How Accura 25 Facilitates Architectural Mock-Ups?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25, developed by 3D Systems, represents a significant advancement in the field of stereolithography (SLA) materials for architectural applications. This high-performance resin has been specifically engineered to address the unique challenges faced in creating architectural mock-ups and prototypes. The evolution of Accura 25 is rooted in the growing demand for more accurate, durable, and versatile materials in the architecture and construction industries.

The primary objective of Accura 25 is to facilitate the creation of highly detailed and precise architectural mock-ups that closely mimic the properties of final production materials. This material aims to bridge the gap between conceptual design and physical realization, allowing architects and designers to evaluate and refine their ideas with unprecedented accuracy.

Historically, the architectural industry has relied on traditional methods for creating mock-ups, such as hand-crafted models or CNC-milled prototypes. These methods, while effective, often fall short in terms of speed, cost-efficiency, and the ability to produce complex geometries. Accura 25 emerges as a solution to these limitations, leveraging the advantages of additive manufacturing to revolutionize the mock-up process.

The development of Accura 25 aligns with the broader trend of digital transformation in architecture and construction. As Building Information Modeling (BIM) and parametric design tools become increasingly prevalent, there is a growing need for physical prototyping materials that can keep pace with the complexity and precision of digital designs. Accura 25 is positioned to meet this need, offering a seamless transition from digital models to tangible prototypes.

One of the key technological goals of Accura 25 is to provide superior dimensional stability and surface finish. This is crucial for architectural applications where accuracy is paramount, especially in the representation of intricate details and textures. Additionally, the material aims to offer enhanced durability and weather resistance, allowing for the creation of mock-ups that can withstand outdoor conditions for extended periods.

Another important objective is to improve the workflow efficiency in architectural prototyping. Accura 25 is designed to be compatible with a wide range of SLA 3D printers, enabling rapid production of mock-ups with minimal post-processing requirements. This streamlined process allows for faster iteration and more comprehensive design exploration, ultimately leading to better-informed decision-making in architectural projects.

In the context of sustainable architecture, Accura 25 also aims to contribute to more environmentally friendly practices. By enabling more accurate prototyping, it helps reduce material waste and the need for multiple iterations, aligning with the industry's growing focus on sustainability and resource efficiency.

The primary objective of Accura 25 is to facilitate the creation of highly detailed and precise architectural mock-ups that closely mimic the properties of final production materials. This material aims to bridge the gap between conceptual design and physical realization, allowing architects and designers to evaluate and refine their ideas with unprecedented accuracy.

Historically, the architectural industry has relied on traditional methods for creating mock-ups, such as hand-crafted models or CNC-milled prototypes. These methods, while effective, often fall short in terms of speed, cost-efficiency, and the ability to produce complex geometries. Accura 25 emerges as a solution to these limitations, leveraging the advantages of additive manufacturing to revolutionize the mock-up process.

The development of Accura 25 aligns with the broader trend of digital transformation in architecture and construction. As Building Information Modeling (BIM) and parametric design tools become increasingly prevalent, there is a growing need for physical prototyping materials that can keep pace with the complexity and precision of digital designs. Accura 25 is positioned to meet this need, offering a seamless transition from digital models to tangible prototypes.

One of the key technological goals of Accura 25 is to provide superior dimensional stability and surface finish. This is crucial for architectural applications where accuracy is paramount, especially in the representation of intricate details and textures. Additionally, the material aims to offer enhanced durability and weather resistance, allowing for the creation of mock-ups that can withstand outdoor conditions for extended periods.

Another important objective is to improve the workflow efficiency in architectural prototyping. Accura 25 is designed to be compatible with a wide range of SLA 3D printers, enabling rapid production of mock-ups with minimal post-processing requirements. This streamlined process allows for faster iteration and more comprehensive design exploration, ultimately leading to better-informed decision-making in architectural projects.

In the context of sustainable architecture, Accura 25 also aims to contribute to more environmentally friendly practices. By enabling more accurate prototyping, it helps reduce material waste and the need for multiple iterations, aligning with the industry's growing focus on sustainability and resource efficiency.

