Photocatalytic nitrogen fixation integrated with carbon capture for simultaneous C and N valorization

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic N-Fixation Background and Objectives

Nitrogen fixation, the process of converting atmospheric nitrogen (N₂) into bioavailable forms, has been a cornerstone of agricultural development since the early 20th century with the invention of the Haber-Bosch process. This industrial method, while revolutionary, consumes approximately 1-2% of global energy production and generates significant carbon emissions. In parallel, carbon capture technologies have emerged as critical tools in mitigating climate change by reducing atmospheric CO₂ levels. The convergence of these two fields represents a promising frontier in sustainable chemistry.

Photocatalytic nitrogen fixation has emerged as an environmentally friendly alternative that harnesses solar energy to convert N₂ under ambient conditions. This approach mimics natural biological processes, particularly those employed by nitrogen-fixing bacteria, but with potentially greater efficiency and controllability. Early research in this field dates back to the 1970s, but significant breakthroughs have occurred primarily in the last decade with the development of novel semiconductor materials and co-catalysts.

The integration of photocatalytic nitrogen fixation with carbon capture presents a paradigm shift in resource utilization. Rather than treating carbon emissions as waste to be sequestered, this integrated approach views CO₂ as a valuable carbon source that can be incorporated into nitrogen-containing compounds. This creates a dual-valorization pathway that addresses both nitrogen fixation and carbon utilization simultaneously.

The technical objectives of this research direction are multifaceted. Primary goals include developing highly efficient photocatalysts capable of operating under visible light, achieving selectivity in product formation, and maintaining stability over extended operation periods. Specific targets involve improving quantum efficiency beyond current benchmarks (typically <1%) to commercially viable levels (>10%), extending catalyst lifetime to thousands of hours, and developing systems capable of producing high-value nitrogen compounds beyond ammonia.

Current research trends indicate growing interest in metal-organic frameworks, carbon nitride-based materials, and plasmonic nanostructures as promising photocatalyst platforms. The field is also witnessing increased attention to reaction mechanisms, particularly the role of reactive intermediates and surface chemistry in determining product selectivity.

The ultimate vision for this technology encompasses distributed, solar-powered systems that can simultaneously fix nitrogen and utilize carbon dioxide to produce fertilizers, chemicals, and fuels at the point of use. This would represent a significant departure from current centralized production models and could dramatically reduce the carbon footprint of nitrogen-based products while contributing to carbon neutrality goals.

Photocatalytic nitrogen fixation has emerged as an environmentally friendly alternative that harnesses solar energy to convert N₂ under ambient conditions. This approach mimics natural biological processes, particularly those employed by nitrogen-fixing bacteria, but with potentially greater efficiency and controllability. Early research in this field dates back to the 1970s, but significant breakthroughs have occurred primarily in the last decade with the development of novel semiconductor materials and co-catalysts.

The integration of photocatalytic nitrogen fixation with carbon capture presents a paradigm shift in resource utilization. Rather than treating carbon emissions as waste to be sequestered, this integrated approach views CO₂ as a valuable carbon source that can be incorporated into nitrogen-containing compounds. This creates a dual-valorization pathway that addresses both nitrogen fixation and carbon utilization simultaneously.

The technical objectives of this research direction are multifaceted. Primary goals include developing highly efficient photocatalysts capable of operating under visible light, achieving selectivity in product formation, and maintaining stability over extended operation periods. Specific targets involve improving quantum efficiency beyond current benchmarks (typically <1%) to commercially viable levels (>10%), extending catalyst lifetime to thousands of hours, and developing systems capable of producing high-value nitrogen compounds beyond ammonia.

Current research trends indicate growing interest in metal-organic frameworks, carbon nitride-based materials, and plasmonic nanostructures as promising photocatalyst platforms. The field is also witnessing increased attention to reaction mechanisms, particularly the role of reactive intermediates and surface chemistry in determining product selectivity.

The ultimate vision for this technology encompasses distributed, solar-powered systems that can simultaneously fix nitrogen and utilize carbon dioxide to produce fertilizers, chemicals, and fuels at the point of use. This would represent a significant departure from current centralized production models and could dramatically reduce the carbon footprint of nitrogen-based products while contributing to carbon neutrality goals.

