Accura 25: Innovative Applications in Footwear Design

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background

Accura 25 is a groundbreaking material developed by 3D Systems, a pioneer in the field of additive manufacturing. This innovative resin has revolutionized the production of functional prototypes and end-use parts, particularly in the footwear industry. Introduced as part of 3D Systems' stereolithography (SLA) portfolio, Accura 25 offers a unique combination of properties that make it ideal for creating intricate and durable shoe components.

The development of Accura 25 stems from the growing demand for advanced materials in the rapidly evolving 3D printing industry. As additive manufacturing technologies have matured, there has been an increasing need for materials that can meet the stringent requirements of various applications, especially in consumer goods sectors like footwear. Accura 25 was specifically engineered to address these needs, offering a balance of strength, flexibility, and detail resolution.

One of the key features of Accura 25 is its ability to mimic the properties of thermoplastic elastomers (TPE) commonly used in traditional shoe manufacturing. This characteristic allows designers and manufacturers to create prototypes and final products that closely resemble the look, feel, and performance of conventionally produced footwear components. The material's flexibility and durability make it particularly suitable for producing midsoles, outsoles, and other structural elements of shoes.

In terms of technical specifications, Accura 25 boasts impressive mechanical properties. It exhibits excellent elongation at break, typically ranging from 250% to 350%, which is crucial for parts that need to withstand repeated flexing and bending. The material also demonstrates good tear strength and abrasion resistance, essential qualities for footwear applications where components are subjected to constant wear and stress.

The introduction of Accura 25 has significantly impacted the footwear design and prototyping process. It enables rapid iteration of designs, allowing manufacturers to quickly produce and test multiple versions of shoe components. This accelerated development cycle has led to more innovative and ergonomic footwear designs, as well as reduced time-to-market for new products.

Furthermore, Accura 25 has opened up new possibilities in customization and personalization of footwear. Its compatibility with 3D printing technologies allows for the creation of complex geometries and lattice structures that can be tailored to individual foot shapes and gait patterns. This level of customization was previously difficult or impossible to achieve with traditional manufacturing methods.

As the footwear industry continues to embrace digital design and manufacturing technologies, materials like Accura 25 are expected to play an increasingly important role. The ongoing research and development in this area are likely to yield further improvements in material properties and processing capabilities, potentially leading to even more innovative applications in footwear design and production.

The development of Accura 25 stems from the growing demand for advanced materials in the rapidly evolving 3D printing industry. As additive manufacturing technologies have matured, there has been an increasing need for materials that can meet the stringent requirements of various applications, especially in consumer goods sectors like footwear. Accura 25 was specifically engineered to address these needs, offering a balance of strength, flexibility, and detail resolution.

One of the key features of Accura 25 is its ability to mimic the properties of thermoplastic elastomers (TPE) commonly used in traditional shoe manufacturing. This characteristic allows designers and manufacturers to create prototypes and final products that closely resemble the look, feel, and performance of conventionally produced footwear components. The material's flexibility and durability make it particularly suitable for producing midsoles, outsoles, and other structural elements of shoes.

In terms of technical specifications, Accura 25 boasts impressive mechanical properties. It exhibits excellent elongation at break, typically ranging from 250% to 350%, which is crucial for parts that need to withstand repeated flexing and bending. The material also demonstrates good tear strength and abrasion resistance, essential qualities for footwear applications where components are subjected to constant wear and stress.

The introduction of Accura 25 has significantly impacted the footwear design and prototyping process. It enables rapid iteration of designs, allowing manufacturers to quickly produce and test multiple versions of shoe components. This accelerated development cycle has led to more innovative and ergonomic footwear designs, as well as reduced time-to-market for new products.

Furthermore, Accura 25 has opened up new possibilities in customization and personalization of footwear. Its compatibility with 3D printing technologies allows for the creation of complex geometries and lattice structures that can be tailored to individual foot shapes and gait patterns. This level of customization was previously difficult or impossible to achieve with traditional manufacturing methods.

As the footwear industry continues to embrace digital design and manufacturing technologies, materials like Accura 25 are expected to play an increasingly important role. The ongoing research and development in this area are likely to yield further improvements in material properties and processing capabilities, potentially leading to even more innovative applications in footwear design and production.

Footwear Market Analysis

The global footwear market has experienced significant growth in recent years, driven by factors such as changing fashion trends, increasing disposable income, and growing health consciousness among consumers. The market size was valued at approximately $365 billion in 2020 and is projected to reach $530 billion by 2027, with a compound annual growth rate (CAGR) of around 5.5% during the forecast period.