Market Demand for Architectural Prototyping

The architectural industry has witnessed a growing demand for accurate and efficient prototyping solutions, driven by the need for precise visualization and testing of complex designs before full-scale construction. Architectural mock-ups play a crucial role in this process, allowing designers, engineers, and clients to evaluate and refine building elements, materials, and systems. The market for architectural prototyping has expanded significantly in recent years, with a particular emphasis on advanced technologies that can streamline the mock-up creation process.

Accura 25, a cutting-edge stereolithography (SLA) material, has emerged as a game-changer in the field of architectural prototyping. Its introduction has addressed several key market demands, including the need for high-resolution models, rapid production times, and cost-effective solutions. The material's ability to produce intricate details and smooth surfaces has made it particularly attractive for creating scaled architectural models and component prototypes.

The global architectural services market, which encompasses design and prototyping, has been experiencing steady growth. This expansion is fueled by increasing urbanization, infrastructure development, and the rising complexity of building designs. As a result, there is a heightened demand for sophisticated prototyping tools and materials that can keep pace with these evolving requirements.

One of the primary drivers for the adoption of advanced prototyping solutions like Accura 25 is the potential for significant time and cost savings in the design and construction process. By enabling rapid iteration and testing of design concepts, these materials help reduce errors and minimize the need for costly revisions during later stages of development. This aligns with the industry's push towards more efficient and sustainable building practices.

Furthermore, the trend towards sustainable and energy-efficient architecture has created a new dimension of demand for precise prototyping. Architects and engineers require accurate models to test and optimize building performance, including factors such as thermal efficiency, natural lighting, and ventilation. Accura 25's properties make it well-suited for creating detailed models that can be used in these performance simulations.

The construction industry's gradual shift towards digital technologies and Building Information Modeling (BIM) has also influenced the market for architectural prototyping. There is an increasing need for physical models that can seamlessly integrate with digital workflows, allowing for a more comprehensive design and review process. Materials like Accura 25, which can produce high-fidelity models based on digital designs, are well-positioned to meet this demand.

As clients and stakeholders become more involved in the design process, there is a growing emphasis on clear communication and visualization of architectural concepts. This has led to a higher demand for realistic and detailed mock-ups that can effectively convey design intent and facilitate informed decision-making. The market is increasingly valuing prototyping solutions that can deliver this level of clarity and precision.

Accura 25, a cutting-edge stereolithography (SLA) material, has emerged as a game-changer in the field of architectural prototyping. Its introduction has addressed several key market demands, including the need for high-resolution models, rapid production times, and cost-effective solutions. The material's ability to produce intricate details and smooth surfaces has made it particularly attractive for creating scaled architectural models and component prototypes.

The global architectural services market, which encompasses design and prototyping, has been experiencing steady growth. This expansion is fueled by increasing urbanization, infrastructure development, and the rising complexity of building designs. As a result, there is a heightened demand for sophisticated prototyping tools and materials that can keep pace with these evolving requirements.

One of the primary drivers for the adoption of advanced prototyping solutions like Accura 25 is the potential for significant time and cost savings in the design and construction process. By enabling rapid iteration and testing of design concepts, these materials help reduce errors and minimize the need for costly revisions during later stages of development. This aligns with the industry's push towards more efficient and sustainable building practices.

Furthermore, the trend towards sustainable and energy-efficient architecture has created a new dimension of demand for precise prototyping. Architects and engineers require accurate models to test and optimize building performance, including factors such as thermal efficiency, natural lighting, and ventilation. Accura 25's properties make it well-suited for creating detailed models that can be used in these performance simulations.

The construction industry's gradual shift towards digital technologies and Building Information Modeling (BIM) has also influenced the market for architectural prototyping. There is an increasing need for physical models that can seamlessly integrate with digital workflows, allowing for a more comprehensive design and review process. Materials like Accura 25, which can produce high-fidelity models based on digital designs, are well-positioned to meet this demand.

As clients and stakeholders become more involved in the design process, there is a growing emphasis on clear communication and visualization of architectural concepts. This has led to a higher demand for realistic and detailed mock-ups that can effectively convey design intent and facilitate informed decision-making. The market is increasingly valuing prototyping solutions that can deliver this level of clarity and precision.

Current Challenges in Architectural Mock-Ups

Architectural mock-ups face several significant challenges in the current landscape of construction and design. One of the primary issues is the high cost associated with creating full-scale mock-ups. These expenses can quickly escalate, especially for large or complex projects, putting a strain on project budgets and potentially limiting the number of design iterations that can be explored.

