Passivation layers and protective coatings to extend photocatalyst lifetime in field reactors

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalyst Passivation Background and Objectives

Photocatalysis has emerged as a promising technology for environmental remediation, renewable energy production, and sustainable chemical synthesis since its discovery in the early 1970s. The field gained significant momentum following Fujishima and Honda's groundbreaking work on water splitting using TiO2 electrodes under UV light irradiation. Over the past five decades, research has expanded from simple semiconductor materials to complex engineered photocatalytic systems with enhanced efficiency and broader spectral response.

The evolution of photocatalytic technology has been marked by several key developments, including the discovery of visible light-active materials, hierarchical nanostructures, and heterojunction systems. Despite these advances, the practical implementation of photocatalysts in field reactors has been severely limited by their operational stability and lifetime. Most laboratory-developed photocatalysts experience rapid deactivation under real-world conditions, with performance degradation occurring within hours or days rather than the months or years required for commercial viability.

This stability challenge stems from multiple degradation mechanisms, including photocorrosion, surface poisoning, leaching of active components, and structural collapse during continuous operation. Photocorrosion, in particular, represents a fundamental challenge for many promising semiconductor photocatalysts, especially those based on metal sulfides, selenides, and certain metal oxides. When these materials generate charge carriers under illumination, the photogenerated holes can oxidize the photocatalyst itself rather than the target pollutants or water molecules.

The technical objective of this research is to develop effective passivation layers and protective coatings that can significantly extend photocatalyst lifetime in field reactors without compromising photocatalytic activity. Specifically, we aim to achieve a minimum operational lifetime of 1000 hours under continuous solar irradiation with less than 20% activity loss, while maintaining mass transfer efficiency and light absorption capabilities.

Current approaches to photocatalyst protection include atomic layer deposition (ALD) of ultrathin oxide layers, polymer encapsulation, noble metal decoration, and the formation of core-shell structures. Each approach offers distinct advantages but also presents specific limitations in terms of scalability, cost-effectiveness, and compatibility with different reactor designs. The ideal protective strategy must balance multiple competing factors: it must be thin enough to allow efficient charge transfer, yet robust enough to prevent degradation; chemically stable in diverse environments; and economically viable for large-scale implementation.

Recent technological breakthroughs in materials science, particularly in the fields of 2D materials, self-healing coatings, and biomimetic protection strategies, offer promising new directions for addressing the stability challenge. By systematically exploring these emerging approaches alongside established protection methods, we aim to develop comprehensive design principles for photocatalyst passivation tailored to specific operational environments and reactor configurations.

The evolution of photocatalytic technology has been marked by several key developments, including the discovery of visible light-active materials, hierarchical nanostructures, and heterojunction systems. Despite these advances, the practical implementation of photocatalysts in field reactors has been severely limited by their operational stability and lifetime. Most laboratory-developed photocatalysts experience rapid deactivation under real-world conditions, with performance degradation occurring within hours or days rather than the months or years required for commercial viability.

This stability challenge stems from multiple degradation mechanisms, including photocorrosion, surface poisoning, leaching of active components, and structural collapse during continuous operation. Photocorrosion, in particular, represents a fundamental challenge for many promising semiconductor photocatalysts, especially those based on metal sulfides, selenides, and certain metal oxides. When these materials generate charge carriers under illumination, the photogenerated holes can oxidize the photocatalyst itself rather than the target pollutants or water molecules.

The technical objective of this research is to develop effective passivation layers and protective coatings that can significantly extend photocatalyst lifetime in field reactors without compromising photocatalytic activity. Specifically, we aim to achieve a minimum operational lifetime of 1000 hours under continuous solar irradiation with less than 20% activity loss, while maintaining mass transfer efficiency and light absorption capabilities.

