Ethical and policy considerations for replacing centralized Haber–Bosch with decentralized PNF technologies

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNF vs Haber-Bosch: Background and Objectives

The Haber-Bosch process, developed in the early 20th century, revolutionized agriculture by enabling industrial-scale nitrogen fixation, converting atmospheric nitrogen into ammonia for fertilizer production. This centralized process currently accounts for approximately 1-2% of global energy consumption and contributes significantly to greenhouse gas emissions, with estimates suggesting it is responsible for about 1.4% of global CO2 emissions. Despite these environmental concerns, the Haber-Bosch process remains fundamental to global food security, supporting roughly 50% of the world's food production through synthetic fertilizers.

Plasma-enabled Nitrogen Fixation (PNF) technologies represent an emerging alternative approach that could potentially decentralize ammonia production. Unlike the Haber-Bosch process, which requires high temperatures (400-500°C) and pressures (150-300 bar), PNF operates at ambient conditions by using non-thermal plasma to break the strong nitrogen triple bond. This fundamental difference creates opportunities for smaller-scale, distributed production systems that could be powered by renewable energy sources.

The technological evolution in this field has accelerated in the past decade, with significant breakthroughs in catalyst development, plasma reactor design, and energy efficiency improvements. Research institutions and startups across North America, Europe, and East Asia have demonstrated increasingly viable PNF systems, though commercial-scale implementation remains limited. The trajectory suggests a potential inflection point in the next 5-10 years as efficiency continues to improve and costs decrease.

The primary objective of this technical research is to evaluate the ethical implications and policy considerations associated with transitioning from centralized Haber-Bosch facilities to decentralized PNF technologies. This includes assessing the environmental impact reduction potential, analyzing the socioeconomic consequences for agricultural communities, and identifying regulatory frameworks that could either facilitate or hinder this transition.

Secondary objectives include mapping the current technological readiness levels of various PNF approaches, identifying critical barriers to widespread adoption, and developing scenarios for potential implementation pathways across different regional contexts. The analysis aims to provide a comprehensive understanding of how policy interventions might shape the ethical outcomes of this technological transition, particularly regarding food security, environmental justice, and economic equity in both developed and developing agricultural economies.

This research acknowledges the complex interplay between technological capabilities, market forces, regulatory environments, and ethical considerations that will ultimately determine whether and how PNF technologies might complement or replace the century-old Haber-Bosch process in the global nitrogen economy.

Plasma-enabled Nitrogen Fixation (PNF) technologies represent an emerging alternative approach that could potentially decentralize ammonia production. Unlike the Haber-Bosch process, which requires high temperatures (400-500°C) and pressures (150-300 bar), PNF operates at ambient conditions by using non-thermal plasma to break the strong nitrogen triple bond. This fundamental difference creates opportunities for smaller-scale, distributed production systems that could be powered by renewable energy sources.

The technological evolution in this field has accelerated in the past decade, with significant breakthroughs in catalyst development, plasma reactor design, and energy efficiency improvements. Research institutions and startups across North America, Europe, and East Asia have demonstrated increasingly viable PNF systems, though commercial-scale implementation remains limited. The trajectory suggests a potential inflection point in the next 5-10 years as efficiency continues to improve and costs decrease.

The primary objective of this technical research is to evaluate the ethical implications and policy considerations associated with transitioning from centralized Haber-Bosch facilities to decentralized PNF technologies. This includes assessing the environmental impact reduction potential, analyzing the socioeconomic consequences for agricultural communities, and identifying regulatory frameworks that could either facilitate or hinder this transition.

Secondary objectives include mapping the current technological readiness levels of various PNF approaches, identifying critical barriers to widespread adoption, and developing scenarios for potential implementation pathways across different regional contexts. The analysis aims to provide a comprehensive understanding of how policy interventions might shape the ethical outcomes of this technological transition, particularly regarding food security, environmental justice, and economic equity in both developed and developing agricultural economies.

This research acknowledges the complex interplay between technological capabilities, market forces, regulatory environments, and ethical considerations that will ultimately determine whether and how PNF technologies might complement or replace the century-old Haber-Bosch process in the global nitrogen economy.