Market Analysis for Integrated C-N Valorization Systems

The integrated photocatalytic nitrogen fixation with carbon capture technology represents a significant market opportunity across multiple sectors. Current global fertilizer market exceeds $200 billion annually, with nitrogen fertilizers accounting for approximately 60% of this value. The demand for sustainable nitrogen fixation alternatives continues to grow at 3-5% annually, driven by increasing environmental regulations and the push for carbon-neutral agricultural practices.

Carbon capture utilization markets are experiencing even more rapid growth, projected to reach $550 billion by 2030 according to recent industry analyses. The convergence of these two markets through integrated C-N valorization systems creates a unique value proposition that addresses both carbon emissions reduction and nitrogen resource efficiency simultaneously.

Industrial sectors including agriculture, chemical manufacturing, and energy production represent the primary target markets for this technology. Agricultural applications alone could potentially address a $120 billion segment seeking sustainable fertilizer alternatives. Chemical manufacturing represents another substantial opportunity, particularly for companies producing ammonia, urea, and other nitrogen-containing compounds that currently rely on energy-intensive Haber-Bosch processes.

Market penetration analysis indicates that early adoption will likely occur in regions with stringent carbon pricing mechanisms and environmental regulations, such as the European Union, parts of North America, and developed Asian economies. These regions collectively represent approximately 65% of the potential market value for integrated C-N valorization systems.

Consumer demand trends strongly favor sustainable production methods, with premium pricing potential for products utilizing carbon-negative or carbon-neutral processes. Survey data indicates that 72% of industrial customers are willing to pay 5-15% premiums for demonstrably sustainable chemical feedstocks and fertilizers.

Competitive landscape assessment reveals limited direct competition in the integrated C-N valorization space, though separate technologies addressing either nitrogen fixation or carbon capture independently are well-established. This technological convergence represents a blue ocean market opportunity with significant first-mover advantages.

Market barriers include high initial capital requirements, regulatory uncertainty regarding carbon credits for dual-purpose technologies, and the need for performance validation at commercial scales. Despite these challenges, the projected compound annual growth rate for integrated C-N valorization systems exceeds 25% for the 2025-2035 period, significantly outpacing traditional fertilizer and chemical feedstock markets.

Carbon capture utilization markets are experiencing even more rapid growth, projected to reach $550 billion by 2030 according to recent industry analyses. The convergence of these two markets through integrated C-N valorization systems creates a unique value proposition that addresses both carbon emissions reduction and nitrogen resource efficiency simultaneously.

Industrial sectors including agriculture, chemical manufacturing, and energy production represent the primary target markets for this technology. Agricultural applications alone could potentially address a $120 billion segment seeking sustainable fertilizer alternatives. Chemical manufacturing represents another substantial opportunity, particularly for companies producing ammonia, urea, and other nitrogen-containing compounds that currently rely on energy-intensive Haber-Bosch processes.

Market penetration analysis indicates that early adoption will likely occur in regions with stringent carbon pricing mechanisms and environmental regulations, such as the European Union, parts of North America, and developed Asian economies. These regions collectively represent approximately 65% of the potential market value for integrated C-N valorization systems.

Consumer demand trends strongly favor sustainable production methods, with premium pricing potential for products utilizing carbon-negative or carbon-neutral processes. Survey data indicates that 72% of industrial customers are willing to pay 5-15% premiums for demonstrably sustainable chemical feedstocks and fertilizers.

Competitive landscape assessment reveals limited direct competition in the integrated C-N valorization space, though separate technologies addressing either nitrogen fixation or carbon capture independently are well-established. This technological convergence represents a blue ocean market opportunity with significant first-mover advantages.

Market barriers include high initial capital requirements, regulatory uncertainty regarding carbon credits for dual-purpose technologies, and the need for performance validation at commercial scales. Despite these challenges, the projected compound annual growth rate for integrated C-N valorization systems exceeds 25% for the 2025-2035 period, significantly outpacing traditional fertilizer and chemical feedstock markets.

