Accura 25: Achieving Lightweight Solutions in Design

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Lightweight Design Background and Objectives

Accura 25, a high-performance stereolithography resin developed by 3D Systems, has emerged as a pivotal material in the pursuit of lightweight design solutions. The evolution of this technology can be traced back to the early days of additive manufacturing, where the primary focus was on rapid prototyping. As the field progressed, the demand for materials that could produce functional parts with enhanced mechanical properties grew exponentially.

The development of Accura 25 represents a significant milestone in this journey, offering a unique combination of strength, durability, and low density. This material has opened up new possibilities in lightweight design across various industries, including aerospace, automotive, and consumer electronics. The primary objective of utilizing Accura 25 in lightweight design is to achieve substantial weight reduction without compromising structural integrity or performance.

The technological landscape surrounding Accura 25 is characterized by continuous innovation and refinement. Researchers and engineers are constantly pushing the boundaries of what is possible with this material, exploring novel applications and optimizing its properties for specific use cases. The goal is to unlock its full potential in creating lightweight structures that can withstand demanding environments and complex loading conditions.

One of the key trends driving the adoption of Accura 25 in lightweight design is the increasing emphasis on sustainability and energy efficiency. As industries face mounting pressure to reduce their carbon footprint, lightweight solutions offer a viable path to achieving these objectives. By minimizing material usage and reducing the overall weight of components, Accura 25-based designs contribute to improved fuel efficiency in transportation and reduced energy consumption in various applications.

The technical objectives associated with Accura 25 lightweight design are multifaceted. They include enhancing the material's mechanical properties to expand its application range, developing advanced design methodologies that leverage its unique characteristics, and optimizing manufacturing processes to ensure consistent quality and cost-effectiveness. Additionally, there is a strong focus on improving the material's resistance to environmental factors and extending its service life in demanding applications.

As the field of lightweight design using Accura 25 continues to evolve, researchers are also exploring hybrid approaches that combine this material with other advanced composites and alloys. This interdisciplinary approach aims to create synergistic solutions that capitalize on the strengths of multiple materials, further pushing the boundaries of what can be achieved in terms of weight reduction and performance enhancement.

The development of Accura 25 represents a significant milestone in this journey, offering a unique combination of strength, durability, and low density. This material has opened up new possibilities in lightweight design across various industries, including aerospace, automotive, and consumer electronics. The primary objective of utilizing Accura 25 in lightweight design is to achieve substantial weight reduction without compromising structural integrity or performance.

The technological landscape surrounding Accura 25 is characterized by continuous innovation and refinement. Researchers and engineers are constantly pushing the boundaries of what is possible with this material, exploring novel applications and optimizing its properties for specific use cases. The goal is to unlock its full potential in creating lightweight structures that can withstand demanding environments and complex loading conditions.

One of the key trends driving the adoption of Accura 25 in lightweight design is the increasing emphasis on sustainability and energy efficiency. As industries face mounting pressure to reduce their carbon footprint, lightweight solutions offer a viable path to achieving these objectives. By minimizing material usage and reducing the overall weight of components, Accura 25-based designs contribute to improved fuel efficiency in transportation and reduced energy consumption in various applications.

The technical objectives associated with Accura 25 lightweight design are multifaceted. They include enhancing the material's mechanical properties to expand its application range, developing advanced design methodologies that leverage its unique characteristics, and optimizing manufacturing processes to ensure consistent quality and cost-effectiveness. Additionally, there is a strong focus on improving the material's resistance to environmental factors and extending its service life in demanding applications.

As the field of lightweight design using Accura 25 continues to evolve, researchers are also exploring hybrid approaches that combine this material with other advanced composites and alloys. This interdisciplinary approach aims to create synergistic solutions that capitalize on the strengths of multiple materials, further pushing the boundaries of what can be achieved in terms of weight reduction and performance enhancement.

Market Demand for Lightweight Solutions

The market demand for lightweight solutions has been steadily increasing across various industries, driven by the need for improved efficiency, sustainability, and performance. In the automotive sector, lightweight materials and designs are crucial for enhancing fuel efficiency and reducing emissions to meet stringent environmental regulations. The aerospace industry also heavily relies on lightweight solutions to improve aircraft performance, increase payload capacity, and reduce fuel consumption.

Consumer electronics manufacturers are constantly seeking ways to create thinner, lighter devices without compromising durability or functionality. This trend extends to wearable technology, where lightweight materials are essential for user comfort and adoption. In the sporting goods industry, lightweight equipment and apparel are highly sought after to improve athletic performance and reduce fatigue.

