Enhancing Automotive Aesthetics Through V12 Engine Design

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution and Design Objectives

The V12 engine has long been synonymous with automotive excellence, representing the pinnacle of engineering prowess and aesthetic appeal in the automotive industry. Its evolution spans over a century, with each iteration pushing the boundaries of performance, efficiency, and design. The journey of the V12 engine began in the early 20th century, initially finding its place in luxury vehicles and high-performance racing cars.

As automotive technology progressed, the V12 engine evolved from a symbol of raw power to an emblem of refined engineering. Manufacturers like Ferrari, Lamborghini, and Aston Martin have been at the forefront of V12 development, continuously refining the engine's design to meet changing market demands and regulatory requirements. The evolution of the V12 has seen significant improvements in fuel efficiency, emissions control, and power output, all while maintaining its distinctive smooth operation and iconic sound.

In recent years, the focus of V12 engine development has shifted towards enhancing not only performance but also the overall aesthetic appeal of vehicles. This shift reflects a growing recognition that the engine is not merely a functional component but an integral part of a car's visual and experiential identity. Designers and engineers are now collaborating more closely than ever to create V12 engines that are not only powerful and efficient but also visually stunning.

The current objectives in V12 engine design are multifaceted. Firstly, there is a push towards further improving fuel efficiency and reducing emissions, in line with global environmental regulations. This challenge is being met through innovations in materials science, advanced combustion technologies, and hybrid integration. Secondly, there is a focus on weight reduction and compact design, aiming to optimize the engine's power-to-weight ratio and improve vehicle dynamics.

Another key objective is the enhancement of the engine's visual appeal. This includes designing engine bays that showcase the V12 as a piece of automotive art, with attention to detail in components like valve covers, intake manifolds, and even visible portions of the cylinder heads. The goal is to create an engine that is as captivating to look at as it is thrilling to drive.

Furthermore, acoustic engineering has become a crucial aspect of V12 design. Engineers are working to preserve and enhance the distinctive V12 sound while meeting increasingly stringent noise regulations. This involves careful tuning of exhaust systems and the use of active sound design technologies.

Lastly, as the automotive industry moves towards electrification, a significant objective for V12 engine design is to find ways to integrate hybrid technologies. This aims to combine the traditional appeal of the V12 with the efficiency and instant torque of electric motors, potentially extending the lifespan of this iconic engine configuration in an evolving automotive landscape.

As automotive technology progressed, the V12 engine evolved from a symbol of raw power to an emblem of refined engineering. Manufacturers like Ferrari, Lamborghini, and Aston Martin have been at the forefront of V12 development, continuously refining the engine's design to meet changing market demands and regulatory requirements. The evolution of the V12 has seen significant improvements in fuel efficiency, emissions control, and power output, all while maintaining its distinctive smooth operation and iconic sound.

In recent years, the focus of V12 engine development has shifted towards enhancing not only performance but also the overall aesthetic appeal of vehicles. This shift reflects a growing recognition that the engine is not merely a functional component but an integral part of a car's visual and experiential identity. Designers and engineers are now collaborating more closely than ever to create V12 engines that are not only powerful and efficient but also visually stunning.

The current objectives in V12 engine design are multifaceted. Firstly, there is a push towards further improving fuel efficiency and reducing emissions, in line with global environmental regulations. This challenge is being met through innovations in materials science, advanced combustion technologies, and hybrid integration. Secondly, there is a focus on weight reduction and compact design, aiming to optimize the engine's power-to-weight ratio and improve vehicle dynamics.

Another key objective is the enhancement of the engine's visual appeal. This includes designing engine bays that showcase the V12 as a piece of automotive art, with attention to detail in components like valve covers, intake manifolds, and even visible portions of the cylinder heads. The goal is to create an engine that is as captivating to look at as it is thrilling to drive.

Furthermore, acoustic engineering has become a crucial aspect of V12 design. Engineers are working to preserve and enhance the distinctive V12 sound while meeting increasingly stringent noise regulations. This involves careful tuning of exhaust systems and the use of active sound design technologies.

