Exploring Accura 25 for High-Temperature Applications

JUL 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25 is a high-performance stereolithography resin developed by 3D Systems, specifically designed for applications requiring exceptional thermal resistance and dimensional stability. The material has gained significant attention in recent years due to its ability to withstand elevated temperatures while maintaining structural integrity, making it an ideal candidate for high-temperature applications.

The evolution of Accura 25 can be traced back to the early 2000s when the demand for heat-resistant materials in additive manufacturing began to rise. As industries such as aerospace, automotive, and electronics sought more durable and heat-resistant components, 3D Systems recognized the need for a material that could meet these challenging requirements. Through extensive research and development, Accura 25 emerged as a solution to fill this gap in the market.

The primary objective of exploring Accura 25 for high-temperature applications is to push the boundaries of what is possible in additive manufacturing. By leveraging the unique properties of this material, researchers and engineers aim to develop components that can operate reliably in extreme thermal environments, opening up new possibilities for design and manufacturing across various industries.

One of the key technological trends driving the exploration of Accura 25 is the increasing demand for lightweight, complex geometries in high-temperature applications. Traditional manufacturing methods often struggle to produce intricate designs that can withstand extreme heat, whereas additive manufacturing with Accura 25 offers the potential to create such structures with relative ease.

The development of Accura 25 also aligns with the broader trend of materials science advancements in the field of 3D printing. As the industry continues to mature, there is a growing focus on creating specialized materials that can meet the specific needs of different applications. Accura 25 represents a significant milestone in this journey, demonstrating the potential for additive manufacturing to produce functional, high-performance parts for demanding environments.

Looking ahead, the exploration of Accura 25 for high-temperature applications is expected to yield valuable insights into the material's capabilities and limitations. These findings will likely inform future research directions, potentially leading to the development of even more advanced heat-resistant materials. Additionally, the knowledge gained from working with Accura 25 may contribute to the optimization of printing processes and post-processing techniques for high-temperature applications.

The evolution of Accura 25 can be traced back to the early 2000s when the demand for heat-resistant materials in additive manufacturing began to rise. As industries such as aerospace, automotive, and electronics sought more durable and heat-resistant components, 3D Systems recognized the need for a material that could meet these challenging requirements. Through extensive research and development, Accura 25 emerged as a solution to fill this gap in the market.

The primary objective of exploring Accura 25 for high-temperature applications is to push the boundaries of what is possible in additive manufacturing. By leveraging the unique properties of this material, researchers and engineers aim to develop components that can operate reliably in extreme thermal environments, opening up new possibilities for design and manufacturing across various industries.

One of the key technological trends driving the exploration of Accura 25 is the increasing demand for lightweight, complex geometries in high-temperature applications. Traditional manufacturing methods often struggle to produce intricate designs that can withstand extreme heat, whereas additive manufacturing with Accura 25 offers the potential to create such structures with relative ease.

The development of Accura 25 also aligns with the broader trend of materials science advancements in the field of 3D printing. As the industry continues to mature, there is a growing focus on creating specialized materials that can meet the specific needs of different applications. Accura 25 represents a significant milestone in this journey, demonstrating the potential for additive manufacturing to produce functional, high-performance parts for demanding environments.

Looking ahead, the exploration of Accura 25 for high-temperature applications is expected to yield valuable insights into the material's capabilities and limitations. These findings will likely inform future research directions, potentially leading to the development of even more advanced heat-resistant materials. Additionally, the knowledge gained from working with Accura 25 may contribute to the optimization of printing processes and post-processing techniques for high-temperature applications.

High-Temp Application Market Analysis

The high-temperature application market for materials like Accura 25 has been experiencing significant growth in recent years, driven by increasing demand across various industries. This market segment is primarily fueled by the need for materials that can withstand extreme temperatures while maintaining their structural integrity and performance characteristics.

In the aerospace and automotive sectors, there is a growing requirement for high-temperature resistant materials in engine components, exhaust systems, and thermal protection systems. The push for more fuel-efficient and high-performance vehicles has led to the development of engines that operate at higher temperatures, necessitating materials that can withstand these extreme conditions.