The construction industry is increasingly adopting lightweight materials for both structural and non-structural applications, aiming to reduce building weight, simplify transportation, and improve energy efficiency. Additionally, the renewable energy sector, particularly wind turbine manufacturers, is exploring lightweight solutions to enhance blade design and overall turbine efficiency.

The global market for lightweight materials is projected to experience significant growth in the coming years. This growth is fueled by advancements in material science, manufacturing processes, and design techniques. Accura 25, a high-performance stereolithography resin, is positioned to play a crucial role in this expanding market by enabling the rapid prototyping and production of lightweight components.

Key drivers for the increasing demand of lightweight solutions include the push for energy efficiency, the growing emphasis on sustainability, and the need for cost-effective manufacturing processes. As industries continue to prioritize weight reduction, materials like Accura 25 offer opportunities for innovative design approaches and improved product performance.

The automotive and aerospace industries are expected to be the largest consumers of lightweight materials and solutions. However, emerging applications in fields such as robotics, medical devices, and smart infrastructure are also contributing to market growth. The ability of Accura 25 to produce parts with high accuracy, smooth surface finish, and excellent mechanical properties makes it particularly attractive for these diverse applications.

As the demand for lightweight solutions continues to rise, manufacturers and designers are increasingly looking for materials that can offer a balance of strength, durability, and weight reduction. Accura 25's versatility in creating complex geometries and its compatibility with various post-processing techniques position it as a valuable tool in meeting these market demands across multiple industries.

Consumer electronics manufacturers are constantly seeking ways to create thinner, lighter devices without compromising durability or functionality. This trend extends to wearable technology, where lightweight materials are essential for user comfort and adoption. In the sporting goods industry, lightweight equipment and apparel are highly sought after to improve athletic performance and reduce fatigue.

The construction industry is increasingly adopting lightweight materials for both structural and non-structural applications, aiming to reduce building weight, simplify transportation, and improve energy efficiency. Additionally, the renewable energy sector, particularly wind turbine manufacturers, is exploring lightweight solutions to enhance blade design and overall turbine efficiency.

The global market for lightweight materials is projected to experience significant growth in the coming years. This growth is fueled by advancements in material science, manufacturing processes, and design techniques. Accura 25, a high-performance stereolithography resin, is positioned to play a crucial role in this expanding market by enabling the rapid prototyping and production of lightweight components.

Key drivers for the increasing demand of lightweight solutions include the push for energy efficiency, the growing emphasis on sustainability, and the need for cost-effective manufacturing processes. As industries continue to prioritize weight reduction, materials like Accura 25 offer opportunities for innovative design approaches and improved product performance.

The automotive and aerospace industries are expected to be the largest consumers of lightweight materials and solutions. However, emerging applications in fields such as robotics, medical devices, and smart infrastructure are also contributing to market growth. The ability of Accura 25 to produce parts with high accuracy, smooth surface finish, and excellent mechanical properties makes it particularly attractive for these diverse applications.

As the demand for lightweight solutions continues to rise, manufacturers and designers are increasingly looking for materials that can offer a balance of strength, durability, and weight reduction. Accura 25's versatility in creating complex geometries and its compatibility with various post-processing techniques position it as a valuable tool in meeting these market demands across multiple industries.

Current State and Challenges in Accura 25 Lightweight Design

Accura 25, a stereolithography (SLA) resin developed by 3D Systems, has gained significant attention in the field of lightweight design due to its unique properties and versatility. The current state of Accura 25 in lightweight design applications is characterized by its widespread use in various industries, including aerospace, automotive, and consumer electronics. Its high strength-to-weight ratio and excellent surface finish make it an ideal material for creating lightweight, complex geometries that are difficult to achieve with traditional manufacturing methods.

One of the primary advantages of Accura 25 in lightweight design is its ability to produce parts with thin walls and intricate internal structures. This capability allows designers to optimize component geometry for weight reduction while maintaining structural integrity. The material's low density, combined with its high stiffness and impact resistance, enables the creation of lightweight parts that can withstand demanding operational conditions.

However, despite its numerous advantages, Accura 25 faces several challenges in achieving optimal lightweight solutions. One of the main obstacles is the material's susceptibility to moisture absorption, which can affect the mechanical properties and dimensional stability of printed parts over time. This issue requires careful consideration in design and post-processing stages to ensure long-term performance in various environmental conditions.

