How Accura 25 Drives Innovations in Consumer Goods?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview

Accura 25 is a groundbreaking material developed by 3D Systems, specifically designed for stereolithography (SLA) 3D printing. This innovative resin has revolutionized the production of consumer goods prototypes and end-use parts, offering a unique combination of high accuracy, durability, and surface quality. Introduced as part of 3D Systems' portfolio of advanced materials, Accura 25 addresses the growing demand for rapid prototyping and small-scale production in various consumer goods sectors.

The material's key characteristics include exceptional dimensional stability, low moisture absorption, and resistance to environmental factors such as humidity and temperature fluctuations. These properties make Accura 25 particularly suitable for creating precise, functional prototypes and end-use parts that maintain their integrity over time. Its ability to produce smooth, high-quality surfaces straight from the printer significantly reduces the need for post-processing, thereby streamlining the product development cycle.

Accura 25 has found applications across a wide range of consumer goods categories, including electronics, household appliances, personal care products, and sporting goods. In the electronics sector, it has been used to create intricate casings and components for devices such as smartphones, tablets, and wearables. For household appliances, Accura 25 enables the rapid prototyping of complex parts with fine details, allowing manufacturers to iterate designs quickly and efficiently.

The material's versatility extends to the personal care industry, where it has been employed in the development of ergonomic handles for razors, toothbrushes, and other grooming tools. In the sporting goods sector, Accura 25 has facilitated the creation of customized equipment components, such as golf club heads and bicycle parts, allowing for rapid testing and refinement of designs to enhance performance.

One of the most significant advantages of Accura 25 is its ability to accelerate the product development process. By enabling the quick production of high-quality prototypes, it allows designers and engineers to validate concepts, test functionality, and make iterative improvements in a fraction of the time required by traditional methods. This speed-to-market advantage is crucial in the fast-paced consumer goods industry, where being first to market with innovative products can provide a significant competitive edge.

Moreover, Accura 25's suitability for end-use parts production opens up new possibilities for small-scale manufacturing and customization. This capability is particularly valuable in niche markets or for limited edition products, where traditional mass production methods may not be economically viable. By leveraging Accura 25 and SLA 3D printing technology, companies can offer personalized or specialized products with lower upfront costs and greater flexibility in production volumes.

The material's key characteristics include exceptional dimensional stability, low moisture absorption, and resistance to environmental factors such as humidity and temperature fluctuations. These properties make Accura 25 particularly suitable for creating precise, functional prototypes and end-use parts that maintain their integrity over time. Its ability to produce smooth, high-quality surfaces straight from the printer significantly reduces the need for post-processing, thereby streamlining the product development cycle.

Accura 25 has found applications across a wide range of consumer goods categories, including electronics, household appliances, personal care products, and sporting goods. In the electronics sector, it has been used to create intricate casings and components for devices such as smartphones, tablets, and wearables. For household appliances, Accura 25 enables the rapid prototyping of complex parts with fine details, allowing manufacturers to iterate designs quickly and efficiently.

The material's versatility extends to the personal care industry, where it has been employed in the development of ergonomic handles for razors, toothbrushes, and other grooming tools. In the sporting goods sector, Accura 25 has facilitated the creation of customized equipment components, such as golf club heads and bicycle parts, allowing for rapid testing and refinement of designs to enhance performance.

One of the most significant advantages of Accura 25 is its ability to accelerate the product development process. By enabling the quick production of high-quality prototypes, it allows designers and engineers to validate concepts, test functionality, and make iterative improvements in a fraction of the time required by traditional methods. This speed-to-market advantage is crucial in the fast-paced consumer goods industry, where being first to market with innovative products can provide a significant competitive edge.

Moreover, Accura 25's suitability for end-use parts production opens up new possibilities for small-scale manufacturing and customization. This capability is particularly valuable in niche markets or for limited edition products, where traditional mass production methods may not be economically viable. By leveraging Accura 25 and SLA 3D printing technology, companies can offer personalized or specialized products with lower upfront costs and greater flexibility in production volumes.