The footwear industry is highly fragmented, with numerous players competing for market share. Key segments include athletic footwear, casual footwear, formal footwear, and others. Athletic footwear dominates the market, accounting for nearly 40% of the total revenue, followed by casual footwear at 30%. The growing popularity of athleisure wear and increasing participation in sports and fitness activities are major contributors to this trend.

Geographically, Asia-Pacific leads the global footwear market, with China and India being the largest producers and consumers. North America and Europe follow, with the United States being a significant market for premium and innovative footwear designs. Emerging markets in Latin America and Africa are also showing promising growth potential.

Consumer preferences are shifting towards more comfortable, sustainable, and technologically advanced footwear. This trend has led to increased demand for eco-friendly materials, customized designs, and smart shoes integrated with digital technologies. The rise of e-commerce has also transformed the retail landscape, with online sales of footwear growing at a faster rate than traditional brick-and-mortar stores.

In the context of Accura 25 and its potential applications in footwear design, there is a growing market demand for innovative materials and manufacturing processes that can enhance product performance, comfort, and sustainability. The 3D printing capabilities of Accura 25 align well with the industry's move towards customization and rapid prototyping.

The footwear market is also witnessing a surge in demand for performance-enhancing features, particularly in the athletic and outdoor segments. This presents opportunities for Accura 25 to be utilized in creating lightweight, durable, and functionally optimized shoe components. Additionally, the material's potential for creating intricate designs and textures could cater to the fashion-conscious consumer base seeking unique and personalized footwear options.

As sustainability becomes increasingly important to consumers, there is a growing market for eco-friendly footwear solutions. If Accura 25 can demonstrate superior recyclability or reduced environmental impact compared to traditional materials, it could gain significant traction in this segment of the market.

The footwear industry is highly fragmented, with numerous players competing for market share. Key segments include athletic footwear, casual footwear, formal footwear, and others. Athletic footwear dominates the market, accounting for nearly 40% of the total revenue, followed by casual footwear at 30%. The growing popularity of athleisure wear and increasing participation in sports and fitness activities are major contributors to this trend.

Geographically, Asia-Pacific leads the global footwear market, with China and India being the largest producers and consumers. North America and Europe follow, with the United States being a significant market for premium and innovative footwear designs. Emerging markets in Latin America and Africa are also showing promising growth potential.

Consumer preferences are shifting towards more comfortable, sustainable, and technologically advanced footwear. This trend has led to increased demand for eco-friendly materials, customized designs, and smart shoes integrated with digital technologies. The rise of e-commerce has also transformed the retail landscape, with online sales of footwear growing at a faster rate than traditional brick-and-mortar stores.

In the context of Accura 25 and its potential applications in footwear design, there is a growing market demand for innovative materials and manufacturing processes that can enhance product performance, comfort, and sustainability. The 3D printing capabilities of Accura 25 align well with the industry's move towards customization and rapid prototyping.

The footwear market is also witnessing a surge in demand for performance-enhancing features, particularly in the athletic and outdoor segments. This presents opportunities for Accura 25 to be utilized in creating lightweight, durable, and functionally optimized shoe components. Additionally, the material's potential for creating intricate designs and textures could cater to the fashion-conscious consumer base seeking unique and personalized footwear options.

As sustainability becomes increasingly important to consumers, there is a growing market for eco-friendly footwear solutions. If Accura 25 can demonstrate superior recyclability or reduced environmental impact compared to traditional materials, it could gain significant traction in this segment of the market.

Accura 25 Properties

Accura 25 is a high-performance stereolithography (SLA) resin developed by 3D Systems, specifically designed for the production of rigid, functional parts. This material exhibits exceptional properties that make it particularly suitable for innovative applications in footwear design.

One of the most notable characteristics of Accura 25 is its outstanding dimensional stability. This property ensures that parts produced using this resin maintain their shape and size over time, even under varying environmental conditions. In the context of footwear design, this stability is crucial for creating precise and long-lasting components, such as shoe lasts, midsoles, and custom orthotics.

The material also boasts excellent surface finish capabilities, allowing for the production of smooth, high-quality parts with minimal post-processing requirements. This attribute is particularly valuable in footwear design, where aesthetics and comfort are paramount. Designers can create intricate patterns and textures directly in the 3D model, knowing that the final printed part will accurately reflect their vision.

