only by the desire for improved display performance but also by the growing emphasis on sustainability in consumer electronics. As QLED technology continues to evolve, it holds the potential to revolutionize the display industry, offering unparalleled visual experiences while minimizing environmental impact through reduced energy consumption.

QLED Market Demand Analysis

The QLED (Quantum Dot Light-Emitting Diode) market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in various applications. The market for QLED technology is expected to continue expanding, with a particular focus on energy-efficient solutions.

Consumer electronics, especially televisions, represent the largest segment of the QLED market. As consumers seek improved picture quality and larger screen sizes, QLED technology has gained traction due to its ability to deliver vibrant colors, high contrast ratios, and excellent brightness levels. The growing popularity of 4K and 8K resolution displays further fuels the demand for QLED panels in the TV sector.

The automotive industry is emerging as a promising market for QLED technology. As vehicles become more technologically advanced, there is an increasing need for high-quality displays in infotainment systems, digital dashboards, and heads-up displays. QLED's energy efficiency and ability to maintain color accuracy in various lighting conditions make it an attractive option for automotive applications.

In the commercial display sector, QLED technology is gaining traction for digital signage, video walls, and large-format displays. The technology's high brightness and wide color gamut capabilities make it suitable for use in retail environments, airports, and other public spaces where visual impact is crucial.

The demand for energy-efficient QLED solutions is particularly strong across all market segments. As energy consumption and environmental concerns become increasingly important to consumers and businesses alike, there is a growing emphasis on developing QLED displays that offer superior performance while minimizing power usage. This trend aligns with global initiatives to reduce carbon emissions and improve energy efficiency in electronic devices.

The healthcare and medical imaging sectors also present opportunities for QLED technology. The need for high-resolution, color-accurate displays in diagnostic equipment and surgical monitors is driving interest in QLED solutions. The technology's ability to reproduce a wide range of colors accurately is particularly valuable in medical imaging applications.

As the QLED market continues to evolve, there is a growing demand for flexible and transparent display solutions. This opens up new possibilities for QLED technology in wearable devices, smart home appliances, and architectural applications. The development of energy-efficient, flexible QLED displays could potentially revolutionize how we interact with technology in our daily lives.

Consumer electronics, especially televisions, represent the largest segment of the QLED market. As consumers seek improved picture quality and larger screen sizes, QLED technology has gained traction due to its ability to deliver vibrant colors, high contrast ratios, and excellent brightness levels. The growing popularity of 4K and 8K resolution displays further fuels the demand for QLED panels in the TV sector.

The automotive industry is emerging as a promising market for QLED technology. As vehicles become more technologically advanced, there is an increasing need for high-quality displays in infotainment systems, digital dashboards, and heads-up displays. QLED's energy efficiency and ability to maintain color accuracy in various lighting conditions make it an attractive option for automotive applications.

In the commercial display sector, QLED technology is gaining traction for digital signage, video walls, and large-format displays. The technology's high brightness and wide color gamut capabilities make it suitable for use in retail environments, airports, and other public spaces where visual impact is crucial.

The demand for energy-efficient QLED solutions is particularly strong across all market segments. As energy consumption and environmental concerns become increasingly important to consumers and businesses alike, there is a growing emphasis on developing QLED displays that offer superior performance while minimizing power usage. This trend aligns with global initiatives to reduce carbon emissions and improve energy efficiency in electronic devices.

The healthcare and medical imaging sectors also present opportunities for QLED technology. The need for high-resolution, color-accurate displays in diagnostic equipment and surgical monitors is driving interest in QLED solutions. The technology's ability to reproduce a wide range of colors accurately is particularly valuable in medical imaging applications.

As the QLED market continues to evolve, there is a growing demand for flexible and transparent display solutions. This opens up new possibilities for QLED technology in wearable devices, smart home appliances, and architectural applications. The development of energy-efficient, flexible QLED displays could potentially revolutionize how we interact with technology in our daily lives.

