Evaluating Rail Gun Performance Across Waterborne Platforms

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Background and Objectives

Rail guns have emerged as a revolutionary technology in naval warfare, offering unprecedented capabilities in long-range precision strikes. The concept of electromagnetic propulsion for projectiles dates back to the early 20th century, but significant advancements in power systems and materials science have recently propelled rail gun technology to the forefront of naval armament research.

The primary objective of rail gun technology is to achieve hypervelocity projectile launches without the use of chemical propellants. This approach offers several advantages, including increased range, reduced ammunition storage requirements, and enhanced safety aboard naval vessels. The ultimate goal is to develop a weapon system capable of delivering kinetic energy projectiles at speeds exceeding Mach 7, with ranges of 100 nautical miles or more.

The evolution of rail gun technology has been marked by several key milestones. Early experiments in the 1980s and 1990s demonstrated the feasibility of electromagnetic launch but were limited by power constraints and material degradation issues. The turn of the 21st century saw renewed interest and investment in rail gun research, driven by advancements in power electronics and the development of more robust materials for rail and projectile construction.

Current research efforts focus on overcoming several critical challenges. These include developing compact, high-energy power systems capable of delivering the massive electrical currents required for rail gun operation, as well as designing rails and projectiles that can withstand the extreme forces and temperatures generated during launch. Additionally, integrating rail gun systems into existing naval platforms presents significant engineering challenges related to space, weight, and power requirements.

The potential applications of rail gun technology extend beyond traditional naval gunfire support. Advanced rail gun systems could potentially provide cost-effective solutions for ballistic missile defense, anti-surface warfare, and even as a first-stage propulsion system for space launch vehicles. As such, the development of rail gun technology has implications not only for naval warfare but also for broader strategic and scientific endeavors.

Evaluating rail gun performance across waterborne platforms requires a comprehensive understanding of the interplay between the weapon system and the naval vessel. Factors such as ship stability, power generation capabilities, and structural integrity all play crucial roles in determining the feasibility and effectiveness of rail gun integration. The ultimate objective is to develop a rail gun system that can be effectively deployed across a range of naval platforms, from destroyers to future all-electric warships, while maintaining consistent performance and reliability.

The primary objective of rail gun technology is to achieve hypervelocity projectile launches without the use of chemical propellants. This approach offers several advantages, including increased range, reduced ammunition storage requirements, and enhanced safety aboard naval vessels. The ultimate goal is to develop a weapon system capable of delivering kinetic energy projectiles at speeds exceeding Mach 7, with ranges of 100 nautical miles or more.

The evolution of rail gun technology has been marked by several key milestones. Early experiments in the 1980s and 1990s demonstrated the feasibility of electromagnetic launch but were limited by power constraints and material degradation issues. The turn of the 21st century saw renewed interest and investment in rail gun research, driven by advancements in power electronics and the development of more robust materials for rail and projectile construction.

Current research efforts focus on overcoming several critical challenges. These include developing compact, high-energy power systems capable of delivering the massive electrical currents required for rail gun operation, as well as designing rails and projectiles that can withstand the extreme forces and temperatures generated during launch. Additionally, integrating rail gun systems into existing naval platforms presents significant engineering challenges related to space, weight, and power requirements.

The potential applications of rail gun technology extend beyond traditional naval gunfire support. Advanced rail gun systems could potentially provide cost-effective solutions for ballistic missile defense, anti-surface warfare, and even as a first-stage propulsion system for space launch vehicles. As such, the development of rail gun technology has implications not only for naval warfare but also for broader strategic and scientific endeavors.

Evaluating rail gun performance across waterborne platforms requires a comprehensive understanding of the interplay between the weapon system and the naval vessel. Factors such as ship stability, power generation capabilities, and structural integrity all play crucial roles in determining the feasibility and effectiveness of rail gun integration. The ultimate objective is to develop a rail gun system that can be effectively deployed across a range of naval platforms, from destroyers to future all-electric warships, while maintaining consistent performance and reliability.

