Accura 25 in the Evolution of Advanced Prototyping

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25 represents a significant milestone in the evolution of advanced prototyping materials. Developed by 3D Systems, this photopolymer resin has played a crucial role in advancing the capabilities of stereolithography (SLA) technology. The journey of Accura 25 began in the early 2000s when the demand for high-performance, durable prototyping materials was rapidly increasing across various industries.

The primary objective behind the development of Accura 25 was to create a material that could bridge the gap between prototype and production parts. Engineers and designers sought a resin that could not only produce accurate prototypes but also withstand functional testing and even serve as end-use parts in certain applications. This ambitious goal drove the research and development efforts at 3D Systems.

Accura 25 was designed to offer a unique combination of properties that were previously difficult to achieve in a single material. These properties included high tensile strength, excellent dimensional stability, and superior surface finish. The material was also engineered to exhibit low moisture absorption and resistance to various environmental factors, making it suitable for a wide range of applications.

The development of Accura 25 coincided with advancements in SLA technology, particularly in the areas of laser precision and build platform mechanics. This synergy between material and machine development allowed for the creation of parts with exceptional accuracy and detail. As a result, Accura 25 quickly gained traction in industries such as aerospace, automotive, and consumer electronics, where precision and performance were paramount.

One of the key technological goals of Accura 25 was to improve the overall efficiency of the prototyping process. By offering a material that could produce parts with properties close to those of injection-molded plastics, it aimed to reduce the need for multiple iterations and material changes during the product development cycle. This had the potential to significantly shorten time-to-market for new products and reduce development costs.

As the adoption of Accura 25 grew, researchers and engineers continued to explore its potential applications and push the boundaries of what was possible with SLA technology. The material became a benchmark for future developments in photopolymer resins, inspiring innovations in areas such as biocompatibility, heat resistance, and mechanical properties.

The primary objective behind the development of Accura 25 was to create a material that could bridge the gap between prototype and production parts. Engineers and designers sought a resin that could not only produce accurate prototypes but also withstand functional testing and even serve as end-use parts in certain applications. This ambitious goal drove the research and development efforts at 3D Systems.

Accura 25 was designed to offer a unique combination of properties that were previously difficult to achieve in a single material. These properties included high tensile strength, excellent dimensional stability, and superior surface finish. The material was also engineered to exhibit low moisture absorption and resistance to various environmental factors, making it suitable for a wide range of applications.

The development of Accura 25 coincided with advancements in SLA technology, particularly in the areas of laser precision and build platform mechanics. This synergy between material and machine development allowed for the creation of parts with exceptional accuracy and detail. As a result, Accura 25 quickly gained traction in industries such as aerospace, automotive, and consumer electronics, where precision and performance were paramount.

One of the key technological goals of Accura 25 was to improve the overall efficiency of the prototyping process. By offering a material that could produce parts with properties close to those of injection-molded plastics, it aimed to reduce the need for multiple iterations and material changes during the product development cycle. This had the potential to significantly shorten time-to-market for new products and reduce development costs.

As the adoption of Accura 25 grew, researchers and engineers continued to explore its potential applications and push the boundaries of what was possible with SLA technology. The material became a benchmark for future developments in photopolymer resins, inspiring innovations in areas such as biocompatibility, heat resistance, and mechanical properties.

Market Demand Analysis for Advanced Prototyping

The market demand for advanced prototyping technologies, particularly Accura 25, has been steadily increasing in recent years. This growth is driven by the need for faster, more accurate, and cost-effective prototyping solutions across various industries. The automotive, aerospace, and consumer electronics sectors are at the forefront of this demand, seeking to reduce product development cycles and improve time-to-market for new innovations.

Accura 25, as a high-performance stereolithography resin, has garnered significant attention due to its exceptional properties. Its ability to produce parts with high detail resolution, smooth surface finish, and dimensional stability makes it particularly attractive for applications requiring precise prototypes. The material's compatibility with a wide range of post-processing techniques further enhances its appeal in the market.

The global 3D printing materials market, which includes advanced resins like Accura 25, is experiencing robust growth. This expansion is fueled by the increasing adoption of additive manufacturing technologies across industries. The automotive sector, in particular, has shown a strong inclination towards using advanced prototyping materials for concept modeling, functional testing, and even small-batch production of specialized parts.

