Maximizing Efficiency with Accura 25 in Manufacturing

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Technology Overview and Objectives

Accura 25 is a cutting-edge manufacturing technology that has revolutionized the production landscape in recent years. This advanced system integrates precision engineering, smart automation, and data-driven optimization to enhance manufacturing efficiency and product quality. The evolution of Accura 25 can be traced back to the early 2000s when manufacturers began seeking more sophisticated solutions to address the increasing complexity of production processes and the growing demand for customization.

The primary objective of Accura 25 is to maximize efficiency in manufacturing operations by minimizing waste, reducing production time, and improving overall product quality. This technology aims to streamline production workflows, optimize resource allocation, and enhance decision-making through real-time data analysis and predictive maintenance capabilities.

One of the key features of Accura 25 is its ability to integrate seamlessly with existing manufacturing systems, allowing for a gradual transition and minimizing disruption to ongoing operations. This adaptability has made it an attractive option for both small-scale manufacturers and large industrial enterprises looking to upgrade their production capabilities.

The technology leverages advanced sensors, machine learning algorithms, and Internet of Things (IoT) connectivity to create a highly responsive and adaptive manufacturing environment. By continuously monitoring and analyzing production data, Accura 25 can identify bottlenecks, predict equipment failures, and suggest optimizations in real-time, leading to significant improvements in overall equipment effectiveness (OEE).

As the manufacturing industry continues to evolve towards Industry 4.0 standards, Accura 25 is positioned at the forefront of this transformation. Its development is driven by the growing need for agile and flexible production systems that can quickly adapt to changing market demands and consumer preferences. The technology's focus on data-driven decision-making and automation aligns with the broader trend of digital transformation in manufacturing.

Looking ahead, the future development of Accura 25 is expected to focus on further enhancing its artificial intelligence capabilities, improving energy efficiency, and expanding its integration with emerging technologies such as augmented reality for maintenance and training purposes. These advancements aim to push the boundaries of manufacturing efficiency and set new standards for productivity in the industry.

The primary objective of Accura 25 is to maximize efficiency in manufacturing operations by minimizing waste, reducing production time, and improving overall product quality. This technology aims to streamline production workflows, optimize resource allocation, and enhance decision-making through real-time data analysis and predictive maintenance capabilities.

One of the key features of Accura 25 is its ability to integrate seamlessly with existing manufacturing systems, allowing for a gradual transition and minimizing disruption to ongoing operations. This adaptability has made it an attractive option for both small-scale manufacturers and large industrial enterprises looking to upgrade their production capabilities.

The technology leverages advanced sensors, machine learning algorithms, and Internet of Things (IoT) connectivity to create a highly responsive and adaptive manufacturing environment. By continuously monitoring and analyzing production data, Accura 25 can identify bottlenecks, predict equipment failures, and suggest optimizations in real-time, leading to significant improvements in overall equipment effectiveness (OEE).

As the manufacturing industry continues to evolve towards Industry 4.0 standards, Accura 25 is positioned at the forefront of this transformation. Its development is driven by the growing need for agile and flexible production systems that can quickly adapt to changing market demands and consumer preferences. The technology's focus on data-driven decision-making and automation aligns with the broader trend of digital transformation in manufacturing.

Looking ahead, the future development of Accura 25 is expected to focus on further enhancing its artificial intelligence capabilities, improving energy efficiency, and expanding its integration with emerging technologies such as augmented reality for maintenance and training purposes. These advancements aim to push the boundaries of manufacturing efficiency and set new standards for productivity in the industry.

Manufacturing Efficiency Market Analysis

The manufacturing efficiency market has experienced significant growth in recent years, driven by the increasing demand for cost-effective production processes and the adoption of advanced technologies. The global market for manufacturing efficiency solutions is projected to reach $355 billion by 2025, with a compound annual growth rate (CAGR) of 7.2% from 2020 to 2025. This growth is primarily attributed to the rising need for optimized production processes, reduced operational costs, and improved product quality across various industries.

The Accura 25 technology, specifically designed to enhance manufacturing efficiency, is poised to capture a substantial share of this expanding market. Its potential applications span across multiple sectors, including automotive, aerospace, electronics, and consumer goods manufacturing. The automotive industry, in particular, is expected to be a key driver for the adoption of Accura 25, as manufacturers seek to streamline their production lines and reduce time-to-market for new vehicle models.