Accura 25 demonstrates remarkable strength and durability, making it ideal for functional prototypes and end-use parts in footwear applications. Its high tensile strength and impact resistance enable the creation of robust shoe components that can withstand the rigors of daily wear. This durability extends the lifespan of footwear products and enhances overall performance.

The resin's low viscosity contributes to its excellent flow properties during the printing process. This characteristic allows for the production of complex geometries and fine details, which are often required in advanced footwear designs. Designers can explore innovative structures, such as lattices and honeycomb patterns, to optimize weight distribution and cushioning in shoe soles.

Another significant property of Accura 25 is its resistance to moisture absorption. This feature is particularly beneficial in footwear applications, as it helps maintain the structural integrity and performance of shoe components even in humid environments or when exposed to perspiration.

The material's thermal properties are also noteworthy. Accura 25 exhibits good heat resistance, allowing printed parts to maintain their shape and functionality across a wide range of temperatures. This characteristic is essential for footwear components that may be subjected to varying environmental conditions or heat during manufacturing processes.

Lastly, Accura 25 offers excellent compatibility with various finishing techniques, including painting, plating, and vapor smoothing. This versatility enables designers to achieve diverse aesthetic effects and functional enhancements, further expanding the possibilities for innovative footwear design.

One of the most notable characteristics of Accura 25 is its outstanding dimensional stability. This property ensures that parts produced using this resin maintain their shape and size over time, even under varying environmental conditions. In the context of footwear design, this stability is crucial for creating precise and long-lasting components, such as shoe lasts, midsoles, and custom orthotics.

The material also boasts excellent surface finish capabilities, allowing for the production of smooth, high-quality parts with minimal post-processing requirements. This attribute is particularly valuable in footwear design, where aesthetics and comfort are paramount. Designers can create intricate patterns and textures directly in the 3D model, knowing that the final printed part will accurately reflect their vision.

Accura 25 demonstrates remarkable strength and durability, making it ideal for functional prototypes and end-use parts in footwear applications. Its high tensile strength and impact resistance enable the creation of robust shoe components that can withstand the rigors of daily wear. This durability extends the lifespan of footwear products and enhances overall performance.

The resin's low viscosity contributes to its excellent flow properties during the printing process. This characteristic allows for the production of complex geometries and fine details, which are often required in advanced footwear designs. Designers can explore innovative structures, such as lattices and honeycomb patterns, to optimize weight distribution and cushioning in shoe soles.

Another significant property of Accura 25 is its resistance to moisture absorption. This feature is particularly beneficial in footwear applications, as it helps maintain the structural integrity and performance of shoe components even in humid environments or when exposed to perspiration.

The material's thermal properties are also noteworthy. Accura 25 exhibits good heat resistance, allowing printed parts to maintain their shape and functionality across a wide range of temperatures. This characteristic is essential for footwear components that may be subjected to varying environmental conditions or heat during manufacturing processes.

Lastly, Accura 25 offers excellent compatibility with various finishing techniques, including painting, plating, and vapor smoothing. This versatility enables designers to achieve diverse aesthetic effects and functional enhancements, further expanding the possibilities for innovative footwear design.

Accura 25 Applications

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for different therapeutic purposes. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery. The formulations can be designed for specific routes of administration or targeted drug delivery.

- Analytical methods for Accura 25: Various analytical techniques and methods have been developed for the detection, quantification, and characterization of Accura 25 in different matrices. These methods may include chromatographic techniques, spectroscopic analyses, or other advanced analytical approaches to ensure the quality and purity of Accura 25-containing products.

- Synthesis and manufacturing processes for Accura 25: Different synthetic routes and manufacturing processes have been developed for the production of Accura 25. These may include novel chemical reactions, catalytic processes, or optimized industrial-scale production methods to improve yield, purity, or cost-effectiveness of Accura 25 synthesis.

- Accura 25 in combination therapies: Accura 25 is used in combination with other active ingredients for enhanced therapeutic effects or to address multiple health conditions simultaneously. These combination therapies may target specific diseases or aim to reduce side effects while maintaining efficacy.

- Novel applications and formulations of Accura 25: Research has explored new applications and formulations for Accura 25 beyond its traditional uses. This includes investigating its potential in different therapeutic areas, developing novel drug delivery systems, or creating improved formulations for enhanced bioavailability or patient compliance.

