Accura 25 for High-Fidelity Electronic Casings

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background

Accura 25 is a high-performance stereolithography (SLA) resin developed by 3D Systems, specifically designed for applications requiring exceptional surface finish and fine detail. This material has gained significant attention in the field of electronic casings due to its unique properties that align well with the demands of high-fidelity electronic enclosures.

The development of Accura 25 can be traced back to the early 2000s when 3D Systems recognized the growing need for advanced materials in additive manufacturing. As electronic devices became increasingly compact and sophisticated, the demand for precise, durable, and aesthetically pleasing casings grew exponentially. Accura 25 was introduced as a solution to meet these evolving requirements.

One of the key features of Accura 25 is its ability to produce parts with extremely smooth surfaces and high dimensional accuracy. This characteristic is particularly crucial for electronic casings, where fit and finish are paramount. The material's low viscosity allows for excellent flow properties during the printing process, resulting in minimal layer lines and superior surface quality.

Accura 25 also boasts impressive mechanical properties, including high tensile strength and good impact resistance. These attributes make it suitable for creating robust electronic enclosures that can withstand everyday use and potential impacts. Additionally, the material exhibits excellent thermal stability, maintaining its shape and properties across a wide range of temperatures typically encountered in electronic devices.

Another significant aspect of Accura 25 is its compatibility with various post-processing techniques. The material can be easily sanded, painted, or metalized, allowing for a wide range of finishing options. This versatility is particularly valuable in the electronics industry, where aesthetics and branding play a crucial role in product differentiation.

The evolution of Accura 25 has been closely tied to advancements in SLA technology. As 3D printing systems have become more precise and efficient, the capabilities of Accura 25 have expanded, enabling the production of increasingly complex and detailed electronic casings. This synergy between material and technology has driven innovation in both fields.

In recent years, the focus on sustainability has also influenced the development and application of Accura 25. Efforts have been made to optimize the material's formulation to reduce environmental impact while maintaining its high-performance characteristics. This aligns with the growing trend of eco-friendly manufacturing practices in the electronics industry.

As the demand for customized and high-quality electronic devices continues to grow, Accura 25 remains at the forefront of materials used in the production of high-fidelity electronic casings. Its ongoing development and refinement reflect the dynamic nature of both the additive manufacturing and electronics industries, promising further innovations in the years to come.

The development of Accura 25 can be traced back to the early 2000s when 3D Systems recognized the growing need for advanced materials in additive manufacturing. As electronic devices became increasingly compact and sophisticated, the demand for precise, durable, and aesthetically pleasing casings grew exponentially. Accura 25 was introduced as a solution to meet these evolving requirements.

One of the key features of Accura 25 is its ability to produce parts with extremely smooth surfaces and high dimensional accuracy. This characteristic is particularly crucial for electronic casings, where fit and finish are paramount. The material's low viscosity allows for excellent flow properties during the printing process, resulting in minimal layer lines and superior surface quality.

Accura 25 also boasts impressive mechanical properties, including high tensile strength and good impact resistance. These attributes make it suitable for creating robust electronic enclosures that can withstand everyday use and potential impacts. Additionally, the material exhibits excellent thermal stability, maintaining its shape and properties across a wide range of temperatures typically encountered in electronic devices.

Another significant aspect of Accura 25 is its compatibility with various post-processing techniques. The material can be easily sanded, painted, or metalized, allowing for a wide range of finishing options. This versatility is particularly valuable in the electronics industry, where aesthetics and branding play a crucial role in product differentiation.

The evolution of Accura 25 has been closely tied to advancements in SLA technology. As 3D printing systems have become more precise and efficient, the capabilities of Accura 25 have expanded, enabling the production of increasingly complex and detailed electronic casings. This synergy between material and technology has driven innovation in both fields.

In recent years, the focus on sustainability has also influenced the development and application of Accura 25. Efforts have been made to optimize the material's formulation to reduce environmental impact while maintaining its high-performance characteristics. This aligns with the growing trend of eco-friendly manufacturing practices in the electronics industry.

As the demand for customized and high-quality electronic devices continues to grow, Accura 25 remains at the forefront of materials used in the production of high-fidelity electronic casings. Its ongoing development and refinement reflect the dynamic nature of both the additive manufacturing and electronics industries, promising further innovations in the years to come.