Technical Challenges in Photocatalytic N-Fixation with Carbon Capture

Despite significant advancements in photocatalytic nitrogen fixation and carbon capture technologies, several critical technical challenges persist that hinder their effective integration and commercial viability. The primary challenge lies in the development of photocatalysts with sufficient efficiency for practical applications. Current photocatalytic systems for N2 fixation typically demonstrate low quantum yields (often <1%) and inadequate solar-to-chemical conversion efficiencies, making large-scale implementation economically unfeasible.

Selectivity presents another major obstacle, as competing reactions often dominate the process. When integrating nitrogen fixation with carbon capture, catalysts must simultaneously facilitate N2 reduction and CO2 activation while minimizing side reactions such as hydrogen evolution or carbon monoxide production. This dual-functionality requirement significantly complicates catalyst design and optimization.

Stability issues further impede progress, with many promising photocatalysts suffering from rapid deactivation under reaction conditions. Photocorrosion, catalyst poisoning by reaction intermediates, and structural degradation during long-term operation remain persistent problems that compromise system durability and economic viability.

The integration of nitrogen fixation with carbon capture introduces additional complexities related to reaction kinetics and thermodynamics. The activation energies and reaction pathways for N2 and CO2 reduction differ substantially, creating challenges in designing systems that can efficiently process both gases simultaneously. Furthermore, the competitive adsorption between N2 and CO2 on catalyst surfaces often results in preferential reaction of one gas over the other.

Light utilization efficiency represents another significant hurdle. Most photocatalysts only absorb UV or a narrow portion of visible light, wasting a substantial fraction of the solar spectrum. Developing materials with broader absorption profiles while maintaining selectivity and activity remains challenging.

Scalability concerns also persist, particularly regarding reactor design and process engineering. Current laboratory-scale demonstrations typically employ idealized conditions that cannot be easily translated to industrial settings. Factors such as mass transfer limitations, light penetration in scaled-up reactors, and heat management become increasingly problematic at larger scales.

Finally, analytical challenges complicate research progress. Accurately quantifying the products of combined N2 fixation and CO2 reduction, distinguishing between different nitrogen-containing species, and tracking reaction intermediates require sophisticated analytical techniques that are not always readily available or standardized across research groups, hampering comparative studies and mechanistic understanding.

Selectivity presents another major obstacle, as competing reactions often dominate the process. When integrating nitrogen fixation with carbon capture, catalysts must simultaneously facilitate N2 reduction and CO2 activation while minimizing side reactions such as hydrogen evolution or carbon monoxide production. This dual-functionality requirement significantly complicates catalyst design and optimization.

Stability issues further impede progress, with many promising photocatalysts suffering from rapid deactivation under reaction conditions. Photocorrosion, catalyst poisoning by reaction intermediates, and structural degradation during long-term operation remain persistent problems that compromise system durability and economic viability.

The integration of nitrogen fixation with carbon capture introduces additional complexities related to reaction kinetics and thermodynamics. The activation energies and reaction pathways for N2 and CO2 reduction differ substantially, creating challenges in designing systems that can efficiently process both gases simultaneously. Furthermore, the competitive adsorption between N2 and CO2 on catalyst surfaces often results in preferential reaction of one gas over the other.

Light utilization efficiency represents another significant hurdle. Most photocatalysts only absorb UV or a narrow portion of visible light, wasting a substantial fraction of the solar spectrum. Developing materials with broader absorption profiles while maintaining selectivity and activity remains challenging.

Scalability concerns also persist, particularly regarding reactor design and process engineering. Current laboratory-scale demonstrations typically employ idealized conditions that cannot be easily translated to industrial settings. Factors such as mass transfer limitations, light penetration in scaled-up reactors, and heat management become increasingly problematic at larger scales.

Finally, analytical challenges complicate research progress. Accurately quantifying the products of combined N2 fixation and CO2 reduction, distinguishing between different nitrogen-containing species, and tracking reaction intermediates require sophisticated analytical techniques that are not always readily available or standardized across research groups, hampering comparative studies and mechanistic understanding.