Lastly, as the automotive industry moves towards electrification, a significant objective for V12 engine design is to find ways to integrate hybrid technologies. This aims to combine the traditional appeal of the V12 with the efficiency and instant torque of electric motors, potentially extending the lifespan of this iconic engine configuration in an evolving automotive landscape.

Market Analysis for V12-Powered Luxury Vehicles

The market for V12-powered luxury vehicles represents a niche yet highly lucrative segment within the automotive industry. This segment caters to ultra-high-net-worth individuals who demand the pinnacle of performance, prestige, and exclusivity in their vehicles. The V12 engine, with its smooth power delivery and distinctive sound, has long been associated with the most prestigious automotive brands and models.

In recent years, the global market for V12-powered luxury vehicles has shown resilience despite broader industry trends towards downsizing and electrification. The primary markets for these vehicles include North America, Europe, and Asia, with emerging markets in the Middle East and China showing significant growth potential.

The demand for V12-powered vehicles is driven by several factors. Firstly, the exclusivity and status symbol associated with V12 engines continue to appeal to wealthy enthusiasts and collectors. Secondly, the unparalleled performance characteristics of V12 engines, including high power output and smooth operation, meet the expectations of discerning customers in the ultra-luxury segment.

However, the market faces challenges from increasingly stringent emissions regulations and a growing focus on environmental sustainability. This has led some manufacturers to explore hybrid V12 powertrains or consider phasing out V12 engines in favor of more efficient alternatives.

Despite these challenges, sales figures for V12-powered vehicles have remained stable in recent years, with some manufacturers reporting increased demand. This resilience can be attributed to the limited production numbers and the loyal customer base that values the unique characteristics of V12 engines.

The market landscape is dominated by a handful of prestigious brands, including Ferrari, Lamborghini, Rolls-Royce, and Aston Martin. These manufacturers have continued to invest in V12 engine development, often positioning their V12 models as flagship offerings that showcase their engineering prowess and brand heritage.

Looking ahead, the market for V12-powered luxury vehicles is expected to evolve. While traditional markets may face pressure from regulatory changes, emerging markets present new opportunities for growth. Additionally, the integration of advanced technologies, such as hybrid systems and lightweight materials, may help address environmental concerns while preserving the allure of V12 engines.

In conclusion, the market for V12-powered luxury vehicles remains a vital, albeit specialized, segment of the automotive industry. The enduring appeal of V12 engines, combined with the prestige they confer, suggests that there will continue to be demand for these vehicles among a select group of enthusiasts and collectors, even as the broader automotive landscape shifts towards electrification.

In recent years, the global market for V12-powered luxury vehicles has shown resilience despite broader industry trends towards downsizing and electrification. The primary markets for these vehicles include North America, Europe, and Asia, with emerging markets in the Middle East and China showing significant growth potential.

The demand for V12-powered vehicles is driven by several factors. Firstly, the exclusivity and status symbol associated with V12 engines continue to appeal to wealthy enthusiasts and collectors. Secondly, the unparalleled performance characteristics of V12 engines, including high power output and smooth operation, meet the expectations of discerning customers in the ultra-luxury segment.

However, the market faces challenges from increasingly stringent emissions regulations and a growing focus on environmental sustainability. This has led some manufacturers to explore hybrid V12 powertrains or consider phasing out V12 engines in favor of more efficient alternatives.

Despite these challenges, sales figures for V12-powered vehicles have remained stable in recent years, with some manufacturers reporting increased demand. This resilience can be attributed to the limited production numbers and the loyal customer base that values the unique characteristics of V12 engines.

The market landscape is dominated by a handful of prestigious brands, including Ferrari, Lamborghini, Rolls-Royce, and Aston Martin. These manufacturers have continued to invest in V12 engine development, often positioning their V12 models as flagship offerings that showcase their engineering prowess and brand heritage.

