How Accura 25 Enhances Automotive Interiors?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25 is a revolutionary material developed by DSM Engineering Materials, specifically designed to enhance automotive interiors. This high-performance resin represents a significant advancement in the field of automotive materials, offering a unique combination of properties that address the evolving needs of the automotive industry.

The development of Accura 25 is rooted in the automotive sector's ongoing pursuit of lightweight, durable, and aesthetically pleasing interior components. As vehicles become more technologically advanced and environmentally conscious, there is an increasing demand for materials that can meet stringent performance requirements while also contributing to overall vehicle efficiency.

The primary objective behind the creation of Accura 25 was to provide automotive manufacturers with a versatile material that could improve the quality, functionality, and sustainability of vehicle interiors. This aligns with the industry's broader goals of enhancing user experience, reducing environmental impact, and optimizing production processes.

Accura 25 builds upon decades of research and development in polymer science, incorporating cutting-edge technologies to achieve its superior characteristics. The material's evolution can be traced through various iterations of automotive-grade resins, each addressing specific challenges faced by the industry at different stages.

One of the key aims in developing Accura 25 was to create a material that could withstand the harsh conditions often encountered in automotive interiors, including exposure to UV radiation, temperature fluctuations, and chemical interactions. Simultaneously, the material needed to maintain a high-quality appearance and feel, crucial for meeting consumer expectations in premium vehicle segments.

Another significant objective was to enhance the design flexibility offered to automotive engineers and designers. Accura 25 was developed with the intention of enabling more complex and intricate interior components, potentially revolutionizing the approach to automotive interior design and manufacturing.

Furthermore, the development of Accura 25 was driven by the automotive industry's push towards more sustainable practices. The material aims to contribute to the reduction of vehicle weight, thereby improving fuel efficiency and reducing emissions. Additionally, considerations for end-of-life recycling and overall environmental impact were integral to the material's development process.

As the automotive industry continues to evolve, with trends such as electrification and autonomous driving reshaping vehicle design, materials like Accura 25 play a crucial role in enabling these transformations. The material's development objectives extend beyond current needs, anticipating future requirements in areas such as integration of electronics, advanced safety features, and novel interior concepts.

The development of Accura 25 is rooted in the automotive sector's ongoing pursuit of lightweight, durable, and aesthetically pleasing interior components. As vehicles become more technologically advanced and environmentally conscious, there is an increasing demand for materials that can meet stringent performance requirements while also contributing to overall vehicle efficiency.

The primary objective behind the creation of Accura 25 was to provide automotive manufacturers with a versatile material that could improve the quality, functionality, and sustainability of vehicle interiors. This aligns with the industry's broader goals of enhancing user experience, reducing environmental impact, and optimizing production processes.

Accura 25 builds upon decades of research and development in polymer science, incorporating cutting-edge technologies to achieve its superior characteristics. The material's evolution can be traced through various iterations of automotive-grade resins, each addressing specific challenges faced by the industry at different stages.

One of the key aims in developing Accura 25 was to create a material that could withstand the harsh conditions often encountered in automotive interiors, including exposure to UV radiation, temperature fluctuations, and chemical interactions. Simultaneously, the material needed to maintain a high-quality appearance and feel, crucial for meeting consumer expectations in premium vehicle segments.

Another significant objective was to enhance the design flexibility offered to automotive engineers and designers. Accura 25 was developed with the intention of enabling more complex and intricate interior components, potentially revolutionizing the approach to automotive interior design and manufacturing.

Furthermore, the development of Accura 25 was driven by the automotive industry's push towards more sustainable practices. The material aims to contribute to the reduction of vehicle weight, thereby improving fuel efficiency and reducing emissions. Additionally, considerations for end-of-life recycling and overall environmental impact were integral to the material's development process.

As the automotive industry continues to evolve, with trends such as electrification and autonomous driving reshaping vehicle design, materials like Accura 25 play a crucial role in enabling these transformations. The material's development objectives extend beyond current needs, anticipating future requirements in areas such as integration of electronics, advanced safety features, and novel interior concepts.

Automotive Interior Market Analysis

The automotive interior market has experienced significant growth and transformation in recent years, driven by increasing consumer demand for comfort, luxury, and advanced technology within vehicles. This market segment encompasses a wide range of components, including seating, dashboard panels, infotainment systems, and interior trim materials. The global automotive interior market size was valued at approximately $123.5 billion in 2020 and is projected to reach $187.3 billion by 2025, growing at a CAGR of 8.7% during the forecast period.