Naval Warfare Market Analysis

The naval warfare market has experienced significant growth in recent years, driven by increasing geopolitical tensions and the modernization of naval forces worldwide. This market segment encompasses a wide range of technologies and systems, including advanced weaponry, surveillance equipment, and communication systems. The global naval warfare market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next decade.

One of the key factors driving market growth is the rising demand for advanced naval weapons systems, particularly in regions with ongoing maritime disputes. Countries are investing heavily in upgrading their naval capabilities to protect their territorial waters and project power across strategic sea lanes. This has led to increased procurement of cutting-edge technologies such as rail guns, which offer significant advantages over traditional naval artillery in terms of range, accuracy, and cost-effectiveness.

The market for rail gun technology in naval applications is still in its nascent stages but shows promising potential. Several major defense contractors and research institutions are actively developing and testing rail gun systems for integration into naval platforms. The United States Navy, in particular, has been at the forefront of rail gun research and development, with successful demonstrations of prototype systems on land-based test sites.

Despite the potential benefits of rail gun technology, there are challenges that need to be addressed before widespread adoption can occur. These include power generation and storage requirements, barrel wear issues, and the need for specialized ammunition. However, ongoing research and development efforts are making steady progress in overcoming these obstacles, which is expected to drive market growth in the coming years.

The market for rail gun technology is likely to see increased competition as more countries invest in this capability. China and Russia have also shown interest in developing their own rail gun systems, which could lead to a new arms race in naval weaponry. This competition is expected to spur further innovation and potentially accelerate the commercialization of rail gun technology for naval applications.

As the technology matures, the integration of rail guns into various waterborne platforms will become a key focus area for naval forces. This includes not only large surface combatants but also smaller vessels and potentially even unmanned surface vehicles. The versatility of rail gun systems across different platform types is expected to expand their market potential and drive demand from a diverse range of naval customers.

One of the key factors driving market growth is the rising demand for advanced naval weapons systems, particularly in regions with ongoing maritime disputes. Countries are investing heavily in upgrading their naval capabilities to protect their territorial waters and project power across strategic sea lanes. This has led to increased procurement of cutting-edge technologies such as rail guns, which offer significant advantages over traditional naval artillery in terms of range, accuracy, and cost-effectiveness.

The market for rail gun technology in naval applications is still in its nascent stages but shows promising potential. Several major defense contractors and research institutions are actively developing and testing rail gun systems for integration into naval platforms. The United States Navy, in particular, has been at the forefront of rail gun research and development, with successful demonstrations of prototype systems on land-based test sites.

Despite the potential benefits of rail gun technology, there are challenges that need to be addressed before widespread adoption can occur. These include power generation and storage requirements, barrel wear issues, and the need for specialized ammunition. However, ongoing research and development efforts are making steady progress in overcoming these obstacles, which is expected to drive market growth in the coming years.

The market for rail gun technology is likely to see increased competition as more countries invest in this capability. China and Russia have also shown interest in developing their own rail gun systems, which could lead to a new arms race in naval weaponry. This competition is expected to spur further innovation and potentially accelerate the commercialization of rail gun technology for naval applications.

As the technology matures, the integration of rail guns into various waterborne platforms will become a key focus area for naval forces. This includes not only large surface combatants but also smaller vessels and potentially even unmanned surface vehicles. The versatility of rail gun systems across different platform types is expected to expand their market potential and drive demand from a diverse range of naval customers.

Rail Gun Challenges on Ships

The integration of rail gun technology on naval vessels presents a unique set of challenges that must be addressed to ensure optimal performance and operational effectiveness. One of the primary obstacles is the substantial power requirements of rail gun systems. Naval platforms must be capable of generating and storing massive amounts of electrical energy to support rail gun operations, which can strain existing power generation and distribution systems.