Looking ahead, the market for V12-powered luxury vehicles is expected to evolve. While traditional markets may face pressure from regulatory changes, emerging markets present new opportunities for growth. Additionally, the integration of advanced technologies, such as hybrid systems and lightweight materials, may help address environmental concerns while preserving the allure of V12 engines.

In conclusion, the market for V12-powered luxury vehicles remains a vital, albeit specialized, segment of the automotive industry. The enduring appeal of V12 engines, combined with the prestige they confer, suggests that there will continue to be demand for these vehicles among a select group of enthusiasts and collectors, even as the broader automotive landscape shifts towards electrification.

V12 Engine Technical Challenges and Constraints

The development of V12 engines for enhancing automotive aesthetics presents several significant technical challenges and constraints. One of the primary hurdles is the complexity of the engine design itself. With twelve cylinders arranged in a V-configuration, engineers must overcome issues related to balancing, vibration control, and thermal management. The intricate layout demands precise engineering to ensure smooth operation and optimal performance across a wide range of speeds.

Weight distribution poses another critical challenge in V12 engine design. The substantial mass of a twelve-cylinder engine can significantly impact the vehicle's center of gravity and overall handling characteristics. Engineers must employ innovative materials and design techniques to minimize weight while maintaining structural integrity and performance. This often involves the use of lightweight alloys and advanced manufacturing processes, which can increase production costs.

Fuel efficiency and emissions compliance represent ongoing constraints in V12 engine development. As global regulations become increasingly stringent, designers must incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation to improve fuel economy and reduce emissions. These systems add layers of complexity to the engine management and can potentially impact the engine's signature sound – a key aesthetic element of V12 engines.

Cooling system design presents unique challenges due to the increased heat generation of twelve cylinders. Engineers must develop sophisticated cooling strategies to maintain optimal operating temperatures across all cylinders, particularly those in the center of the V-configuration which are more prone to heat buildup. This often requires innovative radiator designs and carefully engineered coolant flow paths.

The packaging of a V12 engine within a vehicle's engine bay is another significant constraint. The length and width of these engines can limit design options for the vehicle's front-end architecture and impact aerodynamics. Engineers must work closely with vehicle designers to integrate the engine seamlessly while maintaining the desired aesthetic proportions and functional requirements of the vehicle.

Noise, vibration, and harshness (NVH) management is crucial in V12 engine design, particularly for luxury and high-performance vehicles where refinement is paramount. Achieving the desired balance between a powerful, emotive engine note and acceptable levels of vibration and cabin noise requires extensive engineering and testing. This often involves the use of advanced materials for engine mounts and sophisticated electronic control systems.

Finally, the cost and complexity of manufacturing V12 engines present ongoing challenges. The precision required in producing and assembling these engines demands specialized tooling and highly skilled labor, which can limit production scalability and increase unit costs. This constraint often relegates V12 engines to low-volume, high-end vehicle applications, further emphasizing their role in enhancing automotive aesthetics for premium and luxury segments.

Weight distribution poses another critical challenge in V12 engine design. The substantial mass of a twelve-cylinder engine can significantly impact the vehicle's center of gravity and overall handling characteristics. Engineers must employ innovative materials and design techniques to minimize weight while maintaining structural integrity and performance. This often involves the use of lightweight alloys and advanced manufacturing processes, which can increase production costs.

Fuel efficiency and emissions compliance represent ongoing constraints in V12 engine development. As global regulations become increasingly stringent, designers must incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation to improve fuel economy and reduce emissions. These systems add layers of complexity to the engine management and can potentially impact the engine's signature sound – a key aesthetic element of V12 engines.

Cooling system design presents unique challenges due to the increased heat generation of twelve cylinders. Engineers must develop sophisticated cooling strategies to maintain optimal operating temperatures across all cylinders, particularly those in the center of the V-configuration which are more prone to heat buildup. This often requires innovative radiator designs and carefully engineered coolant flow paths.

The packaging of a V12 engine within a vehicle's engine bay is another significant constraint. The length and width of these engines can limit design options for the vehicle's front-end architecture and impact aerodynamics. Engineers must work closely with vehicle designers to integrate the engine seamlessly while maintaining the desired aesthetic proportions and functional requirements of the vehicle.