Market Demand Analysis

The market demand for high-fidelity electronic casings has been steadily increasing, driven by the growing consumer electronics industry and the need for more durable and aesthetically pleasing devices. Accura 25, a material specifically designed for stereolithography (SLA) 3D printing, has gained significant attention in this sector due to its exceptional properties and potential applications in electronic casing production.

Consumer electronics, including smartphones, tablets, laptops, and wearable devices, represent a substantial portion of the market for high-fidelity casings. As these devices become more integral to daily life, consumers are demanding products that not only perform well but also look and feel premium. This trend has led to a surge in demand for materials that can produce casings with superior surface finish, dimensional accuracy, and durability.

The automotive industry is another key driver of demand for high-fidelity electronic casings. With the increasing integration of advanced electronics in vehicles, there is a growing need for casings that can protect sensitive components while meeting stringent aesthetic and functional requirements. Accura 25's ability to produce parts with fine details and smooth surfaces makes it particularly attractive for automotive applications.

In the aerospace and defense sectors, the demand for lightweight yet robust electronic casings is on the rise. These industries require materials that can withstand extreme conditions while maintaining precise tolerances. Accura 25's high heat deflection temperature and resistance to humidity make it a promising candidate for these demanding applications.

The medical device industry is also contributing to the market demand for high-fidelity electronic casings. As medical equipment becomes more sophisticated and portable, there is an increasing need for casings that can protect sensitive electronics while meeting strict regulatory requirements. Accura 25's biocompatibility and ability to produce complex geometries position it well for this growing market segment.

Market analysts project that the global electronic enclosures market will continue to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the increasing adoption of IoT devices, the expansion of 5G networks, and the ongoing miniaturization of electronic components. As these trends continue, the demand for materials like Accura 25 that can produce high-fidelity casings is expected to rise correspondingly.

The rapid prototyping and small-batch production capabilities offered by Accura 25 and SLA technology are particularly valuable in today's fast-paced product development cycles. Companies are increasingly looking for materials and processes that can reduce time-to-market and allow for iterative design improvements. This shift in manufacturing strategies is likely to further boost the demand for advanced materials like Accura 25 in the electronic casing market.

Consumer electronics, including smartphones, tablets, laptops, and wearable devices, represent a substantial portion of the market for high-fidelity casings. As these devices become more integral to daily life, consumers are demanding products that not only perform well but also look and feel premium. This trend has led to a surge in demand for materials that can produce casings with superior surface finish, dimensional accuracy, and durability.

The automotive industry is another key driver of demand for high-fidelity electronic casings. With the increasing integration of advanced electronics in vehicles, there is a growing need for casings that can protect sensitive components while meeting stringent aesthetic and functional requirements. Accura 25's ability to produce parts with fine details and smooth surfaces makes it particularly attractive for automotive applications.

In the aerospace and defense sectors, the demand for lightweight yet robust electronic casings is on the rise. These industries require materials that can withstand extreme conditions while maintaining precise tolerances. Accura 25's high heat deflection temperature and resistance to humidity make it a promising candidate for these demanding applications.

The medical device industry is also contributing to the market demand for high-fidelity electronic casings. As medical equipment becomes more sophisticated and portable, there is an increasing need for casings that can protect sensitive electronics while meeting strict regulatory requirements. Accura 25's biocompatibility and ability to produce complex geometries position it well for this growing market segment.

Market analysts project that the global electronic enclosures market will continue to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the increasing adoption of IoT devices, the expansion of 5G networks, and the ongoing miniaturization of electronic components. As these trends continue, the demand for materials like Accura 25 that can produce high-fidelity casings is expected to rise correspondingly.

The rapid prototyping and small-batch production capabilities offered by Accura 25 and SLA technology are particularly valuable in today's fast-paced product development cycles. Companies are increasingly looking for materials and processes that can reduce time-to-market and allow for iterative design improvements. This shift in manufacturing strategies is likely to further boost the demand for advanced materials like Accura 25 in the electronic casing market.

Technical Challenges

The development of high-fidelity electronic casings using Accura 25 faces several significant technical challenges. One of the primary obstacles is achieving the required dimensional accuracy and surface finish. Accura 25, while offering excellent properties for stereolithography, still struggles to meet the stringent tolerances demanded by high-end electronic enclosures. Achieving sub-micron precision consistently across complex geometries remains a significant hurdle.