The recoil forces generated by rail gun firing pose another significant challenge. These forces can be orders of magnitude greater than those produced by conventional naval artillery, necessitating robust structural reinforcement of the ship's hull and deck. The integration of such reinforcements must be carefully balanced against weight considerations to maintain vessel stability and maneuverability.

Thermal management is a critical issue in rail gun deployment on ships. The intense heat generated during firing and rapid repetition can lead to barrel erosion and component degradation. Developing effective cooling systems that can operate efficiently in the marine environment is essential for maintaining rail gun performance and longevity.

The marine environment itself presents additional challenges for rail gun systems. Corrosion from saltwater exposure can affect the integrity of rail gun components, particularly the electromagnetic rails. Designing materials and protective measures to withstand these harsh conditions is crucial for long-term reliability.

Accuracy and targeting systems must also be adapted for the dynamic naval environment. Ship motion, including pitch, roll, and yaw, can significantly impact rail gun accuracy at extreme ranges. Advanced fire control systems and stabilization mechanisms are required to compensate for these factors and ensure precision engagement of targets.

Ammunition storage and handling present unique challenges on naval platforms. The specialized projectiles used in rail guns require careful storage to prevent degradation from environmental factors. Additionally, the development of safe and efficient loading mechanisms for rapid fire capability in maritime conditions is essential.

Electromagnetic interference (EMI) is another concern when integrating rail gun technology on ships. The powerful electromagnetic fields generated during rail gun operation can potentially disrupt other onboard electronic systems. Comprehensive EMI shielding and mitigation strategies must be implemented to ensure the coexistence of rail gun systems with critical ship functions.

Lastly, the integration of rail gun systems must consider the overall ship design and mission profile. Balancing the space and weight requirements of rail gun technology with other essential systems and capabilities is crucial for maintaining the vessel's operational versatility and effectiveness across various naval missions.

The recoil forces generated by rail gun firing pose another significant challenge. These forces can be orders of magnitude greater than those produced by conventional naval artillery, necessitating robust structural reinforcement of the ship's hull and deck. The integration of such reinforcements must be carefully balanced against weight considerations to maintain vessel stability and maneuverability.

Thermal management is a critical issue in rail gun deployment on ships. The intense heat generated during firing and rapid repetition can lead to barrel erosion and component degradation. Developing effective cooling systems that can operate efficiently in the marine environment is essential for maintaining rail gun performance and longevity.

The marine environment itself presents additional challenges for rail gun systems. Corrosion from saltwater exposure can affect the integrity of rail gun components, particularly the electromagnetic rails. Designing materials and protective measures to withstand these harsh conditions is crucial for long-term reliability.

Accuracy and targeting systems must also be adapted for the dynamic naval environment. Ship motion, including pitch, roll, and yaw, can significantly impact rail gun accuracy at extreme ranges. Advanced fire control systems and stabilization mechanisms are required to compensate for these factors and ensure precision engagement of targets.

Ammunition storage and handling present unique challenges on naval platforms. The specialized projectiles used in rail guns require careful storage to prevent degradation from environmental factors. Additionally, the development of safe and efficient loading mechanisms for rapid fire capability in maritime conditions is essential.

Electromagnetic interference (EMI) is another concern when integrating rail gun technology on ships. The powerful electromagnetic fields generated during rail gun operation can potentially disrupt other onboard electronic systems. Comprehensive EMI shielding and mitigation strategies must be implemented to ensure the coexistence of rail gun systems with critical ship functions.

Lastly, the integration of rail gun systems must consider the overall ship design and mission profile. Balancing the space and weight requirements of rail gun technology with other essential systems and capabilities is crucial for maintaining the vessel's operational versatility and effectiveness across various naval missions.