QLED Efficiency Challenges

Quantum Dot Light-Emitting Diodes (QLEDs) have emerged as a promising technology for next-generation displays and lighting applications. However, despite their potential advantages, QLEDs face several significant efficiency challenges that hinder their widespread adoption and commercialization.

One of the primary challenges is the external quantum efficiency (EQE) of QLEDs. While considerable progress has been made, current QLEDs still struggle to achieve EQE levels comparable to their organic LED (OLED) counterparts, especially in blue-emitting devices. This limitation is largely due to the inherent properties of quantum dots and the complex charge transport mechanisms within the device structure.

Another critical issue is the charge injection and transport efficiency in QLEDs. The energy level mismatch between the quantum dot emissive layer and the charge transport layers often leads to high turn-on voltages and reduced overall device efficiency. Optimizing the energy level alignment across different layers remains a significant challenge for researchers and engineers in the field.

Stability and lifetime of QLEDs present another major hurdle. The degradation of quantum dots under electrical stress and exposure to oxygen and moisture significantly impacts the long-term performance and reliability of these devices. Developing robust encapsulation techniques and improving the intrinsic stability of quantum dots are crucial areas of ongoing research.

The efficiency roll-off at high current densities, known as efficiency droop, is also a persistent problem in QLEDs. This phenomenon limits the maximum brightness achievable while maintaining high efficiency, which is particularly important for display applications requiring high luminance levels.

Color purity and spectral stability pose additional challenges. While quantum dots offer narrow emission spectra, maintaining color purity over time and under various operating conditions remains difficult. This is especially true for blue-emitting quantum dots, which are crucial for achieving a wide color gamut in display applications.

Manufacturing scalability and cost-effectiveness are also significant barriers to the widespread adoption of QLED technology. Current production methods for high-quality quantum dots and the integration of these materials into device structures are often complex and expensive, limiting their commercial viability.

Addressing these efficiency challenges requires a multidisciplinary approach, combining advances in materials science, device physics, and manufacturing processes. Researchers are exploring various strategies, including novel quantum dot compositions, improved device architectures, and innovative fabrication techniques to overcome these limitations and unlock the full potential of QLED technology.

One of the primary challenges is the external quantum efficiency (EQE) of QLEDs. While considerable progress has been made, current QLEDs still struggle to achieve EQE levels comparable to their organic LED (OLED) counterparts, especially in blue-emitting devices. This limitation is largely due to the inherent properties of quantum dots and the complex charge transport mechanisms within the device structure.

Another critical issue is the charge injection and transport efficiency in QLEDs. The energy level mismatch between the quantum dot emissive layer and the charge transport layers often leads to high turn-on voltages and reduced overall device efficiency. Optimizing the energy level alignment across different layers remains a significant challenge for researchers and engineers in the field.

Stability and lifetime of QLEDs present another major hurdle. The degradation of quantum dots under electrical stress and exposure to oxygen and moisture significantly impacts the long-term performance and reliability of these devices. Developing robust encapsulation techniques and improving the intrinsic stability of quantum dots are crucial areas of ongoing research.

The efficiency roll-off at high current densities, known as efficiency droop, is also a persistent problem in QLEDs. This phenomenon limits the maximum brightness achievable while maintaining high efficiency, which is particularly important for display applications requiring high luminance levels.

Color purity and spectral stability pose additional challenges. While quantum dots offer narrow emission spectra, maintaining color purity over time and under various operating conditions remains difficult. This is especially true for blue-emitting quantum dots, which are crucial for achieving a wide color gamut in display applications.

Manufacturing scalability and cost-effectiveness are also significant barriers to the widespread adoption of QLED technology. Current production methods for high-quality quantum dots and the integration of these materials into device structures are often complex and expensive, limiting their commercial viability.