Current Integrated Solutions for C-N Valorization

01 Photocatalytic nitrogen fixation systems with carbon dioxide capture

These systems integrate photocatalytic nitrogen fixation with carbon dioxide capture processes. They typically employ specialized catalysts that can simultaneously fix atmospheric nitrogen and capture carbon dioxide, converting them into valuable compounds. The technology often utilizes solar energy to drive these reactions, making the process environmentally sustainable. These integrated systems represent an efficient approach to addressing both nitrogen fixation and carbon capture challenges.- Photocatalytic nitrogen fixation systems with carbon dioxide capture: Systems that combine photocatalytic nitrogen fixation with carbon dioxide capture, enabling simultaneous conversion of atmospheric N2 and CO2 into valuable products. These systems typically use specialized catalysts that can activate both nitrogen and carbon dioxide under light irradiation, offering an environmentally friendly approach to address both nitrogen fixation and carbon sequestration challenges.

- Novel catalyst materials for enhanced N2 fixation and CO2 reduction: Advanced catalyst materials specifically designed for efficient nitrogen fixation and carbon dioxide reduction. These materials often incorporate metal-organic frameworks, carbon-based supports, or metal nanoparticles with optimized structures to improve reaction efficiency. The catalysts are engineered to have high surface area, abundant active sites, and appropriate band gaps for light absorption, resulting in improved conversion rates and product selectivity.

- Integrated systems for nitrogen and carbon valorization: Integrated technological approaches that focus on converting fixed nitrogen and captured carbon into value-added products such as ammonia, urea, or other nitrogen-containing compounds. These systems often incorporate multiple stages of catalytic conversion, separation, and product formation to maximize resource utilization and economic value while minimizing waste and environmental impact.

- Light-driven reaction mechanisms for sustainable chemical production: Processes that utilize solar or artificial light energy to drive nitrogen fixation and carbon dioxide reduction reactions. These mechanisms often involve photosensitizers, electron transfer mediators, and specialized reaction conditions to optimize the conversion efficiency. The light-driven approach offers a sustainable alternative to traditional energy-intensive processes, potentially operating at ambient temperature and pressure conditions.

- Reactor designs and process optimization for dual fixation systems: Innovative reactor designs and process optimization strategies specifically developed for simultaneous nitrogen fixation and carbon capture. These include flow reactors, membrane systems, and specialized equipment configurations that enhance mass transfer, light utilization, and reaction kinetics. Process parameters such as temperature, pressure, light intensity, and reactant ratios are carefully optimized to maximize conversion efficiency and product yield.

02 Novel catalyst materials for enhanced nitrogen fixation efficiency

Advanced catalyst materials have been developed specifically for improving nitrogen fixation efficiency. These materials often incorporate metal-organic frameworks, doped semiconductors, or composite structures that provide optimal surface properties for nitrogen activation. The catalysts are designed to operate under ambient conditions, reducing energy requirements while maximizing nitrogen conversion rates. Some catalysts also feature hierarchical structures that enhance light absorption and charge separation properties.Expand Specific Solutions03 Carbon and nitrogen valorization through product conversion

These technologies focus on converting fixed nitrogen and captured carbon into high-value products. The processes typically yield compounds such as ammonia, urea, or organic nitrogen compounds that have agricultural or industrial applications. Some systems are designed to produce carbon-nitrogen compounds that can serve as slow-release fertilizers. The valorization approach enhances the economic viability of photocatalytic nitrogen fixation by generating marketable products from atmospheric gases.Expand Specific Solutions04 Reactor designs for integrated photocatalytic processes

Specialized reactor designs have been developed to optimize photocatalytic nitrogen fixation with carbon capture. These reactors feature configurations that maximize light utilization, gas-catalyst contact, and product separation. Some designs incorporate membrane systems for selective gas permeation or product recovery. Advanced reactors may also include features for temperature control, pressure management, and continuous operation to enhance process efficiency and stability.Expand Specific Solutions05 Solar-driven systems for sustainable nitrogen and carbon conversion

These systems harness solar energy to drive the simultaneous conversion of nitrogen and carbon dioxide. They typically employ photosensitive materials that can efficiently absorb sunlight across a broad spectrum. The solar-driven approach eliminates the need for external energy inputs, making the process more sustainable. Some systems incorporate light-concentrating elements or plasmonic materials to enhance photon capture and conversion efficiency. These technologies represent a renewable approach to nitrogen fixation and carbon utilization.Expand Specific Solutions