Noise, vibration, and harshness (NVH) management is crucial in V12 engine design, particularly for luxury and high-performance vehicles where refinement is paramount. Achieving the desired balance between a powerful, emotive engine note and acceptable levels of vibration and cabin noise requires extensive engineering and testing. This often involves the use of advanced materials for engine mounts and sophisticated electronic control systems.

Finally, the cost and complexity of manufacturing V12 engines present ongoing challenges. The precision required in producing and assembling these engines demands specialized tooling and highly skilled labor, which can limit production scalability and increase unit costs. This constraint often relegates V12 engines to low-volume, high-end vehicle applications, further emphasizing their role in enhancing automotive aesthetics for premium and luxury segments.

Current V12 Engine Design Solutions

01 Engine design visualization and aesthetics

Advanced visualization techniques are employed to enhance the aesthetic appeal of V12 engines. This includes 3D modeling, rendering, and virtual reality applications to showcase the engine's design features and improve its visual impact. These methods allow for detailed examination and presentation of the engine's aesthetics before physical production.- Engine design visualization: Advanced visualization techniques are employed to enhance the aesthetic appeal of V12 engines. This includes 3D modeling, rendering, and virtual reality applications to showcase the engine's design features and allow for interactive exploration of its aesthetics. These tools help in presenting the engine's complex geometry and intricate details in a visually appealing manner.

- Customization and personalization: V12 engine aesthetics can be enhanced through customization and personalization options. This includes the use of various materials, colors, and finishes for engine components, as well as the integration of unique design elements. Customization allows for the creation of visually striking engines that reflect individual preferences or brand identities.

- Integration of lighting elements: Incorporating lighting elements into V12 engine designs can significantly enhance their visual appeal. This may include LED lighting systems, illuminated logos, or strategically placed accent lights to highlight key engine features. The use of lighting can create dramatic effects and draw attention to the engine's aesthetic qualities.

- Aerodynamic styling: Aesthetic considerations in V12 engine design often incorporate aerodynamic principles. This involves shaping engine components and covers to improve airflow while maintaining an attractive appearance. The integration of aerodynamic elements can result in a sleek and modern aesthetic that combines form with function.

- Historical and cultural design influences: V12 engine aesthetics can draw inspiration from historical and cultural design elements. This may include incorporating classic styling cues, retro-inspired details, or cultural motifs into the engine's visual design. Such influences can create a unique aesthetic that appeals to enthusiasts and collectors while paying homage to automotive heritage.

02 Customization and personalization of V12 engines

Customization options for V12 engines focus on enhancing their aesthetic appeal. This includes unique color schemes, surface finishes, and decorative elements that can be applied to engine components. The aim is to create visually striking and personalized engines that reflect individual preferences while maintaining performance.Expand Specific Solutions03 Integration of lighting and visual effects

Innovative lighting solutions are incorporated into V12 engine designs to enhance their visual appeal. This may include LED lighting systems, illuminated components, or dynamic lighting effects that highlight key features of the engine. These visual enhancements contribute to a more dramatic and eye-catching engine appearance.Expand Specific Solutions04 Materials selection for aesthetic enhancement

Careful selection of materials is employed to improve the aesthetic qualities of V12 engines. This includes the use of high-quality metals, carbon fiber, and other advanced materials that not only enhance performance but also contribute to a luxurious and visually appealing engine design. Surface treatments and finishes are also considered to optimize the engine's appearance.Expand Specific Solutions05 Engine cover and compartment design

The design of engine covers and compartments is crucial in showcasing the aesthetics of V12 engines. This involves creating sleek, aerodynamic shapes that complement the engine's appearance while also considering functional aspects such as cooling and accessibility. Transparent or partially transparent engine covers may be used to display the engine's beauty.Expand Specific Solutions