Current Rail Gun Solutions

01 Electromagnetic rail gun design

Electromagnetic rail guns use powerful electromagnetic forces to accelerate projectiles to extremely high velocities. The design focuses on optimizing the electromagnetic coils, power supply, and projectile materials to achieve maximum performance. Key considerations include minimizing energy losses, managing heat generation, and ensuring structural integrity under high stresses.- Electromagnetic rail gun design and performance: Electromagnetic rail guns use powerful electromagnetic forces to accelerate projectiles to extremely high velocities. Key design factors include rail configuration, power supply systems, and projectile design to optimize performance and muzzle velocity. Advanced materials and cooling systems are employed to handle the extreme conditions during firing.

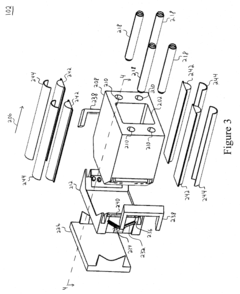

- Projectile design for rail guns: Specialized projectiles are crucial for rail gun performance. Designs focus on aerodynamics, structural integrity to withstand high acceleration forces, and materials that can conduct electricity effectively. Some projectiles incorporate sabots or discarding components to improve launch characteristics and in-flight performance.

- Power supply and energy storage systems: High-performance rail guns require advanced power supply and energy storage systems to deliver the massive electrical currents needed for launching projectiles. This includes capacitor banks, pulse-forming networks, and innovative energy storage solutions to provide rapid, high-energy discharges.

- Cooling and thermal management: Effective cooling and thermal management are essential for maintaining rail gun performance and longevity. Systems may include liquid cooling for rails, advanced heat-resistant materials, and thermal management strategies to dissipate the enormous heat generated during firing and prevent rail degradation.

- Control and targeting systems: Sophisticated control and targeting systems enhance rail gun accuracy and operational effectiveness. These may include advanced fire control computers, precision aiming mechanisms, and integrated sensors for real-time adjustments. Some designs incorporate smart projectiles or guidance systems for improved accuracy at extreme ranges.

02 Projectile design for rail guns

Specialized projectiles are crucial for rail gun performance. These projectiles are designed to withstand the extreme forces and temperatures experienced during launch. Considerations include aerodynamics, material composition, and structural integrity. Advanced projectiles may incorporate features for improved stability, range, and impact effectiveness.Expand Specific Solutions03 Power supply and energy storage systems

High-performance rail guns require advanced power supply and energy storage systems to deliver the massive electrical currents needed for operation. This includes the development of capacitor banks, pulse-forming networks, and high-voltage power sources. Efficient energy management and rapid discharge capabilities are critical for achieving optimal rail gun performance.Expand Specific Solutions04 Rail and conductor materials

The choice of materials for rails and conductors significantly impacts rail gun performance. Research focuses on developing materials that can withstand high temperatures, resist erosion, and maintain conductivity under extreme conditions. Advanced alloys and composite materials are explored to enhance durability and efficiency of the rail gun system.Expand Specific Solutions05 Control systems and performance monitoring

Sophisticated control systems and performance monitoring technologies are essential for optimizing rail gun operation. This includes advanced sensors, real-time data analysis, and adaptive control algorithms. These systems help manage power delivery, projectile acceleration, and overall system efficiency, while also providing valuable data for ongoing performance improvements and maintenance.Expand Specific Solutions

Key Players in Naval Weaponry

The evaluation of rail gun performance across waterborne platforms is currently in an early development stage, with significant research and investment ongoing. The market size is relatively small but growing, driven by military modernization efforts. Technological maturity is still evolving, with key players like Naval Research Laboratory, China North Industries Corp., and Rheinmetall Waffe Munition GmbH leading research efforts. Universities such as Harbin Institute of Technology and Northwestern Polytechnical University are contributing to advancements. The competitive landscape is characterized by a mix of government research institutions, defense contractors, and academic institutions collaborating to overcome technical challenges and improve rail gun capabilities for naval applications.