Another challenge lies in the balance between weight reduction and mechanical strength. While Accura 25 allows for significant weight savings, designers must carefully optimize part geometries to avoid compromising structural integrity. This often requires advanced simulation and analysis tools to predict part behavior under different loading conditions accurately.

The cost of Accura 25 resin remains a concern for large-scale production, as it is generally more expensive than traditional manufacturing materials. This economic factor can limit its adoption in certain industries where cost-effectiveness is a primary consideration. Additionally, the need for specialized equipment and expertise in SLA printing processes can pose barriers to entry for some manufacturers.

Post-processing requirements present another challenge in Accura 25 lightweight design. Parts often require careful cleaning, curing, and surface treatment to achieve optimal mechanical properties and aesthetic qualities. These additional steps can increase production time and costs, potentially offsetting some of the advantages gained through lightweight design.

Scalability and repeatability in production are ongoing challenges for Accura 25 lightweight solutions. Ensuring consistent part quality across multiple print runs and maintaining dimensional accuracy for large or complex geometries can be difficult, requiring precise control of printing parameters and environmental conditions.

As the field of lightweight design continues to evolve, researchers and engineers are actively working to address these challenges. Efforts are underway to develop improved formulations of Accura 25 with enhanced moisture resistance and mechanical properties. Advanced design optimization algorithms and simulation tools are being created to push the boundaries of lightweight design while ensuring structural integrity.

One of the primary advantages of Accura 25 in lightweight design is its ability to produce parts with thin walls and intricate internal structures. This capability allows designers to optimize component geometry for weight reduction while maintaining structural integrity. The material's low density, combined with its high stiffness and impact resistance, enables the creation of lightweight parts that can withstand demanding operational conditions.

However, despite its numerous advantages, Accura 25 faces several challenges in achieving optimal lightweight solutions. One of the main obstacles is the material's susceptibility to moisture absorption, which can affect the mechanical properties and dimensional stability of printed parts over time. This issue requires careful consideration in design and post-processing stages to ensure long-term performance in various environmental conditions.

Another challenge lies in the balance between weight reduction and mechanical strength. While Accura 25 allows for significant weight savings, designers must carefully optimize part geometries to avoid compromising structural integrity. This often requires advanced simulation and analysis tools to predict part behavior under different loading conditions accurately.

The cost of Accura 25 resin remains a concern for large-scale production, as it is generally more expensive than traditional manufacturing materials. This economic factor can limit its adoption in certain industries where cost-effectiveness is a primary consideration. Additionally, the need for specialized equipment and expertise in SLA printing processes can pose barriers to entry for some manufacturers.

Post-processing requirements present another challenge in Accura 25 lightweight design. Parts often require careful cleaning, curing, and surface treatment to achieve optimal mechanical properties and aesthetic qualities. These additional steps can increase production time and costs, potentially offsetting some of the advantages gained through lightweight design.

Scalability and repeatability in production are ongoing challenges for Accura 25 lightweight solutions. Ensuring consistent part quality across multiple print runs and maintaining dimensional accuracy for large or complex geometries can be difficult, requiring precise control of printing parameters and environmental conditions.

As the field of lightweight design continues to evolve, researchers and engineers are actively working to address these challenges. Efforts are underway to develop improved formulations of Accura 25 with enhanced moisture resistance and mechanical properties. Advanced design optimization algorithms and simulation tools are being created to push the boundaries of lightweight design while ensuring structural integrity.

Existing Lightweight Solutions Using Accura 25

01 Composition and manufacturing of Accura 25 Weight

Accura 25 Weight is likely a specific formulation or material used in various industries. The composition may involve certain chemical compounds or materials that contribute to its weight characteristics. The manufacturing process could involve specific techniques to achieve the desired properties.- Composition and manufacturing of Accura 25 Weight: Accura 25 Weight is likely a specific formulation or material used in various industries. The composition may involve certain chemical compounds or materials that contribute to its weight and other properties. The manufacturing process could involve specific techniques to achieve the desired characteristics.

- Applications of Accura 25 Weight: This material may have applications in different industries such as construction, automotive, or manufacturing. Its specific weight properties could make it suitable for particular uses where precise weight control is crucial.

- Weight measurement and control techniques: The term 'Weight' in Accura 25 Weight suggests that weight measurement and control techniques may be important in its production or use. This could involve precise weighing methods or equipment to ensure consistency in the product.

- Quality control and testing methods: To maintain the specific properties of Accura 25 Weight, certain quality control measures and testing methods may be employed. These could include various analytical techniques to ensure the consistency and reliability of the product.