02 Chemical synthesis and manufacturing of Accura 25

Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.Expand Specific Solutions03 Analytical methods for Accura 25

Various analytical techniques are employed to characterize and quantify Accura 25 in different matrices. These methods may include chromatography, spectroscopy, and other advanced analytical tools to ensure quality control and regulatory compliance.Expand Specific Solutions04 Formulations and delivery systems for Accura 25

Different formulations and delivery systems are developed to improve the bioavailability and efficacy of Accura 25. These may include novel drug delivery technologies, controlled release formulations, and targeted delivery systems.Expand Specific Solutions05 Applications of Accura 25 in various industries

Accura 25 finds applications in various industries beyond pharmaceuticals, such as agriculture, materials science, and chemical manufacturing. These applications may involve using Accura 25 as a precursor, catalyst, or additive in different processes.Expand Specific Solutions

Key Footwear Players

The research on Accura 25 in footwear design represents an emerging field with significant potential for innovation. The market is in its early growth stage, characterized by increasing interest from major players in the athletic and performance footwear industry. While the market size is still developing, it is expected to expand rapidly as more companies invest in this technology. The competitive landscape is dominated by established sportswear giants like Nike, Adidas, and PUMA, who are leveraging their R&D capabilities to explore Accura 25 applications. However, smaller specialized companies like Salomon and ECCO are also making strides in this area, potentially disrupting the market with niche innovations.

NIKE, Inc.

Technical Solution: NIKE's Accura 25 technology focuses on innovative footwear design, incorporating advanced 3D printing and computational design. The company utilizes generative design algorithms to create complex, lightweight structures that optimize performance and comfort. NIKE's approach involves using digital data from athletes to inform the design process, resulting in highly personalized footwear solutions. The Accura 25 technology allows for rapid prototyping and iteration, enabling NIKE to bring new designs to market faster[1]. Additionally, NIKE has integrated sustainable materials into the Accura 25 process, reducing waste and improving the overall environmental impact of their footwear production[2].

Strengths: Cutting-edge 3D printing technology, data-driven design process, rapid prototyping capabilities, and focus on sustainability. Weaknesses: Potentially higher production costs and limited scalability for mass production.

PUMA SE

Technical Solution: PUMA's application of Accura 25 technology in footwear design focuses on biomechanical optimization and customization. The company has developed a proprietary system that combines 3D scanning of athletes' feet with motion capture data to create highly personalized midsole structures. PUMA's approach utilizes advanced materials science, incorporating variable density foams and lattice structures to enhance energy return and cushioning. The Accura 25 process allows PUMA to fine-tune shoe designs for specific sports and individual athlete needs, resulting in improved performance and reduced injury risk[3]. PUMA has also integrated this technology into their manufacturing process, enabling on-demand production of customized footwear[4].

Strengths: Highly personalized designs, advanced biomechanical analysis, and on-demand production capabilities. Weaknesses: Potentially higher costs for consumers and limited availability of customization services.

Accura 25 Innovations

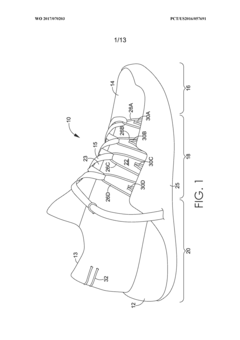

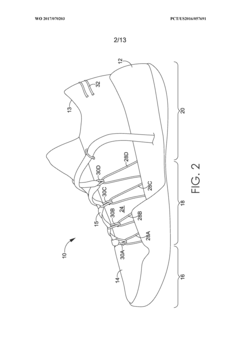

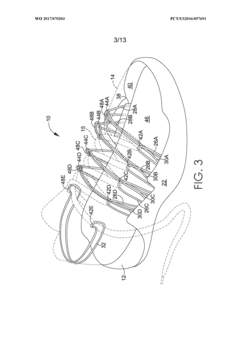

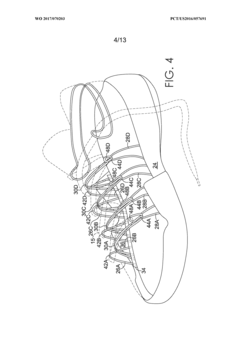

Tensile-strand enclosure system for footwear

PatentWO2017070203A1

Innovation

- Incorporation of tensile strands that are adjustable and integrated into the footwear structure to form a size-adjustable enclosure, providing anchor points for laces to adjust tension and compression across the foot-receiving space.

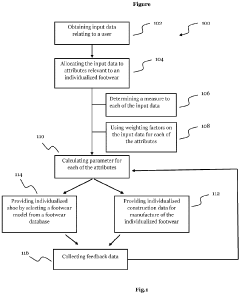

Method and system to provide an individualized footwear

PatentPendingEP3970550A1

Innovation

- A method and system that utilize input data such as anthropometric, biomechanical, and personal preference data to calculate parameters for individualized footwear attributes, providing precise construction data or selecting optimal shoe models from a database, incorporating techniques like 3D scans, pressure plate analysis, and AI algorithms for efficient and effective customization.