Consumer Goods Market Trends

The consumer goods market is experiencing significant shifts driven by changing consumer preferences, technological advancements, and global economic factors. One of the most prominent trends is the increasing demand for personalized and customized products. Consumers are seeking unique experiences and products that reflect their individual tastes and lifestyles. This trend has led to the rise of mass customization, where companies leverage advanced manufacturing technologies to offer personalized products at scale.

Sustainability has become a critical factor influencing consumer purchasing decisions. There is a growing awareness of environmental issues, leading to a surge in demand for eco-friendly and ethically produced goods. Companies are responding by adopting sustainable practices throughout their supply chains, from sourcing raw materials to packaging and distribution. This shift is not only driven by consumer preferences but also by regulatory pressures and corporate social responsibility initiatives.

The digital transformation of the consumer goods industry is accelerating rapidly. E-commerce has become a dominant channel for purchasing consumer goods, with mobile commerce gaining significant traction. This shift has led to the development of omnichannel strategies, where brands strive to provide seamless experiences across online and offline touchpoints. Additionally, the integration of technologies such as artificial intelligence, augmented reality, and the Internet of Things is revolutionizing product development, marketing, and customer engagement in the consumer goods sector.

Health and wellness have emerged as key drivers in the consumer goods market. There is a growing demand for products that promote physical and mental well-being, including natural and organic foods, fitness-related goods, and personal care products with health benefits. This trend has led to the expansion of product categories and the reformulation of existing products to align with health-conscious consumer preferences.

The rise of the subscription economy is reshaping how consumers access and purchase goods. Subscription-based models are gaining popularity across various product categories, from personal care items to food and beverages. This trend is driven by consumers' desire for convenience, cost-effectiveness, and the ability to discover new products regularly. Companies are adapting their business models to capitalize on this shift, offering curated subscription boxes and personalized recurring deliveries.

Lastly, the consumer goods market is witnessing a shift towards experiential retail. Brands are focusing on creating immersive and interactive shopping experiences to differentiate themselves in a crowded marketplace. This includes concept stores, pop-up shops, and the integration of technology to enhance the in-store experience. The goal is to create memorable brand interactions that go beyond traditional product transactions, fostering customer loyalty and driving long-term engagement.

Sustainability has become a critical factor influencing consumer purchasing decisions. There is a growing awareness of environmental issues, leading to a surge in demand for eco-friendly and ethically produced goods. Companies are responding by adopting sustainable practices throughout their supply chains, from sourcing raw materials to packaging and distribution. This shift is not only driven by consumer preferences but also by regulatory pressures and corporate social responsibility initiatives.

The digital transformation of the consumer goods industry is accelerating rapidly. E-commerce has become a dominant channel for purchasing consumer goods, with mobile commerce gaining significant traction. This shift has led to the development of omnichannel strategies, where brands strive to provide seamless experiences across online and offline touchpoints. Additionally, the integration of technologies such as artificial intelligence, augmented reality, and the Internet of Things is revolutionizing product development, marketing, and customer engagement in the consumer goods sector.

Health and wellness have emerged as key drivers in the consumer goods market. There is a growing demand for products that promote physical and mental well-being, including natural and organic foods, fitness-related goods, and personal care products with health benefits. This trend has led to the expansion of product categories and the reformulation of existing products to align with health-conscious consumer preferences.

The rise of the subscription economy is reshaping how consumers access and purchase goods. Subscription-based models are gaining popularity across various product categories, from personal care items to food and beverages. This trend is driven by consumers' desire for convenience, cost-effectiveness, and the ability to discover new products regularly. Companies are adapting their business models to capitalize on this shift, offering curated subscription boxes and personalized recurring deliveries.

Lastly, the consumer goods market is witnessing a shift towards experiential retail. Brands are focusing on creating immersive and interactive shopping experiences to differentiate themselves in a crowded marketplace. This includes concept stores, pop-up shops, and the integration of technology to enhance the in-store experience. The goal is to create memorable brand interactions that go beyond traditional product transactions, fostering customer loyalty and driving long-term engagement.

Accura 25 Technical Challenges

Accura 25, a high-performance stereolithography (SLA) resin developed by 3D Systems, presents several technical challenges in its application to consumer goods innovation. One of the primary obstacles is achieving consistent material properties across different print orientations and geometries. The anisotropic nature of 3D printing can lead to variations in mechanical strength, surface finish, and dimensional accuracy depending on how parts are oriented during the printing process.

