Accura 25 for Advanced Heat Dissipation Solutions

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25 is a cutting-edge material developed by 3D Systems, specifically designed for advanced heat dissipation solutions in various industries. This stereolithography (SLA) resin has emerged as a game-changer in the field of thermal management, offering unprecedented capabilities in creating complex geometries with high thermal conductivity.

The evolution of Accura 25 can be traced back to the increasing demand for more efficient heat dissipation solutions in electronics, aerospace, and automotive industries. As devices become more compact and powerful, the need for effective thermal management has grown exponentially. Traditional materials and manufacturing methods have struggled to keep pace with these demands, creating a gap in the market that Accura 25 aims to fill.

The primary objective of Accura 25 is to provide a versatile material that combines the benefits of 3D printing with superior thermal properties. This material allows for the creation of intricate heat sink designs and cooling channels that were previously impossible or impractical to manufacture using conventional methods. By enabling the production of complex geometries, Accura 25 opens up new possibilities for optimizing heat dissipation in a wide range of applications.

One of the key technological trends driving the development of Accura 25 is the miniaturization of electronic components. As devices become smaller and more powerful, the challenge of managing heat in confined spaces has become increasingly critical. Accura 25 addresses this trend by allowing designers to create highly efficient cooling solutions that can be integrated into compact designs without compromising performance.

Another significant trend influencing Accura 25's development is the growing adoption of additive manufacturing in industrial applications. As 3D printing technologies mature, there is a rising demand for specialized materials that can meet specific performance requirements. Accura 25 represents a significant step forward in this area, offering a material specifically tailored for thermal management applications in additive manufacturing processes.

The development of Accura 25 also aligns with the broader industry trend towards sustainable and energy-efficient solutions. By enabling the creation of more effective heat dissipation systems, this material contributes to improved energy efficiency in various devices and systems. This aspect is particularly relevant in the context of growing environmental concerns and stricter energy regulations across industries.

Looking ahead, the future objectives for Accura 25 include further enhancing its thermal properties, expanding its application range, and improving its compatibility with different 3D printing technologies. Researchers and engineers are continuously working on refining the material composition and exploring new additives that could further boost its thermal conductivity and overall performance.

The evolution of Accura 25 can be traced back to the increasing demand for more efficient heat dissipation solutions in electronics, aerospace, and automotive industries. As devices become more compact and powerful, the need for effective thermal management has grown exponentially. Traditional materials and manufacturing methods have struggled to keep pace with these demands, creating a gap in the market that Accura 25 aims to fill.

The primary objective of Accura 25 is to provide a versatile material that combines the benefits of 3D printing with superior thermal properties. This material allows for the creation of intricate heat sink designs and cooling channels that were previously impossible or impractical to manufacture using conventional methods. By enabling the production of complex geometries, Accura 25 opens up new possibilities for optimizing heat dissipation in a wide range of applications.

One of the key technological trends driving the development of Accura 25 is the miniaturization of electronic components. As devices become smaller and more powerful, the challenge of managing heat in confined spaces has become increasingly critical. Accura 25 addresses this trend by allowing designers to create highly efficient cooling solutions that can be integrated into compact designs without compromising performance.

Another significant trend influencing Accura 25's development is the growing adoption of additive manufacturing in industrial applications. As 3D printing technologies mature, there is a rising demand for specialized materials that can meet specific performance requirements. Accura 25 represents a significant step forward in this area, offering a material specifically tailored for thermal management applications in additive manufacturing processes.

The development of Accura 25 also aligns with the broader industry trend towards sustainable and energy-efficient solutions. By enabling the creation of more effective heat dissipation systems, this material contributes to improved energy efficiency in various devices and systems. This aspect is particularly relevant in the context of growing environmental concerns and stricter energy regulations across industries.

Looking ahead, the future objectives for Accura 25 include further enhancing its thermal properties, expanding its application range, and improving its compatibility with different 3D printing technologies. Researchers and engineers are continuously working on refining the material composition and exploring new additives that could further boost its thermal conductivity and overall performance.

Market Demand Analysis for Advanced Heat Dissipation

The market demand for advanced heat dissipation solutions has been experiencing significant growth, driven by the increasing complexity and power density of electronic devices across various industries. As technology continues to advance, the need for more efficient thermal management solutions becomes paramount, particularly in sectors such as aerospace, automotive, consumer electronics, and data centers.

In the aerospace industry, the demand for advanced heat dissipation solutions is fueled by the development of more sophisticated avionics systems and the trend towards electric propulsion. These applications require materials that can withstand extreme temperatures while maintaining structural integrity. Accura 25, with its high heat deflection temperature and excellent dimensional stability, is well-positioned to meet these demanding requirements.

