Understanding Accura 25’s Role in Jewelry Crafting

JUL 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background

Accura 25 is a high-performance stereolithography (SLA) resin developed by 3D Systems, specifically designed for jewelry applications. This material has revolutionized the jewelry industry by enabling the creation of intricate and detailed patterns that were previously challenging or impossible to achieve through traditional manufacturing methods.

The development of Accura 25 can be traced back to the early 2000s when 3D Systems recognized the growing demand for advanced materials in the jewelry sector. As 3D printing technologies evolved, there was a need for a resin that could meet the exacting standards of jewelry designers and manufacturers. Accura 25 was introduced to address these requirements, offering a unique combination of properties that make it ideal for jewelry production.

One of the key features of Accura 25 is its exceptional resolution and surface finish. The material can reproduce fine details and smooth surfaces, which are crucial in jewelry design. This high level of precision allows for the creation of complex geometries, filigree patterns, and delicate structures that are essential in modern jewelry pieces.

Accura 25 also boasts excellent mechanical properties, including high strength and durability. These characteristics make it suitable not only for prototyping but also for creating functional jewelry components and even final products. The material's stability ensures that printed parts maintain their shape and detail integrity throughout the post-processing stages, which is critical in jewelry manufacturing.

Another significant aspect of Accura 25 is its compatibility with various finishing techniques commonly used in jewelry making. The resin can be easily polished, plated, and set with gemstones, allowing for seamless integration into traditional jewelry production workflows. This versatility has made Accura 25 a popular choice among both established jewelry brands and independent designers looking to push the boundaries of their craft.

The introduction of Accura 25 has had a profound impact on the jewelry industry's design and production processes. It has enabled rapid prototyping, allowing designers to quickly iterate and refine their concepts before committing to final production. This has led to increased creativity and innovation in jewelry design, as well as reduced time-to-market for new collections.

Furthermore, Accura 25 has opened up new possibilities for customization and personalization in jewelry. The ability to easily create one-of-a-kind pieces or small batches of custom designs has transformed the way jewelers approach bespoke creations, offering customers unique and tailored products.

As the jewelry industry continues to embrace digital technologies, Accura 25 remains at the forefront of materials innovation. Its ongoing development and refinement by 3D Systems ensure that it continues to meet the evolving needs of jewelry designers and manufacturers, solidifying its position as a cornerstone material in the intersection of traditional craftsmanship and cutting-edge technology.

The development of Accura 25 can be traced back to the early 2000s when 3D Systems recognized the growing demand for advanced materials in the jewelry sector. As 3D printing technologies evolved, there was a need for a resin that could meet the exacting standards of jewelry designers and manufacturers. Accura 25 was introduced to address these requirements, offering a unique combination of properties that make it ideal for jewelry production.

One of the key features of Accura 25 is its exceptional resolution and surface finish. The material can reproduce fine details and smooth surfaces, which are crucial in jewelry design. This high level of precision allows for the creation of complex geometries, filigree patterns, and delicate structures that are essential in modern jewelry pieces.

Accura 25 also boasts excellent mechanical properties, including high strength and durability. These characteristics make it suitable not only for prototyping but also for creating functional jewelry components and even final products. The material's stability ensures that printed parts maintain their shape and detail integrity throughout the post-processing stages, which is critical in jewelry manufacturing.

Another significant aspect of Accura 25 is its compatibility with various finishing techniques commonly used in jewelry making. The resin can be easily polished, plated, and set with gemstones, allowing for seamless integration into traditional jewelry production workflows. This versatility has made Accura 25 a popular choice among both established jewelry brands and independent designers looking to push the boundaries of their craft.

The introduction of Accura 25 has had a profound impact on the jewelry industry's design and production processes. It has enabled rapid prototyping, allowing designers to quickly iterate and refine their concepts before committing to final production. This has led to increased creativity and innovation in jewelry design, as well as reduced time-to-market for new collections.

Furthermore, Accura 25 has opened up new possibilities for customization and personalization in jewelry. The ability to easily create one-of-a-kind pieces or small batches of custom designs has transformed the way jewelers approach bespoke creations, offering customers unique and tailored products.

As the jewelry industry continues to embrace digital technologies, Accura 25 remains at the forefront of materials innovation. Its ongoing development and refinement by 3D Systems ensure that it continues to meet the evolving needs of jewelry designers and manufacturers, solidifying its position as a cornerstone material in the intersection of traditional craftsmanship and cutting-edge technology.