Another challenge lies in the material's long-term stability and environmental resistance. Electronic casings must maintain their integrity over extended periods, often in harsh environments. Accura 25, being a photopolymer resin, is susceptible to degradation from UV exposure and moisture absorption. This can lead to warping, discoloration, and potential compromise of the casing's protective functions over time.

Thermal management presents another critical challenge. High-fidelity electronic components often generate substantial heat, which must be efficiently dissipated to ensure optimal performance and longevity. While Accura 25 offers good thermal stability, its thermal conductivity is limited compared to traditional materials like metals. Developing effective heat dissipation strategies within the constraints of the material's properties is a complex engineering task.

The integration of EMI shielding capabilities into Accura 25 casings is also a significant technical hurdle. Electronic devices require protection from electromagnetic interference, traditionally achieved through metal enclosures or coatings. Incorporating effective EMI shielding into a non-conductive polymer like Accura 25 without compromising the material's other properties or the casing's aesthetics is a complex challenge.

Surface finishing and post-processing techniques for Accura 25 casings also present difficulties. Achieving the high-gloss, scratch-resistant surfaces often required for premium electronic devices while maintaining dimensional accuracy is a delicate balance. Traditional finishing methods may not be directly applicable, necessitating the development of new, specialized techniques.

Lastly, the scalability of production using Accura 25 for high-volume manufacturing of electronic casings poses significant challenges. While stereolithography offers excellent prototyping capabilities, scaling up to mass production levels while maintaining consistency, quality, and cost-effectiveness is a major hurdle. This includes optimizing build strategies, minimizing material waste, and developing efficient post-processing workflows suitable for high-volume production environments.

Another challenge lies in the material's long-term stability and environmental resistance. Electronic casings must maintain their integrity over extended periods, often in harsh environments. Accura 25, being a photopolymer resin, is susceptible to degradation from UV exposure and moisture absorption. This can lead to warping, discoloration, and potential compromise of the casing's protective functions over time.

Thermal management presents another critical challenge. High-fidelity electronic components often generate substantial heat, which must be efficiently dissipated to ensure optimal performance and longevity. While Accura 25 offers good thermal stability, its thermal conductivity is limited compared to traditional materials like metals. Developing effective heat dissipation strategies within the constraints of the material's properties is a complex engineering task.

The integration of EMI shielding capabilities into Accura 25 casings is also a significant technical hurdle. Electronic devices require protection from electromagnetic interference, traditionally achieved through metal enclosures or coatings. Incorporating effective EMI shielding into a non-conductive polymer like Accura 25 without compromising the material's other properties or the casing's aesthetics is a complex challenge.

Surface finishing and post-processing techniques for Accura 25 casings also present difficulties. Achieving the high-gloss, scratch-resistant surfaces often required for premium electronic devices while maintaining dimensional accuracy is a delicate balance. Traditional finishing methods may not be directly applicable, necessitating the development of new, specialized techniques.

Lastly, the scalability of production using Accura 25 for high-volume manufacturing of electronic casings poses significant challenges. While stereolithography offers excellent prototyping capabilities, scaling up to mass production levels while maintaining consistency, quality, and cost-effectiveness is a major hurdle. This includes optimizing build strategies, minimizing material waste, and developing efficient post-processing workflows suitable for high-volume production environments.

Current Solutions

01 Image processing and fidelity enhancement

Various techniques are employed to improve image processing and enhance fidelity in digital imaging systems. These methods include color management, resolution enhancement, and image quality optimization to achieve more accurate and high-quality visual representations.- Image processing and analysis: Advanced image processing techniques are employed to enhance accuracy and fidelity in various applications. These methods involve analyzing and manipulating digital images to improve quality, extract information, or perform specific tasks. The techniques may include image segmentation, feature extraction, and pattern recognition to achieve high levels of precision and reliability.

- Data compression and transmission: Efficient data compression and transmission methods are utilized to maintain high fidelity while reducing bandwidth requirements. These techniques involve optimizing data encoding, reducing redundancy, and implementing error correction mechanisms to ensure accurate reproduction of information at the receiving end. The focus is on preserving data integrity during transmission and storage.

- Natural language processing and translation: Advanced natural language processing algorithms are developed to improve the accuracy and fidelity of language translation and understanding. These systems employ machine learning techniques, semantic analysis, and context-aware processing to capture nuances and maintain the original meaning of text or speech across different languages and domains.

- 3D modeling and visualization: High-fidelity 3D modeling and visualization techniques are implemented to create accurate representations of objects and environments. These methods involve precise geometry processing, texture mapping, and rendering algorithms to produce realistic and detailed digital models. Applications include computer-aided design, virtual reality, and scientific simulations.