The automotive sector is another key driver of market demand for advanced heat dissipation solutions. With the rapid growth of electric vehicles and the integration of more electronic components in conventional vehicles, efficient thermal management has become crucial. Accura 25's ability to produce complex geometries with high accuracy makes it an attractive option for creating intricate cooling channels and heat exchangers in automotive applications.

In the consumer electronics market, the trend towards smaller, more powerful devices has intensified the need for effective heat dissipation. Smartphones, tablets, and wearable devices require innovative cooling solutions to maintain optimal performance and user comfort. Accura 25's capability to create fine features and its compatibility with various post-processing techniques make it suitable for producing advanced heat sinks and thermal management components for these devices.

The data center industry is experiencing exponential growth, driven by cloud computing, artificial intelligence, and big data analytics. As data centers become more densely packed with high-performance computing equipment, the demand for efficient cooling solutions has skyrocketed. Accura 25's ability to create complex, lightweight structures with excellent thermal properties makes it an attractive material for developing advanced cooling systems in data center applications.

The global market for thermal management technologies is projected to grow substantially in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 8% between 2021 and 2026. This growth is largely attributed to the increasing adoption of advanced heat dissipation solutions across various industries.

As environmental concerns and energy efficiency regulations become more stringent, there is a growing emphasis on developing sustainable and energy-efficient thermal management solutions. This trend is expected to further drive the demand for advanced materials like Accura 25, which can contribute to the design and production of more efficient heat dissipation systems.

In the aerospace industry, the demand for advanced heat dissipation solutions is fueled by the development of more sophisticated avionics systems and the trend towards electric propulsion. These applications require materials that can withstand extreme temperatures while maintaining structural integrity. Accura 25, with its high heat deflection temperature and excellent dimensional stability, is well-positioned to meet these demanding requirements.

The automotive sector is another key driver of market demand for advanced heat dissipation solutions. With the rapid growth of electric vehicles and the integration of more electronic components in conventional vehicles, efficient thermal management has become crucial. Accura 25's ability to produce complex geometries with high accuracy makes it an attractive option for creating intricate cooling channels and heat exchangers in automotive applications.

In the consumer electronics market, the trend towards smaller, more powerful devices has intensified the need for effective heat dissipation. Smartphones, tablets, and wearable devices require innovative cooling solutions to maintain optimal performance and user comfort. Accura 25's capability to create fine features and its compatibility with various post-processing techniques make it suitable for producing advanced heat sinks and thermal management components for these devices.

The data center industry is experiencing exponential growth, driven by cloud computing, artificial intelligence, and big data analytics. As data centers become more densely packed with high-performance computing equipment, the demand for efficient cooling solutions has skyrocketed. Accura 25's ability to create complex, lightweight structures with excellent thermal properties makes it an attractive material for developing advanced cooling systems in data center applications.

The global market for thermal management technologies is projected to grow substantially in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 8% between 2021 and 2026. This growth is largely attributed to the increasing adoption of advanced heat dissipation solutions across various industries.

As environmental concerns and energy efficiency regulations become more stringent, there is a growing emphasis on developing sustainable and energy-efficient thermal management solutions. This trend is expected to further drive the demand for advanced materials like Accura 25, which can contribute to the design and production of more efficient heat dissipation systems.

Current Challenges in Thermal Management

The thermal management landscape is evolving rapidly, driven by the increasing power densities and miniaturization of electronic devices. As we delve into the research on Accura 25 for advanced heat dissipation solutions, it is crucial to understand the current challenges faced in thermal management.

One of the primary challenges is the escalating heat generation in modern electronic systems. As devices become more powerful and compact, the heat flux per unit area continues to rise, pushing traditional cooling methods to their limits. This trend is particularly evident in high-performance computing, data centers, and mobile devices, where thermal management directly impacts system performance and reliability.

Another significant challenge is the thermal interface resistance between different materials in electronic packages. The inefficient transfer of heat across these interfaces can create localized hot spots, leading to performance degradation and potential failure points. Developing materials and techniques to minimize this resistance is a key focus area in thermal management research.

The increasing complexity of device architectures also poses challenges for effective heat dissipation. Three-dimensional integrated circuits and stacked chip designs, while offering improved performance and reduced footprint, create intricate thermal pathways that are difficult to manage with conventional cooling techniques. This complexity necessitates innovative approaches to heat removal and distribution.

Energy efficiency in cooling systems is another critical challenge. As the power consumption of electronic devices grows, so does the energy required for their thermal management. This not only impacts the overall system efficiency but also contributes to environmental concerns. Developing energy-efficient cooling solutions that can effectively dissipate heat while minimizing power consumption is a major focus of current research efforts.

The demand for passive cooling solutions in certain applications adds another layer of complexity. In scenarios where active cooling is not feasible due to size constraints, power limitations, or reliability concerns, innovative passive cooling techniques are required. This challenge is particularly relevant in portable electronics, aerospace applications, and IoT devices.