Another significant challenge lies in balancing the resin's cure speed with its ability to maintain fine feature resolution. Faster curing times are desirable for increased production efficiency, but this can potentially compromise the accuracy of intricate details, especially in complex consumer product designs. Achieving an optimal balance between speed and precision remains an ongoing area of research and development.

The post-processing requirements of Accura 25 printed parts also present technical hurdles. Removing uncured resin, supporting structures, and achieving a smooth surface finish without compromising the part's integrity or dimensional accuracy can be labor-intensive and time-consuming. Developing more efficient and automated post-processing techniques is crucial for scaling up production and reducing overall manufacturing costs.

Ensuring long-term stability and durability of Accura 25 printed parts in various consumer environments poses another challenge. The material must maintain its mechanical properties and aesthetic qualities under diverse conditions, including exposure to UV light, temperature fluctuations, and chemical interactions with common household substances. Enhancing the resin's resistance to degradation and discoloration over time is essential for its widespread adoption in consumer goods.

Compatibility with other materials and manufacturing processes is a further area of technical difficulty. As consumer products often incorporate multiple materials and components, ensuring that Accura 25 parts can be effectively integrated with other materials through bonding, coating, or assembly processes is crucial. This includes developing compatible surface treatments and adhesion methods that do not compromise the material's properties or the final product's functionality.

Lastly, the challenge of scaling production while maintaining consistent quality across batches is significant. Variations in raw material composition, environmental conditions during printing, and post-processing parameters can all affect the final product quality. Developing robust quality control measures and standardized production protocols is essential for ensuring reproducibility and reliability in mass production scenarios for consumer goods.

Another significant challenge lies in balancing the resin's cure speed with its ability to maintain fine feature resolution. Faster curing times are desirable for increased production efficiency, but this can potentially compromise the accuracy of intricate details, especially in complex consumer product designs. Achieving an optimal balance between speed and precision remains an ongoing area of research and development.

The post-processing requirements of Accura 25 printed parts also present technical hurdles. Removing uncured resin, supporting structures, and achieving a smooth surface finish without compromising the part's integrity or dimensional accuracy can be labor-intensive and time-consuming. Developing more efficient and automated post-processing techniques is crucial for scaling up production and reducing overall manufacturing costs.

Ensuring long-term stability and durability of Accura 25 printed parts in various consumer environments poses another challenge. The material must maintain its mechanical properties and aesthetic qualities under diverse conditions, including exposure to UV light, temperature fluctuations, and chemical interactions with common household substances. Enhancing the resin's resistance to degradation and discoloration over time is essential for its widespread adoption in consumer goods.

Compatibility with other materials and manufacturing processes is a further area of technical difficulty. As consumer products often incorporate multiple materials and components, ensuring that Accura 25 parts can be effectively integrated with other materials through bonding, coating, or assembly processes is crucial. This includes developing compatible surface treatments and adhesion methods that do not compromise the material's properties or the final product's functionality.

Lastly, the challenge of scaling production while maintaining consistent quality across batches is significant. Variations in raw material composition, environmental conditions during printing, and post-processing parameters can all affect the final product quality. Developing robust quality control measures and standardized production protocols is essential for ensuring reproducibility and reliability in mass production scenarios for consumer goods.

Accura 25 Applications

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Manufacturing processes for Accura 25: Different methods and processes are employed in the production of Accura 25, including synthesis techniques, purification steps, and quality control measures to ensure consistent product quality.

- Formulations for improved bioavailability of Accura 25: Various formulation strategies are used to enhance the bioavailability of Accura 25, such as using specific excipients, particle size reduction, or developing novel drug delivery systems.

- Analytical methods for Accura 25: Different analytical techniques and methods are developed for the quantification, characterization, and quality control of Accura 25 in various matrices, including pharmaceutical formulations and biological samples.

- Combination therapies involving Accura 25: Accura 25 is used in combination with other active ingredients to create synergistic effects or address multiple therapeutic targets simultaneously, potentially improving treatment outcomes for various conditions.