Key Manufacturers in V12 Engine Production

The V12 engine design market for enhancing automotive aesthetics is in a mature stage, with a relatively stable but niche market size. The technology is well-established, primarily dominated by luxury and high-performance automotive manufacturers. Companies like Ferrari SpA and Toyota Motor Corp. have significant expertise in V12 engine production, while others such as Honda Motor Co., Ltd. and Hyundai Motor Co., Ltd. have dabbled in this space. The market is characterized by high entry barriers due to the specialized nature of V12 engine design and production, limiting competition to established players with substantial R&D capabilities and brand prestige in the luxury automotive sector.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's approach to enhancing automotive aesthetics through V12 engine design is primarily conceptual, as they do not currently produce V12 engines for production vehicles. However, the company has explored V12 concepts in their luxury Genesis brand. Hyundai's design philosophy focuses on integrating advanced technologies with sleek, aerodynamic body styles. In their conceptual V12 designs, Hyundai emphasizes compact packaging to allow for lower hood lines and improved front-end aesthetics. The company explores the use of lightweight materials such as aluminum and carbon fiber to reduce engine weight and improve overall vehicle dynamics[9]. Hyundai also investigates hybrid V12 configurations, combining electric motors with a traditional V12 engine to enhance performance while meeting stringent emissions standards. The company's design approach includes integrating the engine as a visual element, potentially using transparent engine covers or strategically placed vents to showcase the V12 as a centerpiece of the vehicle's aesthetics[10].

Strengths: Innovative design approach, integration of hybrid technologies, and potential for disruption in the luxury market. Weaknesses: Lack of experience in V12 production and potential high development costs for a limited market segment.

Toyota Motor Corp.

Technical Solution: Toyota's approach to enhancing automotive aesthetics through V12 engine design is exemplified in their Lexus LFA supercar. The 4.8-liter V12 engine was developed in collaboration with Yamaha, featuring a compact design that allows for a lower hood line and improved aerodynamics[4]. Toyota employs a dry-sump lubrication system, enabling the engine to be mounted lower in the chassis, contributing to a more balanced and visually appealing silhouette. The engine incorporates titanium valves and ultra-lightweight rocker arms with integrated oil jets for reduced friction and increased reliability[5]. To enhance the auditory experience, Toyota developed a uniquely shaped exhaust manifold that produces a distinct engine note, complementing the car's visual aesthetics. The company also utilizes advanced thermal management techniques to optimize engine performance while maintaining sleek body lines[6].

Strengths: Advanced lightweight materials, innovative engine packaging, and integration with hybrid technology. Weaknesses: Limited experience in high-performance V12 production and higher development costs compared to their mainstream models.

Innovative V12 Engine Technologies

Internal-combustion engine

PatentInactiveUS7389759B2

Innovation

- An internal-combustion engine design featuring a cast aluminum air manifold that directly connects to cylinder heads, eliminating external piping by using pressure to seal connections and integrating cooling and lubrication channels, allowing for a more compact and lightweight structure with reduced parts.

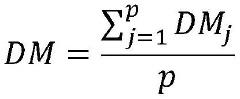

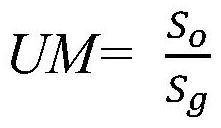

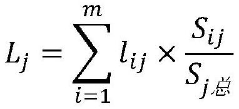

Engine design evaluation method based on machine vision

PatentActiveCN117152084A

Innovation

- Using a method based on machine vision, we collect images from different sides of the engine, perform preprocessing, image recognition and analysis, calculate density, integrity, cold and warm weighted values, color activity, regularity and balance, and combine these indicators to calculate the beauty. degree, and output the design evaluation results.

Environmental Impact of V12 Engines

The environmental impact of V12 engines is a critical consideration in the context of enhancing automotive aesthetics through their design. These powerful engines, known for their smooth operation and distinctive sound, have long been associated with luxury and high-performance vehicles. However, their environmental footprint has become increasingly scrutinized in recent years.

V12 engines typically consume more fuel than smaller engines, resulting in higher carbon dioxide emissions. The average V12 engine produces significantly more CO2 per kilometer driven compared to smaller, more efficient engines. This increased fuel consumption and emissions output contribute to global warming and climate change, raising concerns about the long-term sustainability of V12-powered vehicles.