Several key factors are influencing the growth and evolution of the automotive interior market. Firstly, the rising consumer expectations for premium and personalized interiors have led to increased demand for high-quality materials and customizable options. This trend is particularly evident in the luxury vehicle segment, where manufacturers are incorporating advanced materials like Accura 25 to enhance the overall aesthetics and tactile experience of interior surfaces.

Secondly, the integration of advanced technologies within vehicle interiors is reshaping the market landscape. The proliferation of infotainment systems, digital displays, and connected car features has created new opportunities for interior component suppliers and manufacturers. These technological advancements are not only improving the functionality of vehicle interiors but also contributing to the overall perceived value of the vehicle.

The automotive interior market is also being influenced by the growing emphasis on sustainability and environmental consciousness. Consumers and regulatory bodies are increasingly demanding eco-friendly materials and production processes. This has led to the development of sustainable interior materials, including recycled plastics, bio-based fabrics, and low-emission adhesives. Materials like Accura 25, which offer improved durability and reduced environmental impact, are gaining traction in this context.

Regional variations in market dynamics are notable, with mature markets like North America and Europe focusing on premium interiors and advanced technologies, while emerging markets in Asia-Pacific and Latin America are experiencing rapid growth due to increasing vehicle production and rising disposable incomes. China, in particular, has emerged as a key player in the automotive interior market, driven by its large domestic market and growing automotive manufacturing capabilities.

The competitive landscape of the automotive interior market is characterized by the presence of both established players and innovative startups. Major companies in this space are investing heavily in research and development to create novel interior solutions that address evolving consumer preferences and regulatory requirements. The introduction of materials like Accura 25 represents a significant opportunity for differentiation and value creation in this highly competitive market.

Several key factors are influencing the growth and evolution of the automotive interior market. Firstly, the rising consumer expectations for premium and personalized interiors have led to increased demand for high-quality materials and customizable options. This trend is particularly evident in the luxury vehicle segment, where manufacturers are incorporating advanced materials like Accura 25 to enhance the overall aesthetics and tactile experience of interior surfaces.

Secondly, the integration of advanced technologies within vehicle interiors is reshaping the market landscape. The proliferation of infotainment systems, digital displays, and connected car features has created new opportunities for interior component suppliers and manufacturers. These technological advancements are not only improving the functionality of vehicle interiors but also contributing to the overall perceived value of the vehicle.

The automotive interior market is also being influenced by the growing emphasis on sustainability and environmental consciousness. Consumers and regulatory bodies are increasingly demanding eco-friendly materials and production processes. This has led to the development of sustainable interior materials, including recycled plastics, bio-based fabrics, and low-emission adhesives. Materials like Accura 25, which offer improved durability and reduced environmental impact, are gaining traction in this context.

Regional variations in market dynamics are notable, with mature markets like North America and Europe focusing on premium interiors and advanced technologies, while emerging markets in Asia-Pacific and Latin America are experiencing rapid growth due to increasing vehicle production and rising disposable incomes. China, in particular, has emerged as a key player in the automotive interior market, driven by its large domestic market and growing automotive manufacturing capabilities.

The competitive landscape of the automotive interior market is characterized by the presence of both established players and innovative startups. Major companies in this space are investing heavily in research and development to create novel interior solutions that address evolving consumer preferences and regulatory requirements. The introduction of materials like Accura 25 represents a significant opportunity for differentiation and value creation in this highly competitive market.

Accura 25 Technical Challenges

Accura 25, a high-performance stereolithography resin developed by 3D Systems, presents several technical challenges in its application for enhancing automotive interiors. One of the primary obstacles is achieving consistent part quality across large-scale production. The resin's photopolymerization process can be sensitive to environmental factors such as temperature and humidity, potentially leading to variations in mechanical properties and surface finish.

Another significant challenge lies in optimizing the material's durability to withstand the harsh conditions typical of automotive interiors. While Accura 25 offers excellent clarity and impact resistance, ensuring long-term stability under exposure to UV light, temperature fluctuations, and chemical interactions with automotive fluids remains a complex task. Engineers must develop robust post-processing techniques to enhance the material's resistance to degradation over time.

The integration of Accura 25 components with traditional automotive materials poses additional technical hurdles. Achieving strong, reliable bonds between 3D-printed parts and conventional substrates such as plastics, metals, or fabrics requires the development of specialized adhesives or bonding methods. This integration must maintain structural integrity while accommodating the different thermal expansion coefficients of diverse materials.