Market trends indicate a growing preference for integrated efficiency solutions that combine hardware, software, and data analytics capabilities. Accura 25's comprehensive approach to manufacturing optimization aligns well with this trend, positioning it favorably in the competitive landscape. Additionally, the increasing focus on sustainability and energy efficiency in manufacturing processes is creating new opportunities for technologies like Accura 25 that can help reduce waste and energy consumption.

Geographically, North America and Europe currently dominate the manufacturing efficiency market, accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and government initiatives to promote smart manufacturing in countries like China and India.

The COVID-19 pandemic has further accelerated the adoption of efficiency-enhancing technologies in manufacturing, as companies seek to maintain productivity while adhering to social distancing guidelines and addressing supply chain disruptions. This has created a favorable environment for solutions like Accura 25 that can enable remote monitoring and control of manufacturing processes.

Key market challenges include the high initial investment required for implementing advanced manufacturing efficiency solutions and the need for skilled personnel to operate and maintain these systems. However, the long-term benefits of increased productivity, reduced operational costs, and improved product quality are expected to outweigh these challenges, driving continued market growth and adoption of technologies like Accura 25 in the manufacturing sector.

The Accura 25 technology, specifically designed to enhance manufacturing efficiency, is poised to capture a substantial share of this expanding market. Its potential applications span across multiple sectors, including automotive, aerospace, electronics, and consumer goods manufacturing. The automotive industry, in particular, is expected to be a key driver for the adoption of Accura 25, as manufacturers seek to streamline their production lines and reduce time-to-market for new vehicle models.

Market trends indicate a growing preference for integrated efficiency solutions that combine hardware, software, and data analytics capabilities. Accura 25's comprehensive approach to manufacturing optimization aligns well with this trend, positioning it favorably in the competitive landscape. Additionally, the increasing focus on sustainability and energy efficiency in manufacturing processes is creating new opportunities for technologies like Accura 25 that can help reduce waste and energy consumption.

Geographically, North America and Europe currently dominate the manufacturing efficiency market, accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and government initiatives to promote smart manufacturing in countries like China and India.

The COVID-19 pandemic has further accelerated the adoption of efficiency-enhancing technologies in manufacturing, as companies seek to maintain productivity while adhering to social distancing guidelines and addressing supply chain disruptions. This has created a favorable environment for solutions like Accura 25 that can enable remote monitoring and control of manufacturing processes.

Key market challenges include the high initial investment required for implementing advanced manufacturing efficiency solutions and the need for skilled personnel to operate and maintain these systems. However, the long-term benefits of increased productivity, reduced operational costs, and improved product quality are expected to outweigh these challenges, driving continued market growth and adoption of technologies like Accura 25 in the manufacturing sector.

Accura 25 Current Capabilities and Limitations

Accura 25, a stereolithography (SLA) resin developed by 3D Systems, has established itself as a versatile material in the manufacturing industry. Its current capabilities encompass a wide range of applications, particularly in the production of functional prototypes, master patterns for urethane and silicone molding, and investment casting patterns. The material exhibits excellent dimensional stability, high stiffness, and low viscosity, making it suitable for creating parts with intricate details and smooth surface finishes.

In terms of mechanical properties, Accura 25 demonstrates impressive tensile strength, typically ranging from 52 to 68 MPa, depending on the post-curing process. Its flexural modulus falls between 2,690 and 3,100 MPa, providing sufficient rigidity for various industrial applications. The material also boasts a heat deflection temperature of approximately 62°C at 0.45 MPa, allowing it to maintain its structural integrity under moderate thermal stress.

One of the key advantages of Accura 25 is its compatibility with a wide range of 3D printing systems, including the ProX and ProJet series from 3D Systems. This compatibility ensures that manufacturers can leverage existing equipment to maximize efficiency when working with this material. Additionally, Accura 25 offers relatively quick build speeds and minimal post-processing requirements, contributing to reduced production times and overall manufacturing efficiency.

However, Accura 25 is not without limitations. While it performs well in many applications, it may not be suitable for high-temperature environments or applications requiring extreme durability. The material's heat deflection temperature, while adequate for many uses, can be a limiting factor in scenarios involving prolonged exposure to elevated temperatures.