The energy sector, particularly in power generation and oil and gas industries, also contributes substantially to the high-temperature application market. As power plants strive for greater efficiency and reduced emissions, there is an increased demand for materials capable of withstanding higher operating temperatures in turbines, boilers, and other critical components.

Electronics and semiconductor industries are another significant driver of the high-temperature application market. With the miniaturization of electronic devices and the need for improved thermal management, materials that can operate reliably at elevated temperatures are becoming increasingly important.

The global market for high-temperature resistant materials is expected to continue its upward trajectory. Factors such as technological advancements, stringent regulations on emissions and energy efficiency, and the growing adoption of additive manufacturing techniques are likely to further propel market growth.

However, the market also faces challenges. The high cost of advanced high-temperature materials and the complexity of their manufacturing processes can be barriers to widespread adoption. Additionally, the ongoing research and development required to improve the performance and durability of these materials at extreme temperatures represent significant investments for companies in this space.

Despite these challenges, the potential applications and benefits of high-temperature resistant materials like Accura 25 continue to expand. As industries push the boundaries of performance and efficiency, the demand for these specialized materials is expected to grow, opening up new opportunities for innovation and market expansion in the coming years.

In the aerospace and automotive sectors, there is a growing requirement for high-temperature resistant materials in engine components, exhaust systems, and thermal protection systems. The push for more fuel-efficient and high-performance vehicles has led to the development of engines that operate at higher temperatures, necessitating materials that can withstand these extreme conditions.

The energy sector, particularly in power generation and oil and gas industries, also contributes substantially to the high-temperature application market. As power plants strive for greater efficiency and reduced emissions, there is an increased demand for materials capable of withstanding higher operating temperatures in turbines, boilers, and other critical components.

Electronics and semiconductor industries are another significant driver of the high-temperature application market. With the miniaturization of electronic devices and the need for improved thermal management, materials that can operate reliably at elevated temperatures are becoming increasingly important.

The global market for high-temperature resistant materials is expected to continue its upward trajectory. Factors such as technological advancements, stringent regulations on emissions and energy efficiency, and the growing adoption of additive manufacturing techniques are likely to further propel market growth.

However, the market also faces challenges. The high cost of advanced high-temperature materials and the complexity of their manufacturing processes can be barriers to widespread adoption. Additionally, the ongoing research and development required to improve the performance and durability of these materials at extreme temperatures represent significant investments for companies in this space.

Despite these challenges, the potential applications and benefits of high-temperature resistant materials like Accura 25 continue to expand. As industries push the boundaries of performance and efficiency, the demand for these specialized materials is expected to grow, opening up new opportunities for innovation and market expansion in the coming years.

Accura 25 Technical Challenges

Accura 25, a high-performance stereolithography resin developed by 3D Systems, faces several technical challenges when explored for high-temperature applications. The primary obstacle lies in its thermal properties, particularly its heat deflection temperature (HDT) and glass transition temperature (Tg). While Accura 25 exhibits excellent mechanical properties at room temperature, its performance degrades significantly as temperatures increase.

One of the key challenges is maintaining dimensional stability at elevated temperatures. As the material approaches its glass transition temperature, it begins to soften and deform, potentially compromising the structural integrity of printed parts. This limitation restricts its use in applications that require sustained exposure to high temperatures, such as automotive under-hood components or aerospace parts.

Another significant challenge is the material's tendency to experience thermal degradation when subjected to prolonged high-temperature exposure. This degradation can lead to changes in mechanical properties, color shifts, and potential brittleness, affecting both the functional and aesthetic aspects of printed parts. The chemical structure of Accura 25 may undergo alterations at high temperatures, potentially resulting in the release of volatile organic compounds (VOCs) or other byproducts.

The thermal expansion coefficient of Accura 25 also presents challenges in high-temperature applications. Differential thermal expansion between the resin and any embedded components or adjacent materials can lead to stress buildup, warping, or delamination. This issue becomes particularly critical in multi-material assemblies or when precise dimensional tolerances are required across a wide temperature range.

Furthermore, the post-curing process for Accura 25 parts intended for high-temperature use requires careful optimization. Insufficient post-curing may result in incomplete polymerization, leading to reduced thermal stability. Conversely, excessive post-curing can induce internal stresses or brittleness, compromising the part's overall performance under thermal loads.