Sustainability Aspects

Accura 25, a photopolymer resin developed by 3D Systems, has gained significant attention in the footwear industry for its potential to revolutionize sustainable design practices. This material offers a unique combination of properties that align well with the growing demand for environmentally friendly manufacturing processes in the footwear sector.

One of the key sustainability aspects of Accura 25 is its ability to reduce material waste during the production process. Traditional footwear manufacturing often involves cutting and shaping materials, resulting in significant waste. In contrast, 3D printing with Accura 25 allows for precise material deposition, minimizing excess material usage and reducing overall waste generation.

The durability and longevity of Accura 25 also contribute to its sustainability profile. Footwear produced using this material has shown improved resistance to wear and tear, potentially extending the product lifecycle. This increased durability can lead to a reduction in the frequency of shoe replacements, thereby decreasing the overall environmental impact associated with footwear consumption.

Accura 25's compatibility with recycling processes further enhances its sustainability credentials. Unlike many traditional footwear materials that are difficult to recycle due to complex material compositions, Accura 25 can be more easily separated and recycled at the end of the product's life. This characteristic aligns with circular economy principles, promoting the reuse of materials and reducing the demand for virgin resources.

The energy efficiency of 3D printing processes using Accura 25 is another notable sustainability aspect. Compared to traditional manufacturing methods, 3D printing often requires less energy input, particularly for small to medium production runs. This reduced energy consumption translates to lower carbon emissions associated with footwear production.

Furthermore, the localized production capabilities enabled by 3D printing with Accura 25 can significantly reduce transportation-related emissions. By allowing for on-demand, localized manufacturing, this technology has the potential to shorten supply chains and decrease the carbon footprint associated with global shipping of footwear products.

Accura 25 also presents opportunities for innovative design approaches that can enhance sustainability. For instance, the material's properties allow for the creation of lightweight yet durable structures, potentially reducing the overall material volume required for each shoe. This optimization can lead to further reductions in resource consumption and environmental impact throughout the product lifecycle.

In conclusion, the application of Accura 25 in footwear design represents a significant step towards more sustainable manufacturing practices in the industry. Its potential to reduce waste, improve product longevity, facilitate recycling, and enable energy-efficient, localized production aligns well with the growing emphasis on sustainability in consumer products.

One of the key sustainability aspects of Accura 25 is its ability to reduce material waste during the production process. Traditional footwear manufacturing often involves cutting and shaping materials, resulting in significant waste. In contrast, 3D printing with Accura 25 allows for precise material deposition, minimizing excess material usage and reducing overall waste generation.

The durability and longevity of Accura 25 also contribute to its sustainability profile. Footwear produced using this material has shown improved resistance to wear and tear, potentially extending the product lifecycle. This increased durability can lead to a reduction in the frequency of shoe replacements, thereby decreasing the overall environmental impact associated with footwear consumption.

Accura 25's compatibility with recycling processes further enhances its sustainability credentials. Unlike many traditional footwear materials that are difficult to recycle due to complex material compositions, Accura 25 can be more easily separated and recycled at the end of the product's life. This characteristic aligns with circular economy principles, promoting the reuse of materials and reducing the demand for virgin resources.

The energy efficiency of 3D printing processes using Accura 25 is another notable sustainability aspect. Compared to traditional manufacturing methods, 3D printing often requires less energy input, particularly for small to medium production runs. This reduced energy consumption translates to lower carbon emissions associated with footwear production.

Furthermore, the localized production capabilities enabled by 3D printing with Accura 25 can significantly reduce transportation-related emissions. By allowing for on-demand, localized manufacturing, this technology has the potential to shorten supply chains and decrease the carbon footprint associated with global shipping of footwear products.

Accura 25 also presents opportunities for innovative design approaches that can enhance sustainability. For instance, the material's properties allow for the creation of lightweight yet durable structures, potentially reducing the overall material volume required for each shoe. This optimization can lead to further reductions in resource consumption and environmental impact throughout the product lifecycle.