Jewelry Market Demand

The jewelry market has experienced significant growth and transformation in recent years, driven by changing consumer preferences, technological advancements, and evolving fashion trends. The global jewelry market size was valued at approximately $278 billion in 2021 and is projected to reach $430 billion by 2025, growing at a compound annual growth rate (CAGR) of 8.5%.

Within this expanding market, there is a growing demand for customized and personalized jewelry pieces. Consumers are increasingly seeking unique designs that reflect their individual style and personality. This trend has led to a surge in the popularity of bespoke jewelry services, where customers can collaborate with designers to create one-of-a-kind pieces.

The rise of e-commerce has also significantly impacted the jewelry market, with online sales accounting for an increasing share of total revenue. This shift has created new opportunities for jewelry manufacturers and retailers to reach a broader customer base and offer virtual try-on experiences using augmented reality technologies.

In terms of materials, there is a growing interest in sustainable and ethically sourced jewelry. Consumers are becoming more conscious of the environmental and social impact of their purchases, leading to increased demand for recycled metals, lab-grown diamonds, and conflict-free gemstones.

The luxury jewelry segment continues to show strong growth, particularly in emerging markets such as China and India. High-net-worth individuals are driving demand for premium and ultra-luxury jewelry pieces, often viewing them as investment assets as well as fashion statements.

Technological advancements in jewelry manufacturing, such as 3D printing and computer-aided design (CAD), have opened up new possibilities for intricate and complex designs. These technologies have also reduced production times and costs, making customized jewelry more accessible to a wider range of consumers.

The role of Accura 25 in jewelry crafting aligns with these market trends, particularly in the areas of customization and precision manufacturing. As a high-performance stereolithography resin, Accura 25 enables jewelry designers and manufacturers to create highly detailed prototypes and molds for casting. This capability is especially valuable in meeting the growing demand for personalized and intricate jewelry designs.

Within this expanding market, there is a growing demand for customized and personalized jewelry pieces. Consumers are increasingly seeking unique designs that reflect their individual style and personality. This trend has led to a surge in the popularity of bespoke jewelry services, where customers can collaborate with designers to create one-of-a-kind pieces.

The rise of e-commerce has also significantly impacted the jewelry market, with online sales accounting for an increasing share of total revenue. This shift has created new opportunities for jewelry manufacturers and retailers to reach a broader customer base and offer virtual try-on experiences using augmented reality technologies.

In terms of materials, there is a growing interest in sustainable and ethically sourced jewelry. Consumers are becoming more conscious of the environmental and social impact of their purchases, leading to increased demand for recycled metals, lab-grown diamonds, and conflict-free gemstones.

The luxury jewelry segment continues to show strong growth, particularly in emerging markets such as China and India. High-net-worth individuals are driving demand for premium and ultra-luxury jewelry pieces, often viewing them as investment assets as well as fashion statements.

Technological advancements in jewelry manufacturing, such as 3D printing and computer-aided design (CAD), have opened up new possibilities for intricate and complex designs. These technologies have also reduced production times and costs, making customized jewelry more accessible to a wider range of consumers.

The role of Accura 25 in jewelry crafting aligns with these market trends, particularly in the areas of customization and precision manufacturing. As a high-performance stereolithography resin, Accura 25 enables jewelry designers and manufacturers to create highly detailed prototypes and molds for casting. This capability is especially valuable in meeting the growing demand for personalized and intricate jewelry designs.

Accura 25 Capabilities

Accura 25 is a high-performance stereolithography (SLA) resin specifically designed for jewelry applications. This material offers exceptional capabilities that make it ideal for creating intricate and detailed jewelry patterns, models, and molds. Its primary strengths lie in its ability to produce smooth surfaces, fine details, and complex geometries with high accuracy and precision.

One of the key capabilities of Accura 25 is its excellent resolution and surface finish. When used in SLA 3D printing processes, it can achieve layer thicknesses as low as 25 microns, allowing for the creation of highly detailed and smooth surfaces. This level of precision is crucial in jewelry making, where even the smallest imperfections can be noticeable in the final product.

The material also exhibits outstanding dimensional stability, which is essential for maintaining the integrity of intricate jewelry designs during the printing and post-processing stages. This stability ensures that delicate features and fine details remain intact throughout the entire production process, from initial printing to casting and finishing.