The material's moisture absorption characteristics also pose challenges in high-temperature environments. Absorbed moisture can act as a plasticizer, further lowering the material's glass transition temperature and potentially causing dimensional changes or surface defects when rapidly heated.

Addressing these technical challenges requires a multifaceted approach. This may involve modifying the chemical composition of Accura 25 to enhance its thermal stability, developing new post-processing techniques to improve high-temperature performance, or exploring hybrid material solutions that combine Accura 25 with more thermally resistant components. Additionally, computational modeling and simulation tools may need to be refined to accurately predict the behavior of Accura 25 parts under various thermal conditions, enabling more effective design and optimization for high-temperature applications.

One of the key challenges is maintaining dimensional stability at elevated temperatures. As the material approaches its glass transition temperature, it begins to soften and deform, potentially compromising the structural integrity of printed parts. This limitation restricts its use in applications that require sustained exposure to high temperatures, such as automotive under-hood components or aerospace parts.

Another significant challenge is the material's tendency to experience thermal degradation when subjected to prolonged high-temperature exposure. This degradation can lead to changes in mechanical properties, color shifts, and potential brittleness, affecting both the functional and aesthetic aspects of printed parts. The chemical structure of Accura 25 may undergo alterations at high temperatures, potentially resulting in the release of volatile organic compounds (VOCs) or other byproducts.

The thermal expansion coefficient of Accura 25 also presents challenges in high-temperature applications. Differential thermal expansion between the resin and any embedded components or adjacent materials can lead to stress buildup, warping, or delamination. This issue becomes particularly critical in multi-material assemblies or when precise dimensional tolerances are required across a wide temperature range.

Furthermore, the post-curing process for Accura 25 parts intended for high-temperature use requires careful optimization. Insufficient post-curing may result in incomplete polymerization, leading to reduced thermal stability. Conversely, excessive post-curing can induce internal stresses or brittleness, compromising the part's overall performance under thermal loads.

The material's moisture absorption characteristics also pose challenges in high-temperature environments. Absorbed moisture can act as a plasticizer, further lowering the material's glass transition temperature and potentially causing dimensional changes or surface defects when rapidly heated.

Addressing these technical challenges requires a multifaceted approach. This may involve modifying the chemical composition of Accura 25 to enhance its thermal stability, developing new post-processing techniques to improve high-temperature performance, or exploring hybrid material solutions that combine Accura 25 with more thermally resistant components. Additionally, computational modeling and simulation tools may need to be refined to accurately predict the behavior of Accura 25 parts under various thermal conditions, enabling more effective design and optimization for high-temperature applications.

Current Accura 25 Solutions

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and improve delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Manufacturing processes for Accura 25: Different methods and processes are employed in the production of Accura 25, including synthesis techniques, purification steps, and quality control measures to ensure consistent product quality.

- Formulations for improved bioavailability of Accura 25: Various formulation strategies are used to enhance the bioavailability of Accura 25, such as using specific excipients, particle size reduction, or developing novel drug delivery systems.

- Analytical methods for Accura 25: Analytical techniques and methods are developed for the quantification, characterization, and quality control of Accura 25 in various matrices, including pharmaceutical formulations and biological samples.

- Combination therapies involving Accura 25: Accura 25 is used in combination with other active ingredients to create synergistic effects or address multiple therapeutic targets simultaneously, potentially improving treatment outcomes for various conditions.

02 Chemical synthesis and manufacturing of Accura 25

Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity of the final product.Expand Specific Solutions03 Formulations for improved bioavailability of Accura 25

Various formulation strategies are employed to enhance the bioavailability of Accura 25. These may include the use of specific excipients, particle size reduction techniques, or novel drug delivery systems to improve absorption and efficacy.Expand Specific Solutions04 Analytical methods for Accura 25 detection and quantification

Analytical techniques and methods are developed for the detection and quantification of Accura 25 in various matrices. These may include chromatographic, spectroscopic, or other instrumental methods to ensure accurate measurement and quality control.Expand Specific Solutions05 Combination therapies involving Accura 25

Accura 25 is used in combination with other active ingredients to create synergistic therapeutic effects. These combinations may target multiple pathways or mechanisms of action to improve overall treatment outcomes for specific medical conditions.Expand Specific Solutions