In the aerospace industry, the demand for Accura 25 and similar materials is driven by the need for lightweight, high-strength components that can withstand rigorous testing conditions. The ability to rapidly prototype complex geometries with tight tolerances is crucial in this sector, making advanced resins an essential part of the product development process.

The consumer electronics market is another significant driver of demand for advanced prototyping materials. With product lifecycles becoming shorter and competition intensifying, manufacturers are increasingly relying on rapid prototyping to validate designs and accelerate product launches. Accura 25's ability to produce transparent parts with excellent clarity is particularly valuable in this sector for prototyping display components and optical elements.

The healthcare and medical device industry is emerging as a promising market for advanced prototyping materials. The need for customized medical devices, surgical planning models, and anatomical replicas for training purposes is creating new opportunities for materials like Accura 25. Its biocompatibility and ability to withstand sterilization processes make it suitable for a range of medical applications.

As sustainability becomes a key concern across industries, there is a growing demand for eco-friendly prototyping materials. While Accura 25 offers excellent performance, there is an increasing market interest in materials that offer similar capabilities with reduced environmental impact. This trend is likely to shape future developments in the advanced prototyping materials market.

The COVID-19 pandemic has further accelerated the adoption of advanced prototyping technologies, as companies seek to maintain innovation and product development activities despite disruptions to traditional supply chains and manufacturing processes. This has led to an increased focus on in-house prototyping capabilities, driving demand for versatile materials like Accura 25 that can support a wide range of applications.

Accura 25, as a high-performance stereolithography resin, has garnered significant attention due to its exceptional properties. Its ability to produce parts with high detail resolution, smooth surface finish, and dimensional stability makes it particularly attractive for applications requiring precise prototypes. The material's compatibility with a wide range of post-processing techniques further enhances its appeal in the market.

The global 3D printing materials market, which includes advanced resins like Accura 25, is experiencing robust growth. This expansion is fueled by the increasing adoption of additive manufacturing technologies across industries. The automotive sector, in particular, has shown a strong inclination towards using advanced prototyping materials for concept modeling, functional testing, and even small-batch production of specialized parts.

In the aerospace industry, the demand for Accura 25 and similar materials is driven by the need for lightweight, high-strength components that can withstand rigorous testing conditions. The ability to rapidly prototype complex geometries with tight tolerances is crucial in this sector, making advanced resins an essential part of the product development process.

The consumer electronics market is another significant driver of demand for advanced prototyping materials. With product lifecycles becoming shorter and competition intensifying, manufacturers are increasingly relying on rapid prototyping to validate designs and accelerate product launches. Accura 25's ability to produce transparent parts with excellent clarity is particularly valuable in this sector for prototyping display components and optical elements.

The healthcare and medical device industry is emerging as a promising market for advanced prototyping materials. The need for customized medical devices, surgical planning models, and anatomical replicas for training purposes is creating new opportunities for materials like Accura 25. Its biocompatibility and ability to withstand sterilization processes make it suitable for a range of medical applications.

As sustainability becomes a key concern across industries, there is a growing demand for eco-friendly prototyping materials. While Accura 25 offers excellent performance, there is an increasing market interest in materials that offer similar capabilities with reduced environmental impact. This trend is likely to shape future developments in the advanced prototyping materials market.

The COVID-19 pandemic has further accelerated the adoption of advanced prototyping technologies, as companies seek to maintain innovation and product development activities despite disruptions to traditional supply chains and manufacturing processes. This has led to an increased focus on in-house prototyping capabilities, driving demand for versatile materials like Accura 25 that can support a wide range of applications.

Current State and Challenges in Rapid Prototyping

Rapid prototyping technology has witnessed significant advancements in recent years, with Accura 25 emerging as a notable material in the field of advanced prototyping. The current state of rapid prototyping is characterized by a diverse range of technologies and materials, each offering unique advantages and limitations.

Stereolithography (SLA) and Digital Light Processing (DLP) continue to dominate the high-precision prototyping market, with Accura 25 being a key material in SLA applications. This photopolymer resin offers excellent dimensional stability, high detail resolution, and smooth surface finish, making it ideal for producing functional prototypes and end-use parts in various industries.