Addressing these efficiency challenges requires a multidisciplinary approach, combining advances in materials science, device physics, and manufacturing processes. Researchers are exploring various strategies, including novel quantum dot compositions, improved device architectures, and innovative fabrication techniques to overcome these limitations and unlock the full potential of QLED technology.

Current Energy Efficiency Solutions

01 Quantum dot structure optimization

Improving the structure of quantum dots in QLED devices can enhance energy efficiency. This includes optimizing the size, shape, and composition of quantum dots to increase light emission efficiency and reduce energy loss. Advanced manufacturing techniques and materials can be used to create more uniform and stable quantum dot structures.- Quantum dot structure optimization: Improving the structure of quantum dots can enhance energy efficiency in QLED devices. This includes optimizing the size, shape, and composition of quantum dots to increase light emission efficiency and reduce energy loss. Advanced manufacturing techniques and materials can be used to create more uniform and stable quantum dot structures.

- Electron transport layer enhancement: Enhancing the electron transport layer in QLED devices can improve energy efficiency. This involves developing new materials or modifying existing ones to facilitate better electron flow and reduce energy loss during charge transport. Optimizing the thickness and composition of this layer can lead to more efficient energy conversion.

- Light extraction techniques: Implementing advanced light extraction techniques can increase the overall energy efficiency of QLED displays. This includes using micro-lens arrays, photonic crystals, or nanostructured surfaces to reduce internal reflection and improve light output. These methods help to maximize the amount of light that escapes the device, reducing energy waste.

- Thermal management solutions: Developing effective thermal management solutions is crucial for maintaining QLED energy efficiency. This involves designing heat dissipation structures, using thermally conductive materials, and implementing advanced cooling systems. Proper thermal management prevents performance degradation and extends the lifespan of QLED devices, contributing to long-term energy efficiency.

- Color conversion layer optimization: Optimizing the color conversion layer in QLED displays can lead to improved energy efficiency. This includes developing new quantum dot materials with higher quantum yield, improving the distribution of quantum dots within the layer, and enhancing the interaction between blue light and quantum dots. These improvements result in more efficient color conversion and reduced energy loss.

02 Electron transport layer enhancement

Enhancing the electron transport layer in QLED devices can improve energy efficiency. This involves developing new materials or modifying existing ones to facilitate better electron flow and reduce energy loss during charge transport. Optimizing the thickness and composition of this layer can lead to more efficient energy conversion.Expand Specific Solutions03 Light extraction techniques

Implementing advanced light extraction techniques can increase the overall energy efficiency of QLED displays. This includes using micro-lens arrays, photonic crystals, or surface texturing to reduce internal reflection and improve light output. These methods help to maximize the amount of light emitted from the device, reducing energy waste.Expand Specific Solutions04 Thermal management solutions

Developing effective thermal management solutions is crucial for maintaining QLED energy efficiency. This involves designing heat dissipation structures, using thermally conductive materials, and implementing advanced cooling systems. Proper thermal management prevents performance degradation and extends the lifespan of QLED devices, ensuring sustained energy efficiency.Expand Specific Solutions05 Color conversion layer optimization

Optimizing the color conversion layer in QLED displays can lead to improved energy efficiency. This includes developing new quantum dot materials with higher quantum yield, improving the dispersion of quantum dots in the conversion layer, and optimizing the thickness and composition of the layer. These enhancements result in more efficient color conversion and reduced energy loss.Expand Specific Solutions

Key QLED Manufacturers

The energy-efficient QLED market is in a growth phase, with increasing demand for high-performance, low-power display technologies. The market size is expanding rapidly, driven by consumer electronics and commercial applications. Technologically, QLED is maturing, with companies like BOE Technology Group, Sharp Corp., and TCL China Star Optoelectronics leading innovation. Research institutions such as Zhejiang University and Henan University are contributing to advancements. Emerging players like Nanosys, Inc. and Suzhou Xingshuo Nanotechnology are focusing on quantum dot materials, while established firms like Apple, Inc. are exploring integration possibilities. The competitive landscape is diverse, with a mix of display manufacturers, material suppliers, and technology developers vying for market share and technological breakthroughs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary QLED technology called ADS Pro, which utilizes advanced quantum dot materials and precise light management techniques. Their approach involves optimizing the quantum dot layer structure and employing a unique backlight design to enhance energy efficiency. BOE's QLED panels incorporate a specialized color filter and light guide plate to minimize light loss and improve color accuracy. Additionally, they have implemented an intelligent local dimming algorithm to further reduce power consumption while maintaining high contrast ratios.