Another consideration is the material's sensitivity to UV light and moisture. Prolonged exposure to these elements can lead to degradation of mechanical properties and discoloration over time. This necessitates careful storage and handling practices to maintain the material's integrity throughout the manufacturing process and the lifecycle of the produced parts.

In terms of surface finish, while Accura 25 can achieve smooth surfaces, it may require additional post-processing steps such as sanding or polishing to achieve the highest quality finishes for certain applications. This additional processing can impact overall production time and cost.

Lastly, while Accura 25 offers good dimensional stability, it may experience some shrinkage during the curing process. This shrinkage, typically around 0.3-0.6%, needs to be accounted for in the design phase to ensure final parts meet the required specifications. Careful calibration and compensation strategies are necessary to mitigate this effect and maintain high precision in the manufactured components.

In terms of mechanical properties, Accura 25 demonstrates impressive tensile strength, typically ranging from 52 to 68 MPa, depending on the post-curing process. Its flexural modulus falls between 2,690 and 3,100 MPa, providing sufficient rigidity for various industrial applications. The material also boasts a heat deflection temperature of approximately 62°C at 0.45 MPa, allowing it to maintain its structural integrity under moderate thermal stress.

One of the key advantages of Accura 25 is its compatibility with a wide range of 3D printing systems, including the ProX and ProJet series from 3D Systems. This compatibility ensures that manufacturers can leverage existing equipment to maximize efficiency when working with this material. Additionally, Accura 25 offers relatively quick build speeds and minimal post-processing requirements, contributing to reduced production times and overall manufacturing efficiency.

However, Accura 25 is not without limitations. While it performs well in many applications, it may not be suitable for high-temperature environments or applications requiring extreme durability. The material's heat deflection temperature, while adequate for many uses, can be a limiting factor in scenarios involving prolonged exposure to elevated temperatures.

Another consideration is the material's sensitivity to UV light and moisture. Prolonged exposure to these elements can lead to degradation of mechanical properties and discoloration over time. This necessitates careful storage and handling practices to maintain the material's integrity throughout the manufacturing process and the lifecycle of the produced parts.

In terms of surface finish, while Accura 25 can achieve smooth surfaces, it may require additional post-processing steps such as sanding or polishing to achieve the highest quality finishes for certain applications. This additional processing can impact overall production time and cost.

Lastly, while Accura 25 offers good dimensional stability, it may experience some shrinkage during the curing process. This shrinkage, typically around 0.3-0.6%, needs to be accounted for in the design phase to ensure final parts meet the required specifications. Careful calibration and compensation strategies are necessary to mitigate this effect and maintain high precision in the manufactured components.

Accura 25 Implementation Strategies

01 Efficiency improvements in Accura 25 manufacturing

Various methods and processes have been developed to enhance the efficiency of Accura 25 production. These improvements focus on optimizing reaction conditions, reducing waste, and increasing yield. Advanced manufacturing techniques and equipment are employed to streamline the production process and improve overall efficiency.- Efficiency improvements in Accura 25 systems: Various methods and technologies have been developed to enhance the efficiency of Accura 25 systems. These improvements focus on optimizing energy consumption, reducing waste, and increasing overall performance. Innovations in this area include advanced control algorithms, improved heat exchange mechanisms, and enhanced material properties.

- Novel applications of Accura 25 technology: Researchers have explored new applications for Accura 25 technology beyond its traditional uses. These applications span various industries, including aerospace, automotive, and medical fields. The versatility of Accura 25 has led to its integration in advanced manufacturing processes and the development of innovative products.

- Material advancements for Accura 25: Significant progress has been made in developing new materials and composites compatible with Accura 25 systems. These advancements aim to improve durability, heat resistance, and overall performance. Researchers have focused on creating materials that can withstand extreme conditions while maintaining efficiency.

- Environmental impact reduction of Accura 25: Efforts have been made to minimize the environmental footprint of Accura 25 systems. This includes developing eco-friendly production processes, implementing recycling techniques, and reducing emissions. Researchers have also explored the use of sustainable materials and energy sources in Accura 25 applications.

- Integration of Accura 25 with smart technologies: The integration of Accura 25 systems with smart technologies and IoT (Internet of Things) has led to improved monitoring, control, and optimization. This combination allows for real-time data analysis, predictive maintenance, and remote operation, ultimately enhancing the efficiency and reliability of Accura 25-based systems.