Market Analysis for Decentralized Nitrogen Fixation

The global market for decentralized nitrogen fixation technologies is experiencing significant growth potential as agricultural and industrial sectors seek more sustainable alternatives to the traditional Haber-Bosch process. Current market assessments indicate that the decentralized nitrogen fixation sector could reach substantial market value within the next decade, driven by increasing environmental regulations and the rising costs of conventional fertilizer production.

The primary market segments for decentralized Plasma Nitrogen Fixation (PNF) technologies include small to medium-scale agricultural operations, particularly in regions with limited access to centralized fertilizer distribution networks. Developing countries represent a particularly promising market, where infrastructure limitations often create fertilizer access challenges and price volatility. These regions could benefit significantly from localized production capabilities that reduce dependency on global supply chains.

Market demand analysis reveals strong interest from organic farming operations, which constitute one of the fastest-growing agricultural sectors globally. These operations prioritize sustainable input sources and are willing to adopt innovative technologies that align with their ecological principles. Additionally, remote agricultural communities and regions with unreliable transportation infrastructure demonstrate substantial demand potential for on-site nitrogen fixation solutions.

Competitive landscape assessment shows that while several startups and research institutions are developing decentralized nitrogen fixation technologies, the market remains relatively fragmented with no dominant players. This presents significant opportunities for new entrants with innovative approaches. Current market penetration of decentralized technologies remains limited, primarily due to technical challenges and cost considerations compared to conventional fertilizers.

Economic analysis indicates that while initial capital costs for decentralized PNF systems may be higher than traditional fertilizer purchasing, the long-term operational economics could be favorable, particularly as renewable energy costs continue to decline. The technology offers potential for significant cost advantages in regions with high fertilizer import costs or unreliable supply chains.

Market adoption barriers include technical reliability concerns, farmer familiarity with conventional fertilizers, and the need for specialized knowledge to operate decentralized systems. However, these barriers are gradually diminishing as technology improves and demonstration projects prove effectiveness in real-world conditions.

Growth projections suggest that decentralized nitrogen fixation technologies could capture a meaningful share of the global nitrogen fertilizer market within the next decade, particularly in niche applications and regions where conventional fertilizer access is challenging or expensive. The market is expected to follow an S-curve adoption pattern, with accelerated uptake as technology costs decrease and performance reliability increases.

The primary market segments for decentralized Plasma Nitrogen Fixation (PNF) technologies include small to medium-scale agricultural operations, particularly in regions with limited access to centralized fertilizer distribution networks. Developing countries represent a particularly promising market, where infrastructure limitations often create fertilizer access challenges and price volatility. These regions could benefit significantly from localized production capabilities that reduce dependency on global supply chains.

Market demand analysis reveals strong interest from organic farming operations, which constitute one of the fastest-growing agricultural sectors globally. These operations prioritize sustainable input sources and are willing to adopt innovative technologies that align with their ecological principles. Additionally, remote agricultural communities and regions with unreliable transportation infrastructure demonstrate substantial demand potential for on-site nitrogen fixation solutions.

Competitive landscape assessment shows that while several startups and research institutions are developing decentralized nitrogen fixation technologies, the market remains relatively fragmented with no dominant players. This presents significant opportunities for new entrants with innovative approaches. Current market penetration of decentralized technologies remains limited, primarily due to technical challenges and cost considerations compared to conventional fertilizers.

Economic analysis indicates that while initial capital costs for decentralized PNF systems may be higher than traditional fertilizer purchasing, the long-term operational economics could be favorable, particularly as renewable energy costs continue to decline. The technology offers potential for significant cost advantages in regions with high fertilizer import costs or unreliable supply chains.

Market adoption barriers include technical reliability concerns, farmer familiarity with conventional fertilizers, and the need for specialized knowledge to operate decentralized systems. However, these barriers are gradually diminishing as technology improves and demonstration projects prove effectiveness in real-world conditions.

Growth projections suggest that decentralized nitrogen fixation technologies could capture a meaningful share of the global nitrogen fertilizer market within the next decade, particularly in niche applications and regions where conventional fertilizer access is challenging or expensive. The market is expected to follow an S-curve adoption pattern, with accelerated uptake as technology costs decrease and performance reliability increases.

