Accura 25: Key to Streamlined Production Processes

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25 is a cutting-edge additive manufacturing material developed by 3D Systems, specifically designed for stereolithography (SLA) 3D printing processes. This advanced resin has gained significant attention in the manufacturing industry due to its exceptional properties and potential to revolutionize production processes. The evolution of Accura 25 can be traced back to the early 2000s when 3D Systems began exploring new materials to enhance the capabilities of their SLA technology.

The primary objective of researching Accura 25 for streamlining production processes is to leverage its unique characteristics to optimize manufacturing workflows, reduce costs, and improve overall product quality. This material offers a combination of high strength, durability, and thermal resistance, making it suitable for a wide range of applications across various industries, including automotive, aerospace, and consumer goods.

One of the key drivers behind the development of Accura 25 has been the growing demand for rapid prototyping and small-batch production solutions. As manufacturers seek to reduce time-to-market and increase product customization, materials like Accura 25 have become increasingly valuable. The material's ability to produce functional prototypes and end-use parts with complex geometries has positioned it as a game-changer in the additive manufacturing landscape.

The technical evolution of Accura 25 has focused on improving its mechanical properties, dimensional accuracy, and surface finish. Researchers have worked to optimize the material's formulation to achieve a balance between strength, flexibility, and thermal stability. This ongoing development has resulted in a material that can withstand high temperatures and harsh environments, making it suitable for demanding applications in industries such as aerospace and automotive.

Another significant aspect of Accura 25's development has been its compatibility with post-processing techniques. The material has been engineered to respond well to various finishing methods, including sanding, painting, and plating. This versatility allows manufacturers to achieve the desired surface quality and aesthetic appeal for their final products, further expanding the potential applications of Accura 25 in production processes.

As the adoption of additive manufacturing continues to grow, the research on Accura 25 aims to address key challenges in the industry, such as improving build speed, reducing material waste, and enhancing overall process efficiency. By focusing on these areas, researchers and manufacturers hope to unlock the full potential of Accura 25 in streamlining production processes and enabling more sustainable manufacturing practices.

The primary objective of researching Accura 25 for streamlining production processes is to leverage its unique characteristics to optimize manufacturing workflows, reduce costs, and improve overall product quality. This material offers a combination of high strength, durability, and thermal resistance, making it suitable for a wide range of applications across various industries, including automotive, aerospace, and consumer goods.

One of the key drivers behind the development of Accura 25 has been the growing demand for rapid prototyping and small-batch production solutions. As manufacturers seek to reduce time-to-market and increase product customization, materials like Accura 25 have become increasingly valuable. The material's ability to produce functional prototypes and end-use parts with complex geometries has positioned it as a game-changer in the additive manufacturing landscape.

The technical evolution of Accura 25 has focused on improving its mechanical properties, dimensional accuracy, and surface finish. Researchers have worked to optimize the material's formulation to achieve a balance between strength, flexibility, and thermal stability. This ongoing development has resulted in a material that can withstand high temperatures and harsh environments, making it suitable for demanding applications in industries such as aerospace and automotive.

Another significant aspect of Accura 25's development has been its compatibility with post-processing techniques. The material has been engineered to respond well to various finishing methods, including sanding, painting, and plating. This versatility allows manufacturers to achieve the desired surface quality and aesthetic appeal for their final products, further expanding the potential applications of Accura 25 in production processes.

As the adoption of additive manufacturing continues to grow, the research on Accura 25 aims to address key challenges in the industry, such as improving build speed, reducing material waste, and enhancing overall process efficiency. By focusing on these areas, researchers and manufacturers hope to unlock the full potential of Accura 25 in streamlining production processes and enabling more sustainable manufacturing practices.

Market Demand Analysis

The market demand for Accura 25 in streamlining production processes has been steadily increasing in recent years. This growth is primarily driven by the manufacturing industry's continuous pursuit of efficiency, cost reduction, and quality improvement. Accura 25, a high-performance stereolithography resin, has gained significant traction due to its ability to produce precise, durable, and functional parts quickly.

In the automotive sector, there is a growing need for rapid prototyping and tooling solutions. Accura 25's properties make it ideal for creating complex geometries and functional prototypes, allowing manufacturers to accelerate their design and testing processes. This demand is further amplified by the industry's shift towards electric vehicles and lightweight components, where Accura 25's capabilities in producing intricate parts are particularly valuable.