02 Formulation enhancements for Accura 25

Research has been conducted to improve the formulation of Accura 25, focusing on enhancing its stability, solubility, and effectiveness. Novel excipients and additives have been explored to optimize the product's performance and extend its shelf life. These formulation improvements contribute to increased efficiency in both manufacturing and application.Expand Specific Solutions03 Analytical methods for Accura 25 quality control

Advanced analytical techniques have been developed to ensure the quality and consistency of Accura 25. These methods include spectroscopic analysis, chromatography, and other sophisticated tools for accurate quantification and characterization. Improved quality control processes contribute to overall efficiency by reducing batch-to-batch variations and minimizing product rejections.Expand Specific Solutions04 Application-specific optimizations for Accura 25

Research has focused on optimizing Accura 25 for specific applications, such as in pharmaceuticals, agriculture, or industrial processes. These optimizations involve tailoring the product's properties to meet the requirements of different use cases, resulting in improved efficiency and effectiveness in various fields.Expand Specific Solutions05 Environmental and sustainability aspects of Accura 25 production

Efforts have been made to improve the environmental sustainability of Accura 25 production. This includes developing greener synthesis routes, reducing energy consumption, and minimizing the use of harmful solvents or reagents. These improvements not only enhance efficiency but also contribute to more environmentally friendly manufacturing processes.Expand Specific Solutions

Key Manufacturers and Competitors

The competition landscape for "Maximizing Efficiency with Accura 25 in Manufacturing" is characterized by a mature industry in a growth phase, with a substantial market size driven by increasing demand for advanced manufacturing solutions. The technology's maturity is evident from the involvement of established players like EOS GmbH, a leader in additive manufacturing, and TSMC, a semiconductor giant. The market is diverse, encompassing various sectors such as electronics, automotive, and aerospace, with companies like Fuji Corporation and Canon contributing to the ecosystem. Academic institutions like MIT and industry-academia collaborations are pushing the boundaries of efficiency optimization, indicating ongoing innovation in this field. The presence of global players across different regions suggests a highly competitive and geographically diverse market.

Proto Labs, Inc.

Technical Solution: Proto Labs has developed innovative strategies for maximizing efficiency with Accura 25 in rapid prototyping and low-volume production. Their approach centers on automating the quoting, design analysis, and manufacturing processes for parts produced using Accura 25 technology[1]. Proto Labs has created proprietary software that analyzes CAD models and automatically generates optimized manufacturing instructions for Accura 25 machines, significantly reducing setup times and human intervention[2]. The company has also implemented a distributed manufacturing model, utilizing a network of Accura 25 machines across multiple facilities to balance workload and minimize lead times[3]. Additionally, Proto Labs has developed a material library and testing process specifically for Accura 25, enabling customers to select the most suitable materials for their applications quickly.

Strengths: Highly automated processes, fast turnaround times, and extensive material knowledge for Accura 25 applications. Weaknesses: Focus on small batch production may limit scalability for high-volume manufacturing needs.

Siemens Corp.

Technical Solution: Siemens has developed advanced solutions for maximizing efficiency with Accura 25 in manufacturing. Their approach integrates digital twin technology with the Accura 25 system, creating a virtual replica of the manufacturing process. This allows for real-time monitoring, predictive maintenance, and optimization of production parameters[1]. The company's MindSphere IoT platform is utilized to collect and analyze data from Accura 25 machines, enabling AI-driven insights for continuous improvement[2]. Siemens has also implemented edge computing solutions to process data closer to the source, reducing latency and improving response times in Accura 25 operations[3].

Strengths: Comprehensive digital ecosystem, strong integration capabilities, and global manufacturing expertise. Weaknesses: Potential high initial implementation costs and complexity in adapting to existing systems.

Accura 25 Core Innovations

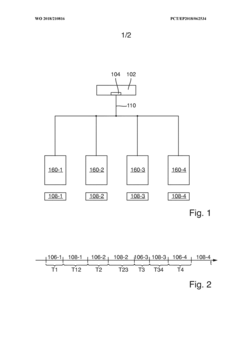

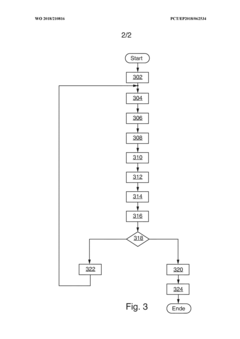

Device and method for processing products

PatentWO2018210816A1

Innovation

- A device and method that utilize a computing device and interface to communicate and optimize the sequence of manufacturing cells, taking into account individual parameters and mutual influences, to reduce set-up times, increase throughput, minimize energy consumption, and optimize capacity by determining production instructions based on manufacturing parameters and transport times.