Accura 25's mechanical properties contribute significantly to its effectiveness in jewelry crafting. It offers a good balance of strength and flexibility, allowing for the creation of both delicate and sturdy structures. This versatility enables jewelers to produce a wide range of designs, from intricate filigree patterns to more substantial pieces, without compromising on quality or detail.

Another notable capability of Accura 25 is its compatibility with various post-processing techniques commonly used in jewelry making. The material can be easily sanded, polished, and painted, allowing for further refinement of the printed models. Additionally, it is suitable for investment casting processes, a crucial step in transforming 3D printed patterns into metal jewelry pieces.

The resin's optical properties also play a role in its effectiveness for jewelry applications. Accura 25 produces parts with a smooth, translucent finish, which aids in visual inspection and quality control of the printed models. This transparency allows jewelers to easily identify any internal defects or inconsistencies before proceeding to the casting stage.

Accura 25's formulation includes additives that enhance its performance in jewelry-specific applications. These additives contribute to improved burnout characteristics during the casting process, resulting in cleaner and more accurate metal castings. This feature is particularly valuable for producing high-quality, complex jewelry pieces with minimal defects.

One of the key capabilities of Accura 25 is its excellent resolution and surface finish. When used in SLA 3D printing processes, it can achieve layer thicknesses as low as 25 microns, allowing for the creation of highly detailed and smooth surfaces. This level of precision is crucial in jewelry making, where even the smallest imperfections can be noticeable in the final product.

The material also exhibits outstanding dimensional stability, which is essential for maintaining the integrity of intricate jewelry designs during the printing and post-processing stages. This stability ensures that delicate features and fine details remain intact throughout the entire production process, from initial printing to casting and finishing.

Accura 25's mechanical properties contribute significantly to its effectiveness in jewelry crafting. It offers a good balance of strength and flexibility, allowing for the creation of both delicate and sturdy structures. This versatility enables jewelers to produce a wide range of designs, from intricate filigree patterns to more substantial pieces, without compromising on quality or detail.

Another notable capability of Accura 25 is its compatibility with various post-processing techniques commonly used in jewelry making. The material can be easily sanded, polished, and painted, allowing for further refinement of the printed models. Additionally, it is suitable for investment casting processes, a crucial step in transforming 3D printed patterns into metal jewelry pieces.

The resin's optical properties also play a role in its effectiveness for jewelry applications. Accura 25 produces parts with a smooth, translucent finish, which aids in visual inspection and quality control of the printed models. This transparency allows jewelers to easily identify any internal defects or inconsistencies before proceeding to the casting stage.

Accura 25's formulation includes additives that enhance its performance in jewelry-specific applications. These additives contribute to improved burnout characteristics during the casting process, resulting in cleaner and more accurate metal castings. This feature is particularly valuable for producing high-quality, complex jewelry pieces with minimal defects.

Accura 25 Applications

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery. The formulations can be tailored for specific therapeutic applications.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Chemical synthesis and manufacturing of Accura 25: Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.

- Formulations for improved bioavailability of Accura 25: Various formulation strategies are employed to enhance the bioavailability of Accura 25. These may include the use of specific excipients, particle size reduction techniques, or novel drug delivery systems.

- Analytical methods for Accura 25 detection and quantification: Analytical techniques are developed for the detection and quantification of Accura 25 in various matrices. These methods may include chromatographic, spectroscopic, or other instrumental techniques for quality control and research purposes.

- Combination therapies involving Accura 25: Accura 25 is used in combination with other active ingredients for synergistic effects in treating various conditions. These combinations may offer improved efficacy, reduced side effects, or broader spectrum of activity compared to monotherapy.

02 Analytical methods for Accura 25

Various analytical techniques are employed to detect, quantify, and characterize Accura 25 in different matrices. These methods may include chromatography, spectroscopy, or other advanced analytical tools to ensure the quality and purity of the compound in pharmaceutical or research applications.Expand Specific Solutions03 Synthesis and production of Accura 25

Different synthetic routes and production methods are developed for Accura 25. These may involve novel chemical reactions, catalysts, or process optimizations to improve yield, purity, or cost-effectiveness in manufacturing the compound at various scales.Expand Specific Solutions04 Formulation of Accura 25 in drug delivery systems

Accura 25 is incorporated into various drug delivery systems to enhance its bioavailability, stability, or targeted delivery. These formulations may include nanoparticles, liposomes, or other advanced delivery technologies to improve the compound's therapeutic efficacy.Expand Specific Solutions05 Applications of Accura 25 in medical devices