Customization and design flexibility, while being strengths of 3D printing technology, also present challenges in terms of scalability and cost-effectiveness. Creating complex, organic shapes or intricate surface textures demands advanced design software and printing parameters optimization. Balancing aesthetic appeal with functional requirements, such as strength and weight reduction, requires sophisticated engineering approaches.

Color consistency and surface finish quality are critical aspects of automotive interior components. Achieving uniform coloration throughout Accura 25 parts, especially for larger components, can be challenging due to the layer-by-layer printing process. Post-processing techniques like painting or coating must be carefully developed to ensure adherence to automotive industry standards for color matching and durability.

Regulatory compliance and safety standards present another layer of technical challenges. Accura 25 components must meet stringent automotive industry requirements for fire resistance, off-gassing, and impact safety. Developing formulations and processing methods that satisfy these regulations while maintaining the material's desirable properties requires extensive research and testing.

Lastly, the challenge of reducing production costs and cycle times to make Accura 25 competitive with traditional manufacturing methods is significant. Optimizing print speeds, minimizing support structures, and streamlining post-processing steps are crucial areas for improvement. Developing more efficient printing strategies and automated post-processing systems is essential for the widespread adoption of Accura 25 in automotive interior applications.

Another significant challenge lies in optimizing the material's durability to withstand the harsh conditions typical of automotive interiors. While Accura 25 offers excellent clarity and impact resistance, ensuring long-term stability under exposure to UV light, temperature fluctuations, and chemical interactions with automotive fluids remains a complex task. Engineers must develop robust post-processing techniques to enhance the material's resistance to degradation over time.

The integration of Accura 25 components with traditional automotive materials poses additional technical hurdles. Achieving strong, reliable bonds between 3D-printed parts and conventional substrates such as plastics, metals, or fabrics requires the development of specialized adhesives or bonding methods. This integration must maintain structural integrity while accommodating the different thermal expansion coefficients of diverse materials.

Customization and design flexibility, while being strengths of 3D printing technology, also present challenges in terms of scalability and cost-effectiveness. Creating complex, organic shapes or intricate surface textures demands advanced design software and printing parameters optimization. Balancing aesthetic appeal with functional requirements, such as strength and weight reduction, requires sophisticated engineering approaches.

Color consistency and surface finish quality are critical aspects of automotive interior components. Achieving uniform coloration throughout Accura 25 parts, especially for larger components, can be challenging due to the layer-by-layer printing process. Post-processing techniques like painting or coating must be carefully developed to ensure adherence to automotive industry standards for color matching and durability.

Regulatory compliance and safety standards present another layer of technical challenges. Accura 25 components must meet stringent automotive industry requirements for fire resistance, off-gassing, and impact safety. Developing formulations and processing methods that satisfy these regulations while maintaining the material's desirable properties requires extensive research and testing.

Lastly, the challenge of reducing production costs and cycle times to make Accura 25 competitive with traditional manufacturing methods is significant. Optimizing print speeds, minimizing support structures, and streamlining post-processing steps are crucial areas for improvement. Developing more efficient printing strategies and automated post-processing systems is essential for the widespread adoption of Accura 25 in automotive interior applications.

Current Accura 25 Implementation Strategies

01 Image processing and enhancement techniques

Various methods for improving image quality and processing, including techniques for enhancing resolution, color accuracy, and overall visual appearance. These techniques may involve advanced algorithms for image interpolation, noise reduction, and sharpening.- Image processing and enhancement techniques: Various methods for improving image quality and processing, including techniques for enhancing resolution, color accuracy, and overall visual appearance. These techniques may involve advanced algorithms for image interpolation, noise reduction, and sharpness enhancement.

- Video encoding and compression: Advancements in video encoding and compression technologies to improve efficiency and quality of video transmission and storage. This includes methods for reducing bitrate while maintaining visual quality, as well as techniques for adapting to different network conditions and device capabilities.

- Display technology improvements: Innovations in display technologies to enhance visual output, including advancements in LCD, OLED, and other display types. These improvements focus on factors such as color gamut, contrast ratio, refresh rate, and energy efficiency to provide a better viewing experience.

- 3D imaging and depth sensing: Development of 3D imaging and depth sensing technologies for various applications, including augmented reality, facial recognition, and object detection. This involves advancements in stereoscopic imaging, time-of-flight sensors, and related processing algorithms.