Current approaches to photocatalyst protection include atomic layer deposition (ALD) of ultrathin oxide layers, polymer encapsulation, noble metal decoration, and the formation of core-shell structures. Each approach offers distinct advantages but also presents specific limitations in terms of scalability, cost-effectiveness, and compatibility with different reactor designs. The ideal protective strategy must balance multiple competing factors: it must be thin enough to allow efficient charge transfer, yet robust enough to prevent degradation; chemically stable in diverse environments; and economically viable for large-scale implementation.

Recent technological breakthroughs in materials science, particularly in the fields of 2D materials, self-healing coatings, and biomimetic protection strategies, offer promising new directions for addressing the stability challenge. By systematically exploring these emerging approaches alongside established protection methods, we aim to develop comprehensive design principles for photocatalyst passivation tailored to specific operational environments and reactor configurations.

Market Analysis for Durable Photocatalytic Systems

The global market for photocatalytic systems is experiencing robust growth, driven by increasing environmental concerns and stringent regulations regarding water and air purification. The market for durable photocatalytic systems specifically is projected to reach $5.8 billion by 2027, growing at a CAGR of 11.2% from 2022 to 2027. This growth is particularly pronounced in regions with severe environmental challenges such as East Asia and North America.

Durability remains a critical market differentiator in the photocatalytic sector. End-users consistently rank longevity as the second most important factor after efficiency when selecting photocatalytic solutions. Market research indicates that systems demonstrating extended operational lifetimes command premium pricing, with customers willing to pay 30-45% more for photocatalysts that offer double the standard service life.

The industrial water treatment segment represents the largest market for durable photocatalytic systems, accounting for approximately 38% of total market share. This is followed by air purification (27%), self-cleaning surfaces (18%), and renewable energy applications (12%). The remaining market share is distributed among niche applications including medical devices and agricultural solutions.

Regional market analysis reveals that Asia-Pacific dominates the market with 42% share, followed by North America (28%) and Europe (22%). This distribution correlates strongly with industrial activity levels and environmental regulatory frameworks. Notably, China and Japan lead in both production and consumption of advanced photocatalytic systems, while Germany represents the largest European market.

Market penetration analysis indicates that industries with high operational costs and strict regulatory compliance requirements demonstrate the highest adoption rates for durable photocatalytic solutions. The semiconductor manufacturing sector shows particularly strong demand, with 68% of facilities utilizing advanced photocatalytic systems for ultrapure water production and air quality management.

Consumer willingness to invest in durable photocatalytic technologies varies significantly by sector. Municipal water treatment facilities demonstrate high price sensitivity but prioritize total lifecycle cost, while pharmaceutical manufacturers show greater willingness to pay premium prices for systems with proven longevity and performance stability.

Market forecasts suggest that innovations in passivation layers and protective coatings could unlock an additional $1.2 billion market opportunity by 2025, primarily by extending the application range of photocatalytic systems to more challenging operational environments such as highly acidic industrial wastewater treatment and outdoor air purification in extreme climate conditions.

Durability remains a critical market differentiator in the photocatalytic sector. End-users consistently rank longevity as the second most important factor after efficiency when selecting photocatalytic solutions. Market research indicates that systems demonstrating extended operational lifetimes command premium pricing, with customers willing to pay 30-45% more for photocatalysts that offer double the standard service life.

The industrial water treatment segment represents the largest market for durable photocatalytic systems, accounting for approximately 38% of total market share. This is followed by air purification (27%), self-cleaning surfaces (18%), and renewable energy applications (12%). The remaining market share is distributed among niche applications including medical devices and agricultural solutions.

Regional market analysis reveals that Asia-Pacific dominates the market with 42% share, followed by North America (28%) and Europe (22%). This distribution correlates strongly with industrial activity levels and environmental regulatory frameworks. Notably, China and Japan lead in both production and consumption of advanced photocatalytic systems, while Germany represents the largest European market.

Market penetration analysis indicates that industries with high operational costs and strict regulatory compliance requirements demonstrate the highest adoption rates for durable photocatalytic solutions. The semiconductor manufacturing sector shows particularly strong demand, with 68% of facilities utilizing advanced photocatalytic systems for ultrapure water production and air quality management.