Accura 25 is utilized in the development of medical devices or diagnostic tools. This may involve its incorporation into sensors, imaging agents, or other medical technologies to enhance diagnostic or therapeutic capabilities in various medical fields.Expand Specific Solutions

Key Players Analysis

The jewelry crafting industry, particularly in relation to Accura 25, is in a mature stage with steady growth. The global market size for precision jewelry manufacturing tools is estimated to be in the billions, driven by demand for high-quality craftsmanship. Technologically, the field is moderately advanced, with companies like Robert Bosch GmbH, Shimano, Inc., and Citizen Watch Co., Ltd. leading innovation in precision engineering and micro-manufacturing. These firms, along with specialized players such as Glendo LLC and LIFEstyle Group GmbH, are pushing the boundaries of accuracy and efficiency in jewelry production tools. The competitive landscape is characterized by a mix of large conglomerates and niche specialists, with ongoing research and development focused on improving precision, materials, and automation in jewelry crafting processes.

Glendo LLC

Technical Solution: Glendo LLC has developed the Accura 25, a precision micro-motor handpiece specifically designed for jewelry crafting. This tool utilizes advanced micro-motor technology to provide jewelers with exceptional control and accuracy during intricate work. The Accura 25 features variable speed control, allowing craftsmen to adjust the rotational speed from 1,000 to 50,000 RPM, catering to a wide range of jewelry-making tasks[1]. The handpiece is ergonomically designed to reduce hand fatigue during prolonged use, with a lightweight body and balanced weight distribution. Additionally, the Accura 25 incorporates a quick-change collet system, enabling rapid tool changes without interrupting workflow[2].

Strengths: Precise control, versatile speed range, ergonomic design, and quick tool changes. Weaknesses: May require specialized training for optimal use, potentially higher cost compared to traditional tools.

Suzhou China Pearl Gem City Co., Ltd.

Technical Solution: While Suzhou China Pearl Gem City Co., Ltd. is not directly involved in developing the Accura 25, they have integrated advanced jewelry crafting tools, including precision micro-motor handpieces, into their pearl processing and jewelry manufacturing operations. The company utilizes state-of-the-art equipment to enhance the quality and efficiency of their pearl jewelry production. Their approach involves combining traditional craftsmanship with modern technology to achieve consistent, high-quality results in pearl drilling, shaping, and setting[3].

Strengths: Integration of advanced tools with traditional techniques, improved efficiency in pearl jewelry production. Weaknesses: Potential dependence on external technology providers, may require ongoing training for staff to adapt to new tools.

Accura 25 Innovations

Necklace

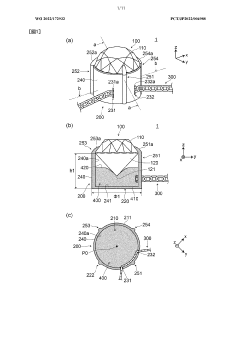

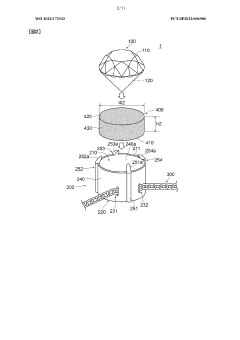

PatentWO2022172932A1

Innovation

- A necklace design featuring cylindrical design part supports with elongated chain holes that prevent chain rotation, combined with an elastic body that restricts chain movement, allowing for easy adjustment of design part spacing and positioning without altering the parts, using a silicone rubber elastic body to secure the chain and facilitate sliding.