Strengths: Advanced quantum dot materials, precise light management, and intelligent local dimming for improved energy efficiency. Weaknesses: Potential higher production costs and complexity in manufacturing process.

Sharp Corp.

Technical Solution: Sharp has developed an innovative QLED technology called IGZO-QLED, which combines their proprietary IGZO (Indium Gallium Zinc Oxide) backplane technology with quantum dot enhancement. This hybrid approach allows for ultra-fine pixel control and reduced power consumption. Sharp's IGZO-QLED displays utilize a unique quantum dot color conversion layer that is optimized for energy efficiency. They have also implemented advanced local dimming techniques and a specialized optical stack to minimize light leakage and improve overall panel efficiency.

Strengths: Integration of IGZO technology for improved pixel control and power efficiency. Weaknesses: Potential limitations in scaling up production and higher initial costs.

QLED Efficiency Breakthroughs

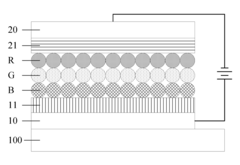

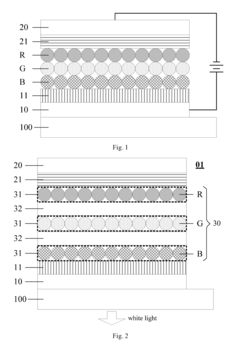

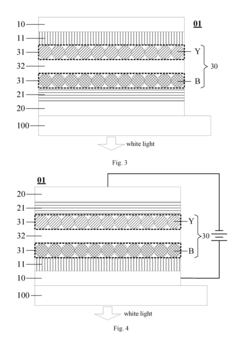

Light emitting device and fabricating method thereof, display device

PatentActiveUS20180054872A1

Innovation

- Incorporating a transparent insulating layer between neighboring QD light-emitting layers of different colors in a light-emitting device, which blocks high-energy exciton transfer and acts as a buffer to maintain light balance and prevent electric leakage.

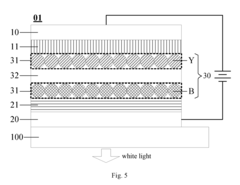

Display device and pixel lighting control method therefor

PatentPendingUS20240013710A1

Innovation

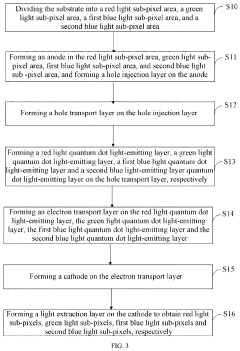

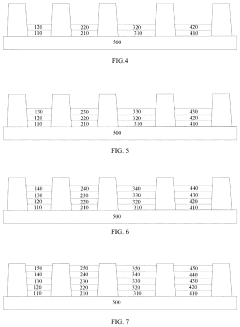

- A display device comprising a plurality of pixels, each including a red light sub-pixel, a green light sub-pixel, a first blue light sub-pixel, and a second blue light sub-pixel, where the first blue light sub-pixel is configured to emit light at high brightness and the second blue light sub-pixel is configured to emit light at low brightness, with the first blue light sub-pixel having high efficiency and the second blue light sub-pixel having a long lifetime, allowing for independent control based on brightness requirements.

Environmental Impact of QLEDs

The environmental impact of Quantum Dot Light-Emitting Diodes (QLEDs) is a crucial consideration in the development and adoption of this technology. As QLEDs gain prominence in display and lighting applications, their potential effects on the environment throughout their lifecycle must be carefully evaluated.