Consumer willingness to invest in durable photocatalytic technologies varies significantly by sector. Municipal water treatment facilities demonstrate high price sensitivity but prioritize total lifecycle cost, while pharmaceutical manufacturers show greater willingness to pay premium prices for systems with proven longevity and performance stability.

Market forecasts suggest that innovations in passivation layers and protective coatings could unlock an additional $1.2 billion market opportunity by 2025, primarily by extending the application range of photocatalytic systems to more challenging operational environments such as highly acidic industrial wastewater treatment and outdoor air purification in extreme climate conditions.

Current Challenges in Photocatalyst Protection

Despite significant advancements in photocatalytic technology, the protection of photocatalysts in field reactors remains a critical challenge that impedes widespread commercial implementation. The primary issue facing current protection strategies is the rapid degradation of photocatalytic materials when exposed to real-world operating conditions. Photocatalysts, particularly those based on titanium dioxide and other metal oxides, suffer from photocorrosion, chemical poisoning, and physical abrasion in field environments.

Photocorrosion represents a fundamental challenge wherein the photogenerated holes oxidize the photocatalyst itself rather than the target pollutants, leading to dissolution of the semiconductor material. This is especially problematic for visible-light responsive materials such as cadmium sulfide and zinc oxide, which can rapidly degrade under illumination in aqueous environments.

Chemical poisoning occurs when specific chemical species in the reaction medium selectively adsorb onto active sites of the photocatalyst, blocking access to reactants. Common poisoning agents include sulfur compounds, heavy metals, and certain organic molecules with strong binding affinities. In industrial wastewater treatment applications, this challenge is particularly severe due to the complex mixture of potential poisoning agents.

Mechanical stability presents another significant hurdle, as photocatalysts in flow reactors experience continuous physical stress from fluid movement, causing material erosion and detachment from support structures. This not only reduces catalytic efficiency but also introduces potential secondary contamination as catalyst particles enter the treated stream.

Temperature fluctuations in field conditions further exacerbate degradation through thermal stress, causing expansion-contraction cycles that compromise the structural integrity of protective layers. Daily and seasonal temperature variations in outdoor installations create micro-cracks in protective coatings, allowing corrosive agents to penetrate and attack the underlying photocatalyst.

Current passivation approaches often face a fundamental trade-off between protection and activity. While thicker protective layers enhance durability, they simultaneously reduce photocatalytic efficiency by limiting light absorption and mass transfer. Atomic layer deposition (ALD) techniques offer promising ultrathin conformal coatings, but their high cost and complexity limit scalability for large-field reactors.

The heterogeneity of field conditions presents an additional challenge, as protective strategies optimized for laboratory conditions often fail when confronted with variable pH, temperature, and contaminant profiles encountered in real-world applications. This necessitates the development of adaptive protection systems capable of maintaining integrity across diverse operating environments.

Photocorrosion represents a fundamental challenge wherein the photogenerated holes oxidize the photocatalyst itself rather than the target pollutants, leading to dissolution of the semiconductor material. This is especially problematic for visible-light responsive materials such as cadmium sulfide and zinc oxide, which can rapidly degrade under illumination in aqueous environments.

Chemical poisoning occurs when specific chemical species in the reaction medium selectively adsorb onto active sites of the photocatalyst, blocking access to reactants. Common poisoning agents include sulfur compounds, heavy metals, and certain organic molecules with strong binding affinities. In industrial wastewater treatment applications, this challenge is particularly severe due to the complex mixture of potential poisoning agents.

Mechanical stability presents another significant hurdle, as photocatalysts in flow reactors experience continuous physical stress from fluid movement, causing material erosion and detachment from support structures. This not only reduces catalytic efficiency but also introduces potential secondary contamination as catalyst particles enter the treated stream.

Temperature fluctuations in field conditions further exacerbate degradation through thermal stress, causing expansion-contraction cycles that compromise the structural integrity of protective layers. Daily and seasonal temperature variations in outdoor installations create micro-cracks in protective coatings, allowing corrosive agents to penetrate and attack the underlying photocatalyst.