Technical Barriers and Global Development Status

The global transition from centralized Haber-Bosch (HB) processes to decentralized Plasma Nitrogen Fixation (PNF) technologies faces significant technical barriers. Current PNF systems demonstrate energy efficiency rates of only 2-3% compared to the 50-60% efficiency of industrial HB processes. This substantial efficiency gap represents the primary technical obstacle to widespread adoption, as it directly impacts economic viability and environmental benefits.

Material limitations constitute another major challenge. PNF reactors require electrodes capable of withstanding extreme plasma conditions while maintaining catalytic properties. Current electrode materials suffer from rapid degradation under plasma conditions, with typical lifespans of only 500-1000 operating hours before requiring replacement. This degradation significantly increases maintenance costs and reduces system reliability.

Scale-up challenges persist across different geographical regions. Laboratory-scale PNF systems producing grams of fixed nitrogen must be scaled to agricultural requirements of kilograms or tons. The physics of plasma discharges often don't scale linearly, creating engineering complexities that vary by implementation context and available infrastructure.

Globally, PNF technology development shows significant regional disparities. North American and European research institutions lead in fundamental plasma physics research and prototype development, with approximately 65% of published research originating from these regions. Asian countries, particularly China and Japan, are rapidly accelerating their research programs, focusing on novel electrode materials and system integration approaches.

Developing nations, which could benefit most from decentralized nitrogen fixation, currently contribute less than 5% to global PNF research. This creates a concerning technology access gap that may perpetuate agricultural inequalities if not addressed through international collaboration and technology transfer initiatives.

Regulatory frameworks for PNF technologies remain underdeveloped worldwide. Only 12 countries have established specific safety and performance standards for agricultural plasma technologies, creating uncertainty for manufacturers and potential adopters. This regulatory vacuum slows commercialization efforts and investment, particularly in regions with limited technical governance capacity.

The intellectual property landscape shows concentration among a few key players, with five multinational corporations and three research universities holding 70% of core PNF patents. This concentration raises concerns about technology access and affordability, especially for smallholder farmers in developing regions who might benefit most from decentralized nitrogen fixation capabilities.

Material limitations constitute another major challenge. PNF reactors require electrodes capable of withstanding extreme plasma conditions while maintaining catalytic properties. Current electrode materials suffer from rapid degradation under plasma conditions, with typical lifespans of only 500-1000 operating hours before requiring replacement. This degradation significantly increases maintenance costs and reduces system reliability.

Scale-up challenges persist across different geographical regions. Laboratory-scale PNF systems producing grams of fixed nitrogen must be scaled to agricultural requirements of kilograms or tons. The physics of plasma discharges often don't scale linearly, creating engineering complexities that vary by implementation context and available infrastructure.

Globally, PNF technology development shows significant regional disparities. North American and European research institutions lead in fundamental plasma physics research and prototype development, with approximately 65% of published research originating from these regions. Asian countries, particularly China and Japan, are rapidly accelerating their research programs, focusing on novel electrode materials and system integration approaches.

Developing nations, which could benefit most from decentralized nitrogen fixation, currently contribute less than 5% to global PNF research. This creates a concerning technology access gap that may perpetuate agricultural inequalities if not addressed through international collaboration and technology transfer initiatives.

Regulatory frameworks for PNF technologies remain underdeveloped worldwide. Only 12 countries have established specific safety and performance standards for agricultural plasma technologies, creating uncertainty for manufacturers and potential adopters. This regulatory vacuum slows commercialization efforts and investment, particularly in regions with limited technical governance capacity.

The intellectual property landscape shows concentration among a few key players, with five multinational corporations and three research universities holding 70% of core PNF patents. This concentration raises concerns about technology access and affordability, especially for smallholder farmers in developing regions who might benefit most from decentralized nitrogen fixation capabilities.