- Machine learning for image and video enhancement: Application of machine learning and artificial intelligence techniques to improve image and video quality. This includes the use of neural networks for super-resolution, object recognition, and automated image editing to enhance visual content.

02 3D printing and additive manufacturing improvements

Advancements in 3D printing technologies, focusing on enhancing accuracy, speed, and material properties. This includes innovations in printer design, material formulations, and post-processing techniques to achieve higher precision and better surface finish.Expand Specific Solutions03 Optical systems and lens technology

Developments in optical systems, including improvements in lens design, manufacturing, and coating technologies. These advancements aim to enhance image quality, reduce aberrations, and improve overall performance in various applications such as cameras, microscopes, and other optical instruments.Expand Specific Solutions04 Digital signal processing and data compression

Innovations in digital signal processing algorithms and data compression techniques, particularly for video and audio applications. These advancements focus on improving encoding efficiency, reducing bandwidth requirements, and enhancing overall quality of digital media.Expand Specific Solutions05 Precision measurement and calibration systems

Advancements in measurement technologies and calibration systems for improving accuracy and reliability in various industrial and scientific applications. This includes innovations in sensor technologies, data analysis algorithms, and calibration methodologies.Expand Specific Solutions

Key Players in Automotive Interior Industry

The automotive interior enhancement market, exemplified by Accura 25, is in a growth phase characterized by increasing demand for advanced, comfortable, and aesthetically pleasing vehicle interiors. The global automotive interior market is projected to reach significant size, driven by consumer preferences for luxury and technology integration. Technologically, this field is rapidly evolving, with companies like Honda Motor Co., Ltd., TS TECH CO., LTD., and Faurecia Innenraum Systeme GmbH leading innovations. These firms are investing in smart materials, ergonomic designs, and sustainable solutions to enhance vehicle interiors, indicating a moderate to high level of technological maturity with ongoing advancements.

Volkswagen AG

Technical Solution: Volkswagen AG has developed an innovative approach to enhancing automotive interiors using Accura 25 technology. Their solution involves integrating advanced materials and smart surfaces to create a more immersive and responsive cabin environment. The company has implemented a new generation of haptic feedback controls, utilizing Accura 25's precision to create seamless, touch-sensitive surfaces throughout the interior[1]. This technology allows for the elimination of traditional buttons and knobs, resulting in a cleaner, more modern aesthetic. Additionally, Volkswagen has incorporated Accura 25 into their ambient lighting systems, enabling dynamic color changes and personalized lighting scenarios that respond to driver preferences and external conditions[3].

Strengths: Cutting-edge user interface, improved aesthetics, and personalization options. Weaknesses: Potential for higher costs and increased complexity in manufacturing and maintenance.

GM Global Technology Operations LLC

Technical Solution: GM's implementation of Accura 25 focuses on enhancing the overall comfort and functionality of automotive interiors. Their approach includes the development of smart seating systems that utilize Accura 25's precision sensors to automatically adjust to individual passengers' body types and preferences[2]. The technology also enables advanced climate control features, with micro-adjustments to airflow and temperature based on real-time occupant data. GM has further integrated Accura 25 into their infotainment systems, creating gesture-controlled interfaces that reduce driver distraction and improve safety[4]. The company has also utilized the technology to develop self-cleaning surfaces within the interior, enhancing hygiene and reducing maintenance requirements.

Strengths: Enhanced comfort, improved safety features, and innovative hygiene solutions. Weaknesses: Potential for system complexity and higher initial costs.