Harbin Engineering University

Technical Solution: Harbin Engineering University has made significant contributions to rail gun research for waterborne platforms, focusing on electromagnetic launch technology and naval integration. Their approach emphasizes high-efficiency electromagnetic energy conversion and advanced cooling systems for sustained firing rates. The university has developed novel rail designs using composite materials that offer improved durability and conductivity[7]. Their research includes sophisticated numerical modeling of plasma dynamics during projectile launch, leading to optimized rail geometries for reduced erosion. Harbin Engineering University has also pioneered the development of compact, high-current pulse forming networks suitable for shipboard installation, achieving reported current pulses of over 3 million amperes[8]. Additionally, they have made progress in projectile design, creating aerodynamically stable rounds capable of maintaining accuracy over extended ranges in maritime conditions.

Strengths: Advanced electromagnetic modeling, innovative rail materials, and compact pulsed power systems. Weaknesses: Limited full-scale testing data available, and potential challenges in scaling up to operational systems.

Nanjing University of Science & Technology

Technical Solution: Nanjing University of Science & Technology (NUST) has developed a comprehensive approach to rail gun technology for naval applications. Their research focuses on high-energy pulsed power systems and advanced projectile designs optimized for maritime environments. NUST has made significant progress in developing ultra-capacitors with high energy density and rapid discharge capabilities, crucial for rail gun operations[9]. Their rail gun system incorporates innovative rail designs using nano-structured materials to enhance conductivity and heat dissipation. NUST has also developed sophisticated electromagnetic simulations to optimize the rail geometry and minimize rail erosion during high-energy launches. Their projectile research includes the development of fin-stabilized rounds with low-drag profiles, designed to maintain accuracy over long distances in varying atmospheric conditions. NUST's rail gun prototypes have reportedly achieved muzzle velocities exceeding 2,500 m/s with projectile masses of several kilograms[10].

Strengths: Advanced pulsed power technology, innovative rail materials, and sophisticated electromagnetic modeling. Weaknesses: Limited data on full-scale naval integration and potential challenges in scaling up to operational power levels.

Core Rail Gun Innovations

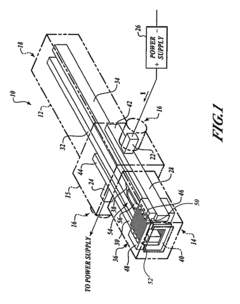

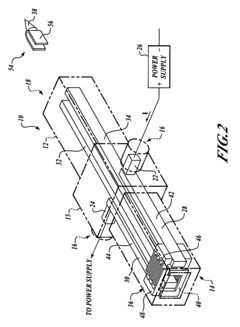

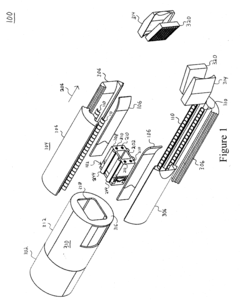

Electromagnetic launcher with augmenting breech

PatentActiveUS7730821B2

Innovation

- The design includes a slidable electromagnetic launcher housing with augmentation conductors and main conductors connected via a current cross-over connection, allowing for recoil accommodation while maintaining electrical contact, and reducing overall inductance by limiting augmentation to early stages of the launch cycle, facilitating faster current rise and balanced weight distribution.

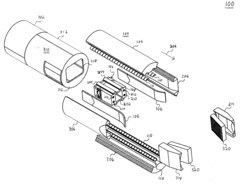

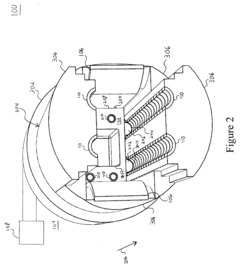

Railgun system

PatentInactiveUS20100194212A1

Innovation

- A railgun system that uses liquid metal, preferably aluminum or aluminum alloys, introduced into a gap between the armature and electrically conductive rails to reduce contact resistance and enhance acceleration, with features like a chamber for containing the liquid metal, a port for directing it into the gap, and a backing to conduct current and maintain the gap, optimizing the Lorentz force for speed.