Current Decentralized PNF Implementation Approaches

01 Portable and decentralized PNF systems

Portable plasma nitrogen fixation systems enable decentralized production of nitrogen compounds in remote or agricultural areas. These compact units can be deployed on-site, reducing dependency on centralized fertilizer production and distribution networks. The systems are designed for mobility and ease of use, allowing farmers and small-scale operators to produce nitrogen fertilizers locally, cutting transportation costs and environmental impact.- Portable and decentralized plasma nitrogen fixation systems: Decentralized plasma nitrogen fixation technologies enable on-site production of nitrogen compounds without relying on centralized facilities. These portable systems can be deployed in remote agricultural areas, allowing farmers to produce their own nitrogen fertilizers locally. The technology typically includes compact plasma reactors that can operate with minimal infrastructure requirements, making nitrogen fixation accessible in areas without industrial facilities.

- Renewable energy integration with plasma nitrogen fixation: Integration of renewable energy sources with plasma nitrogen fixation technologies enables sustainable and decentralized production of nitrogen compounds. These systems can utilize solar, wind, or other renewable energy sources to power plasma reactors, making them independent from the conventional power grid. This approach reduces carbon footprint while enabling nitrogen fixation in remote locations with limited access to traditional energy infrastructure.

- Modular plasma reactor designs for scalable nitrogen fixation: Modular plasma reactor designs allow for scalable and decentralized nitrogen fixation operations. These systems can be expanded or reduced based on local needs, making them suitable for various applications from small farms to larger agricultural operations. The modular approach enables easier maintenance, replacement of components, and gradual investment in nitrogen fixation capacity, supporting decentralized implementation across different scales.

- Smart control systems for decentralized plasma nitrogen fixation: Advanced control systems enhance the efficiency and usability of decentralized plasma nitrogen fixation technologies. These smart systems incorporate sensors, automation, and data analytics to optimize the nitrogen fixation process under varying conditions. Remote monitoring and control capabilities allow operators to manage multiple decentralized units efficiently, while predictive maintenance features ensure reliable operation in remote locations without specialized technical support.

- Plasma catalysis techniques for enhanced nitrogen fixation efficiency: Innovative plasma catalysis techniques improve the efficiency of decentralized nitrogen fixation processes. These approaches combine plasma technology with catalytic materials to reduce energy requirements and increase nitrogen conversion rates. By enhancing reaction efficiency, these technologies make decentralized plasma nitrogen fixation more economically viable for small-scale applications, supporting wider adoption of localized fertilizer production systems.

02 Renewable energy integration with PNF technology

Integration of renewable energy sources with plasma nitrogen fixation technologies enables sustainable and decentralized nitrogen production. These systems utilize solar, wind, or other renewable energy to power plasma generators, making nitrogen fixation possible in off-grid locations. This approach reduces carbon footprint while enabling distributed production models that can operate independently from fossil fuel-based energy infrastructure.Expand Specific Solutions03 Modular PNF reactor designs for scalable deployment

Modular plasma nitrogen fixation reactor designs allow for scalable and flexible deployment across various settings. These systems feature standardized components that can be assembled in different configurations based on production needs. The modular approach enables gradual capacity expansion and facilitates maintenance, making PNF technology more accessible for decentralized applications from small farms to community-level implementations.Expand Specific Solutions04 Smart control systems for decentralized PNF operations

Advanced control and monitoring systems enable efficient operation of decentralized plasma nitrogen fixation units. These smart systems incorporate sensors, IoT connectivity, and automated process control to optimize nitrogen production while minimizing energy consumption. Remote monitoring capabilities allow for technical support from afar, making it feasible to operate decentralized units with minimal specialized personnel on-site.Expand Specific Solutions05 Plasma catalysis methods for improved nitrogen fixation efficiency

Novel plasma catalysis methods enhance the efficiency of nitrogen fixation processes, making smaller decentralized units more viable. These approaches combine plasma technology with specialized catalysts to reduce energy requirements and increase nitrogen conversion rates. By improving process efficiency, these innovations enable smaller-scale, distributed PNF systems that can operate economically at lower production volumes suitable for localized applications.Expand Specific Solutions

Industry Leaders in Alternative Fertilizer Production

The transition from centralized Haber-Bosch to decentralized Plasma Nitrogen Fixation (PNF) technologies represents an emerging market in early development stages. While the global nitrogen fertilizer market exceeds $100 billion annually, PNF technologies remain in the research and demonstration phase. Technologically, companies like Apple, Oracle, and MIT are exploring digital monitoring and control systems for PNF implementation, while energy companies including State Grid Corp. of China and Saudi Aramco are investigating integration with renewable energy systems. Research institutions such as Massachusetts Institute of Technology and Rice University lead fundamental innovation, while telecommunications giants like Ericsson, Nokia, and Huawei could provide connectivity solutions for distributed PNF systems. The ethical and policy landscape requires balancing agricultural productivity with environmental sustainability, necessitating collaborative frameworks between technology providers and regulatory bodies.