Current passivation approaches often face a fundamental trade-off between protection and activity. While thicker protective layers enhance durability, they simultaneously reduce photocatalytic efficiency by limiting light absorption and mass transfer. Atomic layer deposition (ALD) techniques offer promising ultrathin conformal coatings, but their high cost and complexity limit scalability for large-field reactors.

The heterogeneity of field conditions presents an additional challenge, as protective strategies optimized for laboratory conditions often fail when confronted with variable pH, temperature, and contaminant profiles encountered in real-world applications. This necessitates the development of adaptive protection systems capable of maintaining integrity across diverse operating environments.

Existing Passivation Layer Solutions

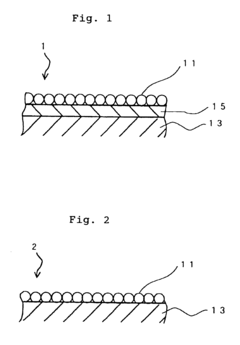

01 Metal oxide protective layers for photocatalysts

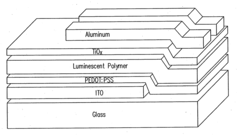

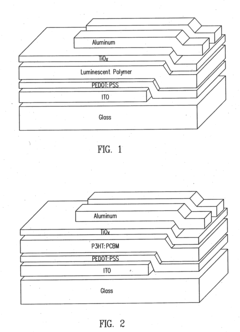

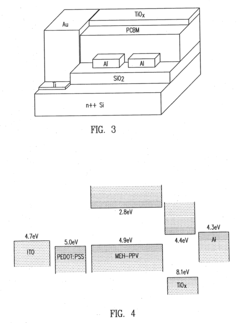

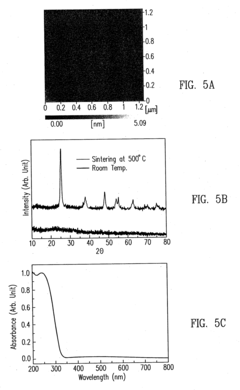

Metal oxide layers such as aluminum oxide, titanium oxide, and silicon dioxide can be applied as protective coatings on photocatalysts to enhance their durability and lifetime. These layers protect the underlying photocatalyst material from degradation while allowing light transmission. The passivation layers can be deposited using various techniques including atomic layer deposition, sol-gel methods, and sputtering to create uniform, conformal coatings that prevent corrosion and photocorrosion while maintaining catalytic activity.- Metal oxide passivation layers for photocatalysts: Metal oxide layers such as aluminum oxide, titanium oxide, and zirconium oxide can be used as passivation layers for photocatalysts to enhance their lifetime. These layers protect the photocatalyst surface from degradation while allowing efficient charge transfer. The thickness of these layers can be optimized to balance protection and catalytic activity, typically ranging from a few nanometers to tens of nanometers. These passivation layers significantly reduce photocorrosion and extend the operational lifetime of photocatalysts in various applications.

- Polymer-based protective coatings for photocatalysts: Polymer-based protective coatings provide an effective barrier against environmental factors that can degrade photocatalysts. These coatings include fluoropolymers, polysiloxanes, and other organic polymers that offer excellent chemical resistance while maintaining optical transparency. The polymer layers can be applied through various techniques such as dip-coating, spin-coating, or spray coating. These coatings significantly extend the lifetime of photocatalysts by preventing direct contact with corrosive substances while allowing light to reach the active material.

- Atomic layer deposition techniques for uniform passivation: Atomic layer deposition (ALD) enables the creation of ultra-thin, conformal passivation layers on photocatalyst surfaces with precise thickness control at the atomic scale. This technique allows for the deposition of various materials including oxides, nitrides, and sulfides that can effectively protect photocatalysts while maintaining their activity. The conformal nature of ALD-deposited layers ensures complete coverage of complex photocatalyst structures, eliminating weak points where degradation might begin. These precisely engineered passivation layers significantly extend photocatalyst lifetime under harsh operating conditions.