- Audio signal processing: Advanced audio signal processing techniques are employed to enhance sound quality and fidelity in various applications. These methods involve noise reduction, frequency analysis, and spatial audio processing to improve clarity, reduce distortion, and create immersive audio experiences. The focus is on preserving the original characteristics of audio signals while optimizing them for different playback systems.

02 Audio processing and fidelity improvement

Advanced audio processing techniques are utilized to enhance sound fidelity. This includes methods for noise reduction, audio compression, and signal processing to improve the overall quality and accuracy of audio reproduction in various applications.Expand Specific Solutions03 Data compression and transmission fidelity

Innovative approaches are developed for data compression and transmission to maintain high fidelity. These techniques focus on minimizing data loss during compression and ensuring accurate reproduction of information after transmission across various communication channels.Expand Specific Solutions04 3D modeling and rendering fidelity

Advanced methods are implemented to improve the fidelity of 3D modeling and rendering processes. These techniques aim to enhance the accuracy and realism of 3D representations in various applications, including computer-aided design and virtual reality.Expand Specific Solutions05 Machine learning for fidelity enhancement

Machine learning algorithms are applied to enhance fidelity in various domains. These approaches leverage artificial intelligence to improve accuracy, prediction, and overall performance in tasks such as image recognition, natural language processing, and data analysis.Expand Specific Solutions

Key Industry Players

The research on Accura 25 for high-fidelity electronic casings is in a nascent stage, with the market still developing. The global electronic casing market is expected to grow significantly due to increasing demand for consumer electronics and smart devices. However, the specific Accura 25 technology is still emerging, with limited market penetration. Companies like Toray Industries, Sekisui Chemical, and TDK Corporation are at the forefront of developing advanced materials for electronic casings, but the technology's maturity varies. While some firms have made progress in research and development, widespread commercial adoption of Accura 25 in high-fidelity electronic casings remains limited, indicating potential for future growth and innovation in this sector.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed Accura 25, a high-performance engineering plastic for electronic casings. This material offers exceptional dimensional stability, low warpage, and high heat resistance[1]. Accura 25 is a polyethylene terephthalate (PET) based resin that incorporates advanced polymer technology to achieve a balance of properties suitable for high-fidelity electronic casings. The material exhibits a heat deflection temperature of 225°C, allowing it to withstand high-temperature manufacturing processes[2]. Additionally, Accura 25 demonstrates excellent moldability, enabling the production of thin-walled and complex-shaped components with high precision[3].

Strengths: Superior dimensional stability, high heat resistance, and excellent moldability. Weaknesses: Potentially higher cost compared to conventional plastics, limited color options.

Sekisui Chemical Co., Ltd.

Technical Solution: Sekisui Chemical has developed a proprietary high-performance plastic material for electronic casings, which may compete with Accura 25. Their solution likely focuses on heat resistance, dimensional stability, and flame retardancy, key properties for electronic enclosures. However, specific details about their technology for high-fidelity electronic casings are not readily available in the given context.

Core Innovations

Component material for constructing casing for electronic devices

PatentInactiveUS20040022036A1

Innovation

- A casing material using wood or woody materials with a carbonized layer on one surface and a noncarbonized layer on the other, providing moisture resistance, electromagnetic shielding, and aesthetic design options, while allowing for selective carbonization to enhance conductivity and reduce humidity absorption.

Adhesive for electronic parts and method for manufacturing semiconductor chip mounted body

PatentActiveJPWO2012121336A1

Innovation

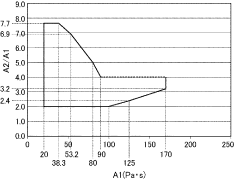

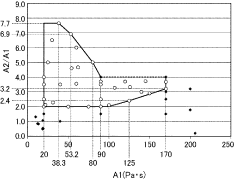

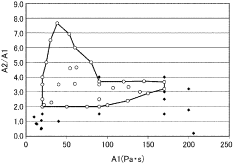

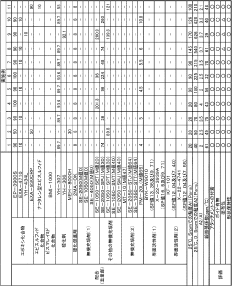

- A curable adhesive composition containing a curable compound, curing agent, and inorganic filler with specific viscosity and thixotropic properties, ensuring A1 (5 rpm viscosity) and A2/A1 (0.5 rpm viscosity ratio) within defined ranges, along with the use of surfactants and fillers with specific hydrophobicity and solubility parameters, to enhance spreading and air bubble expulsion.