One of the primary environmental concerns associated with QLEDs is the use of heavy metals in quantum dot production. Cadmium-based quantum dots, in particular, have raised significant environmental and health concerns due to the toxic nature of cadmium. However, recent advancements in QLED technology have led to the development of cadmium-free alternatives, such as indium phosphide-based quantum dots, which offer a more environmentally friendly option.

The manufacturing process of QLEDs also contributes to their environmental footprint. The production of quantum dots and the assembly of QLED displays involve energy-intensive processes and the use of various chemicals. However, compared to traditional LED and OLED technologies, QLEDs have the potential for more efficient manufacturing processes, which could lead to reduced energy consumption and waste generation in the long term.

Energy efficiency is a key factor in assessing the environmental impact of QLEDs. These devices have demonstrated superior energy efficiency compared to conventional display technologies, particularly in terms of power consumption and brightness. The improved energy efficiency of QLEDs can contribute to reduced electricity usage and, consequently, lower greenhouse gas emissions associated with power generation.

The longevity of QLED devices is another important aspect to consider. QLEDs have shown promising results in terms of lifespan and resistance to degradation, potentially leading to reduced electronic waste generation. However, the end-of-life management of QLED products remains a challenge, as the recycling of quantum dot materials and other components requires specialized processes to prevent environmental contamination.

As QLED technology continues to evolve, researchers and manufacturers are focusing on developing more sustainable production methods and materials. This includes exploring bio-based quantum dots, improving recycling techniques, and optimizing device structures for enhanced efficiency and durability. These efforts aim to minimize the environmental impact of QLEDs throughout their lifecycle, from production to disposal.

In conclusion, while QLEDs offer significant advantages in terms of energy efficiency and display performance, their environmental impact remains a complex issue that requires ongoing research and innovation. As the technology matures, it is crucial to balance the benefits of QLEDs with sustainable practices to ensure their responsible development and implementation in various applications.

One of the primary environmental concerns associated with QLEDs is the use of heavy metals in quantum dot production. Cadmium-based quantum dots, in particular, have raised significant environmental and health concerns due to the toxic nature of cadmium. However, recent advancements in QLED technology have led to the development of cadmium-free alternatives, such as indium phosphide-based quantum dots, which offer a more environmentally friendly option.

The manufacturing process of QLEDs also contributes to their environmental footprint. The production of quantum dots and the assembly of QLED displays involve energy-intensive processes and the use of various chemicals. However, compared to traditional LED and OLED technologies, QLEDs have the potential for more efficient manufacturing processes, which could lead to reduced energy consumption and waste generation in the long term.

Energy efficiency is a key factor in assessing the environmental impact of QLEDs. These devices have demonstrated superior energy efficiency compared to conventional display technologies, particularly in terms of power consumption and brightness. The improved energy efficiency of QLEDs can contribute to reduced electricity usage and, consequently, lower greenhouse gas emissions associated with power generation.

The longevity of QLED devices is another important aspect to consider. QLEDs have shown promising results in terms of lifespan and resistance to degradation, potentially leading to reduced electronic waste generation. However, the end-of-life management of QLED products remains a challenge, as the recycling of quantum dot materials and other components requires specialized processes to prevent environmental contamination.

As QLED technology continues to evolve, researchers and manufacturers are focusing on developing more sustainable production methods and materials. This includes exploring bio-based quantum dots, improving recycling techniques, and optimizing device structures for enhanced efficiency and durability. These efforts aim to minimize the environmental impact of QLEDs throughout their lifecycle, from production to disposal.

In conclusion, while QLEDs offer significant advantages in terms of energy efficiency and display performance, their environmental impact remains a complex issue that requires ongoing research and innovation. As the technology matures, it is crucial to balance the benefits of QLEDs with sustainable practices to ensure their responsible development and implementation in various applications.