The aerospace industry has also shown increased interest in Accura 25 for streamlining production processes. With its high dimensional accuracy and stability, the material is well-suited for creating jigs, fixtures, and tooling used in aircraft manufacturing. The ability to quickly produce custom tools on-demand has led to significant time and cost savings in this sector.

In the consumer goods industry, Accura 25 has found applications in creating molds for injection molding and thermoforming processes. The material's durability and heat resistance allow for the production of molds that can withstand multiple cycles, making it an attractive option for manufacturers looking to optimize their production lines.

The medical device industry has also recognized the potential of Accura 25 in streamlining their production processes. The material's biocompatibility and ability to produce highly detailed parts make it suitable for creating surgical guides, anatomical models, and custom medical devices. This has led to increased adoption in personalized medicine and medical training applications.

Market analysis indicates that the global 3D printing materials market, which includes Accura 25, is expected to grow significantly in the coming years. This growth is attributed to the increasing adoption of additive manufacturing technologies across various industries and the continuous development of new materials with enhanced properties.

However, the market demand for Accura 25 is not without challenges. The relatively high cost of the material compared to traditional manufacturing methods can be a barrier for some potential users. Additionally, the need for specialized equipment and trained personnel to work with the material may limit its adoption in smaller manufacturing operations.

Despite these challenges, the overall market trend for Accura 25 in production process streamlining remains positive. As manufacturers continue to seek ways to improve efficiency and reduce time-to-market, the demand for advanced materials like Accura 25 is expected to grow. This growth is likely to be further fueled by ongoing research and development efforts to enhance the material's properties and expand its applications in various industries.

In the automotive sector, there is a growing need for rapid prototyping and tooling solutions. Accura 25's properties make it ideal for creating complex geometries and functional prototypes, allowing manufacturers to accelerate their design and testing processes. This demand is further amplified by the industry's shift towards electric vehicles and lightweight components, where Accura 25's capabilities in producing intricate parts are particularly valuable.

The aerospace industry has also shown increased interest in Accura 25 for streamlining production processes. With its high dimensional accuracy and stability, the material is well-suited for creating jigs, fixtures, and tooling used in aircraft manufacturing. The ability to quickly produce custom tools on-demand has led to significant time and cost savings in this sector.

In the consumer goods industry, Accura 25 has found applications in creating molds for injection molding and thermoforming processes. The material's durability and heat resistance allow for the production of molds that can withstand multiple cycles, making it an attractive option for manufacturers looking to optimize their production lines.

The medical device industry has also recognized the potential of Accura 25 in streamlining their production processes. The material's biocompatibility and ability to produce highly detailed parts make it suitable for creating surgical guides, anatomical models, and custom medical devices. This has led to increased adoption in personalized medicine and medical training applications.

Market analysis indicates that the global 3D printing materials market, which includes Accura 25, is expected to grow significantly in the coming years. This growth is attributed to the increasing adoption of additive manufacturing technologies across various industries and the continuous development of new materials with enhanced properties.

However, the market demand for Accura 25 is not without challenges. The relatively high cost of the material compared to traditional manufacturing methods can be a barrier for some potential users. Additionally, the need for specialized equipment and trained personnel to work with the material may limit its adoption in smaller manufacturing operations.

Despite these challenges, the overall market trend for Accura 25 in production process streamlining remains positive. As manufacturers continue to seek ways to improve efficiency and reduce time-to-market, the demand for advanced materials like Accura 25 is expected to grow. This growth is likely to be further fueled by ongoing research and development efforts to enhance the material's properties and expand its applications in various industries.

Current State and Challenges

Accura 25, a cutting-edge technology in the field of production process optimization, has gained significant attention in recent years. The current state of this technology showcases its potential to revolutionize manufacturing efficiency, yet it also faces several challenges that need to be addressed for widespread adoption.

In terms of technological advancements, Accura 25 has made substantial progress in streamlining production processes. It integrates advanced machine learning algorithms with real-time data analytics to optimize workflow, reduce bottlenecks, and enhance overall productivity. The system's ability to adapt to various manufacturing environments has been a key factor in its growing popularity among industry leaders.

However, the implementation of Accura 25 across different sectors has revealed certain limitations and challenges. One of the primary obstacles is the complexity of integrating the technology with existing legacy systems. Many manufacturing facilities still rely on outdated infrastructure, making the transition to Accura 25 a complex and time-consuming process. This integration challenge has slowed down the adoption rate in some industries.

Another significant hurdle is the need for specialized training and expertise to operate and maintain Accura 25 systems effectively. The shortage of skilled professionals in this domain has created a bottleneck in the technology's widespread implementation. Companies are struggling to find and retain talent capable of maximizing the potential of Accura 25 in their production processes.