Agency for Science, Technology & Research

Technical Solution: Singapore's A*STAR has developed an innovative microreactor-based nitrogen fixation technology designed specifically for urban and peri-urban agricultural applications. Their system utilizes advanced nanocatalysts combined with precisely controlled plasma generation to achieve nitrogen fixation under mild conditions. A*STAR's approach emphasizes miniaturization and automation, creating compact units that can be deployed in vertical farming operations, community gardens, and other space-constrained environments. The technology incorporates AI-driven control systems that optimize energy usage based on real-time monitoring of soil conditions and plant requirements. A*STAR has conducted extensive policy research on the regulatory frameworks needed to support distributed fertilizer production in densely populated regions, addressing safety concerns and integration with existing agricultural practices.

Strengths: Highly compact and automated system suitable for urban environments; precision application reduces fertilizer waste; sophisticated control systems optimize energy usage. Weaknesses: Higher unit production costs than larger systems; limited production capacity per unit; requires reliable electricity infrastructure.

National Technology & Engineering Solutions of Sandia LLC

Technical Solution: Sandia National Laboratories has developed a solar-thermal nitrogen fixation technology that represents a hybrid approach between conventional Haber-Bosch and purely electrical PNF systems. Their innovation uses concentrated solar power to generate the high temperatures needed for nitrogen activation, while employing novel catalysts that operate at lower pressures than conventional processes. The system incorporates thermal storage components that allow for continuous operation despite solar intermittency. Sandia's approach includes comprehensive system modeling that optimizes deployment based on local solar resources, agricultural needs, and infrastructure constraints. Their research extends beyond technical development to include detailed policy frameworks for transitioning rural communities to decentralized fertilizer production, addressing regulatory barriers, safety standards, and economic incentives needed to support adoption.

Strengths: Highly efficient use of solar thermal energy; reduced dependence on electrical infrastructure; thermal storage enables consistent production. Weaknesses: Geographic limitations based on solar resource availability; larger physical footprint than purely electrical systems; more complex installation requirements than simpler PNF technologies.

Key Patents and Innovations in PNF Technologies

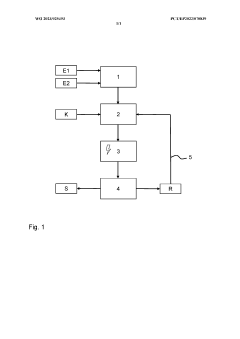

Method of nitrogen fixation in a plasma reactor

PatentWO2023025493A1

Innovation

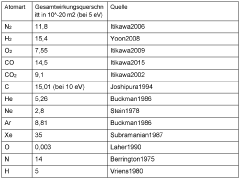

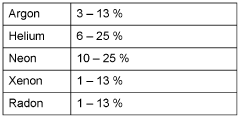

- A plasma reactor process that calculates optimal mixing ratios of gaseous starting materials based on total cross sections for ionization and excitation, using gaseous catalysts to achieve high electron densities and initiate chemical reactions efficiently, allowing for three-dimensional reaction sites and reduced energy input.

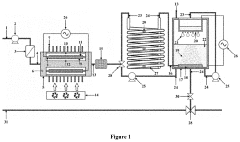

Method And Apparatus For Producing Liquid Nitrogen Fertilizer And Plasma Activated Water

PatentActiveUS20210130246A1

Innovation

- A method and apparatus using two plasma reactors in tandem, with cylindrical electrodes and a dielectric tube for stable dielectric barrier discharge, and a secondary plasma reactor with liquid electrodes to enhance NOx gas absorption and reduce maintenance, coupled with an absorption unit and recirculation system to increase the efficiency of nitrogen compound production.