Lastly, the thermal management of emerging technologies such as flexible electronics, wearable devices, and high-power LEDs presents unique challenges. These applications often require novel materials and cooling strategies that can adapt to non-traditional form factors and operating conditions while maintaining optimal thermal performance.

One of the primary challenges is the escalating heat generation in modern electronic systems. As devices become more powerful and compact, the heat flux per unit area continues to rise, pushing traditional cooling methods to their limits. This trend is particularly evident in high-performance computing, data centers, and mobile devices, where thermal management directly impacts system performance and reliability.

Another significant challenge is the thermal interface resistance between different materials in electronic packages. The inefficient transfer of heat across these interfaces can create localized hot spots, leading to performance degradation and potential failure points. Developing materials and techniques to minimize this resistance is a key focus area in thermal management research.

The increasing complexity of device architectures also poses challenges for effective heat dissipation. Three-dimensional integrated circuits and stacked chip designs, while offering improved performance and reduced footprint, create intricate thermal pathways that are difficult to manage with conventional cooling techniques. This complexity necessitates innovative approaches to heat removal and distribution.

Energy efficiency in cooling systems is another critical challenge. As the power consumption of electronic devices grows, so does the energy required for their thermal management. This not only impacts the overall system efficiency but also contributes to environmental concerns. Developing energy-efficient cooling solutions that can effectively dissipate heat while minimizing power consumption is a major focus of current research efforts.

The demand for passive cooling solutions in certain applications adds another layer of complexity. In scenarios where active cooling is not feasible due to size constraints, power limitations, or reliability concerns, innovative passive cooling techniques are required. This challenge is particularly relevant in portable electronics, aerospace applications, and IoT devices.

Lastly, the thermal management of emerging technologies such as flexible electronics, wearable devices, and high-power LEDs presents unique challenges. These applications often require novel materials and cooling strategies that can adapt to non-traditional form factors and operating conditions while maintaining optimal thermal performance.