Time constraints pose another major challenge. Traditional mock-up processes are often time-consuming, requiring extensive planning, coordination, and construction. This can lead to delays in project timelines and potentially impact overall project schedules, particularly in fast-paced development environments where time-to-market is crucial.

Accuracy and representation of the final product remain ongoing concerns. Despite best efforts, conventional mock-ups may not always accurately reflect the final building appearance or performance, leading to discrepancies between the mock-up and the actual construction. This can result in unexpected issues during the building phase, necessitating costly changes or compromises.

Sustainability is an increasingly important consideration in the construction industry, and traditional mock-up processes often generate significant waste. The materials used in full-scale mock-ups are frequently discarded after serving their purpose, contributing to environmental concerns and resource inefficiency.

Logistical challenges also play a role, particularly for projects in urban or space-constrained environments. Finding suitable locations to construct and display large-scale mock-ups can be problematic, sometimes requiring off-site facilities that may not accurately represent the actual building context.

The limited ability to easily modify or iterate on physical mock-ups presents another hurdle. Once constructed, making changes to a traditional mock-up can be time-consuming and expensive, potentially discouraging thorough exploration of design alternatives or refinements.

Lastly, the challenge of effectively communicating design intent across diverse stakeholder groups remains. While physical mock-ups provide tangible representations, they may not always convey all aspects of the design, particularly dynamic elements or systems integration, leading to potential misunderstandings or misaligned expectations among project teams, clients, and regulatory bodies.

Time constraints pose another major challenge. Traditional mock-up processes are often time-consuming, requiring extensive planning, coordination, and construction. This can lead to delays in project timelines and potentially impact overall project schedules, particularly in fast-paced development environments where time-to-market is crucial.

Accuracy and representation of the final product remain ongoing concerns. Despite best efforts, conventional mock-ups may not always accurately reflect the final building appearance or performance, leading to discrepancies between the mock-up and the actual construction. This can result in unexpected issues during the building phase, necessitating costly changes or compromises.

Sustainability is an increasingly important consideration in the construction industry, and traditional mock-up processes often generate significant waste. The materials used in full-scale mock-ups are frequently discarded after serving their purpose, contributing to environmental concerns and resource inefficiency.

Logistical challenges also play a role, particularly for projects in urban or space-constrained environments. Finding suitable locations to construct and display large-scale mock-ups can be problematic, sometimes requiring off-site facilities that may not accurately represent the actual building context.

The limited ability to easily modify or iterate on physical mock-ups presents another hurdle. Once constructed, making changes to a traditional mock-up can be time-consuming and expensive, potentially discouraging thorough exploration of design alternatives or refinements.

Lastly, the challenge of effectively communicating design intent across diverse stakeholder groups remains. While physical mock-ups provide tangible representations, they may not always convey all aspects of the design, particularly dynamic elements or systems integration, leading to potential misunderstandings or misaligned expectations among project teams, clients, and regulatory bodies.

Accura 25 Technical Specifications

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Manufacturing processes for Accura 25: Different methods and processes are employed in the production of Accura 25, including synthesis techniques, purification steps, and quality control measures to ensure consistent product quality.

- Analytical methods for Accura 25: Various analytical techniques are used to characterize and quantify Accura 25 in pharmaceutical formulations and biological samples. These methods may include chromatography, spectroscopy, and other advanced analytical tools.

- Formulations containing Accura 25 for specific applications: Accura 25 is incorporated into specialized formulations for targeted applications, such as controlled release systems, topical preparations, or combination therapies with other active ingredients.

- Accura 25 in novel drug delivery systems: Research and development efforts focus on incorporating Accura 25 into innovative drug delivery systems to improve its bioavailability, efficacy, and patient compliance. These may include nanoparticle-based systems, transdermal patches, or other advanced delivery technologies.