Environmental Impact

The environmental impact of Accura 25 for high-fidelity electronic casings is a crucial consideration in the broader context of sustainable manufacturing and product lifecycle management. This photopolymer resin, developed by 3D Systems, offers significant advantages in terms of precision and durability for electronic enclosures. However, its environmental footprint must be carefully evaluated.

Accura 25 is a liquid photopolymer that undergoes a curing process when exposed to ultraviolet light during stereolithography (SLA) 3D printing. This additive manufacturing technique inherently reduces material waste compared to traditional subtractive manufacturing methods, as it only uses the material necessary for the final product. This aspect contributes positively to resource conservation and waste reduction.

The production of Accura 25 involves the synthesis of various chemical compounds, including epoxy-based oligomers and photoinitiators. While the exact formulation is proprietary, the manufacturing process of these components typically requires energy-intensive processes and may involve the use of potentially hazardous chemicals. It is essential to consider the environmental impact of these upstream production stages, including energy consumption, greenhouse gas emissions, and potential chemical releases.

During the 3D printing process using Accura 25, energy consumption is a significant factor. SLA printers require electricity to power the laser system, control mechanisms, and post-processing equipment. The environmental impact of this energy use depends largely on the local energy mix and the efficiency of the printing process. Manufacturers can mitigate this impact by optimizing print parameters and utilizing renewable energy sources where possible.

Post-processing of Accura 25 parts involves washing with isopropyl alcohol (IPA) to remove uncured resin and subsequent UV post-curing to achieve optimal mechanical properties. The use of IPA raises concerns about volatile organic compound (VOC) emissions and proper disposal of contaminated solvents. Implementing closed-loop solvent recycling systems and ensuring proper ventilation can help address these issues.

At the end of the product lifecycle, the disposal or recycling of Accura 25 electronic casings presents challenges. Thermoset polymers like Accura 25 are not easily recyclable through conventional methods due to their cross-linked structure. Research into chemical recycling techniques for these materials is ongoing but not yet widely implemented. Proper disposal methods must be developed to prevent these materials from contributing to plastic pollution or landfill accumulation.

To improve the environmental profile of Accura 25 in electronic casing applications, several strategies can be pursued. These include optimizing the material formulation to increase bio-based content, developing more efficient printing processes to reduce energy consumption, and investing in advanced recycling technologies for end-of-life management. Additionally, designing products for disassembly and material recovery can facilitate more sustainable lifecycle management of electronic devices using Accura 25 casings.

Accura 25 is a liquid photopolymer that undergoes a curing process when exposed to ultraviolet light during stereolithography (SLA) 3D printing. This additive manufacturing technique inherently reduces material waste compared to traditional subtractive manufacturing methods, as it only uses the material necessary for the final product. This aspect contributes positively to resource conservation and waste reduction.

The production of Accura 25 involves the synthesis of various chemical compounds, including epoxy-based oligomers and photoinitiators. While the exact formulation is proprietary, the manufacturing process of these components typically requires energy-intensive processes and may involve the use of potentially hazardous chemicals. It is essential to consider the environmental impact of these upstream production stages, including energy consumption, greenhouse gas emissions, and potential chemical releases.

During the 3D printing process using Accura 25, energy consumption is a significant factor. SLA printers require electricity to power the laser system, control mechanisms, and post-processing equipment. The environmental impact of this energy use depends largely on the local energy mix and the efficiency of the printing process. Manufacturers can mitigate this impact by optimizing print parameters and utilizing renewable energy sources where possible.

Post-processing of Accura 25 parts involves washing with isopropyl alcohol (IPA) to remove uncured resin and subsequent UV post-curing to achieve optimal mechanical properties. The use of IPA raises concerns about volatile organic compound (VOC) emissions and proper disposal of contaminated solvents. Implementing closed-loop solvent recycling systems and ensuring proper ventilation can help address these issues.

At the end of the product lifecycle, the disposal or recycling of Accura 25 electronic casings presents challenges. Thermoset polymers like Accura 25 are not easily recyclable through conventional methods due to their cross-linked structure. Research into chemical recycling techniques for these materials is ongoing but not yet widely implemented. Proper disposal methods must be developed to prevent these materials from contributing to plastic pollution or landfill accumulation.