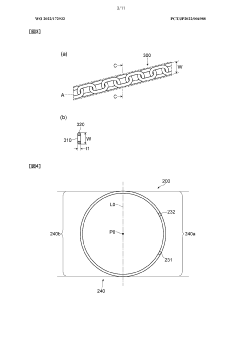

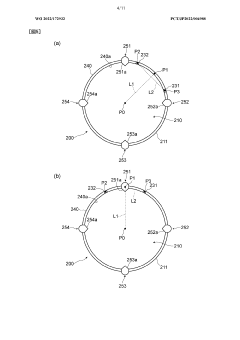

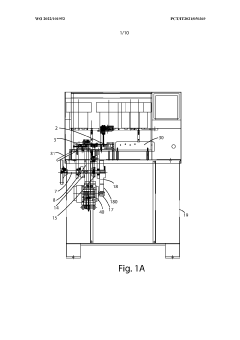

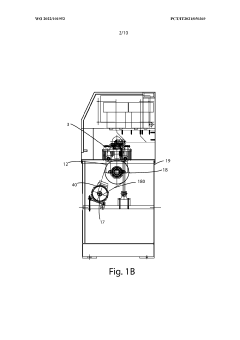

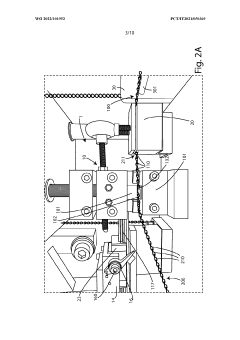

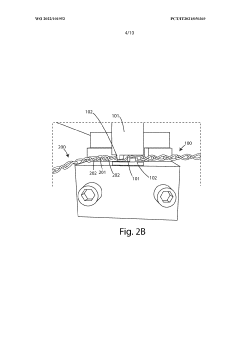

Machine for the production of jewellery and relative method

PatentWO2022101952A1

Innovation

- A machine and method that utilize a mechanical locking system to insert and securely hold ceramic, polymeric, or natural stone inserts within chain links, allowing for deformation and clamping without welding, enabling the production of jewelry with inserts of any shape or symmetry, and accommodating various sizes and shapes within a single chain.

Material Sustainability

Accura 25, a material used in jewelry crafting, presents significant opportunities for enhancing sustainability in the industry. This photopolymer resin, developed by 3D Systems, offers a unique combination of properties that align with sustainable practices in jewelry production.

The material's high resolution and smooth surface finish reduce the need for extensive post-processing, minimizing waste and energy consumption. This efficiency in production contributes to a more sustainable manufacturing process, as it reduces the overall environmental impact associated with jewelry creation.

Accura 25's durability and resistance to wear ensure that jewelry pieces crafted from this material have a longer lifespan. This longevity directly addresses the issue of disposable fashion, promoting a more sustainable approach to jewelry consumption. By creating pieces that last, the demand for frequent replacements is reduced, conserving resources in the long term.

The material's compatibility with various finishing techniques allows for versatile design options without the need for additional resources. This versatility enables jewelers to create intricate designs with minimal material waste, further enhancing the sustainability profile of the jewelry-making process.

Accura 25's ability to be recycled and reused in the production process is a key factor in its sustainability. Unused material and support structures can be repurposed, significantly reducing waste and promoting a circular economy within jewelry manufacturing. This recycling capability aligns with the growing demand for environmentally responsible production methods in the luxury goods sector.

The material's low toxicity and minimal environmental impact during production and use contribute to a safer working environment and reduced ecological footprint. This aspect is particularly important as consumers become increasingly conscious of the environmental and ethical implications of their purchases.

Furthermore, Accura 25's role in additive manufacturing processes allows for on-demand production, reducing overstock and minimizing the resources tied up in inventory. This lean approach to production aligns with sustainable business practices and helps optimize resource utilization in the jewelry industry.

As the jewelry sector continues to evolve, materials like Accura 25 play a crucial role in driving sustainability initiatives. By enabling more efficient production methods, promoting longevity in products, and supporting circular economy principles, Accura 25 represents a significant step towards a more sustainable future in jewelry crafting.

The material's high resolution and smooth surface finish reduce the need for extensive post-processing, minimizing waste and energy consumption. This efficiency in production contributes to a more sustainable manufacturing process, as it reduces the overall environmental impact associated with jewelry creation.

Accura 25's durability and resistance to wear ensure that jewelry pieces crafted from this material have a longer lifespan. This longevity directly addresses the issue of disposable fashion, promoting a more sustainable approach to jewelry consumption. By creating pieces that last, the demand for frequent replacements is reduced, conserving resources in the long term.

The material's compatibility with various finishing techniques allows for versatile design options without the need for additional resources. This versatility enables jewelers to create intricate designs with minimal material waste, further enhancing the sustainability profile of the jewelry-making process.

Accura 25's ability to be recycled and reused in the production process is a key factor in its sustainability. Unused material and support structures can be repurposed, significantly reducing waste and promoting a circular economy within jewelry manufacturing. This recycling capability aligns with the growing demand for environmentally responsible production methods in the luxury goods sector.

The material's low toxicity and minimal environmental impact during production and use contribute to a safer working environment and reduced ecological footprint. This aspect is particularly important as consumers become increasingly conscious of the environmental and ethical implications of their purchases.