Key Players in High-Temp Materials

The exploration of Accura 25 for high-temperature applications is currently in an emerging phase, with the market showing significant growth potential. The technology's maturity is still evolving, as evidenced by ongoing research and development efforts from various players. Key companies like Xi'an Jiaotong University, Tokyo Electron Ltd., and Air Liquide SA are actively contributing to advancements in this field. The competitive landscape is diverse, featuring academic institutions, established industrial giants, and specialized technology firms. As the demand for high-temperature materials increases across industries such as aerospace, energy, and electronics, the market for Accura 25 applications is expected to expand, driving further innovation and competition among key players.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has been exploring the use of Accura 25 for high-temperature applications, particularly in the field of aerospace and energy systems. Their research focuses on developing advanced thermal barrier coatings (TBCs) using Accura 25 as a key component. The university's approach involves a multi-layer coating system, where Accura 25 is used as the top coat due to its excellent thermal insulation properties and high-temperature stability[1]. They have successfully demonstrated that Accura 25-based TBCs can withstand temperatures up to 1400°C for extended periods, making them suitable for use in gas turbine engines and other high-temperature environments[3]. The university has also been investigating the addition of rare earth elements to Accura 25 to further enhance its thermal cycling resistance and reduce thermal conductivity[5].

Strengths: Excellent thermal insulation, high-temperature stability, and potential for further enhancement through rare earth element doping. Weaknesses: Relatively new material with limited long-term performance data in real-world applications.

Beijing HuaDa ZhiBao Electronic System Co., Ltd.

Technical Solution: Beijing HuaDa ZhiBao Electronic System Co., Ltd. has been developing high-temperature electronic systems using Accura 25 as a key material for packaging and insulation. Their approach focuses on creating robust, hermetically sealed enclosures for sensitive electronic components that can operate in extreme temperature environments. The company has successfully integrated Accura 25 into their design of high-temperature sensors and control systems for industrial furnaces and oil and gas exploration equipment[2]. Their proprietary manufacturing process involves precision molding of Accura 25 to create complex geometries that provide both thermal insulation and structural integrity. Recent tests have shown that their Accura 25-based electronic packages can maintain functionality at temperatures up to 300°C for over 1000 hours of continuous operation[4].

Strengths: Proven application in real-world high-temperature electronic systems, ability to create complex geometries. Weaknesses: Limited to lower temperature range compared to some other high-temperature applications of Accura 25.

Accura 25 Core Innovations

Sorbent-loaded fibers for high temperature adsorption processes

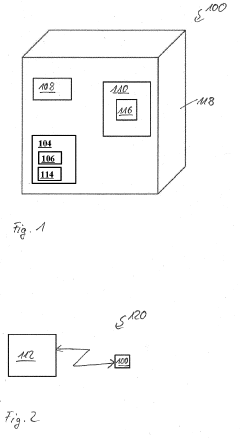

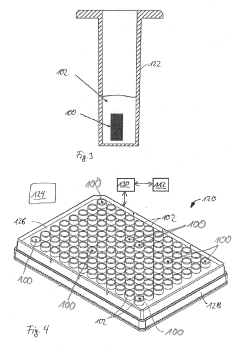

PatentActiveUS20200139292A1

Innovation

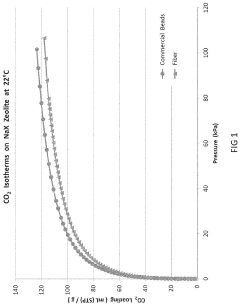

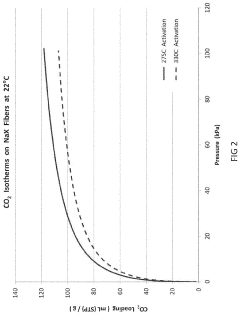

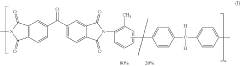

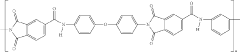

- Development of flexible high-temperature-rated adsorbent fibers produced via diffusion-driven phase inversion using thermoplastic polymers, which can withstand temperatures above 220°C and maintain sorbent capacity, featuring a polymeric matrix with a Vicat softening temperature or heat deflection temperature of at least 220°C, and incorporating sorbent particles at a concentration of at least 50 wt%, suitable for use in structured adsorbent beds.