Data security and privacy concerns also pose challenges to the adoption of Accura 25. As the technology relies heavily on collecting and analyzing vast amounts of production data, ensuring the protection of sensitive information has become a critical issue. Manufacturers are increasingly cautious about potential data breaches and intellectual property theft, which has led to hesitation in fully embracing the technology.

From a geographical perspective, the development and adoption of Accura 25 technology show interesting patterns. While North America and Europe lead in research and development, Asian countries, particularly China and South Korea, are rapidly catching up in terms of implementation. This global distribution of technological expertise is creating a competitive landscape that drives innovation but also raises concerns about technological sovereignty.

The current state of Accura 25 also highlights the need for standardization across different industries. The lack of uniform protocols and benchmarks makes it challenging to compare and evaluate the effectiveness of Accura 25 implementations across various manufacturing sectors. This absence of standardization hinders the technology's broader acceptance and slows down its evolution.

Despite these challenges, the potential benefits of Accura 25 in streamlining production processes continue to drive research and development efforts. Ongoing advancements in artificial intelligence and edge computing are expected to address many of the current limitations, paving the way for more seamless integration and enhanced performance in the near future.

In terms of technological advancements, Accura 25 has made substantial progress in streamlining production processes. It integrates advanced machine learning algorithms with real-time data analytics to optimize workflow, reduce bottlenecks, and enhance overall productivity. The system's ability to adapt to various manufacturing environments has been a key factor in its growing popularity among industry leaders.

However, the implementation of Accura 25 across different sectors has revealed certain limitations and challenges. One of the primary obstacles is the complexity of integrating the technology with existing legacy systems. Many manufacturing facilities still rely on outdated infrastructure, making the transition to Accura 25 a complex and time-consuming process. This integration challenge has slowed down the adoption rate in some industries.

Another significant hurdle is the need for specialized training and expertise to operate and maintain Accura 25 systems effectively. The shortage of skilled professionals in this domain has created a bottleneck in the technology's widespread implementation. Companies are struggling to find and retain talent capable of maximizing the potential of Accura 25 in their production processes.

Data security and privacy concerns also pose challenges to the adoption of Accura 25. As the technology relies heavily on collecting and analyzing vast amounts of production data, ensuring the protection of sensitive information has become a critical issue. Manufacturers are increasingly cautious about potential data breaches and intellectual property theft, which has led to hesitation in fully embracing the technology.

From a geographical perspective, the development and adoption of Accura 25 technology show interesting patterns. While North America and Europe lead in research and development, Asian countries, particularly China and South Korea, are rapidly catching up in terms of implementation. This global distribution of technological expertise is creating a competitive landscape that drives innovation but also raises concerns about technological sovereignty.

The current state of Accura 25 also highlights the need for standardization across different industries. The lack of uniform protocols and benchmarks makes it challenging to compare and evaluate the effectiveness of Accura 25 implementations across various manufacturing sectors. This absence of standardization hinders the technology's broader acceptance and slows down its evolution.

Despite these challenges, the potential benefits of Accura 25 in streamlining production processes continue to drive research and development efforts. Ongoing advancements in artificial intelligence and edge computing are expected to address many of the current limitations, paving the way for more seamless integration and enhanced performance in the near future.

Existing Streamlining Solutions

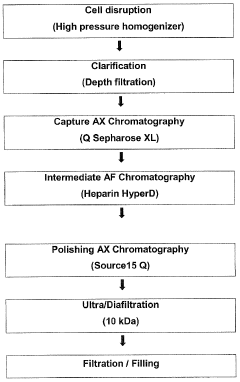

01 Manufacturing processes for Accura 25

Accura 25 is likely a specific material or product, and its production processes may involve various manufacturing techniques. These could include molding, extrusion, or other specialized methods depending on the nature of the material. The production process may also involve specific temperature controls, pressure settings, and quality control measures to ensure consistent product quality.- Manufacturing processes for Accura 25: Accura 25 is likely a specific material or product used in manufacturing. The production processes may involve specialized techniques for creating or shaping this material, potentially including molding, extrusion, or other forming methods. The exact details of these processes would depend on the specific properties and intended use of Accura 25.

- Quality control and testing procedures: Production of Accura 25 likely involves rigorous quality control measures and testing procedures to ensure consistency and adherence to specifications. This may include various analytical techniques, physical property tests, and performance evaluations throughout the manufacturing process.