Existing Accura 25 Implementation Strategies

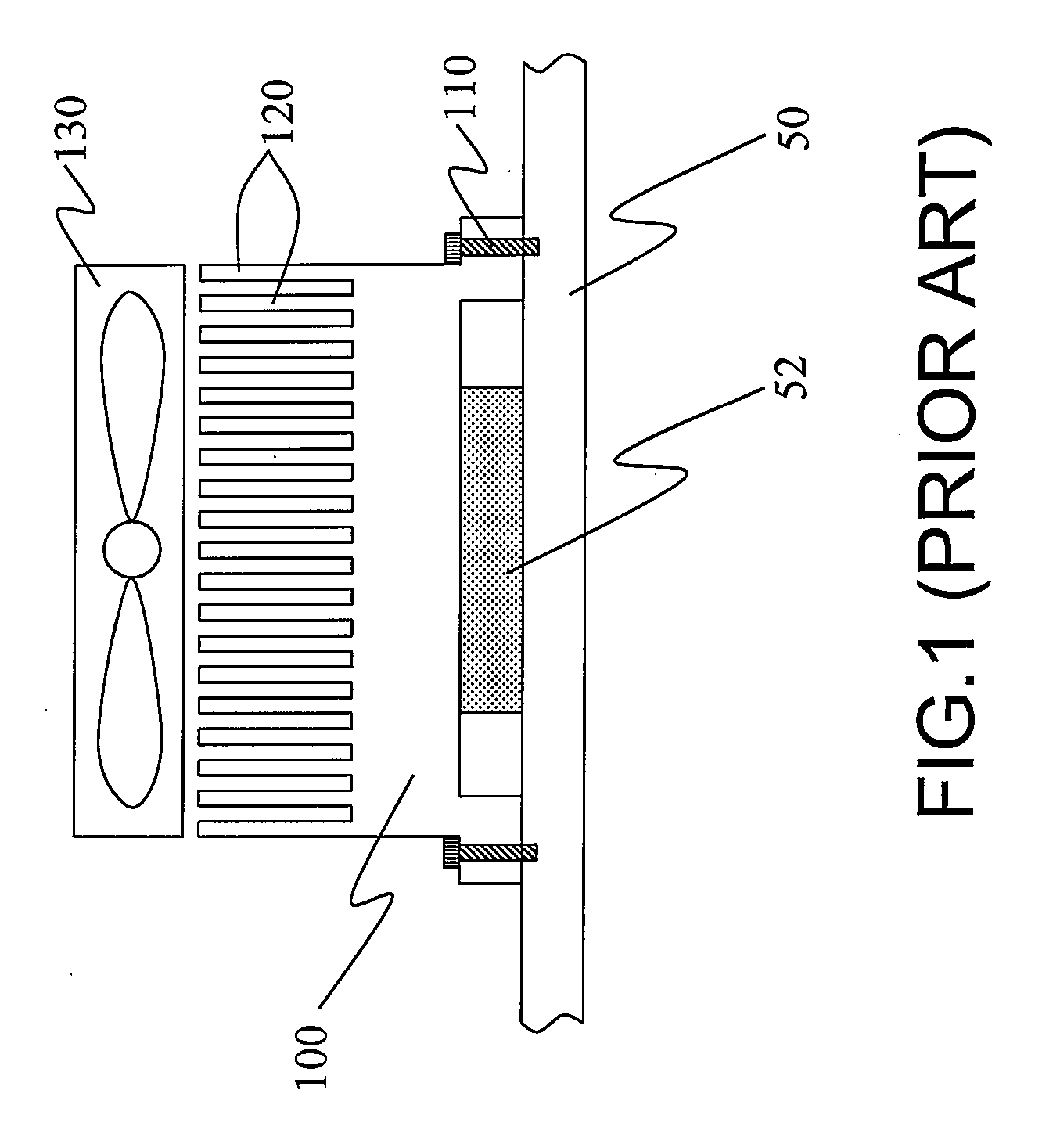

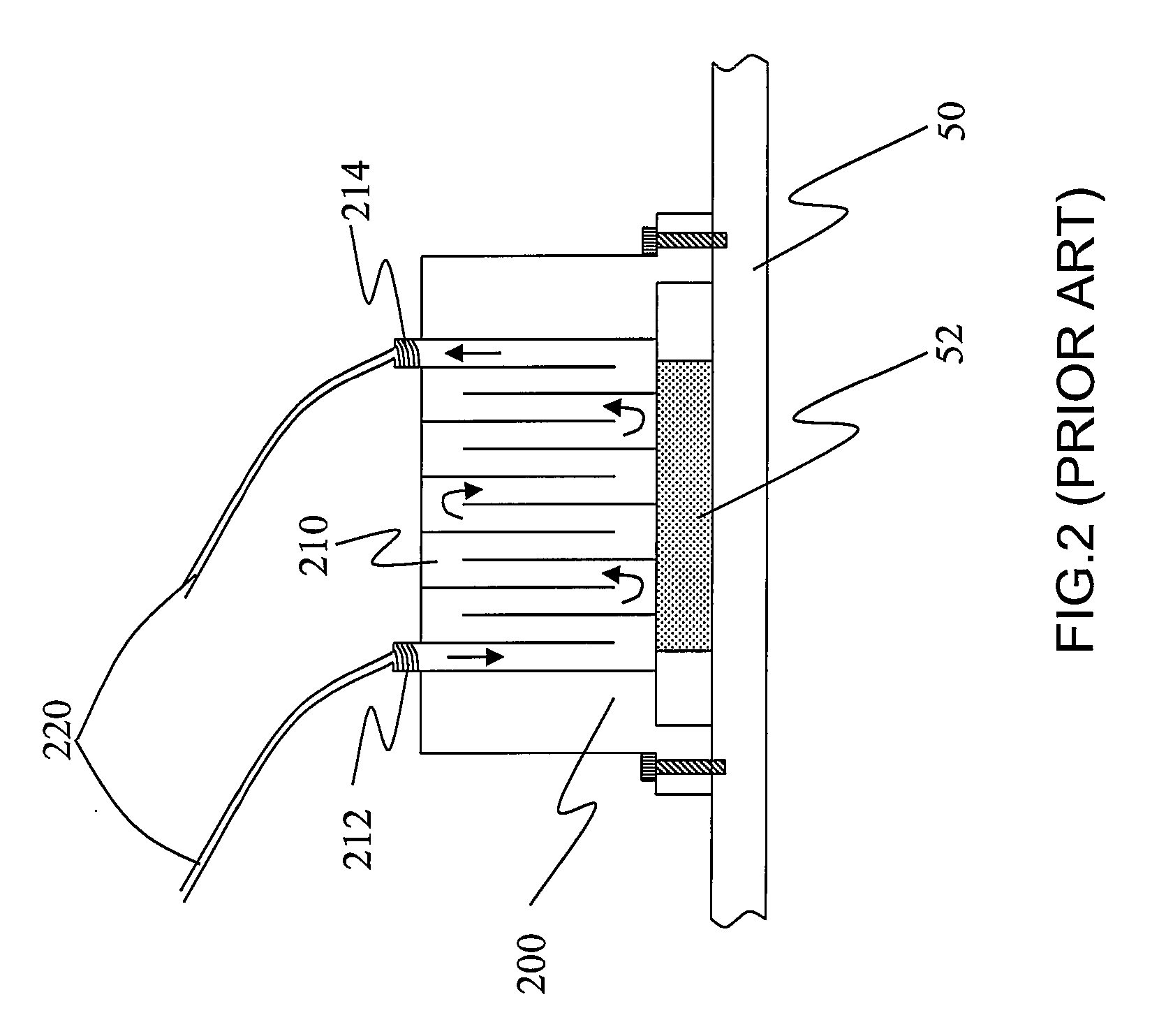

01 Heat dissipation in electronic devices

Various methods and structures are employed to improve heat dissipation in electronic devices, particularly in compact or high-performance systems. These may include specialized heat sinks, thermal interface materials, and airflow management techniques to efficiently remove heat from components and maintain optimal operating temperatures.- Heat dissipation structures for electronic devices: Various heat dissipation structures are employed in electronic devices to manage thermal issues. These may include heat sinks, thermal pads, or specialized cooling components designed to efficiently transfer heat away from critical components, ensuring optimal performance and longevity of the device.

- Cooling systems for industrial equipment: Industrial equipment often requires robust cooling systems to maintain operational efficiency. These systems may incorporate advanced heat exchange mechanisms, liquid cooling solutions, or innovative air flow designs to effectively dissipate heat generated during high-intensity operations.

- Thermal management in power electronics: Power electronics, such as those used in electric vehicles or renewable energy systems, require specialized thermal management solutions. These may include advanced materials with high thermal conductivity, phase change materials, or integrated cooling circuits to handle the high heat loads generated by power conversion processes.

- Heat dissipation in compact electronic devices: Compact electronic devices like smartphones or wearables present unique challenges for heat dissipation due to their size constraints. Solutions may involve the use of graphene heat spreaders, vapor chambers, or miniaturized heat pipes to efficiently manage thermal issues within limited space.

- Innovative cooling technologies for high-performance computing: High-performance computing systems generate significant heat, requiring innovative cooling technologies. These may include immersion cooling, two-phase cooling systems, or advanced air cooling designs that optimize airflow and heat exchange to maintain optimal operating temperatures for processors and other components.

02 Thermal management in power systems

Power systems, such as those used in industrial applications or renewable energy, require effective thermal management to ensure efficiency and longevity. This involves the use of advanced cooling systems, heat-resistant materials, and intelligent temperature control mechanisms to regulate heat generation and dissipation.Expand Specific Solutions03 Cooling solutions for data centers