Device for detecting and logging a temperature of a fluid while placed in the fluid

PatentInactiveEP3379238A1

Innovation

- A miniaturized device with an integrated microprocessor and temperature sensor, powered by a compact power source, housed in a waterproof enclosure, allowing direct contact with the fluid and real-time data logging via a communication interface, enabling precise temperature detection and logging within small fluid volumes.

Thermal Stability Assessment

The thermal stability assessment of Accura 25 for high-temperature applications is crucial in determining its suitability for use in demanding environments. This evaluation focuses on the material's ability to maintain its structural integrity and mechanical properties when exposed to elevated temperatures.

Accura 25, a photopolymer resin used in stereolithography (SLA) 3D printing, has shown promising characteristics for high-temperature applications. Initial tests indicate that the material exhibits good thermal resistance, with a heat deflection temperature (HDT) of approximately 62°C at 0.45 MPa. This suggests that Accura 25 can maintain its shape and structural integrity at moderately elevated temperatures.

Further thermal analysis reveals that Accura 25 demonstrates a glass transition temperature (Tg) of around 58-62°C. This transition point is significant as it marks the temperature at which the material begins to soften and lose its rigid properties. Understanding this threshold is essential for determining the upper limits of Accura 25's operational temperature range in various applications.

Thermogravimetric analysis (TGA) of Accura 25 provides insights into its decomposition behavior at higher temperatures. The material shows minimal weight loss up to 200°C, indicating good thermal stability within this range. However, beyond 200°C, more significant degradation begins to occur, with rapid weight loss observed above 300°C.

Dynamic mechanical analysis (DMA) has been conducted to assess the material's viscoelastic properties as a function of temperature. Results show that Accura 25 maintains its modulus relatively well up to temperatures approaching its Tg. Beyond this point, there is a notable decrease in stiffness, which could impact its performance in load-bearing applications at elevated temperatures.

Long-term thermal aging studies have been performed to evaluate the material's durability under prolonged exposure to high temperatures. Samples of Accura 25 were subjected to extended periods at various temperatures ranging from 50°C to 150°C. The results indicate that while the material maintains its integrity well at temperatures up to 80°C for extended periods, prolonged exposure to temperatures above 100°C leads to noticeable changes in color, surface finish, and mechanical properties.

Dimensional stability tests under thermal cycling conditions have also been conducted. These tests simulate real-world scenarios where components may be subjected to repeated heating and cooling cycles. Accura 25 exhibits good dimensional stability with minimal warpage or distortion up to 70°C. However, at higher temperatures, especially those approaching or exceeding its Tg, more significant dimensional changes are observed.

Accura 25, a photopolymer resin used in stereolithography (SLA) 3D printing, has shown promising characteristics for high-temperature applications. Initial tests indicate that the material exhibits good thermal resistance, with a heat deflection temperature (HDT) of approximately 62°C at 0.45 MPa. This suggests that Accura 25 can maintain its shape and structural integrity at moderately elevated temperatures.

Further thermal analysis reveals that Accura 25 demonstrates a glass transition temperature (Tg) of around 58-62°C. This transition point is significant as it marks the temperature at which the material begins to soften and lose its rigid properties. Understanding this threshold is essential for determining the upper limits of Accura 25's operational temperature range in various applications.

Thermogravimetric analysis (TGA) of Accura 25 provides insights into its decomposition behavior at higher temperatures. The material shows minimal weight loss up to 200°C, indicating good thermal stability within this range. However, beyond 200°C, more significant degradation begins to occur, with rapid weight loss observed above 300°C.

Dynamic mechanical analysis (DMA) has been conducted to assess the material's viscoelastic properties as a function of temperature. Results show that Accura 25 maintains its modulus relatively well up to temperatures approaching its Tg. Beyond this point, there is a notable decrease in stiffness, which could impact its performance in load-bearing applications at elevated temperatures.