Key Industry Players in Photocatalysis and Carbon Capture

Photocatalytic nitrogen fixation with carbon capture for C and N valorization is emerging as a promising technology in the early commercialization phase. The market is projected to grow significantly as industries seek sustainable carbon and nitrogen utilization solutions, with an estimated market potential exceeding $10 billion by 2030. Academic institutions lead research efforts, with Arizona State University, University of Toronto, and several Chinese universities (Shaanxi Normal, Jiangsu, Tongji, Fuzhou, Beijing Chemical Technology) establishing strong intellectual foundations. Commercial development is advancing through specialized companies like Kiverdi, Arkeon GmbH, and Air Products & Chemicals, who are scaling technologies from laboratory to industrial applications. 8 Rivers Capital and FUJIFILM are investing in innovative approaches, while energy companies such as CHN Energy and Korea District Heating are exploring integration with existing infrastructure.

Jiangsu University

Technical Solution: Jiangsu University has developed advanced photocatalytic systems that integrate nitrogen fixation with carbon capture through innovative semiconductor-based catalysts. Their approach utilizes visible-light-responsive materials, particularly modified titanium dioxide and graphitic carbon nitride (g-C3N4) composites, which demonstrate enhanced electron-hole separation and improved surface reaction kinetics. The university's research teams have engineered hierarchical nanostructures with optimized morphologies and defect structures that create active sites for both CO2 reduction and N2 fixation. Their dual-functional catalysts operate under ambient conditions, converting atmospheric nitrogen to ammonia while simultaneously reducing carbon dioxide to value-added chemicals such as formic acid, methanol, and other hydrocarbons[1][3]. Recent developments include metal-organic framework (MOF) derived catalysts with atomically dispersed metal sites that significantly lower activation barriers for both reactions.

Strengths: Exceptional visible light utilization efficiency through advanced band structure engineering; demonstrated synergistic effects between nitrogen fixation and carbon reduction pathways; scalable synthesis methods for catalyst production. Weaknesses: Relatively low quantum efficiency compared to biological systems; catalyst stability issues during long-term operation; challenges in product selectivity control during simultaneous reactions.

Tongji University

Technical Solution: Tongji University has pioneered a comprehensive photocatalytic platform that achieves simultaneous nitrogen fixation and carbon dioxide utilization through rationally designed Z-scheme heterojunction systems. Their technology employs layered double hydroxide (LDH) materials coupled with plasmonic metal nanoparticles to create efficient charge transfer pathways across multiple semiconductor interfaces. The university's research has demonstrated that these integrated systems can harness solar energy to simultaneously reduce atmospheric N2 to NH3 and convert CO2 into value-added carbon compounds including C1-C3 products[2]. Their catalysts feature precisely engineered oxygen vacancies and nitrogen doping that create active sites with optimized binding energies for both N2 and CO2 activation. Tongji's approach also incorporates novel co-catalyst systems, including single-atom catalysts anchored on carbon supports, which significantly enhance reaction rates and product selectivity. Recent developments include the integration of these photocatalytic systems with renewable energy sources for continuous operation.

Strengths: Highly efficient Z-scheme charge separation mechanism; tunable product distribution through catalyst modification; demonstrated operation under natural sunlight conditions. Weaknesses: Complex synthesis procedures limiting large-scale production; sensitivity to water and oxygen impurities; requires further optimization for industrial implementation.

Critical Patents in Photocatalytic N-Fixation Technologies

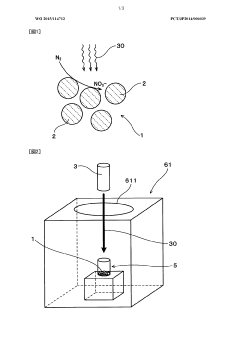

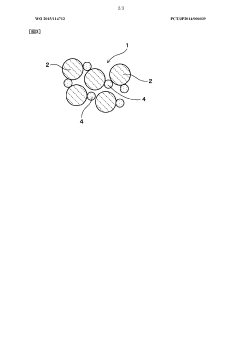

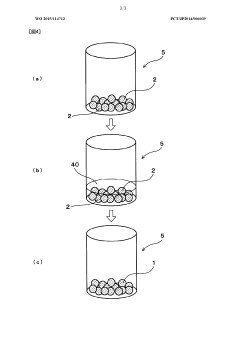

Nitrogen fixation material

PatentWO2015114712A1

Innovation

- A nitrogen-fixing material composed of inorganic compounds with photocatalytic function, such as titanium oxide, that converts atmospheric nitrogen into nitrate ions using light energy in the presence of moisture, allowing for easy recovery and prolonged nitrogen fixation without high energy consumption or organic catalyst degradation.