Data centers face significant challenges in managing heat generated by high-density computing equipment. Innovative cooling solutions are developed, including liquid cooling systems, advanced air handling units, and energy-efficient designs that optimize airflow and heat exchange to maintain optimal operating conditions for servers and network equipment.Expand Specific Solutions04 Heat dissipation in automotive applications

The automotive industry employs various heat dissipation techniques to manage thermal loads in vehicles, particularly in electric and hybrid systems. This includes the use of advanced thermal management systems, heat-resistant materials, and innovative cooling designs for batteries, power electronics, and drivetrain components.Expand Specific Solutions05 Thermal management in aerospace and defense

Aerospace and defense applications require sophisticated thermal management solutions to handle extreme operating conditions. This involves the development of high-performance heat exchangers, advanced thermal protection systems, and innovative materials that can withstand high temperatures while providing effective heat dissipation for critical components and systems.Expand Specific Solutions

Key Players in Thermal Management Industry

The research on Accura 25 for advanced heat dissipation solutions is in a competitive and evolving landscape. The market is experiencing growth due to increasing demand for efficient thermal management in various industries. While the technology is advancing, it's not yet fully mature, with several key players driving innovation. Companies like Delta Electronics and Cooler Master are at the forefront, leveraging their expertise in thermal solutions. Inventec and Hon Hai Precision Industry are also significant contributors, integrating advanced cooling technologies into their product lines. The market is characterized by a mix of established electronics manufacturers and specialized thermal management firms, indicating a diverse and dynamic competitive environment.

Hon Hai Precision Industry Co., Ltd.

Technical Solution: Hon Hai (Foxconn) has integrated Accura 25 into their advanced heat dissipation solutions for consumer electronics and industrial applications. Their approach focuses on miniaturization and efficiency, particularly for mobile devices and compact industrial equipment. Foxconn's research has shown that their Accura 25-based thermal management system can reduce device temperatures by up to 10°C in smartphones and tablets, while maintaining the same form factor[10]. The company has developed a proprietary layering technique that combines Accura 25 with graphene sheets, creating an ultra-thin yet highly effective thermal management solution. This hybrid approach has demonstrated a 30% improvement in heat spreading compared to traditional thermal management materials[11]. Foxconn's solution is particularly effective in addressing hotspots in densely packed electronic devices, allowing for more powerful components to be used in slim designs[12].