Air pollution is another significant environmental issue associated with V12 engines. These engines emit higher levels of nitrogen oxides (NOx) and particulate matter, which can have detrimental effects on air quality and human health. In urban areas, where air pollution is already a pressing concern, the use of V12 engines exacerbates existing environmental challenges.

The manufacturing process of V12 engines also has environmental implications. The production of these complex powerplants requires more resources and energy compared to smaller engines, leading to increased industrial emissions and resource depletion. Additionally, the materials used in V12 engines, such as rare earth elements for catalytic converters, can have significant environmental impacts during extraction and processing.

Despite these environmental concerns, advancements in engine technology have led to improvements in V12 engine efficiency and emissions control. Modern V12 engines incorporate features like direct fuel injection, variable valve timing, and advanced engine management systems to optimize performance while reducing fuel consumption and emissions. Some manufacturers have also explored hybridization of V12 engines, combining them with electric motors to improve efficiency and reduce environmental impact.

The automotive industry's shift towards electrification poses a significant challenge to the future of V12 engines. As governments worldwide implement stricter emissions regulations and push for the adoption of electric vehicles, the long-term viability of V12 engines in production vehicles is uncertain. This transition may lead to V12 engines becoming increasingly rare, potentially enhancing their appeal as collectors' items or limited-production specialty engines.

In conclusion, while V12 engines continue to captivate automotive enthusiasts with their performance and aesthetic appeal, their environmental impact remains a significant concern. Balancing the desire for high-performance, aesthetically pleasing engines with the need for environmental sustainability will be a key challenge for automotive designers and engineers in the coming years.

V12 engines typically consume more fuel than smaller engines, resulting in higher carbon dioxide emissions. The average V12 engine produces significantly more CO2 per kilometer driven compared to smaller, more efficient engines. This increased fuel consumption and emissions output contribute to global warming and climate change, raising concerns about the long-term sustainability of V12-powered vehicles.

Air pollution is another significant environmental issue associated with V12 engines. These engines emit higher levels of nitrogen oxides (NOx) and particulate matter, which can have detrimental effects on air quality and human health. In urban areas, where air pollution is already a pressing concern, the use of V12 engines exacerbates existing environmental challenges.

The manufacturing process of V12 engines also has environmental implications. The production of these complex powerplants requires more resources and energy compared to smaller engines, leading to increased industrial emissions and resource depletion. Additionally, the materials used in V12 engines, such as rare earth elements for catalytic converters, can have significant environmental impacts during extraction and processing.

Despite these environmental concerns, advancements in engine technology have led to improvements in V12 engine efficiency and emissions control. Modern V12 engines incorporate features like direct fuel injection, variable valve timing, and advanced engine management systems to optimize performance while reducing fuel consumption and emissions. Some manufacturers have also explored hybridization of V12 engines, combining them with electric motors to improve efficiency and reduce environmental impact.

The automotive industry's shift towards electrification poses a significant challenge to the future of V12 engines. As governments worldwide implement stricter emissions regulations and push for the adoption of electric vehicles, the long-term viability of V12 engines in production vehicles is uncertain. This transition may lead to V12 engines becoming increasingly rare, potentially enhancing their appeal as collectors' items or limited-production specialty engines.

In conclusion, while V12 engines continue to captivate automotive enthusiasts with their performance and aesthetic appeal, their environmental impact remains a significant concern. Balancing the desire for high-performance, aesthetically pleasing engines with the need for environmental sustainability will be a key challenge for automotive designers and engineers in the coming years.

V12 Engine Sound Engineering

The sound engineering of V12 engines plays a crucial role in enhancing automotive aesthetics and creating a distinctive auditory experience. V12 engines are renowned for their smooth, powerful, and harmonious sound profile, which contributes significantly to the overall appeal of high-performance vehicles. The engineering process involves a complex interplay of various factors, including exhaust system design, intake manifold configuration, and engine firing order.