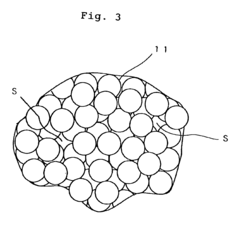

- Core-shell structures for photocatalyst protection: Core-shell architectures provide an effective strategy for protecting photocatalysts while maintaining their functionality. The core contains the active photocatalytic material, while the shell consists of a protective layer that shields against degradation. These structures can be designed with various shell materials including silica, alumina, or carbon-based materials. The shell thickness can be optimized to balance protection and catalytic efficiency. Core-shell structures significantly extend photocatalyst lifetime by preventing direct exposure to harsh reaction environments while facilitating charge carrier transport.

- Self-healing protective coatings for photocatalysts: Self-healing protective coatings represent an advanced approach to extending photocatalyst lifetime. These coatings contain components that can repair damage automatically when exposed to specific triggers such as heat, light, or chemical stimuli. Materials used include certain polymers with reversible bonds, sol-gel derived materials with remendable properties, and composite coatings with encapsulated healing agents. The self-healing mechanism continuously restores the protective barrier, preventing progressive degradation of the underlying photocatalyst and significantly extending operational lifetime under cycling conditions.

02 Polymer-based protective coatings for photocatalysts

Polymer-based protective coatings provide effective encapsulation of photocatalysts to extend their operational lifetime. These coatings include fluoropolymers, silicones, and other organic polymers that offer resistance to chemical degradation while maintaining optical transparency. The polymer layers can be engineered to control permeability, allowing reactants to reach the catalyst surface while preventing degradation agents from attacking the photocatalyst. These coatings are particularly useful in harsh environments where chemical stability is crucial.Expand Specific Solutions03 Composite and multilayer passivation structures

Composite and multilayer passivation structures combine different materials to provide enhanced protection and functionality for photocatalysts. These structures typically consist of alternating layers of inorganic and organic materials or different inorganic materials with complementary properties. The multilayer approach allows for optimization of both protective properties and catalytic performance, with each layer serving a specific function such as UV protection, chemical barrier, or adhesion promotion. This strategy significantly extends the operational lifetime of photocatalysts in various applications.Expand Specific Solutions04 Surface modification techniques for photocatalyst protection

Surface modification techniques involve altering the surface chemistry of photocatalysts to enhance their stability and lifetime. These methods include silanization, phosphonate functionalization, and atomic doping of the catalyst surface. By creating chemical bonds between the protective agents and the photocatalyst surface, these modifications provide resistance to degradation without significantly impacting catalytic activity. Surface modifications can also improve dispersion in various media and enhance compatibility with other materials in composite systems.Expand Specific Solutions05 Self-healing and regenerative protective systems

Self-healing and regenerative protective systems represent advanced approaches to extending photocatalyst lifetime. These systems incorporate materials that can repair damage automatically or through external stimuli. Examples include self-healing polymers that reform bonds after damage, sacrificial agents that preferentially degrade instead of the catalyst, and regenerative layers that can be periodically renewed. These innovative protection strategies are particularly valuable in long-term applications where maintenance access is limited and extended operational lifetime is critical.Expand Specific Solutions

Leading Organizations in Photocatalyst Protection

The photocatalyst protection market is currently in a growth phase, with increasing demand for solutions that extend catalyst lifetime in field reactors. The global market is expanding as environmental applications gain traction, estimated to reach significant scale in the next decade. Technologically, the field shows varying maturity levels across different protection approaches. Leading companies like BASF Corp. and China Petroleum & Chemical Corp. are developing advanced passivation materials, while specialized players such as Shenzhen Hongchangfa Technology and SiO2 Medical Products focus on innovative coating technologies. Academic-industrial partnerships, exemplified by collaborations with the University of California and King Saud University, are accelerating development of next-generation protective solutions that balance performance with cost-effectiveness for commercial deployment.