Maritime Regulations Impact

The implementation of rail gun technology on waterborne platforms is subject to a complex web of maritime regulations that significantly impact its development, testing, and deployment. These regulations span international maritime law, national defense policies, and environmental protection standards.

International maritime law, particularly the United Nations Convention on the Law of the Sea (UNCLOS), plays a crucial role in governing the use of rail guns on naval vessels. UNCLOS establishes guidelines for territorial waters, exclusive economic zones, and the high seas, which directly affect where and how rail guns can be tested and deployed. The convention's provisions on peaceful passage and military activities in different maritime zones must be carefully considered when evaluating rail gun performance across various waterborne platforms.

National defense policies of individual countries also shape the regulatory landscape for rail gun technology. Many nations have specific regulations governing the development and use of advanced weapon systems on naval vessels. These policies often include restrictions on the power output, projectile velocity, and operational range of shipboard weapons, which can directly impact the design and testing parameters for rail guns.

Environmental protection standards pose another significant regulatory challenge for rail gun implementation. The high-energy discharge and electromagnetic fields generated by rail guns raise concerns about potential impacts on marine ecosystems. Regulations such as the Marine Mammal Protection Act in the United States require extensive environmental impact assessments before new weapon systems can be tested in oceanic environments.

Safety regulations for shipboard personnel and equipment also influence rail gun development. The intense electromagnetic fields and high-energy discharges associated with rail gun operation necessitate stringent safety protocols and shielding requirements. These safety considerations must be integrated into the design of both the rail gun systems and the vessels that will carry them.

Furthermore, arms control agreements and export regulations play a role in shaping the development and proliferation of rail gun technology. International agreements like the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies may impose restrictions on the sharing of rail gun technology between nations, potentially limiting collaborative research and development efforts.

The regulatory landscape also extends to the electromagnetic spectrum management, as rail guns can potentially interfere with communication and navigation systems. Compliance with international frequency allocation agreements and electromagnetic compatibility standards is essential for the successful integration of rail guns into existing naval architectures.

International maritime law, particularly the United Nations Convention on the Law of the Sea (UNCLOS), plays a crucial role in governing the use of rail guns on naval vessels. UNCLOS establishes guidelines for territorial waters, exclusive economic zones, and the high seas, which directly affect where and how rail guns can be tested and deployed. The convention's provisions on peaceful passage and military activities in different maritime zones must be carefully considered when evaluating rail gun performance across various waterborne platforms.

National defense policies of individual countries also shape the regulatory landscape for rail gun technology. Many nations have specific regulations governing the development and use of advanced weapon systems on naval vessels. These policies often include restrictions on the power output, projectile velocity, and operational range of shipboard weapons, which can directly impact the design and testing parameters for rail guns.

Environmental protection standards pose another significant regulatory challenge for rail gun implementation. The high-energy discharge and electromagnetic fields generated by rail guns raise concerns about potential impacts on marine ecosystems. Regulations such as the Marine Mammal Protection Act in the United States require extensive environmental impact assessments before new weapon systems can be tested in oceanic environments.

Safety regulations for shipboard personnel and equipment also influence rail gun development. The intense electromagnetic fields and high-energy discharges associated with rail gun operation necessitate stringent safety protocols and shielding requirements. These safety considerations must be integrated into the design of both the rail gun systems and the vessels that will carry them.

Furthermore, arms control agreements and export regulations play a role in shaping the development and proliferation of rail gun technology. International agreements like the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies may impose restrictions on the sharing of rail gun technology between nations, potentially limiting collaborative research and development efforts.

The regulatory landscape also extends to the electromagnetic spectrum management, as rail guns can potentially interfere with communication and navigation systems. Compliance with international frequency allocation agreements and electromagnetic compatibility standards is essential for the successful integration of rail guns into existing naval architectures.