To improve the environmental profile of Accura 25 in electronic casing applications, several strategies can be pursued. These include optimizing the material formulation to increase bio-based content, developing more efficient printing processes to reduce energy consumption, and investing in advanced recycling technologies for end-of-life management. Additionally, designing products for disassembly and material recovery can facilitate more sustainable lifecycle management of electronic devices using Accura 25 casings.

Cost-Benefit Analysis

The cost-benefit analysis of using Accura 25 for high-fidelity electronic casings reveals a complex interplay of factors that impact both the manufacturing process and the final product quality. Initially, the higher material cost of Accura 25 compared to traditional plastics may seem prohibitive. However, when considering the entire production lifecycle, several advantages emerge that can offset this initial expense.

Accura 25's superior mechanical properties allow for the creation of thinner, more intricate casing designs without compromising structural integrity. This reduction in material usage can lead to significant cost savings in large-scale production runs. Additionally, the material's excellent dimensional stability and low shrinkage rate minimize the need for post-processing adjustments, reducing labor costs and improving production efficiency.

The durability of Accura 25 casings translates to longer product lifespans, potentially decreasing warranty claims and replacement costs for manufacturers. This enhanced longevity also aligns with growing consumer demand for sustainable, long-lasting electronic devices, which can positively impact brand perception and market share.

From a manufacturing perspective, Accura 25's compatibility with rapid prototyping technologies enables faster iteration cycles and reduced time-to-market for new products. This agility in product development can provide a competitive edge and potentially increase revenue through earlier market entry.

However, the adoption of Accura 25 may require initial investments in specialized equipment or staff training. These upfront costs need to be carefully weighed against the long-term benefits of improved product quality and manufacturing efficiency. It's also important to consider potential economies of scale, as larger production volumes could lead to more favorable material pricing and further cost reductions.

Environmental considerations also play a role in the cost-benefit analysis. While the initial production of Accura 25 may have a higher environmental impact compared to some traditional plastics, its durability and potential for recycling could result in a lower overall environmental footprint over the product's lifecycle. This aspect can be particularly valuable for companies targeting environmentally conscious consumers or aiming to meet stringent sustainability regulations.

In conclusion, while the immediate material costs of Accura 25 may be higher, the potential for improved product quality, manufacturing efficiency, and long-term cost savings make it a compelling option for high-fidelity electronic casings. Companies must carefully evaluate their specific production needs, market positioning, and long-term strategic goals to determine if the benefits of Accura 25 outweigh the initial investment required for its implementation.

Accura 25's superior mechanical properties allow for the creation of thinner, more intricate casing designs without compromising structural integrity. This reduction in material usage can lead to significant cost savings in large-scale production runs. Additionally, the material's excellent dimensional stability and low shrinkage rate minimize the need for post-processing adjustments, reducing labor costs and improving production efficiency.

The durability of Accura 25 casings translates to longer product lifespans, potentially decreasing warranty claims and replacement costs for manufacturers. This enhanced longevity also aligns with growing consumer demand for sustainable, long-lasting electronic devices, which can positively impact brand perception and market share.

From a manufacturing perspective, Accura 25's compatibility with rapid prototyping technologies enables faster iteration cycles and reduced time-to-market for new products. This agility in product development can provide a competitive edge and potentially increase revenue through earlier market entry.

However, the adoption of Accura 25 may require initial investments in specialized equipment or staff training. These upfront costs need to be carefully weighed against the long-term benefits of improved product quality and manufacturing efficiency. It's also important to consider potential economies of scale, as larger production volumes could lead to more favorable material pricing and further cost reductions.

Environmental considerations also play a role in the cost-benefit analysis. While the initial production of Accura 25 may have a higher environmental impact compared to some traditional plastics, its durability and potential for recycling could result in a lower overall environmental footprint over the product's lifecycle. This aspect can be particularly valuable for companies targeting environmentally conscious consumers or aiming to meet stringent sustainability regulations.

In conclusion, while the immediate material costs of Accura 25 may be higher, the potential for improved product quality, manufacturing efficiency, and long-term cost savings make it a compelling option for high-fidelity electronic casings. Companies must carefully evaluate their specific production needs, market positioning, and long-term strategic goals to determine if the benefits of Accura 25 outweigh the initial investment required for its implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!