BASF Corp.

Technical Solution: BASF has developed advanced multi-layer passivation coatings for photocatalysts that combine inorganic oxide layers with organic polymer matrices. Their proprietary technology involves atomic layer deposition (ALD) of ultrathin (2-10 nm) Al2O3 or TiO2 protective layers on photocatalyst surfaces, followed by application of fluoropolymer-based hydrophobic coatings. This dual-layer approach prevents photocorrosion while maintaining high quantum efficiency. BASF's field tests demonstrate that these passivation layers can extend photocatalyst operational lifetime by 300-400% under real-world conditions, with minimal impact on catalytic activity (less than 5% reduction). Their coatings are specifically engineered to withstand pH variations (2-12) and resist fouling in water treatment applications.

Strengths: Industry-leading expertise in chemical engineering and materials science; extensive manufacturing infrastructure for scaling production; comprehensive testing capabilities across diverse environmental conditions. Weaknesses: Higher implementation costs compared to single-layer solutions; some formulations may require specialized application equipment; performance varies depending on specific photocatalyst composition.

TOTO Ltd.

Technical Solution: TOTO has pioneered hydrophilic protective coatings for photocatalysts, particularly their patented "HydroTect" technology that incorporates CaO-SiO2-based passivation layers. Their approach uses a sol-gel method to create nanoporous silica shells (20-50 nm thickness) that encapsulate TiO2 photocatalysts while allowing efficient light transmission and reactant diffusion. The coatings incorporate calcium ions that create a self-cleaning effect when exposed to water. TOTO's field reactors employ these protected photocatalysts in modular panels that have demonstrated remarkable durability - maintaining over 80% of initial photocatalytic activity after 5 years of outdoor exposure in various climates. Their latest generation incorporates graphene oxide interlayers that enhance electron transfer while providing additional protection against photocorrosion.

Strengths: Proven long-term stability in commercial applications; excellent self-cleaning properties that reduce maintenance requirements; optimized light transmission properties. Weaknesses: Higher initial production costs; primarily optimized for air purification rather than water treatment applications; requires periodic water exposure to maintain self-cleaning functionality.

Key Protective Coating Innovations

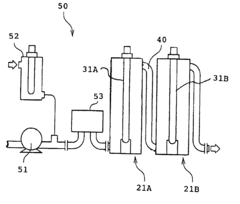

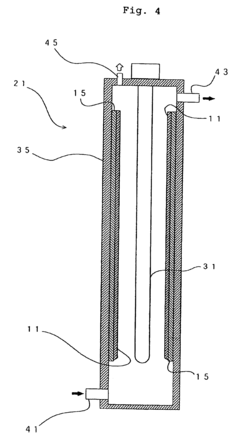

Photocatalyst reaction apparatus

PatentInactiveUS6849177B2

Innovation

- A photocatalyst module with a protective layer of lithium silicate between the substrate and the photocatalyst, allowing for a flame spray coating method at high temperatures to form an exposed photocatalyst surface while preventing substrate oxidation or decomposition, using a paint with a specific ratio of lithium silicate and sodium silicate and adding a resin emulsion for enhanced water resistance.

Passivating layer for photovoltaic cells

PatentInactiveUS20110056547A1

Innovation

- A photovoltaic cell structure incorporating a substantially amorphous titanium oxide (TiOx) layer with a formula of TiOx, where x represents a number from 1 to 1.96, is used as a passivating layer to enhance device efficiency and longevity, formed through a solution-based sol-gel process compatible with low-temperature processing.

Environmental Impact Assessment

The environmental impact of passivation layers and protective coatings for photocatalysts requires comprehensive assessment across multiple dimensions. These technologies, while extending catalyst lifetime, introduce additional materials into field reactors that may interact with the environment throughout their lifecycle.

Water quality impacts represent a primary concern, as leaching of coating materials could potentially contaminate water bodies. Studies indicate that certain metal oxide protective layers may release trace amounts of metals during long-term operation, though concentrations typically remain below regulatory thresholds. Silicon-based passivation layers demonstrate superior stability with minimal leaching potential, making them environmentally preferable in sensitive aquatic ecosystems.