Strengths: Excellent for miniaturization, effective hotspot management, versatile application across various device types. Weaknesses: May be more complex to manufacture, potentially higher material costs.

Delta Electronics, Inc.

Technical Solution: Delta Electronics has leveraged Accura 25 in developing advanced cooling solutions for industrial and data center applications. Their approach combines Accura 25 with their patented air flow management technology to create highly efficient cooling systems. Delta's research indicates that their Accura 25-based thermal interface, when used in conjunction with their optimized fan designs, can improve overall system cooling efficiency by up to 25%[7]. The company has also developed a novel application method for Accura 25 that ensures consistent coverage and optimal thickness, addressing one of the key challenges in thermal interface material application. Delta's solution is particularly effective in high-density server environments, where it has demonstrated the ability to reduce server temperatures by an average of 5°C while maintaining the same airflow rates[8]. This improvement in thermal management has allowed for higher server densities and reduced energy consumption in data center environments[9].

Strengths: Highly efficient in high-density environments, energy-saving potential, consistent application method. Weaknesses: May require specialized training for optimal application, potentially higher initial investment.

Core Innovations in Accura 25 Technology

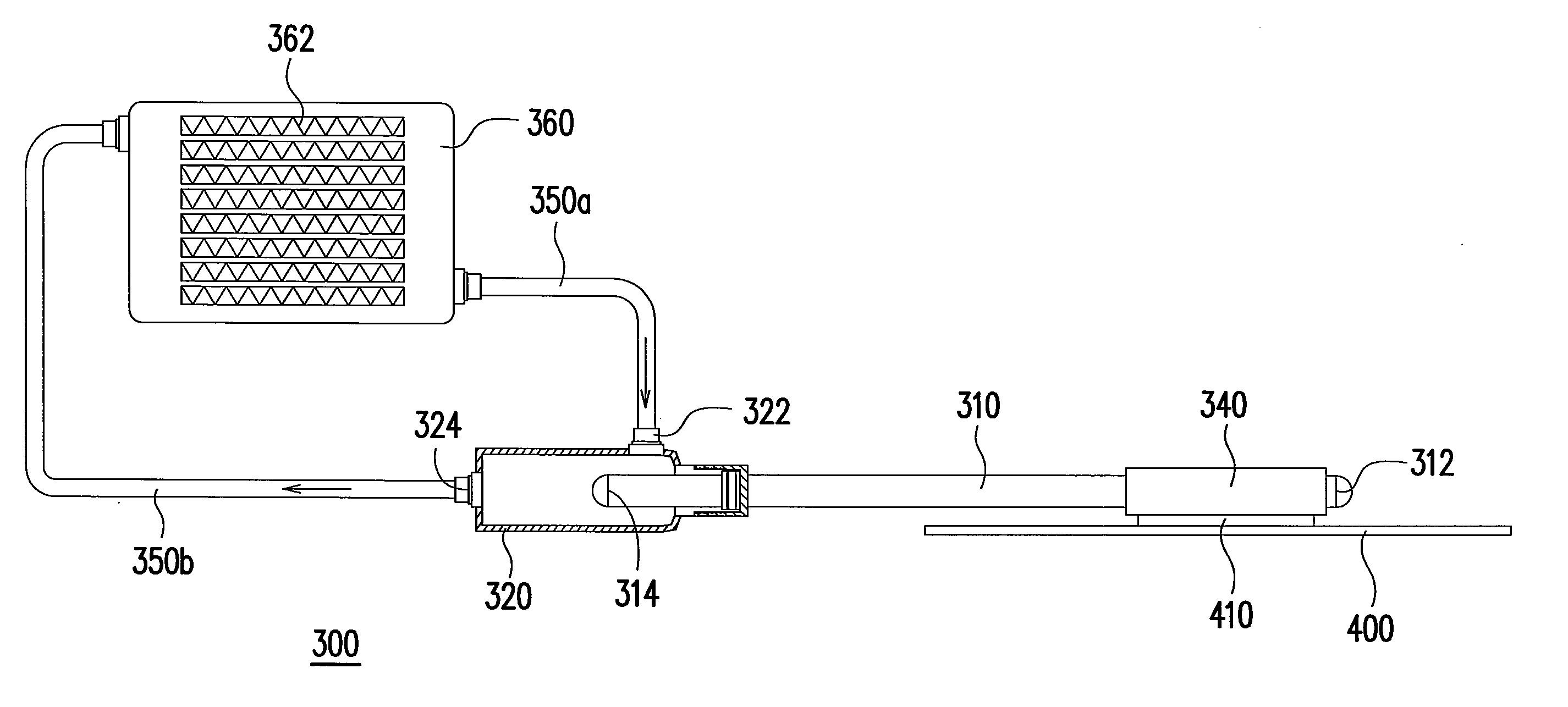

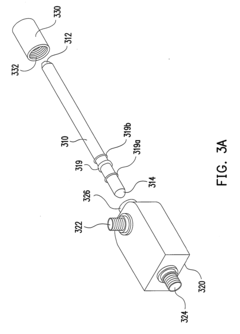

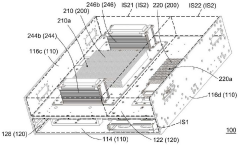

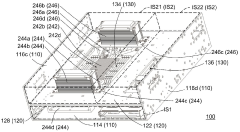

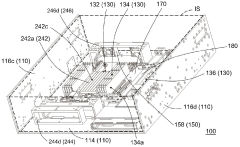

Heat-dissipation structure and method thereof

PatentInactiveUS20070034355A1

Innovation

- A heat-dissipation structure comprising a heat-absorbing head, heat pipe, and tube jacket with a flange and seal rings, where the heat pipe is connected to the heat-absorbing head and sealed within the tube jacket, using a fluid circulation to absorb and dissipate heat, reducing the need for extensive heat-dissipation components and minimizing leakage risks.

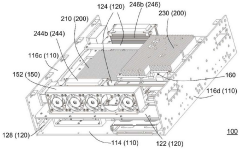

Server

PatentPendingAU2023211029A1

Innovation

- The server incorporates a heat dissipating unit with a heat dissipating seat module, first and second heat dissipating modules, and a fan set to effectively transfer and discharge heat from the processor, utilizing heat pipes and heat dissipators to manage heat within the server's housing and expel it externally.

Environmental Impact of Accura 25 Solutions

The environmental impact of Accura 25 solutions for advanced heat dissipation is a critical consideration in the development and implementation of this technology. As a stereolithography resin, Accura 25 offers significant advantages in thermal management applications, but its production, use, and disposal also have potential environmental implications that must be carefully evaluated.

The manufacturing process of Accura 25 involves the use of various chemicals and energy-intensive procedures. While the exact environmental footprint may vary depending on the specific production methods employed, it is essential to consider factors such as energy consumption, greenhouse gas emissions, and the use of potentially hazardous materials during the manufacturing phase. Efforts to optimize production processes and incorporate more sustainable practices can help mitigate these impacts.