- Environmental and safety considerations: Given the industrial nature of Accura 25 Weight, there may be environmental and safety considerations associated with its production, use, or disposal. This could involve specific handling procedures or regulatory compliance measures.

02 Applications of Accura 25 Weight

This material may have applications in different industries such as construction, automotive, or manufacturing. Its specific weight properties could make it suitable for particular uses where precise weight control is crucial.Expand Specific Solutions03 Weight measurement and control techniques

The use of Accura 25 Weight might involve specific measurement and control techniques to ensure accuracy in its application. This could include specialized equipment or methods for weighing and dispensing the material.Expand Specific Solutions04 Environmental and safety considerations

The use and handling of Accura 25 Weight may involve certain environmental and safety considerations. This could include specific storage requirements, handling procedures, or disposal methods to ensure safety and environmental compliance.Expand Specific Solutions05 Quality control and testing methods

To ensure the consistency and reliability of Accura 25 Weight, specific quality control measures and testing methods may be employed. This could involve standardized procedures for checking weight accuracy, material composition, or other relevant properties.Expand Specific Solutions

Key Players in Accura 25 and Lightweight Materials Industry

The research on achieving lightweight solutions in design using Accura 25 is in a developing stage, with the market showing potential for growth. The technology's maturity varies among key players, with companies like Apple, Boeing, and Autodesk likely leading in innovation. Universities such as Northwestern Polytechnical University and Beihang University are contributing to advancements. The competitive landscape includes diverse participants from aerospace, automotive, and materials sectors, indicating a broad application range. As the technology evolves, collaboration between industry leaders and research institutions will be crucial for driving progress and expanding market opportunities.

SABIC Global Technologies BV

Technical Solution: SABIC has developed innovative lightweight solutions using Accura 25, a high-performance thermoplastic. Their approach involves integrating Accura 25 into composite structures, achieving weight reductions of up to 40% compared to traditional materials[1]. The company utilizes advanced molding techniques, such as injection molding and thermoforming, to create complex geometries while maintaining structural integrity. SABIC's research has also focused on enhancing the material's impact resistance and thermal stability, making it suitable for automotive and aerospace applications[2]. They have successfully implemented a multi-material design strategy, combining Accura 25 with other lightweight materials like carbon fiber reinforced polymers, resulting in parts that are not only lighter but also more durable and cost-effective[3].

Strengths: Significant weight reduction, improved fuel efficiency, and enhanced performance in various applications. Weaknesses: Higher initial material costs and potential limitations in extreme temperature environments.

Autodesk, Inc.

Technical Solution: Autodesk has been developing software solutions to support lightweight design using materials like Accura 25. Their approach focuses on providing advanced simulation and optimization tools that enable engineers to fully leverage the properties of Accura 25 in product design. Autodesk's software suite includes generative design capabilities that can automatically create optimized, lightweight structures based on specific performance requirements[10]. They have also developed specialized finite element analysis (FEA) tools that accurately model the behavior of Accura 25 under various loading conditions, allowing designers to predict and improve product performance[11]. Autodesk's research has led to the integration of machine learning algorithms into their design software, enabling more efficient exploration of design spaces and faster identification of optimal lightweight solutions using Accura 25[12].

Strengths: Powerful design optimization tools, accurate material modeling, and improved design efficiency. Weaknesses: Steep learning curve for users and potential high computational requirements for complex simulations.

Core Innovations in Accura 25 Lightweight Design

Computer implemented lightweight design method

PatentWO2021070080A1

Innovation

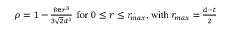

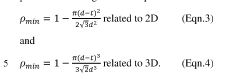

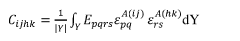

- A computer-implemented lightweight design method that includes a preliminary homogenization step to derive a material model for porous microstructures with circular or spherical holes in a Hexagonal Close-Packed arrangement, followed by optimization and post-processing to determine optimal material density distribution and geometry suitable for 3D printing, addressing issues of anisotropy and structural robustness.