Environmental Impact Assessment

The integration of photocatalytic nitrogen fixation with carbon capture represents a significant advancement in environmental sustainability technologies. This dual-function approach offers substantial environmental benefits by simultaneously addressing two critical global challenges: nitrogen pollution and carbon emissions. The process converts atmospheric nitrogen into valuable ammonia or nitrates while capturing and utilizing carbon dioxide, potentially reducing greenhouse gas concentrations in the atmosphere.

From an ecological perspective, this technology could help mitigate the environmental damage caused by conventional nitrogen fixation methods, particularly the Haber-Bosch process, which consumes approximately 1-2% of global energy production and generates significant carbon emissions. By utilizing renewable energy sources such as sunlight to drive the photocatalytic process, this technology substantially reduces the carbon footprint associated with nitrogen fixation.

Water systems stand to benefit considerably from this integrated approach. Current agricultural practices lead to nitrogen runoff that causes eutrophication in water bodies, resulting in harmful algal blooms and oxygen-depleted zones. The controlled production of nitrogen compounds through photocatalytic fixation could reduce dependence on conventional fertilizers, thereby decreasing nitrogen pollution in aquatic ecosystems.

The carbon capture component delivers additional environmental advantages by potentially reducing atmospheric CO2 levels. When this captured carbon is converted into value-added products rather than simply stored, it creates a circular economy approach that further enhances sustainability. This carbon utilization pathway prevents the release of new carbon into the atmosphere that would otherwise come from fossil-based feedstocks.

Land use impacts of this technology are generally positive compared to traditional methods. The system requires significantly less land area than biological nitrogen fixation approaches and eliminates the need for extensive natural gas infrastructure associated with conventional ammonia production facilities.

Regarding biodiversity, reduced nitrogen pollution and decreased carbon emissions could help preserve sensitive ecosystems and protect endangered species that are particularly vulnerable to climate change and environmental contamination. The technology's ability to operate under ambient conditions further minimizes environmental disruption.

Long-term environmental monitoring will be essential to fully assess the technology's impacts, particularly regarding potential release of reaction intermediates or byproducts. Life cycle assessment studies indicate that the net environmental benefit depends heavily on the energy sources powering the system and the efficiency of the catalysts employed. As catalyst materials continue to improve and renewable energy becomes more prevalent, the environmental advantages of this integrated approach are expected to increase substantially.

From an ecological perspective, this technology could help mitigate the environmental damage caused by conventional nitrogen fixation methods, particularly the Haber-Bosch process, which consumes approximately 1-2% of global energy production and generates significant carbon emissions. By utilizing renewable energy sources such as sunlight to drive the photocatalytic process, this technology substantially reduces the carbon footprint associated with nitrogen fixation.

Water systems stand to benefit considerably from this integrated approach. Current agricultural practices lead to nitrogen runoff that causes eutrophication in water bodies, resulting in harmful algal blooms and oxygen-depleted zones. The controlled production of nitrogen compounds through photocatalytic fixation could reduce dependence on conventional fertilizers, thereby decreasing nitrogen pollution in aquatic ecosystems.

The carbon capture component delivers additional environmental advantages by potentially reducing atmospheric CO2 levels. When this captured carbon is converted into value-added products rather than simply stored, it creates a circular economy approach that further enhances sustainability. This carbon utilization pathway prevents the release of new carbon into the atmosphere that would otherwise come from fossil-based feedstocks.

Land use impacts of this technology are generally positive compared to traditional methods. The system requires significantly less land area than biological nitrogen fixation approaches and eliminates the need for extensive natural gas infrastructure associated with conventional ammonia production facilities.

Regarding biodiversity, reduced nitrogen pollution and decreased carbon emissions could help preserve sensitive ecosystems and protect endangered species that are particularly vulnerable to climate change and environmental contamination. The technology's ability to operate under ambient conditions further minimizes environmental disruption.