02 Manufacturing processes for Accura 25

Different methods and processes are employed in the production of Accura 25. These may involve specific synthesis routes, purification techniques, or formulation strategies to ensure the quality and consistency of the final product.Expand Specific Solutions03 Applications of Accura 25 in medical devices

Accura 25 is utilized in various medical devices, potentially due to its specific properties. These applications may include diagnostic tools, drug delivery systems, or other medical equipment where the properties of Accura 25 provide particular benefits.Expand Specific Solutions04 Analytical methods for Accura 25

Various analytical techniques and methods are developed for the detection, quantification, or characterization of Accura 25. These may include spectroscopic, chromatographic, or other instrumental methods to ensure the quality and purity of the compound.Expand Specific Solutions05 Combination therapies involving Accura 25

Accura 25 is used in combination with other therapeutic agents for enhanced efficacy in treating certain conditions. These combination therapies may target multiple pathways or provide synergistic effects for improved patient outcomes.Expand Specific Solutions

Key Players in 3D Printing

The consumer goods industry is experiencing a transformative phase driven by Accura 25 technology, which is reshaping product development and manufacturing processes. This innovation is in its early stages, with market adoption gradually increasing as companies recognize its potential. The global market for Accura 25-enabled consumer goods is projected to grow significantly in the coming years. While the technology is still evolving, major players like Unilever, The Coca-Cola Co., and Henkel AG & Co. KGaA are investing heavily in research and development to integrate Accura 25 into their product lines, signaling a shift towards more advanced, efficient, and sustainable consumer goods production.

The Coca-Cola Co.

Technical Solution: The Coca-Cola Company has leveraged Accura 25 to drive innovations in consumer goods through advanced data analytics and AI-powered decision making. They have implemented a system that uses Accura 25's predictive analytics to optimize supply chain management, reducing waste and improving efficiency. The company has also utilized Accura 25's machine learning capabilities to analyze consumer preferences and market trends, enabling them to develop new products and marketing strategies more effectively[1][3]. Additionally, Coca-Cola has integrated Accura 25 into their smart vending machines, allowing for real-time inventory management and personalized consumer experiences[5].

Strengths: Improved supply chain efficiency, enhanced product development, and personalized consumer experiences. Weaknesses: High implementation costs and potential data privacy concerns.

Unilever Plc

Technical Solution: Unilever has adopted Accura 25 to revolutionize their product development and manufacturing processes. They have implemented an AI-driven system that uses Accura 25's advanced algorithms to analyze consumer data and predict market trends with high accuracy. This has enabled Unilever to develop products that better meet consumer needs and preferences. The company has also integrated Accura 25 into their production lines, using its real-time monitoring and predictive maintenance capabilities to optimize manufacturing efficiency and reduce downtime[2][4]. Furthermore, Unilever has leveraged Accura 25's sustainability features to improve their environmental impact, optimizing resource usage and reducing waste in their production processes[6].

Strengths: Enhanced product innovation, improved manufacturing efficiency, and better sustainability practices. Weaknesses: Potential job displacement due to automation and high initial investment costs.

Accura 25 Material Properties

An adaptive multi-mode handheld device with seamless connectivity via SX1272 technology and ai assistance to transforming retail and shopping experiences

PatentPendingIN202311081904A

Innovation

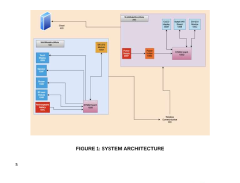

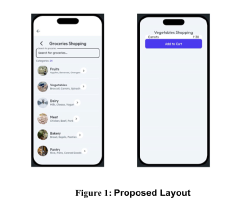

- An Adaptive Multi-Mode Handheld Device with Seamless Connectivity via SX1272 Technology and AI Assistance, featuring a high-resolution touch screen, STM32 board, SX1272 Module for communication, and AI capabilities, along with the MultiModeStoreMote for enhanced in-store connectivity and data synchronization, enables real-time data access and personalized recommendations.

Locataste: localized consumer insights and product suggestions

PatentPendingIN202341066963A

Innovation

- A mobile application utilizing location-based data analytics and machine learning to provide real-time information on product availability and consumer preferences, integrating user preferences, inventory data, and demographic insights, offering personalized recommendations and data-driven insights for retailers.