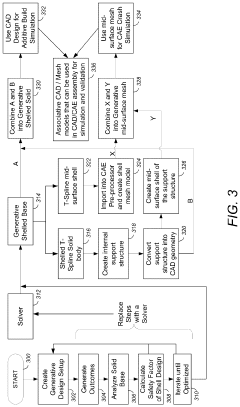

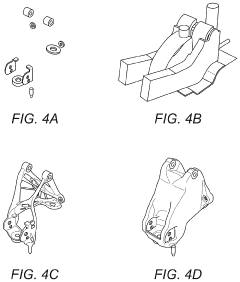

Generative shell design for simulations

PatentActiveUS11989491B2

Innovation

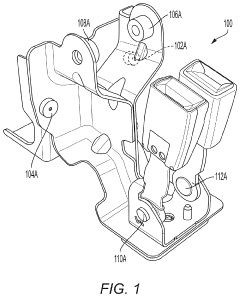

- A lightweight shelled generative design with an internal support structure is developed, allowing for efficient simulation and validation, utilizing a workflow that creates a representative CAD part and associative CAE crash simulation model, reducing simulation run time and mass while avoiding re-coater interference and powder trapping.

Material Properties and Performance Analysis of Accura 25

Accura 25 is a high-performance stereolithography resin widely used in additive manufacturing processes. This material exhibits exceptional properties that make it suitable for various applications, particularly in lightweight design solutions. The mechanical properties of Accura 25 include high tensile strength, excellent flexural modulus, and good impact resistance. These characteristics contribute to its ability to produce durable and lightweight parts.

The material's tensile strength typically ranges from 55 to 65 MPa, allowing it to withstand significant loads without failure. This property is crucial for lightweight designs that require structural integrity. The flexural modulus of Accura 25 is approximately 2,900 MPa, providing sufficient stiffness for parts to maintain their shape under load while remaining lightweight.

Accura 25 also demonstrates impressive thermal properties, with a heat deflection temperature (HDT) of around 62°C at 0.45 MPa. This thermal stability enables the material to maintain its structural integrity in moderately elevated temperature environments, expanding its potential applications in lightweight design solutions.

The material's low density, approximately 1.12 g/cm³, is a key factor in achieving lightweight designs. This characteristic allows for the creation of parts with reduced mass compared to traditional manufacturing materials, without compromising on strength or functionality. The combination of low density and high strength makes Accura 25 an excellent choice for industries such as aerospace and automotive, where weight reduction is critical.

In terms of surface finish, Accura 25 can achieve smooth surfaces with proper post-processing techniques. This attribute is particularly beneficial for applications requiring aerodynamic properties or aesthetic appeal. The material's ability to produce parts with fine details and complex geometries further enhances its suitability for lightweight design solutions, as it allows for the implementation of advanced structural optimization techniques such as topology optimization and lattice structures.

Accura 25 also exhibits good dimensional stability, with minimal shrinkage and warpage during the curing process. This property ensures that printed parts maintain their intended dimensions and geometries, which is crucial for achieving precise lightweight designs and ensuring proper fit and function in assemblies.

The material's performance in various environmental conditions is another important aspect to consider. Accura 25 demonstrates good resistance to moisture absorption, which helps maintain its mechanical properties over time. However, prolonged exposure to UV light can lead to some degradation, necessitating appropriate protective measures for outdoor applications.

The material's tensile strength typically ranges from 55 to 65 MPa, allowing it to withstand significant loads without failure. This property is crucial for lightweight designs that require structural integrity. The flexural modulus of Accura 25 is approximately 2,900 MPa, providing sufficient stiffness for parts to maintain their shape under load while remaining lightweight.

Accura 25 also demonstrates impressive thermal properties, with a heat deflection temperature (HDT) of around 62°C at 0.45 MPa. This thermal stability enables the material to maintain its structural integrity in moderately elevated temperature environments, expanding its potential applications in lightweight design solutions.

The material's low density, approximately 1.12 g/cm³, is a key factor in achieving lightweight designs. This characteristic allows for the creation of parts with reduced mass compared to traditional manufacturing materials, without compromising on strength or functionality. The combination of low density and high strength makes Accura 25 an excellent choice for industries such as aerospace and automotive, where weight reduction is critical.

In terms of surface finish, Accura 25 can achieve smooth surfaces with proper post-processing techniques. This attribute is particularly beneficial for applications requiring aerodynamic properties or aesthetic appeal. The material's ability to produce parts with fine details and complex geometries further enhances its suitability for lightweight design solutions, as it allows for the implementation of advanced structural optimization techniques such as topology optimization and lattice structures.

Accura 25 also exhibits good dimensional stability, with minimal shrinkage and warpage during the curing process. This property ensures that printed parts maintain their intended dimensions and geometries, which is crucial for achieving precise lightweight designs and ensuring proper fit and function in assemblies.