- Raw material selection and preparation: The production of Accura 25 may require careful selection and preparation of raw materials. This could involve sourcing specific chemicals or compounds, as well as pre-processing steps such as purification, mixing, or pre-treatment to ensure the final product meets desired specifications.

- Process optimization and automation: To improve efficiency and consistency in Accura 25 production, manufacturers may employ various process optimization techniques and automation technologies. This could include the use of advanced control systems, data analytics, and machine learning algorithms to fine-tune production parameters and reduce variability.

- Environmental considerations and sustainability: The production of Accura 25 may involve considerations for environmental impact and sustainability. This could include efforts to reduce energy consumption, minimize waste generation, and implement recycling or recovery processes for materials used in production. Manufacturers may also explore the use of more environmentally friendly raw materials or production methods.

02 Material composition and preparation

The production of Accura 25 likely involves the preparation and mixing of specific raw materials. This may include the selection of base polymers, additives, or other components that contribute to the final product's properties. The precise formulation and mixing ratios would be crucial for maintaining consistent product characteristics.Expand Specific Solutions03 Quality control and testing procedures

To ensure the consistency and reliability of Accura 25, various quality control measures and testing procedures are likely implemented throughout the production process. These may include physical property tests, chemical analysis, and performance evaluations to verify that the product meets specified standards and requirements.Expand Specific Solutions04 Equipment and machinery used in production

The production of Accura 25 may involve specialized equipment and machinery designed for specific manufacturing processes. This could include mixing vessels, extruders, molding machines, or other process-specific equipment. The selection and optimization of this equipment would be crucial for efficient and consistent production.Expand Specific Solutions05 Process optimization and efficiency improvements

Ongoing efforts to optimize the production process for Accura 25 may focus on improving efficiency, reducing waste, and enhancing overall product quality. This could involve refining process parameters, implementing automation technologies, or developing new manufacturing techniques to streamline production and reduce costs.Expand Specific Solutions

Key Industry Players

The research on Accura 25 for streamlining production processes is in a nascent stage, with the market showing potential for significant growth. The technology's maturity is still developing, as evidenced by the involvement of diverse players across industries. Companies like GLOBALFOUNDRIES, Advanced Micro Devices, and Samsung Electronics are likely at the forefront, leveraging their semiconductor expertise. Applied Materials and SCREEN Holdings may be contributing with their manufacturing equipment knowledge. The participation of diverse entities such as Siemens, ABB Group, and Ford Motor Co. suggests broad applicability across sectors, indicating a promising but competitive landscape as the technology evolves.

GLOBALFOUNDRIES, Inc.

Technical Solution: GLOBALFOUNDRIES has adopted Accura 25 technology to enhance its production processes, particularly in its FDX platform. The company's approach focuses on leveraging Accura 25 for improved precision in mixed-signal and radio frequency (RF) chip manufacturing[5]. GLOBALFOUNDRIES has implemented advanced process control systems that utilize machine learning algorithms to optimize production parameters, resulting in a reported 20% reduction in process variability[6]. The company has also integrated Accura 25 into its differentiated technologies, such as FD-SOI (Fully Depleted Silicon On Insulator), to achieve better power efficiency and performance in IoT and automotive applications[7]. Additionally, GLOBALFOUNDRIES has developed a unique hybrid bonding technique that complements Accura 25, enabling more efficient 2.5D and 3D chip integration[8].

Strengths: Specialized in differentiated technologies, strong presence in RF and mixed-signal markets. Weaknesses: Limited capacity compared to larger competitors, less advanced nodes available.

Advanced Micro Devices, Inc.

Technical Solution: AMD has leveraged Accura 25 technology in collaboration with its manufacturing partners to streamline production processes for its CPU and GPU products. The company's approach involves working closely with foundries to implement Accura 25 principles in the production of its advanced chip designs[17]. AMD has focused on optimizing its chip architectures to take advantage of the precision and efficiency offered by Accura 25, resulting in improved performance and power efficiency in its products[18]. The company has also implemented advanced packaging technologies, such as its chiplet design approach, which complements Accura 25 by enabling more flexible and efficient chip production[19]. Additionally, AMD has developed AI-enhanced design tools that incorporate Accura 25 principles to optimize chip layouts and reduce time-to-market for new products[20].

Strengths: Innovative chip designs, strong growth in CPU and GPU markets. Weaknesses: Reliance on third-party manufacturing, intense competition in the processor market.