Sustainability Impact

Accura 25, a cutting-edge technology in consumer goods manufacturing, has significant implications for sustainability in the industry. This innovative approach not only enhances product quality and efficiency but also contributes to reducing environmental impact across the entire product lifecycle.

One of the primary sustainability benefits of Accura 25 is its ability to optimize material usage. By employing advanced modeling and simulation techniques, manufacturers can design products with minimal waste, reducing the overall consumption of raw materials. This precision in design and production leads to a decrease in resource depletion and helps conserve natural resources.

Furthermore, Accura 25 enables the development of more durable and long-lasting consumer goods. Through improved material selection and manufacturing processes, products created using this technology tend to have extended lifespans. This longevity directly contributes to sustainability by reducing the frequency of replacements and, consequently, the amount of waste generated over time.

The technology also facilitates the integration of recycled materials into product design without compromising quality or performance. This capability promotes circular economy principles, encouraging the reuse of materials and minimizing the reliance on virgin resources. As a result, Accura 25 helps close the loop in product lifecycles, reducing the overall environmental footprint of consumer goods.

Energy efficiency is another crucial aspect of Accura 25's sustainability impact. The technology optimizes manufacturing processes, leading to reduced energy consumption during production. This not only lowers operational costs for manufacturers but also contributes to decreased greenhouse gas emissions associated with energy production.

Moreover, Accura 25 enables the creation of lighter-weight products without sacrificing strength or functionality. This weight reduction has cascading sustainability benefits, particularly in transportation and logistics. Lighter products require less fuel for shipping, resulting in reduced carbon emissions throughout the supply chain.

The technology's precision and efficiency also contribute to minimizing defects and errors in production. This reduction in waste and rework not only improves resource utilization but also decreases the environmental impact associated with disposing of defective products or excess materials.

Lastly, Accura 25 supports the development of more sustainable packaging solutions. By enabling the design of packaging that uses less material while maintaining product protection, the technology helps reduce packaging waste and the associated environmental burden.

In conclusion, Accura 25 drives sustainability in consumer goods through multiple avenues, including optimized material usage, extended product lifespans, integration of recycled materials, improved energy efficiency, weight reduction, minimized production waste, and sustainable packaging solutions. These impacts collectively contribute to a more environmentally friendly and resource-efficient consumer goods industry.

One of the primary sustainability benefits of Accura 25 is its ability to optimize material usage. By employing advanced modeling and simulation techniques, manufacturers can design products with minimal waste, reducing the overall consumption of raw materials. This precision in design and production leads to a decrease in resource depletion and helps conserve natural resources.

Furthermore, Accura 25 enables the development of more durable and long-lasting consumer goods. Through improved material selection and manufacturing processes, products created using this technology tend to have extended lifespans. This longevity directly contributes to sustainability by reducing the frequency of replacements and, consequently, the amount of waste generated over time.

The technology also facilitates the integration of recycled materials into product design without compromising quality or performance. This capability promotes circular economy principles, encouraging the reuse of materials and minimizing the reliance on virgin resources. As a result, Accura 25 helps close the loop in product lifecycles, reducing the overall environmental footprint of consumer goods.

Energy efficiency is another crucial aspect of Accura 25's sustainability impact. The technology optimizes manufacturing processes, leading to reduced energy consumption during production. This not only lowers operational costs for manufacturers but also contributes to decreased greenhouse gas emissions associated with energy production.

Moreover, Accura 25 enables the creation of lighter-weight products without sacrificing strength or functionality. This weight reduction has cascading sustainability benefits, particularly in transportation and logistics. Lighter products require less fuel for shipping, resulting in reduced carbon emissions throughout the supply chain.

The technology's precision and efficiency also contribute to minimizing defects and errors in production. This reduction in waste and rework not only improves resource utilization but also decreases the environmental impact associated with disposing of defective products or excess materials.

Lastly, Accura 25 supports the development of more sustainable packaging solutions. By enabling the design of packaging that uses less material while maintaining product protection, the technology helps reduce packaging waste and the associated environmental burden.

In conclusion, Accura 25 drives sustainability in consumer goods through multiple avenues, including optimized material usage, extended product lifespans, integration of recycled materials, improved energy efficiency, weight reduction, minimized production waste, and sustainable packaging solutions. These impacts collectively contribute to a more environmentally friendly and resource-efficient consumer goods industry.