One of the key aspects of V12 engine sound engineering is the exhaust system design. Engineers carefully tune the length, diameter, and configuration of exhaust pipes to achieve the desired acoustic characteristics. The use of resonators and mufflers is strategically implemented to shape the sound waves and create a balanced tone. Advanced materials such as titanium or Inconel are often employed to enhance sound quality while reducing weight.

The intake manifold design also plays a vital role in shaping the engine's sound. By optimizing the length and cross-sectional area of intake runners, engineers can influence the air flow dynamics and consequently the engine's acoustic signature. Variable intake systems, which can adjust the runner length based on engine speed, allow for a broader range of pleasing sounds across different operating conditions.

Engine firing order is another critical factor in V12 sound engineering. The sequence in which cylinders fire affects the engine's vibration characteristics and harmonic content. Engineers experiment with various firing orders to achieve the optimal balance between smoothness and an engaging sound profile. Some manufacturers have even developed unique firing orders to create a distinctive auditory identity for their V12 engines.

Active sound design technologies have become increasingly prevalent in modern V12-powered vehicles. These systems use electronic sound generators and the vehicle's audio system to enhance or modify the engine's natural sound. While controversial among purists, these technologies allow for greater flexibility in sound tuning and can help meet stringent noise regulations without compromising the emotional appeal of the V12 engine note.

The pursuit of the perfect V12 engine sound often involves extensive testing and refinement. Acoustic engineers utilize sophisticated measurement tools and analysis software to capture and analyze engine sounds in various operating conditions. This data-driven approach allows for precise tuning and optimization of the engine's acoustic characteristics.

In conclusion, V12 engine sound engineering is a multifaceted discipline that combines technical expertise with artistic sensibility. The goal is to create an auditory experience that not only complements the vehicle's performance but also evokes an emotional response from drivers and enthusiasts alike. As automotive technology continues to evolve, the challenge for engineers will be to preserve and enhance the iconic V12 sound while adapting to changing regulatory landscapes and consumer expectations.

One of the key aspects of V12 engine sound engineering is the exhaust system design. Engineers carefully tune the length, diameter, and configuration of exhaust pipes to achieve the desired acoustic characteristics. The use of resonators and mufflers is strategically implemented to shape the sound waves and create a balanced tone. Advanced materials such as titanium or Inconel are often employed to enhance sound quality while reducing weight.

The intake manifold design also plays a vital role in shaping the engine's sound. By optimizing the length and cross-sectional area of intake runners, engineers can influence the air flow dynamics and consequently the engine's acoustic signature. Variable intake systems, which can adjust the runner length based on engine speed, allow for a broader range of pleasing sounds across different operating conditions.

Engine firing order is another critical factor in V12 sound engineering. The sequence in which cylinders fire affects the engine's vibration characteristics and harmonic content. Engineers experiment with various firing orders to achieve the optimal balance between smoothness and an engaging sound profile. Some manufacturers have even developed unique firing orders to create a distinctive auditory identity for their V12 engines.

Active sound design technologies have become increasingly prevalent in modern V12-powered vehicles. These systems use electronic sound generators and the vehicle's audio system to enhance or modify the engine's natural sound. While controversial among purists, these technologies allow for greater flexibility in sound tuning and can help meet stringent noise regulations without compromising the emotional appeal of the V12 engine note.

The pursuit of the perfect V12 engine sound often involves extensive testing and refinement. Acoustic engineers utilize sophisticated measurement tools and analysis software to capture and analyze engine sounds in various operating conditions. This data-driven approach allows for precise tuning and optimization of the engine's acoustic characteristics.

In conclusion, V12 engine sound engineering is a multifaceted discipline that combines technical expertise with artistic sensibility. The goal is to create an auditory experience that not only complements the vehicle's performance but also evokes an emotional response from drivers and enthusiasts alike. As automotive technology continues to evolve, the challenge for engineers will be to preserve and enhance the iconic V12 sound while adapting to changing regulatory landscapes and consumer expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!