However, the rapid prototyping industry faces several challenges. One of the primary concerns is the need for faster production speeds without compromising quality. While Accura 25 provides superior results, the layer-by-layer curing process in SLA can be time-consuming for large or complex parts. This has led to ongoing research into optimizing light sources and resin formulations to accelerate print speeds.

Material costs remain a significant challenge, particularly for high-performance resins like Accura 25. The specialized nature of these materials contributes to their higher price point, which can limit accessibility for smaller businesses or educational institutions. Efforts are underway to develop more cost-effective alternatives that maintain similar performance characteristics.

Another hurdle in the rapid prototyping landscape is the need for improved post-processing techniques. While Accura 25 produces parts with excellent surface finish, many applications still require additional treatments such as sanding, painting, or coating. Streamlining these post-processing steps is crucial for reducing overall production time and costs.

Sustainability is an emerging challenge in the industry. As the use of rapid prototyping technologies expands, concerns about the environmental impact of materials like Accura 25 are growing. Researchers are exploring bio-based alternatives and recycling methods to address these concerns and promote more sustainable practices in additive manufacturing.

Interoperability between different rapid prototyping systems and materials remains a challenge. While Accura 25 is optimized for specific SLA systems, there is a growing demand for materials that can be used across multiple platforms. This would provide greater flexibility and cost-effectiveness for users who operate diverse prototyping equipment.

Lastly, the rapid evolution of technology presents a continuous challenge for both manufacturers and users. Keeping pace with new developments, such as improvements in Accura 25 or the introduction of competing materials, requires ongoing investment in research, equipment upgrades, and staff training. This rapid change can create barriers to entry for new players in the market and challenges for established companies in maintaining their competitive edge.

Stereolithography (SLA) and Digital Light Processing (DLP) continue to dominate the high-precision prototyping market, with Accura 25 being a key material in SLA applications. This photopolymer resin offers excellent dimensional stability, high detail resolution, and smooth surface finish, making it ideal for producing functional prototypes and end-use parts in various industries.

However, the rapid prototyping industry faces several challenges. One of the primary concerns is the need for faster production speeds without compromising quality. While Accura 25 provides superior results, the layer-by-layer curing process in SLA can be time-consuming for large or complex parts. This has led to ongoing research into optimizing light sources and resin formulations to accelerate print speeds.

Material costs remain a significant challenge, particularly for high-performance resins like Accura 25. The specialized nature of these materials contributes to their higher price point, which can limit accessibility for smaller businesses or educational institutions. Efforts are underway to develop more cost-effective alternatives that maintain similar performance characteristics.

Another hurdle in the rapid prototyping landscape is the need for improved post-processing techniques. While Accura 25 produces parts with excellent surface finish, many applications still require additional treatments such as sanding, painting, or coating. Streamlining these post-processing steps is crucial for reducing overall production time and costs.

Sustainability is an emerging challenge in the industry. As the use of rapid prototyping technologies expands, concerns about the environmental impact of materials like Accura 25 are growing. Researchers are exploring bio-based alternatives and recycling methods to address these concerns and promote more sustainable practices in additive manufacturing.

Interoperability between different rapid prototyping systems and materials remains a challenge. While Accura 25 is optimized for specific SLA systems, there is a growing demand for materials that can be used across multiple platforms. This would provide greater flexibility and cost-effectiveness for users who operate diverse prototyping equipment.

Lastly, the rapid evolution of technology presents a continuous challenge for both manufacturers and users. Keeping pace with new developments, such as improvements in Accura 25 or the introduction of competing materials, requires ongoing investment in research, equipment upgrades, and staff training. This rapid change can create barriers to entry for new players in the market and challenges for established companies in maintaining their competitive edge.

Existing Solutions Using Accura 25

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Manufacturing processes for Accura 25: Different methods and processes are employed in the production of Accura 25, including synthesis techniques, purification steps, and quality control measures to ensure consistent product quality.

- Analytical methods for Accura 25: Various analytical techniques are used to characterize and quantify Accura 25 in pharmaceutical formulations and biological samples. These methods may include chromatography, spectroscopy, and other advanced analytical tools.

- Formulations containing Accura 25 for specific applications: Accura 25 is incorporated into specialized formulations for targeted applications, such as controlled release systems, topical preparations, or combination therapies with other active ingredients.