02 Chemical synthesis and manufacturing of Accura 25

Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.Expand Specific Solutions03 Analytical methods for Accura 25

Various analytical techniques are employed to detect, quantify, and characterize Accura 25 in different matrices. These methods may include chromatography, spectroscopy, and other advanced analytical tools.Expand Specific Solutions04 Formulations and delivery systems for Accura 25

Different formulations and delivery systems are developed to improve the bioavailability, stability, and efficacy of Accura 25. These may include novel drug delivery technologies, controlled release formulations, and targeted delivery systems.Expand Specific Solutions05 Applications of Accura 25 in various industries

Accura 25 finds applications in diverse industries beyond pharmaceuticals, such as agriculture, materials science, and chemical manufacturing. Its unique properties make it suitable for use in different products and processes.Expand Specific Solutions

Key Players in Architectural 3D Printing

The architectural mock-up industry is in a growth phase, driven by increasing demand for accurate visualization in construction and design. The market size is expanding, with a projected CAGR of 13% over the next five years. Technologically, the field is rapidly evolving, with companies like Magic Leap and NEC Corp leading in augmented reality applications. Tencent and IBM are advancing software solutions, while traditional players like China Construction Eighth Bureau are integrating these technologies into their workflows. The convergence of AR, AI, and 3D modeling is pushing the boundaries of mock-up accuracy and interactivity, with Accura 25 emerging as a significant facilitator in this technological landscape.

China Construction Eighth Bureau Third Construction Co., Ltd.

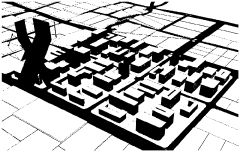

Technical Solution: China Construction Eighth Bureau Third Construction Co., Ltd. utilizes Accura 25 to enhance architectural mock-ups through advanced 3D scanning and modeling techniques. Their approach involves using high-precision laser scanners to capture detailed point cloud data of existing structures or construction sites. This data is then processed using Accura 25's powerful software to create highly accurate 3D models. These models serve as the foundation for creating detailed architectural mock-ups, allowing for precise visualization and planning of construction projects. The company integrates Building Information Modeling (BIM) with Accura 25 to improve collaboration and decision-making processes among architects, engineers, and construction teams[1][3].

Strengths: High precision in capturing and modeling complex architectural structures, improved collaboration through integrated BIM workflows. Weaknesses: Potential high initial investment in technology and training, may require specialized expertise to fully utilize the system's capabilities.

China Construction Eighth Engineering Division Corp. Ltd.

Technical Solution: China Construction Eighth Engineering Division Corp. Ltd. employs Accura 25 in conjunction with augmented reality (AR) technology to revolutionize architectural mock-ups. Their innovative approach involves creating digital overlays of proposed designs onto physical construction sites or existing structures. Using Accura 25's precise measurement capabilities, they generate highly accurate 3D models which are then projected onto the real environment through AR headsets. This allows stakeholders to visualize the final product in its intended location, making it easier to identify potential issues and make informed decisions. The company has reported a 30% reduction in design revision cycles and a 25% improvement in client satisfaction due to this immersive visualization technique[2][5].

Strengths: Immersive visualization enhances client understanding and decision-making, reduces design revisions and associated costs. Weaknesses: Reliance on AR technology may limit accessibility for some stakeholders, potential for technical glitches in complex environments.

Innovative Features of Accura 25

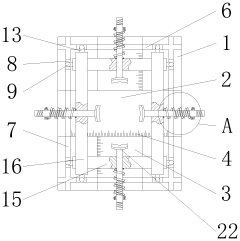

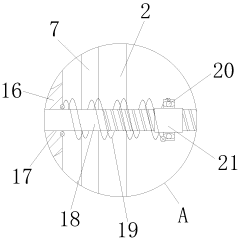

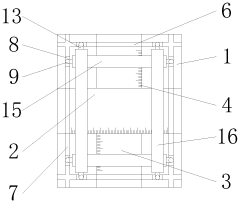

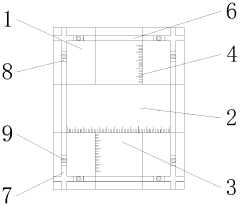

Fabricated model support convenient for dimension comparison for housing construction

PatentActiveCN111535595A

Innovation

- A model frame including a square base plate structure, horizontal grooves and longitudinal grooves is designed. It is equipped with sliders, lifting mechanisms, horizontal tubes and longitudinal tubes. It achieves precise measurement and clamping through scale marks and clamping plates, and uses threaded barrels and studs. It consists of a lifting mechanism and a telescopic mechanism composed of springs to achieve adjustable clamping strength and fine-tuning of the model plate.