Long-term environmental monitoring will be essential to fully assess the technology's impacts, particularly regarding potential release of reaction intermediates or byproducts. Life cycle assessment studies indicate that the net environmental benefit depends heavily on the energy sources powering the system and the efficiency of the catalysts employed. As catalyst materials continue to improve and renewable energy becomes more prevalent, the environmental advantages of this integrated approach are expected to increase substantially.

Scalability and Industrial Implementation Pathways

The scalability of photocatalytic nitrogen fixation integrated with carbon capture represents a critical challenge for industrial implementation. Current laboratory-scale demonstrations, while promising, operate at efficiencies and throughputs that fall significantly short of commercial viability. Scaling these systems requires addressing several engineering challenges, including reactor design optimization, light penetration limitations in larger reactors, and maintaining uniform catalyst distribution across increased surface areas.

Industrial implementation pathways must consider modular approaches that allow for incremental scaling while managing capital expenditure risks. Pilot plant demonstrations of 10-100 kg/day production capacity represent the next logical development stage, allowing for process optimization before full commercial deployment. These pilot facilities would ideally be situated adjacent to existing industrial carbon emission sources, such as power plants or cement factories, to leverage waste CO2 streams directly.

Material requirements present another significant scaling consideration. Current photocatalysts often rely on precious metals or rare earth elements that may face supply constraints at industrial scales. Research into earth-abundant alternatives and catalyst recycling methodologies will be essential for sustainable large-scale implementation. Additionally, standardized manufacturing processes for catalyst production must be developed to ensure consistent performance across industrial-scale operations.

Energy integration strategies will determine economic viability at scale. While photocatalytic processes utilize solar energy, supplementary power requirements for pumping, separation, and purification must be addressed. Hybrid systems incorporating renewable energy sources could create self-sustaining production facilities with minimal carbon footprints, enhancing the overall environmental benefits of the technology.

Regulatory frameworks and carbon pricing mechanisms will significantly influence implementation timelines. Regions with established carbon markets or nitrogen management regulations may offer early adoption opportunities through financial incentives that improve economic feasibility. Strategic partnerships between technology developers, industrial gas companies, and agricultural product manufacturers could accelerate commercialization by creating complete value chains for the carbon and nitrogen products.

The projected timeline for industrial implementation suggests initial commercial demonstrations within 5-7 years, with widespread adoption potentially occurring within 10-15 years, contingent upon technological breakthroughs in catalyst efficiency and reactor design. This timeline aligns with global decarbonization targets, positioning the technology as a potential contributor to mid-century climate goals.

Industrial implementation pathways must consider modular approaches that allow for incremental scaling while managing capital expenditure risks. Pilot plant demonstrations of 10-100 kg/day production capacity represent the next logical development stage, allowing for process optimization before full commercial deployment. These pilot facilities would ideally be situated adjacent to existing industrial carbon emission sources, such as power plants or cement factories, to leverage waste CO2 streams directly.

Material requirements present another significant scaling consideration. Current photocatalysts often rely on precious metals or rare earth elements that may face supply constraints at industrial scales. Research into earth-abundant alternatives and catalyst recycling methodologies will be essential for sustainable large-scale implementation. Additionally, standardized manufacturing processes for catalyst production must be developed to ensure consistent performance across industrial-scale operations.

Energy integration strategies will determine economic viability at scale. While photocatalytic processes utilize solar energy, supplementary power requirements for pumping, separation, and purification must be addressed. Hybrid systems incorporating renewable energy sources could create self-sustaining production facilities with minimal carbon footprints, enhancing the overall environmental benefits of the technology.

Regulatory frameworks and carbon pricing mechanisms will significantly influence implementation timelines. Regions with established carbon markets or nitrogen management regulations may offer early adoption opportunities through financial incentives that improve economic feasibility. Strategic partnerships between technology developers, industrial gas companies, and agricultural product manufacturers could accelerate commercialization by creating complete value chains for the carbon and nitrogen products.

The projected timeline for industrial implementation suggests initial commercial demonstrations within 5-7 years, with widespread adoption potentially occurring within 10-15 years, contingent upon technological breakthroughs in catalyst efficiency and reactor design. This timeline aligns with global decarbonization targets, positioning the technology as a potential contributor to mid-century climate goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!