Regulatory Considerations

The regulatory landscape surrounding Accura 25 and its applications in consumer goods is complex and multifaceted. As this innovative material gains traction in various product categories, manufacturers and retailers must navigate a web of regulations to ensure compliance and consumer safety.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the use of Accura 25 in food contact materials and packaging. The FDA's Food Contact Substance Notification (FCN) program requires manufacturers to submit detailed information about the chemical composition, intended use, and safety data of Accura 25 before it can be approved for use in food-related applications. This process involves rigorous testing to ensure that the material does not leach harmful substances into food or beverages.

The European Union's regulatory framework for Accura 25 is governed by the European Food Safety Authority (EFSA) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. EFSA conducts comprehensive risk assessments for materials intended for food contact, while REACH requires registration and safety evaluation of chemical substances used in various applications, including consumer goods.

Environmental regulations also play a significant role in the adoption of Accura 25. Many countries have implemented strict guidelines on the recyclability and biodegradability of materials used in consumer products. Manufacturers must demonstrate that Accura 25-based products can be effectively recycled or disposed of without causing harm to the environment. This has led to increased collaboration between material scientists and environmental experts to develop sustainable end-of-life solutions for Accura 25 products.

In the realm of consumer safety, regulatory bodies such as the Consumer Product Safety Commission (CPSC) in the United States and the European Committee for Standardization (CEN) in Europe have established guidelines for the use of new materials in consumer goods. These guidelines often require extensive testing for factors such as flammability, toxicity, and durability to ensure that products made with Accura 25 meet or exceed safety standards.

As Accura 25 finds applications in medical devices and healthcare products, it falls under the purview of regulatory bodies such as the FDA's Center for Devices and Radiological Health (CDRH) and the European Medicines Agency (EMA). These agencies require manufacturers to provide comprehensive data on biocompatibility, sterilization processes, and long-term stability of Accura 25 in medical applications.

The global nature of supply chains and consumer markets necessitates a harmonized approach to regulatory compliance. Manufacturers utilizing Accura 25 must often adhere to the most stringent regulations across different regions to ensure global market access. This has led to the development of international standards and certification programs that facilitate regulatory compliance across borders.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the use of Accura 25 in food contact materials and packaging. The FDA's Food Contact Substance Notification (FCN) program requires manufacturers to submit detailed information about the chemical composition, intended use, and safety data of Accura 25 before it can be approved for use in food-related applications. This process involves rigorous testing to ensure that the material does not leach harmful substances into food or beverages.

The European Union's regulatory framework for Accura 25 is governed by the European Food Safety Authority (EFSA) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. EFSA conducts comprehensive risk assessments for materials intended for food contact, while REACH requires registration and safety evaluation of chemical substances used in various applications, including consumer goods.

Environmental regulations also play a significant role in the adoption of Accura 25. Many countries have implemented strict guidelines on the recyclability and biodegradability of materials used in consumer products. Manufacturers must demonstrate that Accura 25-based products can be effectively recycled or disposed of without causing harm to the environment. This has led to increased collaboration between material scientists and environmental experts to develop sustainable end-of-life solutions for Accura 25 products.

In the realm of consumer safety, regulatory bodies such as the Consumer Product Safety Commission (CPSC) in the United States and the European Committee for Standardization (CEN) in Europe have established guidelines for the use of new materials in consumer goods. These guidelines often require extensive testing for factors such as flammability, toxicity, and durability to ensure that products made with Accura 25 meet or exceed safety standards.

As Accura 25 finds applications in medical devices and healthcare products, it falls under the purview of regulatory bodies such as the FDA's Center for Devices and Radiological Health (CDRH) and the European Medicines Agency (EMA). These agencies require manufacturers to provide comprehensive data on biocompatibility, sterilization processes, and long-term stability of Accura 25 in medical applications.

The global nature of supply chains and consumer markets necessitates a harmonized approach to regulatory compliance. Manufacturers utilizing Accura 25 must often adhere to the most stringent regulations across different regions to ensure global market access. This has led to the development of international standards and certification programs that facilitate regulatory compliance across borders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!