- Accura 25 in medical devices and diagnostic applications: Accura 25 is utilized in the development of medical devices and diagnostic tools, potentially enhancing their performance or serving as a key component in novel healthcare technologies.

02 Manufacturing processes for Accura 25

Different methods and processes are employed in the production of Accura 25, including synthesis techniques, purification steps, and quality control measures to ensure consistent product quality.Expand Specific Solutions03 Analytical methods for Accura 25

Various analytical techniques are used to characterize and quantify Accura 25 in pharmaceutical formulations and biological samples. These methods may include chromatography, spectroscopy, and other advanced analytical tools.Expand Specific Solutions04 Formulations containing Accura 25 for specific applications

Accura 25 is incorporated into specialized formulations for targeted applications, such as controlled release systems, topical preparations, or combination therapies with other active ingredients.Expand Specific Solutions05 Accura 25 in medical devices and diagnostic applications

Accura 25 is utilized in the development of medical devices and diagnostic tools, potentially enhancing their performance or serving as a key component in novel healthcare technologies.Expand Specific Solutions

Key Players in Advanced Prototyping Industry

The research on Accura 25 in advanced prototyping is at a nascent stage, with the market still developing and showing potential for significant growth. The technology's maturity varies across different players, with established semiconductor companies like Taiwan Semiconductor Manufacturing Co., Ltd. and Renesas Electronics Corp. likely having more advanced capabilities. Emerging players such as Macso Technologies Ltd. and Syntekabio, Inc. are also contributing to the field's evolution. The competitive landscape is diverse, including both industry giants and innovative startups, indicating a dynamic environment for technological advancements. As the technology progresses, we can expect increased collaboration between academic institutions like Fudan University and industry leaders to drive further innovation in this space.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has been at the forefront of advanced prototyping in semiconductor manufacturing, particularly with their Accura 25 technology. This technology is part of their N3 (3nm) process node, which represents a significant leap in chip manufacturing precision. The Accura 25 system utilizes extreme ultraviolet (EUV) lithography to achieve unprecedented accuracy in chip production[1]. It enables the creation of more complex and densely packed integrated circuits, with feature sizes as small as 3 nanometers. This advancement allows for the production of chips with higher transistor density, improved performance, and lower power consumption compared to previous generations[2][3].

Strengths: Industry-leading precision in chip manufacturing, enabling production of cutting-edge 3nm chips. Weaknesses: High cost of implementation and potential yield challenges in early stages of adoption.

Renesas Electronics Corp.

Technical Solution: Renesas has been actively involved in the evolution of advanced prototyping, particularly in the automotive and industrial sectors. Their approach to Accura 25-level precision involves the development of advanced microcontrollers and system-on-chips (SoCs) that leverage the latest manufacturing processes. Renesas' R-Car series, for instance, utilizes advanced prototyping techniques to create highly integrated automotive computing platforms. These chips incorporate multiple CPU cores, GPU, and dedicated accelerators for tasks such as image recognition and AI processing, all while maintaining high reliability and safety standards required for automotive applications[8][9].

Strengths: Strong presence in automotive and industrial markets with specialized chip designs. Weaknesses: Faces intense competition in rapidly evolving markets.

Core Innovations in Accura 25 Technology

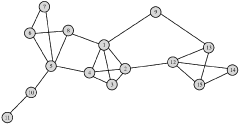

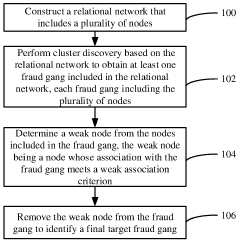

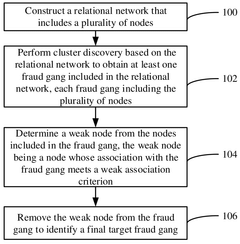

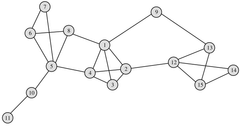

Fraud gang identification method and device

PatentActiveSG11202005960WA

Innovation

- A fraud gang identification method and device that constructs a relational network, performs cluster discovery, determines weak nodes based on association criteria, and removes them to identify a final target fraud gang, improving identification precision.