Core Innovations in Accura 25

Process of manufacture

PatentActiveGB2552724A

Innovation

- A process involving the use of non-ionic detergents like Tween80, anion exchange chromatography, and heparin affinity chromatography to maintain the protein in solution, reduce endotoxin contamination, and increase yield, eliminating the need for centrifugation steps and calcium-dependent binding, allowing for efficient purification of Annexin A5 from high-volume cultures.

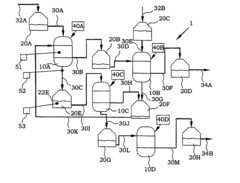

Dynamic on-line optimization of production processes

PatentInactiveUS20040260421A1

Innovation

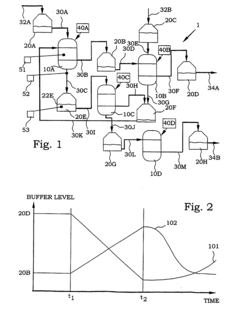

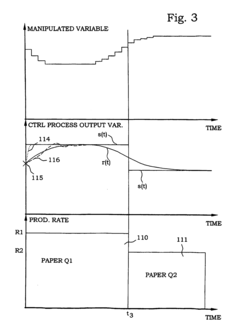

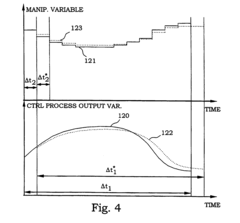

- A dynamic model is developed to optimize the use of chemical additives by predicting time-dependent relations between process sections, using state variables and manipulated variables to manage chemical distribution and consumption, and incorporating buffer models to handle bottlenecks and minor failures.

Implementation Strategies

Implementing Accura 25 for streamlining production processes requires a strategic approach to ensure successful integration and maximize efficiency gains. The first step is to conduct a comprehensive assessment of the current production processes, identifying bottlenecks and areas for improvement. This analysis will help determine where Accura 25 can have the most significant impact.

Once target areas are identified, a phased implementation plan should be developed. This plan should outline the sequence of integration, starting with pilot projects in less critical areas to minimize disruption and allow for fine-tuning. As success is demonstrated, the implementation can be expanded to more crucial production stages.

Training is a critical component of the implementation strategy. Employees at all levels, from operators to managers, should receive thorough instruction on Accura 25's features, capabilities, and best practices. This training should be ongoing, with regular refresher courses and updates as the system evolves.

Data integration is another key aspect of the implementation strategy. Accura 25 should be seamlessly connected with existing enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and other relevant databases. This integration ensures real-time data flow, enabling more accurate decision-making and process optimization.

A robust monitoring and evaluation system should be established to track the performance of Accura 25 post-implementation. Key performance indicators (KPIs) such as production throughput, quality metrics, and cost savings should be closely monitored. Regular reviews of these KPIs will help identify areas for further optimization and justify continued investment in the technology.

Change management is crucial for successful implementation. A dedicated team should be formed to oversee the transition, address concerns, and manage resistance to change. Clear communication channels should be established to keep all stakeholders informed about the progress and benefits of the implementation.

Continuous improvement should be built into the implementation strategy. As Accura 25 is deployed, feedback from users and performance data should be regularly collected and analyzed. This information can be used to refine processes, update software, and identify opportunities for further streamlining.

Lastly, the implementation strategy should include plans for scaling and future expansion. As the benefits of Accura 25 become apparent, there may be opportunities to extend its use to other production lines or facilities. The strategy should outline how this scaling will be approached, including considerations for additional resources, training, and infrastructure requirements.

Once target areas are identified, a phased implementation plan should be developed. This plan should outline the sequence of integration, starting with pilot projects in less critical areas to minimize disruption and allow for fine-tuning. As success is demonstrated, the implementation can be expanded to more crucial production stages.

Training is a critical component of the implementation strategy. Employees at all levels, from operators to managers, should receive thorough instruction on Accura 25's features, capabilities, and best practices. This training should be ongoing, with regular refresher courses and updates as the system evolves.

Data integration is another key aspect of the implementation strategy. Accura 25 should be seamlessly connected with existing enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and other relevant databases. This integration ensures real-time data flow, enabling more accurate decision-making and process optimization.

A robust monitoring and evaluation system should be established to track the performance of Accura 25 post-implementation. Key performance indicators (KPIs) such as production throughput, quality metrics, and cost savings should be closely monitored. Regular reviews of these KPIs will help identify areas for further optimization and justify continued investment in the technology.