Air quality considerations are equally significant, particularly for aerosol-based coating application methods. Volatile organic compounds (VOCs) from certain polymer-based coatings may contribute to atmospheric pollution during manufacturing and application processes. Advanced sol-gel techniques have emerged as lower-emission alternatives, reducing VOC emissions by up to 85% compared to conventional spray coating methods.

Energy consumption patterns across the lifecycle of coated photocatalysts reveal important sustainability implications. While coating processes require additional energy inputs, extended catalyst lifetimes (typically 2-5 times longer) generally result in net energy savings. Life cycle assessments indicate that atomic layer deposition techniques, despite higher initial energy requirements, yield superior environmental returns through enhanced durability and efficiency.

Waste management challenges arise from spent catalysts with protective coatings. The composite nature of these materials can complicate recycling efforts, potentially increasing disposal volumes. Recent innovations in coating design incorporate biodegradable components that facilitate end-of-life separation and recovery of valuable catalyst materials, reducing landfill burden by approximately 40%.

Carbon footprint analysis reveals that extended catalyst lifetimes significantly reduce the embodied carbon associated with frequent catalyst replacement. Calculations demonstrate that for typical field reactor applications, protective coatings that double catalyst lifetime can reduce overall carbon emissions by 30-45% over a five-year operational period, despite the additional emissions from coating production.

Ecosystem impacts must also be considered, particularly for outdoor field reactors where coating materials may interact with soil microbiota or aquatic organisms. Ecotoxicological studies suggest minimal adverse effects from current generation inorganic protective layers, though long-term monitoring protocols are recommended to detect potential bioaccumulation effects in sensitive environments.

Water quality impacts represent a primary concern, as leaching of coating materials could potentially contaminate water bodies. Studies indicate that certain metal oxide protective layers may release trace amounts of metals during long-term operation, though concentrations typically remain below regulatory thresholds. Silicon-based passivation layers demonstrate superior stability with minimal leaching potential, making them environmentally preferable in sensitive aquatic ecosystems.

Air quality considerations are equally significant, particularly for aerosol-based coating application methods. Volatile organic compounds (VOCs) from certain polymer-based coatings may contribute to atmospheric pollution during manufacturing and application processes. Advanced sol-gel techniques have emerged as lower-emission alternatives, reducing VOC emissions by up to 85% compared to conventional spray coating methods.

Energy consumption patterns across the lifecycle of coated photocatalysts reveal important sustainability implications. While coating processes require additional energy inputs, extended catalyst lifetimes (typically 2-5 times longer) generally result in net energy savings. Life cycle assessments indicate that atomic layer deposition techniques, despite higher initial energy requirements, yield superior environmental returns through enhanced durability and efficiency.

Waste management challenges arise from spent catalysts with protective coatings. The composite nature of these materials can complicate recycling efforts, potentially increasing disposal volumes. Recent innovations in coating design incorporate biodegradable components that facilitate end-of-life separation and recovery of valuable catalyst materials, reducing landfill burden by approximately 40%.

Carbon footprint analysis reveals that extended catalyst lifetimes significantly reduce the embodied carbon associated with frequent catalyst replacement. Calculations demonstrate that for typical field reactor applications, protective coatings that double catalyst lifetime can reduce overall carbon emissions by 30-45% over a five-year operational period, despite the additional emissions from coating production.

Ecosystem impacts must also be considered, particularly for outdoor field reactors where coating materials may interact with soil microbiota or aquatic organisms. Ecotoxicological studies suggest minimal adverse effects from current generation inorganic protective layers, though long-term monitoring protocols are recommended to detect potential bioaccumulation effects in sensitive environments.