Furthermore, Accura 25's role in additive manufacturing processes allows for on-demand production, reducing overstock and minimizing the resources tied up in inventory. This lean approach to production aligns with sustainable business practices and helps optimize resource utilization in the jewelry industry.

As the jewelry sector continues to evolve, materials like Accura 25 play a crucial role in driving sustainability initiatives. By enabling more efficient production methods, promoting longevity in products, and supporting circular economy principles, Accura 25 represents a significant step towards a more sustainable future in jewelry crafting.

Design Customization

Accura 25, a high-performance stereolithography resin, has revolutionized the jewelry crafting industry by enabling unprecedented levels of design customization. This material's exceptional properties allow for the creation of intricate and complex jewelry designs that were previously challenging or impossible to produce using traditional manufacturing methods.

The high resolution and fine detail capabilities of Accura 25 enable jewelers to incorporate elaborate patterns, textures, and intricate geometries into their designs. This level of precision allows for the creation of unique, personalized pieces that cater to individual customer preferences. Designers can now experiment with complex lattice structures, organic shapes, and delicate filigree work, pushing the boundaries of conventional jewelry design.

Furthermore, Accura 25's ability to produce smooth surfaces and sharp edges contributes to the overall quality and aesthetics of the final product. This characteristic is particularly valuable in creating detailed engravings, custom settings for gemstones, and intricate clasps or closures. The material's versatility also allows for the seamless integration of various design elements, such as combining traditional motifs with modern, avant-garde concepts.

The customization potential extends beyond aesthetics to functional aspects of jewelry design. Accura 25 enables the creation of adjustable components, interchangeable parts, and modular designs. This flexibility allows customers to personalize their jewelry not only in terms of appearance but also in terms of functionality and wearability.

Another significant advantage of using Accura 25 for design customization is the rapid prototyping capability it offers. Jewelers can quickly iterate through multiple design variations, allowing for real-time adjustments based on customer feedback or design improvements. This iterative process facilitates a more collaborative approach between designers and clients, resulting in highly personalized and satisfactory end products.

The material's compatibility with various post-processing techniques further enhances its customization potential. Accura 25 parts can be easily finished, polished, and plated, allowing for a wide range of surface treatments and color options. This versatility enables designers to offer customers an extensive palette of finishes, from matte to high-gloss, and various metallic appearances without compromising the intricate details of the design.

In the context of mass customization, Accura 25 plays a crucial role in bridging the gap between unique, handcrafted pieces and scalable production. Its use in 3D printing allows for efficient production of customized designs without the need for extensive retooling or mold-making, making it economically viable to offer personalized jewelry on a larger scale.

The high resolution and fine detail capabilities of Accura 25 enable jewelers to incorporate elaborate patterns, textures, and intricate geometries into their designs. This level of precision allows for the creation of unique, personalized pieces that cater to individual customer preferences. Designers can now experiment with complex lattice structures, organic shapes, and delicate filigree work, pushing the boundaries of conventional jewelry design.

Furthermore, Accura 25's ability to produce smooth surfaces and sharp edges contributes to the overall quality and aesthetics of the final product. This characteristic is particularly valuable in creating detailed engravings, custom settings for gemstones, and intricate clasps or closures. The material's versatility also allows for the seamless integration of various design elements, such as combining traditional motifs with modern, avant-garde concepts.

The customization potential extends beyond aesthetics to functional aspects of jewelry design. Accura 25 enables the creation of adjustable components, interchangeable parts, and modular designs. This flexibility allows customers to personalize their jewelry not only in terms of appearance but also in terms of functionality and wearability.

Another significant advantage of using Accura 25 for design customization is the rapid prototyping capability it offers. Jewelers can quickly iterate through multiple design variations, allowing for real-time adjustments based on customer feedback or design improvements. This iterative process facilitates a more collaborative approach between designers and clients, resulting in highly personalized and satisfactory end products.

The material's compatibility with various post-processing techniques further enhances its customization potential. Accura 25 parts can be easily finished, polished, and plated, allowing for a wide range of surface treatments and color options. This versatility enables designers to offer customers an extensive palette of finishes, from matte to high-gloss, and various metallic appearances without compromising the intricate details of the design.

In the context of mass customization, Accura 25 plays a crucial role in bridging the gap between unique, handcrafted pieces and scalable production. Its use in 3D printing allows for efficient production of customized designs without the need for extensive retooling or mold-making, making it economically viable to offer personalized jewelry on a larger scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!