Regulatory Framework for Agricultural Technologies

The regulatory landscape for agricultural technologies is undergoing significant transformation as decentralized Plasma Nitrogen Fixation (PNF) technologies emerge as alternatives to the centralized Haber-Bosch process. Current regulatory frameworks primarily address conventional fertilizer production, distribution, and application, with limited provisions for novel nitrogen fixation technologies operating at local scales.

National agricultural policies in major food-producing countries have historically favored centralized production systems through subsidies, tax incentives, and infrastructure support. These policies create inherent barriers to the adoption of decentralized technologies, requiring comprehensive regulatory reform to establish a level playing field for PNF innovations.

Environmental regulations present both challenges and opportunities for PNF technologies. While these technologies promise reduced greenhouse gas emissions and nitrogen runoff compared to conventional fertilizers, they must navigate complex permitting processes designed for industrial-scale operations. Regulatory bodies need to develop proportionate frameworks that maintain environmental safeguards while accommodating the distributed nature of PNF systems.

Safety standards represent another critical regulatory consideration. The Haber-Bosch process operates under established industrial safety protocols, whereas decentralized PNF technologies introduce new operational paradigms requiring appropriate safety guidelines. Regulatory agencies must develop standards addressing the unique risk profiles of on-farm nitrogen fixation, including operator training requirements and equipment certification processes.

Intellectual property protection frameworks significantly impact technology diffusion pathways. Current patent landscapes favor large agrochemical corporations with extensive legal resources, potentially limiting small-scale innovation in PNF technologies. Regulatory reforms should consider alternative intellectual property models that balance innovation incentives with accessibility for smallholder farmers and developing regions.

International trade regulations add another layer of complexity. As decentralized PNF technologies reduce dependence on imported fertilizers, existing trade agreements and tariff structures may require adjustment. Regulatory harmonization across borders becomes essential to prevent technical barriers to trade while ensuring consistent safety and environmental standards.

Certification and quality assurance mechanisms represent a final regulatory frontier. Unlike standardized commercial fertilizers with established quality metrics, PNF technologies produce nitrogen inputs with potentially variable characteristics. Developing appropriate testing protocols and performance standards will be crucial for farmer adoption and regulatory compliance, requiring collaboration between industry stakeholders, research institutions, and regulatory authorities.

National agricultural policies in major food-producing countries have historically favored centralized production systems through subsidies, tax incentives, and infrastructure support. These policies create inherent barriers to the adoption of decentralized technologies, requiring comprehensive regulatory reform to establish a level playing field for PNF innovations.

Environmental regulations present both challenges and opportunities for PNF technologies. While these technologies promise reduced greenhouse gas emissions and nitrogen runoff compared to conventional fertilizers, they must navigate complex permitting processes designed for industrial-scale operations. Regulatory bodies need to develop proportionate frameworks that maintain environmental safeguards while accommodating the distributed nature of PNF systems.

Safety standards represent another critical regulatory consideration. The Haber-Bosch process operates under established industrial safety protocols, whereas decentralized PNF technologies introduce new operational paradigms requiring appropriate safety guidelines. Regulatory agencies must develop standards addressing the unique risk profiles of on-farm nitrogen fixation, including operator training requirements and equipment certification processes.

Intellectual property protection frameworks significantly impact technology diffusion pathways. Current patent landscapes favor large agrochemical corporations with extensive legal resources, potentially limiting small-scale innovation in PNF technologies. Regulatory reforms should consider alternative intellectual property models that balance innovation incentives with accessibility for smallholder farmers and developing regions.

International trade regulations add another layer of complexity. As decentralized PNF technologies reduce dependence on imported fertilizers, existing trade agreements and tariff structures may require adjustment. Regulatory harmonization across borders becomes essential to prevent technical barriers to trade while ensuring consistent safety and environmental standards.

Certification and quality assurance mechanisms represent a final regulatory frontier. Unlike standardized commercial fertilizers with established quality metrics, PNF technologies produce nitrogen inputs with potentially variable characteristics. Developing appropriate testing protocols and performance standards will be crucial for farmer adoption and regulatory compliance, requiring collaboration between industry stakeholders, research institutions, and regulatory authorities.