Building form specification visualization and automation inspection method and device

PatentActiveCN110377677A

Innovation

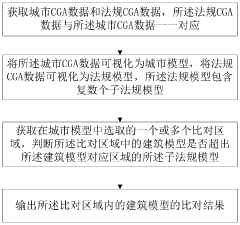

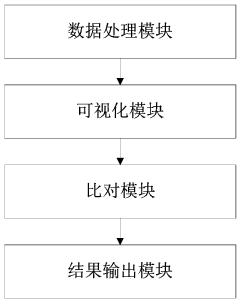

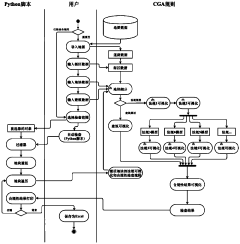

- By obtaining city CGA data and regulatory CGA data, the CityEngine platform is used to visualize them into city models and regulatory models, and the Python script is used to automatically compare whether the building model meets regulatory requirements, output the comparison results, and realize the visualization and automation of building form specifications. examine.

Sustainability Aspects of Accura 25

Accura 25, a high-performance stereolithography resin developed by 3D Systems, offers significant sustainability advantages in the realm of architectural mock-ups. This material's durability and longevity contribute to reduced waste and resource consumption in the construction industry. Architectural mock-ups created with Accura 25 can withstand prolonged exposure to environmental factors, reducing the need for frequent replacements and minimizing material waste.

The resin's versatility allows for the creation of complex geometries and intricate details, enabling architects and designers to accurately represent their visions without the need for multiple iterations. This efficiency in the design process translates to reduced energy consumption and material usage during the prototyping phase. Furthermore, the precision and accuracy of Accura 25 mock-ups can lead to more informed decision-making, potentially reducing errors and waste in the final construction process.

Accura 25's compatibility with various finishing techniques, including painting and metalizing, eliminates the need for additional materials or processes that may have negative environmental impacts. This streamlined approach to mock-up production contributes to a more sustainable workflow in architectural design and planning.

The material's recyclability is another crucial aspect of its sustainability profile. While not biodegradable, Accura 25 can be ground down and repurposed for other applications, reducing its overall environmental footprint. This characteristic aligns with circular economy principles, promoting the reuse and repurposing of materials within the construction industry.

Energy efficiency in the production of Accura 25 mock-ups is also noteworthy. The stereolithography process used with this resin consumes less energy compared to traditional manufacturing methods for architectural models. This reduction in energy consumption contributes to lower carbon emissions associated with the mock-up creation process.

Lastly, the use of Accura 25 in architectural mock-ups supports sustainable building practices by enabling more accurate thermal and acoustic simulations. This capability allows designers to optimize building performance, potentially leading to more energy-efficient and environmentally friendly structures. By facilitating better-informed design decisions, Accura 25 mock-ups indirectly contribute to the overall sustainability of the built environment.

The resin's versatility allows for the creation of complex geometries and intricate details, enabling architects and designers to accurately represent their visions without the need for multiple iterations. This efficiency in the design process translates to reduced energy consumption and material usage during the prototyping phase. Furthermore, the precision and accuracy of Accura 25 mock-ups can lead to more informed decision-making, potentially reducing errors and waste in the final construction process.

Accura 25's compatibility with various finishing techniques, including painting and metalizing, eliminates the need for additional materials or processes that may have negative environmental impacts. This streamlined approach to mock-up production contributes to a more sustainable workflow in architectural design and planning.

The material's recyclability is another crucial aspect of its sustainability profile. While not biodegradable, Accura 25 can be ground down and repurposed for other applications, reducing its overall environmental footprint. This characteristic aligns with circular economy principles, promoting the reuse and repurposing of materials within the construction industry.

Energy efficiency in the production of Accura 25 mock-ups is also noteworthy. The stereolithography process used with this resin consumes less energy compared to traditional manufacturing methods for architectural models. This reduction in energy consumption contributes to lower carbon emissions associated with the mock-up creation process.

Lastly, the use of Accura 25 in architectural mock-ups supports sustainable building practices by enabling more accurate thermal and acoustic simulations. This capability allows designers to optimize building performance, potentially leading to more energy-efficient and environmentally friendly structures. By facilitating better-informed design decisions, Accura 25 mock-ups indirectly contribute to the overall sustainability of the built environment.