Semiconductor device and method of manufacturing the same

PatentActiveUS20100321705A1

Innovation

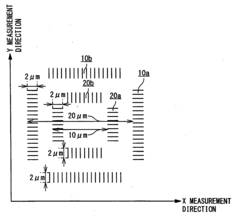

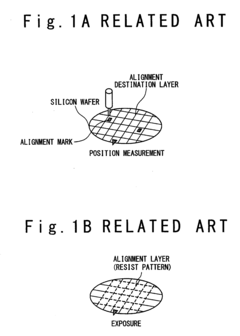

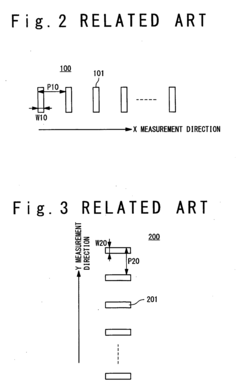

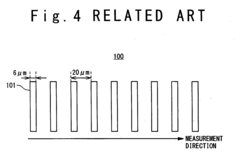

- The use of alignment marks with bar marks arranged in a first direction and interconnection marks along a second direction, where the space between adjacent interconnection marks is shorter than the wavelength of the detection beam, improving measurement accuracy while adhering to design constraints.

Environmental Impact of Prototyping Materials

The environmental impact of prototyping materials, particularly in the context of Accura 25 and advanced prototyping, is a critical consideration in the evolution of rapid prototyping technologies. Accura 25 is a photopolymer resin used in stereolithography (SLA) 3D printing, known for its high accuracy and smooth surface finish. However, like many prototyping materials, it raises environmental concerns that warrant careful examination.

Accura 25, being a photopolymer, is derived from petroleum-based sources, which inherently contributes to the depletion of non-renewable resources. The production process of this material involves energy-intensive manufacturing steps, leading to a significant carbon footprint. Additionally, the curing process of Accura 25 during 3D printing releases volatile organic compounds (VOCs), which can have adverse effects on air quality and human health if not properly managed.

The disposal of Accura 25 prototypes and waste material presents another environmental challenge. Unlike some thermoplastics used in other 3D printing methods, photopolymer resins are not easily recyclable. Used or failed prints often end up in landfills, contributing to long-term environmental pollution due to their slow degradation rates. Furthermore, improper disposal of liquid resin can lead to soil and water contamination.

However, it's important to note that the use of Accura 25 in advanced prototyping also offers some environmental benefits. The high accuracy and quality of prototypes produced with this material can lead to reduced iterations in product development cycles, potentially lowering overall material consumption and waste. Additionally, the ability to create complex geometries with Accura 25 enables the design of more efficient products, which can have positive environmental impacts during their lifecycle.

Efforts are being made to mitigate the environmental impact of Accura 25 and similar materials. Research is ongoing to develop bio-based alternatives that maintain the desirable properties of photopolymers while reducing reliance on petroleum-based sources. Improved resin formulations aim to minimize VOC emissions and enhance biodegradability. Moreover, advancements in recycling technologies for photopolymers are being explored to create a more circular economy for these materials.

In the broader context of advanced prototyping, the environmental impact of materials like Accura 25 is driving innovation towards more sustainable practices. This includes the development of closed-loop systems for resin recycling, the implementation of more energy-efficient 3D printing processes, and the exploration of alternative, environmentally friendly materials that can match or exceed the performance of current photopolymers.

Accura 25, being a photopolymer, is derived from petroleum-based sources, which inherently contributes to the depletion of non-renewable resources. The production process of this material involves energy-intensive manufacturing steps, leading to a significant carbon footprint. Additionally, the curing process of Accura 25 during 3D printing releases volatile organic compounds (VOCs), which can have adverse effects on air quality and human health if not properly managed.

The disposal of Accura 25 prototypes and waste material presents another environmental challenge. Unlike some thermoplastics used in other 3D printing methods, photopolymer resins are not easily recyclable. Used or failed prints often end up in landfills, contributing to long-term environmental pollution due to their slow degradation rates. Furthermore, improper disposal of liquid resin can lead to soil and water contamination.

However, it's important to note that the use of Accura 25 in advanced prototyping also offers some environmental benefits. The high accuracy and quality of prototypes produced with this material can lead to reduced iterations in product development cycles, potentially lowering overall material consumption and waste. Additionally, the ability to create complex geometries with Accura 25 enables the design of more efficient products, which can have positive environmental impacts during their lifecycle.