In conclusion, the application of Accura 25 in footwear design represents a significant step towards more sustainable manufacturing practices in the industry. Its potential to reduce waste, improve product longevity, facilitate recycling, and enable energy-efficient, localized production aligns well with the growing emphasis on sustainability in consumer products.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of Accura 25 in footwear design. As an innovative material, Accura 25 must adhere to various regulations and standards to ensure its safety, quality, and environmental sustainability in the footwear industry.

The primary regulatory bodies overseeing the use of materials in footwear include the European Chemicals Agency (ECHA), the U.S. Consumer Product Safety Commission (CPSC), and the International Organization for Standardization (ISO). These organizations set guidelines and standards that manufacturers must follow when incorporating new materials like Accura 25 into their products.

One of the key regulatory aspects for Accura 25 is its compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations in the European Union. This regulation ensures that the material does not contain harmful substances that could pose risks to human health or the environment. Manufacturers using Accura 25 must provide detailed information about its chemical composition and potential hazards.

In the United States, the CPSC enforces the Consumer Product Safety Improvement Act (CPSIA), which sets limits on certain substances in consumer products, including footwear. Accura 25 must meet these requirements, particularly regarding lead content and phthalates, to be used in shoes sold in the U.S. market.

The ISO has established several standards relevant to footwear materials, such as ISO 20871 for physical and mechanical tests and ISO 20344 for personal protective equipment testing methods. Accura 25 should be tested and certified according to these standards to ensure its performance and durability in footwear applications.

Environmental regulations also play a significant role in the use of Accura 25. Many countries have implemented regulations to promote sustainable and eco-friendly materials in consumer products. Manufacturers using Accura 25 should consider its environmental impact throughout its lifecycle, from production to disposal, to comply with these regulations and meet consumer expectations for sustainable footwear.

Occupational safety regulations are another important consideration, especially for footwear designed for specific work environments. Accura 25 used in safety shoes or boots must meet standards set by organizations like the Occupational Safety and Health Administration (OSHA) in the United States or the European Agency for Safety and Health at Work (EU-OSHA).

To ensure ongoing compliance, manufacturers and designers working with Accura 25 should establish robust quality control processes and maintain detailed documentation of their compliance efforts. Regular testing and certification of products made with Accura 25 will be necessary to demonstrate continued adherence to evolving regulatory requirements.

As regulations continue to evolve, staying informed about changes and updates in regulatory requirements will be crucial for companies using Accura 25 in footwear design. This may involve ongoing collaboration with regulatory experts and participation in industry associations to stay ahead of compliance challenges and opportunities.

The primary regulatory bodies overseeing the use of materials in footwear include the European Chemicals Agency (ECHA), the U.S. Consumer Product Safety Commission (CPSC), and the International Organization for Standardization (ISO). These organizations set guidelines and standards that manufacturers must follow when incorporating new materials like Accura 25 into their products.

One of the key regulatory aspects for Accura 25 is its compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations in the European Union. This regulation ensures that the material does not contain harmful substances that could pose risks to human health or the environment. Manufacturers using Accura 25 must provide detailed information about its chemical composition and potential hazards.

In the United States, the CPSC enforces the Consumer Product Safety Improvement Act (CPSIA), which sets limits on certain substances in consumer products, including footwear. Accura 25 must meet these requirements, particularly regarding lead content and phthalates, to be used in shoes sold in the U.S. market.

The ISO has established several standards relevant to footwear materials, such as ISO 20871 for physical and mechanical tests and ISO 20344 for personal protective equipment testing methods. Accura 25 should be tested and certified according to these standards to ensure its performance and durability in footwear applications.

Environmental regulations also play a significant role in the use of Accura 25. Many countries have implemented regulations to promote sustainable and eco-friendly materials in consumer products. Manufacturers using Accura 25 should consider its environmental impact throughout its lifecycle, from production to disposal, to comply with these regulations and meet consumer expectations for sustainable footwear.

Occupational safety regulations are another important consideration, especially for footwear designed for specific work environments. Accura 25 used in safety shoes or boots must meet standards set by organizations like the Occupational Safety and Health Administration (OSHA) in the United States or the European Agency for Safety and Health at Work (EU-OSHA).

To ensure ongoing compliance, manufacturers and designers working with Accura 25 should establish robust quality control processes and maintain detailed documentation of their compliance efforts. Regular testing and certification of products made with Accura 25 will be necessary to demonstrate continued adherence to evolving regulatory requirements.

As regulations continue to evolve, staying informed about changes and updates in regulatory requirements will be crucial for companies using Accura 25 in footwear design. This may involve ongoing collaboration with regulatory experts and participation in industry associations to stay ahead of compliance challenges and opportunities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!