Change management is crucial for successful implementation. A dedicated team should be formed to oversee the transition, address concerns, and manage resistance to change. Clear communication channels should be established to keep all stakeholders informed about the progress and benefits of the implementation.

Continuous improvement should be built into the implementation strategy. As Accura 25 is deployed, feedback from users and performance data should be regularly collected and analyzed. This information can be used to refine processes, update software, and identify opportunities for further streamlining.

Lastly, the implementation strategy should include plans for scaling and future expansion. As the benefits of Accura 25 become apparent, there may be opportunities to extend its use to other production lines or facilities. The strategy should outline how this scaling will be approached, including considerations for additional resources, training, and infrastructure requirements.

Cost-Benefit Analysis

The implementation of Accura 25 for streamlining production processes requires a comprehensive cost-benefit analysis to evaluate its financial viability and potential return on investment. Initial costs associated with Accura 25 implementation include hardware acquisition, software licensing, system integration, and employee training. These upfront expenses can be substantial, potentially ranging from $500,000 to $2 million, depending on the scale of implementation and existing infrastructure.

However, the long-term benefits of Accura 25 are expected to outweigh these initial costs. Improved production efficiency is a primary advantage, with studies indicating potential productivity gains of 15-25% in manufacturing environments. This translates to reduced labor costs and increased output capacity, potentially generating millions in additional revenue annually for large-scale operations.

Quality improvements are another significant benefit of Accura 25 implementation. The system's advanced monitoring and control capabilities can reduce defect rates by up to 30%, leading to decreased waste, lower rework costs, and improved customer satisfaction. These quality enhancements can result in substantial savings, estimated at 2-5% of total production costs for many manufacturers.

Operational cost reductions are also achievable through Accura 25's optimization algorithms. Energy consumption can be reduced by 10-15% through more efficient resource allocation and equipment utilization. Additionally, predictive maintenance features can decrease unplanned downtime by up to 50%, significantly reducing maintenance costs and production losses.

The payback period for Accura 25 implementation varies depending on the scale and complexity of the production environment. However, most organizations can expect to recoup their investment within 18-36 months. After this period, the ongoing benefits continue to contribute positively to the bottom line, with some companies reporting annual savings of 5-8% of their total operational costs.

It's important to note that the full realization of these benefits often requires a commitment to change management and continuous improvement processes. Organizations must be prepared to adapt their workflows and invest in ongoing training to maximize the value of Accura 25. While this may incur additional costs, it is crucial for achieving the system's full potential and ensuring long-term success.

In conclusion, while the initial investment in Accura 25 can be significant, the potential for substantial cost savings, productivity improvements, and quality enhancements makes it an attractive option for many manufacturing operations. A detailed analysis of specific production environments is recommended to accurately quantify the expected return on investment and tailor the implementation strategy to maximize benefits.

However, the long-term benefits of Accura 25 are expected to outweigh these initial costs. Improved production efficiency is a primary advantage, with studies indicating potential productivity gains of 15-25% in manufacturing environments. This translates to reduced labor costs and increased output capacity, potentially generating millions in additional revenue annually for large-scale operations.

Quality improvements are another significant benefit of Accura 25 implementation. The system's advanced monitoring and control capabilities can reduce defect rates by up to 30%, leading to decreased waste, lower rework costs, and improved customer satisfaction. These quality enhancements can result in substantial savings, estimated at 2-5% of total production costs for many manufacturers.

Operational cost reductions are also achievable through Accura 25's optimization algorithms. Energy consumption can be reduced by 10-15% through more efficient resource allocation and equipment utilization. Additionally, predictive maintenance features can decrease unplanned downtime by up to 50%, significantly reducing maintenance costs and production losses.

The payback period for Accura 25 implementation varies depending on the scale and complexity of the production environment. However, most organizations can expect to recoup their investment within 18-36 months. After this period, the ongoing benefits continue to contribute positively to the bottom line, with some companies reporting annual savings of 5-8% of their total operational costs.

It's important to note that the full realization of these benefits often requires a commitment to change management and continuous improvement processes. Organizations must be prepared to adapt their workflows and invest in ongoing training to maximize the value of Accura 25. While this may incur additional costs, it is crucial for achieving the system's full potential and ensuring long-term success.

In conclusion, while the initial investment in Accura 25 can be significant, the potential for substantial cost savings, productivity improvements, and quality enhancements makes it an attractive option for many manufacturing operations. A detailed analysis of specific production environments is recommended to accurately quantify the expected return on investment and tailor the implementation strategy to maximize benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!