Efforts are being made to mitigate the environmental impact of Accura 25 and similar materials. Research is ongoing to develop bio-based alternatives that maintain the desirable properties of photopolymers while reducing reliance on petroleum-based sources. Improved resin formulations aim to minimize VOC emissions and enhance biodegradability. Moreover, advancements in recycling technologies for photopolymers are being explored to create a more circular economy for these materials.

In the broader context of advanced prototyping, the environmental impact of materials like Accura 25 is driving innovation towards more sustainable practices. This includes the development of closed-loop systems for resin recycling, the implementation of more energy-efficient 3D printing processes, and the exploration of alternative, environmentally friendly materials that can match or exceed the performance of current photopolymers.

Intellectual Property Landscape for Accura 25

The intellectual property landscape surrounding Accura 25 reflects the rapid evolution and competitive nature of advanced prototyping technologies. As a key material in stereolithography (SLA) 3D printing, Accura 25 has been the subject of numerous patents and innovations since its introduction. The patent portfolio primarily focuses on the material composition, processing techniques, and applications of this high-performance resin.

3D Systems, the developer of Accura 25, holds several foundational patents related to the material's formulation and its use in SLA processes. These patents cover the specific chemical composition that provides Accura 25 with its unique balance of strength, accuracy, and surface finish. Additionally, patents exist for specialized post-processing techniques that enhance the material's mechanical properties and durability.

Competing companies have also filed patents for similar photopolymer resins, aiming to develop alternatives with comparable or superior characteristics. These patents often focus on modifying the resin chemistry to improve specific properties such as heat resistance, flexibility, or biocompatibility. Some patents explore the integration of additives or nanoparticles to enhance the material's performance in specific applications.

The application-specific patents for Accura 25 and related materials span various industries. In the automotive sector, patents cover the use of Accura 25 for rapid prototyping of complex components and functional testing models. The aerospace industry has patents related to the production of lightweight, high-precision parts for wind tunnel testing and concept validation.

In the medical field, patents exist for utilizing Accura 25 in the creation of anatomical models for surgical planning and education. These patents often address the material's ability to replicate fine details and its compatibility with sterilization processes. The dental industry has also seen patents for using Accura 25 in the production of clear aligners and surgical guides.

Recent patent activity indicates a trend towards developing more sustainable and eco-friendly versions of high-performance SLA resins. This includes patents for bio-based alternatives to traditional petroleum-derived resins and methods for improving the recyclability and end-of-life management of printed parts.

The intellectual property landscape also extends to the 3D printing hardware optimized for use with Accura 25 and similar materials. Patents in this area cover innovations in laser systems, resin delivery mechanisms, and build platform designs that enhance the printing speed and quality when using these advanced resins.

3D Systems, the developer of Accura 25, holds several foundational patents related to the material's formulation and its use in SLA processes. These patents cover the specific chemical composition that provides Accura 25 with its unique balance of strength, accuracy, and surface finish. Additionally, patents exist for specialized post-processing techniques that enhance the material's mechanical properties and durability.

Competing companies have also filed patents for similar photopolymer resins, aiming to develop alternatives with comparable or superior characteristics. These patents often focus on modifying the resin chemistry to improve specific properties such as heat resistance, flexibility, or biocompatibility. Some patents explore the integration of additives or nanoparticles to enhance the material's performance in specific applications.

The application-specific patents for Accura 25 and related materials span various industries. In the automotive sector, patents cover the use of Accura 25 for rapid prototyping of complex components and functional testing models. The aerospace industry has patents related to the production of lightweight, high-precision parts for wind tunnel testing and concept validation.

In the medical field, patents exist for utilizing Accura 25 in the creation of anatomical models for surgical planning and education. These patents often address the material's ability to replicate fine details and its compatibility with sterilization processes. The dental industry has also seen patents for using Accura 25 in the production of clear aligners and surgical guides.

Recent patent activity indicates a trend towards developing more sustainable and eco-friendly versions of high-performance SLA resins. This includes patents for bio-based alternatives to traditional petroleum-derived resins and methods for improving the recyclability and end-of-life management of printed parts.

The intellectual property landscape also extends to the 3D printing hardware optimized for use with Accura 25 and similar materials. Patents in this area cover innovations in laser systems, resin delivery mechanisms, and build platform designs that enhance the printing speed and quality when using these advanced resins.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!