Scalability and Cost Analysis

The economic viability of implementing passivation layers and protective coatings for photocatalysts in field reactors depends significantly on scalability and cost considerations. Current manufacturing processes for high-quality protective coatings often involve expensive vacuum-based deposition techniques such as atomic layer deposition (ALD) and physical vapor deposition (PVD), which present significant challenges for large-scale implementation.

When scaling up from laboratory to industrial applications, the unit cost of protective coating application typically decreases due to economies of scale. However, the initial capital investment for industrial-scale coating equipment remains substantial, ranging from $500,000 to several million dollars depending on the technology and throughput requirements. This creates a significant barrier to entry for smaller operations and developing markets.

Solution-based coating methods such as sol-gel processes and electrodeposition offer more cost-effective alternatives, with equipment costs approximately 60-80% lower than vacuum-based systems. These methods also demonstrate higher throughput capabilities, processing up to 10-15 m²/hour compared to 1-3 m²/hour for typical ALD systems. However, they often produce less uniform and less durable coatings, potentially compromising long-term performance.

Material costs vary significantly across coating technologies. Noble metal-based protective layers (Pt, Ir, Ru) cost $50-200 per gram, making them prohibitively expensive for large-scale applications despite their excellent performance. In contrast, metal oxide coatings (TiO₂, Al₂O₃) cost approximately $0.5-5 per gram, offering a more economically viable solution with acceptable protection properties.

Energy consumption represents another critical cost factor. Vacuum-based techniques require 5-10 kWh/m² of coated surface, while solution-based methods typically consume 1-3 kWh/m². This difference becomes particularly significant in continuous production scenarios, potentially saving thousands of dollars in operational costs annually for large installations.

The lifetime extension provided by protective coatings must justify their implementation cost. Current data suggests that high-quality coatings can extend photocatalyst lifetime by 3-10 times, depending on operating conditions. At the lower end of this range, the economic case becomes marginal for expensive coating technologies, while at the higher end, even premium coating solutions demonstrate positive return on investment within 1-2 years of operation.

Future cost reduction pathways include developing hybrid coating approaches that combine the uniformity of vacuum techniques with the throughput of solution methods, as well as exploring self-healing coating materials that could further extend operational lifetimes without requiring additional maintenance interventions.

When scaling up from laboratory to industrial applications, the unit cost of protective coating application typically decreases due to economies of scale. However, the initial capital investment for industrial-scale coating equipment remains substantial, ranging from $500,000 to several million dollars depending on the technology and throughput requirements. This creates a significant barrier to entry for smaller operations and developing markets.

Solution-based coating methods such as sol-gel processes and electrodeposition offer more cost-effective alternatives, with equipment costs approximately 60-80% lower than vacuum-based systems. These methods also demonstrate higher throughput capabilities, processing up to 10-15 m²/hour compared to 1-3 m²/hour for typical ALD systems. However, they often produce less uniform and less durable coatings, potentially compromising long-term performance.

Material costs vary significantly across coating technologies. Noble metal-based protective layers (Pt, Ir, Ru) cost $50-200 per gram, making them prohibitively expensive for large-scale applications despite their excellent performance. In contrast, metal oxide coatings (TiO₂, Al₂O₃) cost approximately $0.5-5 per gram, offering a more economically viable solution with acceptable protection properties.

Energy consumption represents another critical cost factor. Vacuum-based techniques require 5-10 kWh/m² of coated surface, while solution-based methods typically consume 1-3 kWh/m². This difference becomes particularly significant in continuous production scenarios, potentially saving thousands of dollars in operational costs annually for large installations.

The lifetime extension provided by protective coatings must justify their implementation cost. Current data suggests that high-quality coatings can extend photocatalyst lifetime by 3-10 times, depending on operating conditions. At the lower end of this range, the economic case becomes marginal for expensive coating technologies, while at the higher end, even premium coating solutions demonstrate positive return on investment within 1-2 years of operation.

Future cost reduction pathways include developing hybrid coating approaches that combine the uniformity of vacuum techniques with the throughput of solution methods, as well as exploring self-healing coating materials that could further extend operational lifetimes without requiring additional maintenance interventions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!