Accura 25 Material Properties Analysis

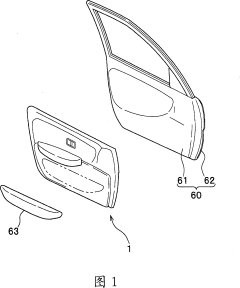

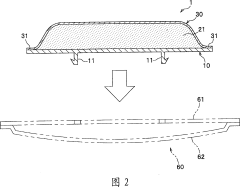

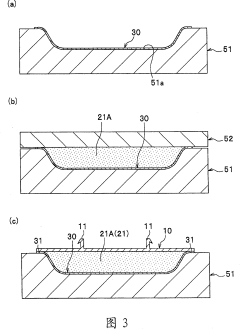

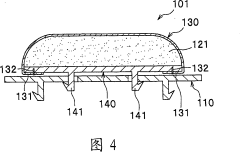

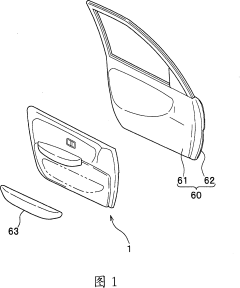

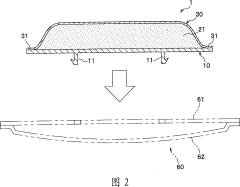

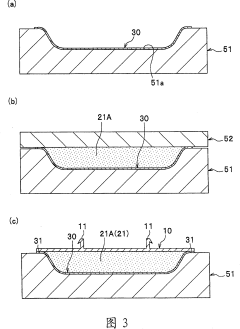

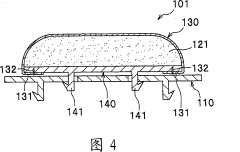

Decorative part

PatentInactiveCN101204862B

Innovation

- A buffer layer made of gel elastomer with a JISA hardness of 5 degrees or less or an ASKER-C hardness of 20 degrees or less is used, covered with a translucent and stretchable skin, and a light source is installed on the back to illuminate the buffer. layer and skin, improving touch and aesthetics.

Decorative part

PatentInactiveCN101204862A

Innovation

- Decorative parts that use a buffer layer made of gel elastomer with a JISA hardness of 5 degrees or less or an ASKER-C hardness of 20 degrees or less and cover the buffer layer with a stretchable skin for use in the interior of automobiles. Decoration to enhance tactility and aesthetics.

Environmental Impact Assessment

The environmental impact assessment of Accura 25 in enhancing automotive interiors reveals both positive and negative aspects. On the positive side, Accura 25's durability and longevity contribute to reduced waste generation over time. The material's resistance to wear and tear means fewer replacements are needed, potentially decreasing the overall environmental footprint of vehicle interiors.

Furthermore, Accura 25's lightweight properties can lead to improved fuel efficiency in vehicles. By reducing the overall weight of the vehicle, less fuel is consumed, resulting in lower greenhouse gas emissions during the vehicle's operational lifetime. This aligns with global efforts to reduce carbon footprints in the automotive industry.

The material's recyclability is another environmental advantage. Accura 25 can be recycled at the end of its life cycle, reducing the amount of waste sent to landfills. This circular economy approach helps conserve resources and minimize the environmental impact of automotive interior production.

However, the production process of Accura 25 does raise some environmental concerns. The manufacturing of this advanced material may involve energy-intensive processes and the use of certain chemicals. These factors could contribute to increased carbon emissions and potential chemical waste during production.

Water usage in the manufacturing process is another consideration. Depending on the specific production techniques employed, significant amounts of water may be required, potentially straining local water resources in manufacturing regions.

The long-term effects of Accura 25 on ecosystems, particularly if improperly disposed of, need further study. While the material is recyclable, ensuring proper end-of-life management is crucial to prevent environmental contamination.

Efforts to mitigate these environmental impacts are ongoing. Manufacturers are exploring more sustainable production methods, including the use of renewable energy sources in manufacturing facilities and developing more eco-friendly chemical processes. Additionally, research into bio-based alternatives for some components of Accura 25 is underway, aiming to reduce reliance on petroleum-based raw materials.

Overall, while Accura 25 offers several environmental benefits in its application, particularly in terms of vehicle efficiency and longevity, continued focus on sustainable production methods and end-of-life management is essential to maximize its positive environmental impact in automotive interior enhancement.

Furthermore, Accura 25's lightweight properties can lead to improved fuel efficiency in vehicles. By reducing the overall weight of the vehicle, less fuel is consumed, resulting in lower greenhouse gas emissions during the vehicle's operational lifetime. This aligns with global efforts to reduce carbon footprints in the automotive industry.

The material's recyclability is another environmental advantage. Accura 25 can be recycled at the end of its life cycle, reducing the amount of waste sent to landfills. This circular economy approach helps conserve resources and minimize the environmental impact of automotive interior production.

However, the production process of Accura 25 does raise some environmental concerns. The manufacturing of this advanced material may involve energy-intensive processes and the use of certain chemicals. These factors could contribute to increased carbon emissions and potential chemical waste during production.

Water usage in the manufacturing process is another consideration. Depending on the specific production techniques employed, significant amounts of water may be required, potentially straining local water resources in manufacturing regions.

The long-term effects of Accura 25 on ecosystems, particularly if improperly disposed of, need further study. While the material is recyclable, ensuring proper end-of-life management is crucial to prevent environmental contamination.