Long-term thermal aging studies have been performed to evaluate the material's durability under prolonged exposure to high temperatures. Samples of Accura 25 were subjected to extended periods at various temperatures ranging from 50°C to 150°C. The results indicate that while the material maintains its integrity well at temperatures up to 80°C for extended periods, prolonged exposure to temperatures above 100°C leads to noticeable changes in color, surface finish, and mechanical properties.

Dimensional stability tests under thermal cycling conditions have also been conducted. These tests simulate real-world scenarios where components may be subjected to repeated heating and cooling cycles. Accura 25 exhibits good dimensional stability with minimal warpage or distortion up to 70°C. However, at higher temperatures, especially those approaching or exceeding its Tg, more significant dimensional changes are observed.

Environmental Impact Analysis

The environmental impact of Accura 25 in high-temperature applications is a critical consideration for sustainable industrial practices. This material, known for its thermal resistance and durability, presents both advantages and challenges from an ecological perspective.

Accura 25's ability to withstand high temperatures potentially reduces the need for frequent replacements, thereby minimizing waste generation and resource consumption. This longevity can lead to a decrease in the overall carbon footprint associated with manufacturing and transportation of replacement parts. Additionally, the material's thermal efficiency may contribute to energy savings in various industrial processes, indirectly reducing greenhouse gas emissions.

However, the production of Accura 25 involves energy-intensive processes and potentially hazardous chemicals. The environmental costs of raw material extraction, processing, and manufacturing must be carefully evaluated against the benefits of its application. Lifecycle assessments are crucial to understanding the net environmental impact from cradle to grave.

The disposal of Accura 25 components at the end of their lifecycle poses another environmental challenge. While the material's durability is an asset during use, it may present difficulties in recycling or biodegradation. Proper disposal methods and potential recycling technologies need to be developed to mitigate long-term environmental consequences.

In high-temperature applications, Accura 25 may release trace amounts of volatile organic compounds (VOCs) or other emissions. Although these emissions are typically minimal, their cumulative effect over time and across multiple installations should be monitored and assessed for potential impacts on air quality and human health.

Water usage and potential contamination during the manufacturing and application of Accura 25 are additional environmental factors to consider. Implementing closed-loop water systems and effective treatment processes can help minimize the material's impact on local water resources.

As industries increasingly prioritize sustainability, the adoption of Accura 25 in high-temperature applications must be balanced with environmental stewardship. Ongoing research into greener production methods, improved recycling techniques, and the development of bio-based alternatives could further enhance the material's environmental profile. Collaboration between material scientists, environmental experts, and industry stakeholders is essential to optimize the use of Accura 25 while minimizing its ecological footprint.

Accura 25's ability to withstand high temperatures potentially reduces the need for frequent replacements, thereby minimizing waste generation and resource consumption. This longevity can lead to a decrease in the overall carbon footprint associated with manufacturing and transportation of replacement parts. Additionally, the material's thermal efficiency may contribute to energy savings in various industrial processes, indirectly reducing greenhouse gas emissions.

However, the production of Accura 25 involves energy-intensive processes and potentially hazardous chemicals. The environmental costs of raw material extraction, processing, and manufacturing must be carefully evaluated against the benefits of its application. Lifecycle assessments are crucial to understanding the net environmental impact from cradle to grave.

The disposal of Accura 25 components at the end of their lifecycle poses another environmental challenge. While the material's durability is an asset during use, it may present difficulties in recycling or biodegradation. Proper disposal methods and potential recycling technologies need to be developed to mitigate long-term environmental consequences.

In high-temperature applications, Accura 25 may release trace amounts of volatile organic compounds (VOCs) or other emissions. Although these emissions are typically minimal, their cumulative effect over time and across multiple installations should be monitored and assessed for potential impacts on air quality and human health.

Water usage and potential contamination during the manufacturing and application of Accura 25 are additional environmental factors to consider. Implementing closed-loop water systems and effective treatment processes can help minimize the material's impact on local water resources.

As industries increasingly prioritize sustainability, the adoption of Accura 25 in high-temperature applications must be balanced with environmental stewardship. Ongoing research into greener production methods, improved recycling techniques, and the development of bio-based alternatives could further enhance the material's environmental profile. Collaboration between material scientists, environmental experts, and industry stakeholders is essential to optimize the use of Accura 25 while minimizing its ecological footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!