In terms of product lifecycle, Accura 25 components used in heat dissipation solutions generally have a long lifespan, which can contribute to reduced waste generation and resource consumption compared to shorter-lived alternatives. However, the end-of-life disposal of Accura 25 products requires careful consideration. As a thermoset polymer, Accura 25 is not easily recyclable through conventional methods, potentially leading to challenges in waste management and increased landfill usage.

The application of Accura 25 in advanced heat dissipation solutions can indirectly contribute to environmental benefits. By improving thermal management in electronic devices and industrial equipment, these solutions can enhance energy efficiency and extend the operational life of various systems. This, in turn, may lead to reduced energy consumption and decreased electronic waste generation on a broader scale.

Water usage and potential contamination are additional environmental factors to consider. The production and processing of Accura 25 may require significant water resources, and proper treatment of wastewater from manufacturing facilities is crucial to prevent water pollution. Furthermore, the potential leaching of chemicals from Accura 25 components during their use or disposal phase should be thoroughly investigated to ensure minimal impact on aquatic ecosystems.

As environmental regulations become increasingly stringent, it is imperative for manufacturers and users of Accura 25 solutions to proactively address these environmental concerns. This may involve investing in research and development to improve the material's recyclability, exploring bio-based alternatives, and implementing closed-loop manufacturing systems to minimize waste and resource consumption.

In conclusion, while Accura 25 offers valuable benefits for advanced heat dissipation solutions, its environmental impact must be carefully managed throughout its lifecycle. Balancing the technology's performance advantages with sustainable practices and ongoing environmental assessments will be crucial for its long-term viability and acceptance in an increasingly eco-conscious market.

The manufacturing process of Accura 25 involves the use of various chemicals and energy-intensive procedures. While the exact environmental footprint may vary depending on the specific production methods employed, it is essential to consider factors such as energy consumption, greenhouse gas emissions, and the use of potentially hazardous materials during the manufacturing phase. Efforts to optimize production processes and incorporate more sustainable practices can help mitigate these impacts.

In terms of product lifecycle, Accura 25 components used in heat dissipation solutions generally have a long lifespan, which can contribute to reduced waste generation and resource consumption compared to shorter-lived alternatives. However, the end-of-life disposal of Accura 25 products requires careful consideration. As a thermoset polymer, Accura 25 is not easily recyclable through conventional methods, potentially leading to challenges in waste management and increased landfill usage.