Environmental Considerations

Environmental considerations play a crucial role in evaluating rail gun performance across waterborne platforms. The marine environment presents unique challenges that significantly impact the operation, maintenance, and overall effectiveness of rail gun systems. Saltwater exposure is a primary concern, as it can lead to accelerated corrosion of metal components, potentially compromising the structural integrity and electrical conductivity of the rail gun. This necessitates the development and implementation of advanced corrosion-resistant materials and protective coatings to ensure long-term reliability in maritime settings.

Temperature fluctuations and humidity levels in marine environments also affect rail gun performance. Extreme temperature variations can cause thermal expansion and contraction of components, potentially leading to misalignments or structural stress. High humidity levels may impact the electrical systems, requiring robust insulation and moisture-resistant designs to maintain optimal functionality. Additionally, the constant motion and vibration experienced on waterborne platforms introduce further complexities, necessitating advanced stabilization systems and shock-absorbing mechanisms to maintain targeting accuracy and structural stability during operation.

The electromagnetic signature of rail guns poses another environmental consideration. In naval applications, minimizing electromagnetic emissions is crucial for maintaining stealth capabilities. Engineers must develop innovative shielding techniques and emission control systems to reduce the detectability of rail gun systems without compromising their performance. Furthermore, the acoustic signature generated during rail gun firing must be carefully managed to minimize its impact on marine life and comply with environmental regulations.

Sea states and weather conditions significantly influence rail gun effectiveness on waterborne platforms. High waves, strong winds, and adverse weather can affect targeting accuracy and limit operational windows. Advanced fire control systems and predictive algorithms must be developed to compensate for platform motion and environmental factors, ensuring consistent performance across various sea conditions. Moreover, the potential for saltwater spray or submersion during extreme weather events necessitates the implementation of robust sealing and waterproofing measures to protect sensitive components.

Environmental impact assessments are essential when evaluating rail gun performance in marine settings. The high-energy projectiles fired by rail guns may have implications for marine ecosystems, particularly in coastal areas or during naval exercises. Research into eco-friendly projectile designs and the development of strategies to minimize environmental disturbance are critical aspects of rail gun technology advancement for waterborne platforms. Additionally, considerations must be made for the safe disposal or recycling of spent components and materials to align with maritime environmental protection standards.

Temperature fluctuations and humidity levels in marine environments also affect rail gun performance. Extreme temperature variations can cause thermal expansion and contraction of components, potentially leading to misalignments or structural stress. High humidity levels may impact the electrical systems, requiring robust insulation and moisture-resistant designs to maintain optimal functionality. Additionally, the constant motion and vibration experienced on waterborne platforms introduce further complexities, necessitating advanced stabilization systems and shock-absorbing mechanisms to maintain targeting accuracy and structural stability during operation.

The electromagnetic signature of rail guns poses another environmental consideration. In naval applications, minimizing electromagnetic emissions is crucial for maintaining stealth capabilities. Engineers must develop innovative shielding techniques and emission control systems to reduce the detectability of rail gun systems without compromising their performance. Furthermore, the acoustic signature generated during rail gun firing must be carefully managed to minimize its impact on marine life and comply with environmental regulations.

Sea states and weather conditions significantly influence rail gun effectiveness on waterborne platforms. High waves, strong winds, and adverse weather can affect targeting accuracy and limit operational windows. Advanced fire control systems and predictive algorithms must be developed to compensate for platform motion and environmental factors, ensuring consistent performance across various sea conditions. Moreover, the potential for saltwater spray or submersion during extreme weather events necessitates the implementation of robust sealing and waterproofing measures to protect sensitive components.

Environmental impact assessments are essential when evaluating rail gun performance in marine settings. The high-energy projectiles fired by rail guns may have implications for marine ecosystems, particularly in coastal areas or during naval exercises. Research into eco-friendly projectile designs and the development of strategies to minimize environmental disturbance are critical aspects of rail gun technology advancement for waterborne platforms. Additionally, considerations must be made for the safe disposal or recycling of spent components and materials to align with maritime environmental protection standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!