Environmental Impact Assessment

The transition from centralized Haber-Bosch processes to decentralized Plasma Nitrogen Fixation (PNF) technologies represents a significant shift in ammonia production with profound environmental implications. Current Haber-Bosch facilities contribute approximately 1.4% of global CO2 emissions, requiring high temperatures (400-500°C) and pressures (150-300 bar), while consuming 1-2% of the world's total energy production. This centralized model necessitates extensive transportation networks, further increasing the carbon footprint of fertilizer distribution.

Decentralized PNF technologies offer substantial environmental benefits through dramatic reductions in greenhouse gas emissions. Operating at ambient temperatures and pressures, PNF systems can potentially reduce the carbon intensity of ammonia production by 60-90% when powered by renewable energy sources. This represents a critical pathway toward meeting international climate commitments under the Paris Agreement and supporting agricultural sustainability goals.

Water resource impacts also differ significantly between these technologies. Conventional Haber-Bosch processes require substantial water inputs for cooling and steam generation, with water consumption estimated at 20-25 tons per ton of ammonia produced. PNF technologies generally demonstrate lower water requirements, though specific consumption varies by implementation. This advantage becomes particularly significant in water-stressed agricultural regions where fertilizer is most needed.

Land use considerations reveal additional environmental dimensions. Centralized production creates concentrated environmental impacts around industrial facilities, including air pollution, soil contamination, and potential groundwater issues. Decentralized PNF systems distribute these impacts across multiple smaller facilities, potentially reducing acute environmental stress at any single location, though requiring careful management to prevent cumulative effects across multiple sites.

Biodiversity impacts warrant careful assessment in this technological transition. While both systems affect ecosystems through nitrogen pollution, decentralized production could either mitigate or exacerbate these effects depending on implementation. Localized production may reduce transportation-related pollution incidents but could introduce new ecological pressures in previously unaffected areas if improperly managed.

Lifecycle assessment studies indicate that PNF technologies could reduce overall environmental footprints by 40-70% compared to conventional systems when considering combined factors of energy use, emissions, resource consumption, and waste generation. However, these benefits depend heavily on renewable energy integration and operational efficiency of deployed systems.

The environmental resilience of decentralized systems presents another advantage, as distributed production networks demonstrate greater adaptability to climate disruptions and extreme weather events. This resilience factor becomes increasingly important as climate change intensifies, potentially securing more stable fertilizer supplies for agricultural systems facing environmental uncertainties.

Decentralized PNF technologies offer substantial environmental benefits through dramatic reductions in greenhouse gas emissions. Operating at ambient temperatures and pressures, PNF systems can potentially reduce the carbon intensity of ammonia production by 60-90% when powered by renewable energy sources. This represents a critical pathway toward meeting international climate commitments under the Paris Agreement and supporting agricultural sustainability goals.

Water resource impacts also differ significantly between these technologies. Conventional Haber-Bosch processes require substantial water inputs for cooling and steam generation, with water consumption estimated at 20-25 tons per ton of ammonia produced. PNF technologies generally demonstrate lower water requirements, though specific consumption varies by implementation. This advantage becomes particularly significant in water-stressed agricultural regions where fertilizer is most needed.

Land use considerations reveal additional environmental dimensions. Centralized production creates concentrated environmental impacts around industrial facilities, including air pollution, soil contamination, and potential groundwater issues. Decentralized PNF systems distribute these impacts across multiple smaller facilities, potentially reducing acute environmental stress at any single location, though requiring careful management to prevent cumulative effects across multiple sites.

Biodiversity impacts warrant careful assessment in this technological transition. While both systems affect ecosystems through nitrogen pollution, decentralized production could either mitigate or exacerbate these effects depending on implementation. Localized production may reduce transportation-related pollution incidents but could introduce new ecological pressures in previously unaffected areas if improperly managed.

Lifecycle assessment studies indicate that PNF technologies could reduce overall environmental footprints by 40-70% compared to conventional systems when considering combined factors of energy use, emissions, resource consumption, and waste generation. However, these benefits depend heavily on renewable energy integration and operational efficiency of deployed systems.

The environmental resilience of decentralized systems presents another advantage, as distributed production networks demonstrate greater adaptability to climate disruptions and extreme weather events. This resilience factor becomes increasingly important as climate change intensifies, potentially securing more stable fertilizer supplies for agricultural systems facing environmental uncertainties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!