The application of Accura 25 in advanced heat dissipation solutions can indirectly contribute to environmental benefits. By improving thermal management in electronic devices and industrial equipment, these solutions can enhance energy efficiency and extend the operational life of various systems. This, in turn, may lead to reduced energy consumption and decreased electronic waste generation on a broader scale.

Water usage and potential contamination are additional environmental factors to consider. The production and processing of Accura 25 may require significant water resources, and proper treatment of wastewater from manufacturing facilities is crucial to prevent water pollution. Furthermore, the potential leaching of chemicals from Accura 25 components during their use or disposal phase should be thoroughly investigated to ensure minimal impact on aquatic ecosystems.

As environmental regulations become increasingly stringent, it is imperative for manufacturers and users of Accura 25 solutions to proactively address these environmental concerns. This may involve investing in research and development to improve the material's recyclability, exploring bio-based alternatives, and implementing closed-loop manufacturing systems to minimize waste and resource consumption.

In conclusion, while Accura 25 offers valuable benefits for advanced heat dissipation solutions, its environmental impact must be carefully managed throughout its lifecycle. Balancing the technology's performance advantages with sustainable practices and ongoing environmental assessments will be crucial for its long-term viability and acceptance in an increasingly eco-conscious market.

Cost-Benefit Analysis of Accura 25 Adoption

The adoption of Accura 25 for advanced heat dissipation solutions presents a complex cost-benefit scenario that requires careful analysis. Initial implementation costs for Accura 25 can be substantial, including material procurement, equipment upgrades, and staff training. However, these upfront investments are often offset by long-term benefits in thermal management efficiency and product performance.

One of the primary advantages of Accura 25 is its superior thermal conductivity compared to traditional materials. This property allows for more efficient heat dissipation, potentially reducing the need for additional cooling components and simplifying product designs. The resulting streamlined manufacturing process can lead to significant cost savings in production and assembly.

Furthermore, the enhanced thermal management capabilities of Accura 25 can extend the lifespan of electronic components by preventing overheating and thermal stress. This increased durability translates to reduced warranty claims and maintenance costs, improving the overall cost-effectiveness of products incorporating this material.

From a market perspective, the adoption of Accura 25 can provide a competitive edge. Products with improved thermal performance often command premium prices and attract customers seeking high-reliability solutions. This potential for increased revenue and market share should be factored into the cost-benefit analysis.

However, it is crucial to consider the scalability of Accura 25 implementation. While benefits may be clear for high-end or specialized products, the cost-effectiveness for mass-market applications may vary. A thorough analysis of production volumes, target markets, and pricing strategies is essential to determine the optimal scale of adoption.

Environmental considerations also play a role in the cost-benefit analysis. Accura 25's potential to reduce energy consumption in cooling systems aligns with sustainability goals and may lead to cost savings in energy-intensive applications. Additionally, compliance with evolving environmental regulations may be easier to achieve with advanced materials like Accura 25, potentially avoiding future retrofit costs or penalties.

In conclusion, while the initial costs of adopting Accura 25 may be significant, the long-term benefits in performance, efficiency, and market positioning can outweigh these expenses for many applications. A comprehensive cost-benefit analysis should consider not only immediate financial impacts but also long-term strategic advantages and potential for innovation in thermal management solutions.

One of the primary advantages of Accura 25 is its superior thermal conductivity compared to traditional materials. This property allows for more efficient heat dissipation, potentially reducing the need for additional cooling components and simplifying product designs. The resulting streamlined manufacturing process can lead to significant cost savings in production and assembly.

Furthermore, the enhanced thermal management capabilities of Accura 25 can extend the lifespan of electronic components by preventing overheating and thermal stress. This increased durability translates to reduced warranty claims and maintenance costs, improving the overall cost-effectiveness of products incorporating this material.

From a market perspective, the adoption of Accura 25 can provide a competitive edge. Products with improved thermal performance often command premium prices and attract customers seeking high-reliability solutions. This potential for increased revenue and market share should be factored into the cost-benefit analysis.

However, it is crucial to consider the scalability of Accura 25 implementation. While benefits may be clear for high-end or specialized products, the cost-effectiveness for mass-market applications may vary. A thorough analysis of production volumes, target markets, and pricing strategies is essential to determine the optimal scale of adoption.

Environmental considerations also play a role in the cost-benefit analysis. Accura 25's potential to reduce energy consumption in cooling systems aligns with sustainability goals and may lead to cost savings in energy-intensive applications. Additionally, compliance with evolving environmental regulations may be easier to achieve with advanced materials like Accura 25, potentially avoiding future retrofit costs or penalties.

In conclusion, while the initial costs of adopting Accura 25 may be significant, the long-term benefits in performance, efficiency, and market positioning can outweigh these expenses for many applications. A comprehensive cost-benefit analysis should consider not only immediate financial impacts but also long-term strategic advantages and potential for innovation in thermal management solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!