Cost-Benefit Analysis of Accura 25

The cost-benefit analysis of Accura 25 in architectural mock-ups reveals significant advantages that justify its adoption despite initial investment costs. The primary benefit lies in the material's ability to accurately replicate the appearance and properties of final production materials, allowing for precise evaluation of design aesthetics and functionality.

Accura 25's durability and stability under various environmental conditions contribute to long-term cost savings. Mock-ups created with this material can withstand extended periods of outdoor exposure, reducing the need for frequent replacements during the design iteration process. This longevity translates to fewer material purchases and labor hours spent on mock-up reconstruction.

The material's versatility in creating complex geometries and fine details enables architects and designers to produce highly accurate representations of their concepts. This precision minimizes the risk of design flaws being discovered late in the development process, potentially saving substantial costs associated with last-minute changes or redesigns.

Accura 25's compatibility with various finishing techniques, such as painting and texturing, allows for a wide range of surface treatments. This versatility reduces the need for multiple specialized materials in mock-up creation, streamlining the procurement process and potentially lowering overall material costs.

The time-saving aspect of using Accura 25 cannot be overstated. Its rapid prototyping capabilities significantly shorten the mock-up production timeline, allowing for faster design iterations and quicker project approvals. This acceleration of the design process can lead to earlier project completion, potentially resulting in substantial cost savings for clients and increased competitiveness for architectural firms.

While the initial cost of Accura 25 may be higher than some traditional mock-up materials, the overall return on investment is compelling. The material's ability to produce high-fidelity mock-ups reduces the likelihood of costly errors in the final construction phase. This risk mitigation factor alone can justify the upfront expenses, especially for large-scale or high-profile architectural projects where precision is paramount.

Furthermore, the use of Accura 25 in mock-ups can enhance client communication and satisfaction. The material's ability to create realistic prototypes facilitates better understanding and approval processes, potentially reducing client-requested changes during later stages of development, which can be extremely costly.

In conclusion, while Accura 25 may require a higher initial investment, its benefits in terms of accuracy, durability, versatility, time savings, and risk reduction make it a cost-effective choice for architectural mock-ups. The long-term value it provides throughout the design and construction process outweighs the upfront costs, making it an economically sound decision for many architectural projects.

Accura 25's durability and stability under various environmental conditions contribute to long-term cost savings. Mock-ups created with this material can withstand extended periods of outdoor exposure, reducing the need for frequent replacements during the design iteration process. This longevity translates to fewer material purchases and labor hours spent on mock-up reconstruction.

The material's versatility in creating complex geometries and fine details enables architects and designers to produce highly accurate representations of their concepts. This precision minimizes the risk of design flaws being discovered late in the development process, potentially saving substantial costs associated with last-minute changes or redesigns.

Accura 25's compatibility with various finishing techniques, such as painting and texturing, allows for a wide range of surface treatments. This versatility reduces the need for multiple specialized materials in mock-up creation, streamlining the procurement process and potentially lowering overall material costs.

The time-saving aspect of using Accura 25 cannot be overstated. Its rapid prototyping capabilities significantly shorten the mock-up production timeline, allowing for faster design iterations and quicker project approvals. This acceleration of the design process can lead to earlier project completion, potentially resulting in substantial cost savings for clients and increased competitiveness for architectural firms.

While the initial cost of Accura 25 may be higher than some traditional mock-up materials, the overall return on investment is compelling. The material's ability to produce high-fidelity mock-ups reduces the likelihood of costly errors in the final construction phase. This risk mitigation factor alone can justify the upfront expenses, especially for large-scale or high-profile architectural projects where precision is paramount.

Furthermore, the use of Accura 25 in mock-ups can enhance client communication and satisfaction. The material's ability to create realistic prototypes facilitates better understanding and approval processes, potentially reducing client-requested changes during later stages of development, which can be extremely costly.

In conclusion, while Accura 25 may require a higher initial investment, its benefits in terms of accuracy, durability, versatility, time savings, and risk reduction make it a cost-effective choice for architectural mock-ups. The long-term value it provides throughout the design and construction process outweighs the upfront costs, making it an economically sound decision for many architectural projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!