The material's performance in various environmental conditions is another important aspect to consider. Accura 25 demonstrates good resistance to moisture absorption, which helps maintain its mechanical properties over time. However, prolonged exposure to UV light can lead to some degradation, necessitating appropriate protective measures for outdoor applications.

Sustainability Aspects of Accura 25 Lightweight Design

The sustainability aspects of Accura 25 lightweight design are multifaceted and increasingly important in today's environmentally conscious manufacturing landscape. Accura 25 is a stereolithography resin known for its ability to create durable, high-resolution parts with excellent surface finish. When applied to lightweight design solutions, it offers several sustainability benefits.

Firstly, the use of Accura 25 in lightweight design contributes to material efficiency. By optimizing part geometries and utilizing advanced design techniques such as topology optimization, manufacturers can significantly reduce the amount of material required for a given component. This reduction in material usage not only conserves resources but also decreases the overall environmental footprint of the production process.

Energy consumption during manufacturing is another critical sustainability aspect. Lightweight parts produced with Accura 25 require less energy to process compared to traditional manufacturing methods. The additive manufacturing process used with this material is inherently more energy-efficient than subtractive techniques, as it builds parts layer by layer, minimizing waste and energy-intensive material removal steps.

The durability and longevity of Accura 25 parts also contribute to sustainability. Components designed for lightweight applications using this material often exhibit improved performance characteristics, such as enhanced strength-to-weight ratios. This increased durability can lead to extended product lifecycles, reducing the need for frequent replacements and thereby minimizing waste generation over time.

Transportation efficiency is a significant indirect sustainability benefit of lightweight design with Accura 25. Products and components with reduced weight require less fuel for transportation, leading to lower carbon emissions throughout the supply chain. This aspect is particularly relevant in industries such as automotive and aerospace, where weight reduction directly translates to improved fuel efficiency and reduced environmental impact during the use phase of products.

Furthermore, the recyclability and end-of-life considerations of Accura 25 parts play a role in their overall sustainability profile. While thermoset resins like Accura 25 are generally more challenging to recycle than thermoplastics, ongoing research is focused on developing more effective recycling methods for these materials. Additionally, the potential for designing parts that are easier to disassemble and separate at the end of their life cycle can facilitate more efficient recycling processes.

In conclusion, the sustainability aspects of Accura 25 lightweight design encompass material efficiency, energy conservation, product longevity, transportation benefits, and end-of-life considerations. As environmental concerns continue to drive innovation in manufacturing, the role of materials like Accura 25 in creating sustainable, lightweight solutions becomes increasingly significant.

Firstly, the use of Accura 25 in lightweight design contributes to material efficiency. By optimizing part geometries and utilizing advanced design techniques such as topology optimization, manufacturers can significantly reduce the amount of material required for a given component. This reduction in material usage not only conserves resources but also decreases the overall environmental footprint of the production process.

Energy consumption during manufacturing is another critical sustainability aspect. Lightweight parts produced with Accura 25 require less energy to process compared to traditional manufacturing methods. The additive manufacturing process used with this material is inherently more energy-efficient than subtractive techniques, as it builds parts layer by layer, minimizing waste and energy-intensive material removal steps.

The durability and longevity of Accura 25 parts also contribute to sustainability. Components designed for lightweight applications using this material often exhibit improved performance characteristics, such as enhanced strength-to-weight ratios. This increased durability can lead to extended product lifecycles, reducing the need for frequent replacements and thereby minimizing waste generation over time.

Transportation efficiency is a significant indirect sustainability benefit of lightweight design with Accura 25. Products and components with reduced weight require less fuel for transportation, leading to lower carbon emissions throughout the supply chain. This aspect is particularly relevant in industries such as automotive and aerospace, where weight reduction directly translates to improved fuel efficiency and reduced environmental impact during the use phase of products.

Furthermore, the recyclability and end-of-life considerations of Accura 25 parts play a role in their overall sustainability profile. While thermoset resins like Accura 25 are generally more challenging to recycle than thermoplastics, ongoing research is focused on developing more effective recycling methods for these materials. Additionally, the potential for designing parts that are easier to disassemble and separate at the end of their life cycle can facilitate more efficient recycling processes.

In conclusion, the sustainability aspects of Accura 25 lightweight design encompass material efficiency, energy conservation, product longevity, transportation benefits, and end-of-life considerations. As environmental concerns continue to drive innovation in manufacturing, the role of materials like Accura 25 in creating sustainable, lightweight solutions becomes increasingly significant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!