Efforts to mitigate these environmental impacts are ongoing. Manufacturers are exploring more sustainable production methods, including the use of renewable energy sources in manufacturing facilities and developing more eco-friendly chemical processes. Additionally, research into bio-based alternatives for some components of Accura 25 is underway, aiming to reduce reliance on petroleum-based raw materials.

Overall, while Accura 25 offers several environmental benefits in its application, particularly in terms of vehicle efficiency and longevity, continued focus on sustainable production methods and end-of-life management is essential to maximize its positive environmental impact in automotive interior enhancement.

Cost-Benefit Analysis of Accura 25

The implementation of Accura 25 in automotive interiors presents a compelling case for cost-benefit analysis. This advanced material offers significant advantages in terms of design flexibility, durability, and aesthetic appeal, which must be weighed against its production and implementation costs.

From a cost perspective, Accura 25 initially requires a higher investment compared to traditional interior materials. The specialized manufacturing process and the material itself contribute to increased upfront expenses. Additionally, retooling and adjusting production lines to accommodate Accura 25 components may incur substantial costs for automotive manufacturers.

However, the long-term benefits of Accura 25 can potentially outweigh these initial expenditures. The material's superior durability translates to reduced maintenance and replacement costs over the vehicle's lifetime. Its resistance to wear, scratches, and environmental factors ensures that interior components maintain their appearance and functionality for extended periods, potentially lowering warranty claims and improving customer satisfaction.

The design flexibility offered by Accura 25 allows for more intricate and innovative interior designs. This can lead to increased perceived value of the vehicle, potentially justifying higher price points and improving profit margins. The material's ability to create seamless, complex shapes also streamlines the manufacturing process, potentially reducing assembly time and associated labor costs.

Furthermore, Accura 25's lightweight properties contribute to overall vehicle weight reduction. This can result in improved fuel efficiency or extended range in electric vehicles, offering long-term cost savings for consumers and helping manufacturers meet increasingly stringent environmental regulations.

The material's recyclability and potential for sustainable production align with growing consumer demand for eco-friendly vehicles. This can enhance brand image and appeal to environmentally conscious market segments, potentially increasing sales and market share.

In terms of scalability, as production volumes increase and manufacturing processes are optimized, the cost per unit of Accura 25 components is likely to decrease. This economies of scale effect could further improve the cost-benefit ratio over time, making the material more economically viable for a wider range of vehicle models and market segments.

Ultimately, the cost-benefit analysis of Accura 25 in automotive interiors must consider both immediate financial implications and long-term value creation. While the initial investment may be higher, the potential for enhanced product differentiation, improved customer satisfaction, and operational efficiencies presents a compelling case for its adoption in the competitive automotive market.

From a cost perspective, Accura 25 initially requires a higher investment compared to traditional interior materials. The specialized manufacturing process and the material itself contribute to increased upfront expenses. Additionally, retooling and adjusting production lines to accommodate Accura 25 components may incur substantial costs for automotive manufacturers.

However, the long-term benefits of Accura 25 can potentially outweigh these initial expenditures. The material's superior durability translates to reduced maintenance and replacement costs over the vehicle's lifetime. Its resistance to wear, scratches, and environmental factors ensures that interior components maintain their appearance and functionality for extended periods, potentially lowering warranty claims and improving customer satisfaction.

The design flexibility offered by Accura 25 allows for more intricate and innovative interior designs. This can lead to increased perceived value of the vehicle, potentially justifying higher price points and improving profit margins. The material's ability to create seamless, complex shapes also streamlines the manufacturing process, potentially reducing assembly time and associated labor costs.

Furthermore, Accura 25's lightweight properties contribute to overall vehicle weight reduction. This can result in improved fuel efficiency or extended range in electric vehicles, offering long-term cost savings for consumers and helping manufacturers meet increasingly stringent environmental regulations.

The material's recyclability and potential for sustainable production align with growing consumer demand for eco-friendly vehicles. This can enhance brand image and appeal to environmentally conscious market segments, potentially increasing sales and market share.

In terms of scalability, as production volumes increase and manufacturing processes are optimized, the cost per unit of Accura 25 components is likely to decrease. This economies of scale effect could further improve the cost-benefit ratio over time, making the material more economically viable for a wider range of vehicle models and market segments.

Ultimately, the cost-benefit analysis of Accura 25 in automotive interiors must consider both immediate financial implications and long-term value creation. While the initial investment may be higher, the potential for enhanced product differentiation, improved customer satisfaction, and operational efficiencies presents a compelling case for its adoption in the competitive automotive market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!