QLED Manufacturing Processes

QLED manufacturing processes have evolved significantly to enhance energy efficiency and overall performance. The production of Quantum Dot Light-Emitting Diodes (QLEDs) involves several critical steps, each contributing to the device's final characteristics and energy consumption.

The process begins with the synthesis of quantum dots, typically using colloidal chemistry methods. Precise control over size, shape, and composition is crucial for achieving the desired optical properties. Advanced techniques such as hot-injection and continuous flow reactors have been developed to improve uniformity and scalability.

Substrate preparation is the next vital step. High-quality glass or flexible substrates are cleaned and treated to ensure optimal adhesion and electrical properties. Plasma cleaning and UV-ozone treatments are commonly employed to remove contaminants and activate the surface.

Deposition of the various layers follows, often utilizing vacuum deposition techniques. The electron transport layer (ETL) is typically deposited first, followed by the quantum dot emissive layer. Thermal evaporation and solution processing are two primary methods used for QD layer deposition, with recent advancements in inkjet printing showing promise for large-scale manufacturing.

The hole transport layer (HTL) is then applied, usually through thermal evaporation or solution processing. Selection of appropriate HTL materials is critical for energy efficiency, as it affects charge injection and transport properties.

Cathode deposition completes the device structure, often using low work function metals like aluminum or calcium. Advanced techniques such as sputtering or e-beam evaporation are employed to ensure uniform and defect-free cathode layers.

Encapsulation is a crucial final step to protect the device from environmental degradation. Thin-film encapsulation techniques, such as atomic layer deposition (ALD), have shown significant improvements in device lifetime and stability.

Throughout the manufacturing process, stringent quality control measures are implemented to ensure consistency and performance. In-situ monitoring techniques, such as ellipsometry and photoluminescence spectroscopy, are used to optimize layer thicknesses and compositions.

Recent developments in QLED manufacturing have focused on enhancing energy efficiency. These include the integration of tandem structures to improve light outcoupling, the development of novel quantum dot materials with higher quantum yields, and the optimization of charge transport layers to reduce energy barriers.

The process begins with the synthesis of quantum dots, typically using colloidal chemistry methods. Precise control over size, shape, and composition is crucial for achieving the desired optical properties. Advanced techniques such as hot-injection and continuous flow reactors have been developed to improve uniformity and scalability.

Substrate preparation is the next vital step. High-quality glass or flexible substrates are cleaned and treated to ensure optimal adhesion and electrical properties. Plasma cleaning and UV-ozone treatments are commonly employed to remove contaminants and activate the surface.

Deposition of the various layers follows, often utilizing vacuum deposition techniques. The electron transport layer (ETL) is typically deposited first, followed by the quantum dot emissive layer. Thermal evaporation and solution processing are two primary methods used for QD layer deposition, with recent advancements in inkjet printing showing promise for large-scale manufacturing.

The hole transport layer (HTL) is then applied, usually through thermal evaporation or solution processing. Selection of appropriate HTL materials is critical for energy efficiency, as it affects charge injection and transport properties.

Cathode deposition completes the device structure, often using low work function metals like aluminum or calcium. Advanced techniques such as sputtering or e-beam evaporation are employed to ensure uniform and defect-free cathode layers.

Encapsulation is a crucial final step to protect the device from environmental degradation. Thin-film encapsulation techniques, such as atomic layer deposition (ALD), have shown significant improvements in device lifetime and stability.

Throughout the manufacturing process, stringent quality control measures are implemented to ensure consistency and performance. In-situ monitoring techniques, such as ellipsometry and photoluminescence spectroscopy, are used to optimize layer thicknesses and compositions.

Recent developments in QLED manufacturing have focused on enhancing energy efficiency. These include the integration of tandem structures to improve light outcoupling, the development of novel quantum dot materials with higher quantum yields, and the optimization of charge transport layers to reduce energy barriers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!