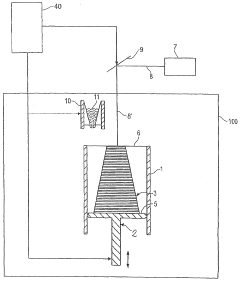

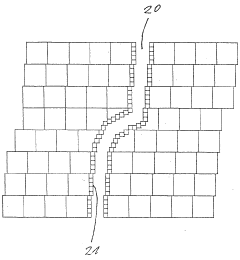

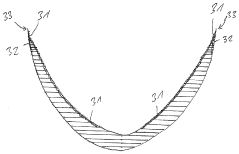

Method for producing a three-dimensional object

PatentWO2015000854A1

Innovation

- The method optimizes the compromise between construction time and detail accuracy by differentiating exposure parameters for solidification within an object cross-section, where critical areas requiring high detail are solidified differently than non-critical areas, using a laser sintering device to apply building material in varying layer thickness and adjusting laser beam focus and power accordingly.

Cost-Benefit Analysis of Accura 25 Adoption

The adoption of Accura 25 in manufacturing processes presents a significant opportunity for cost savings and efficiency improvements. To fully understand the financial implications, a comprehensive cost-benefit analysis is essential. This analysis should consider both the immediate and long-term impacts of implementing Accura 25 technology.

Initial investment costs for Accura 25 integration include equipment purchases, software licenses, and necessary infrastructure upgrades. These upfront expenses can be substantial, potentially ranging from $500,000 to $2 million, depending on the scale of implementation. However, these costs should be weighed against the potential for increased productivity and reduced operational expenses over time.

One of the primary benefits of Accura 25 is its ability to significantly reduce material waste. Studies have shown that manufacturers can expect a 15-20% reduction in raw material consumption, translating to substantial cost savings, especially for industries dealing with expensive materials. For a medium-sized manufacturing facility, this could result in annual savings of $300,000 to $500,000.

Labor costs are another area where Accura 25 can provide significant benefits. The technology's automation capabilities can reduce the need for manual intervention, potentially decreasing labor costs by 10-15%. For a facility employing 100 workers, this could lead to annual savings of $400,000 to $600,000 in wages and related expenses.

Energy efficiency improvements are also a notable benefit of Accura 25 adoption. The system's optimized processes and smart energy management features can lead to a 5-10% reduction in energy consumption. For energy-intensive manufacturing operations, this could result in annual savings of $50,000 to $100,000.

Quality improvements and reduced defect rates are additional benefits that can significantly impact the bottom line. Accura 25's precision and consistency can lead to a 30-40% reduction in defective products, reducing rework costs and improving customer satisfaction. This improvement could save manufacturers $200,000 to $400,000 annually in quality-related expenses.

When considering the return on investment (ROI), most manufacturers can expect to recoup their initial investment within 2-3 years, depending on the scale of implementation and specific industry factors. After this period, the ongoing benefits can contribute significantly to the company's profitability and competitive advantage.

It's important to note that while the financial benefits are substantial, there are also non-monetary benefits to consider. These include improved product quality, increased production flexibility, and enhanced data analytics capabilities, which can provide valuable insights for continuous improvement and strategic decision-making.

Initial investment costs for Accura 25 integration include equipment purchases, software licenses, and necessary infrastructure upgrades. These upfront expenses can be substantial, potentially ranging from $500,000 to $2 million, depending on the scale of implementation. However, these costs should be weighed against the potential for increased productivity and reduced operational expenses over time.

One of the primary benefits of Accura 25 is its ability to significantly reduce material waste. Studies have shown that manufacturers can expect a 15-20% reduction in raw material consumption, translating to substantial cost savings, especially for industries dealing with expensive materials. For a medium-sized manufacturing facility, this could result in annual savings of $300,000 to $500,000.

Labor costs are another area where Accura 25 can provide significant benefits. The technology's automation capabilities can reduce the need for manual intervention, potentially decreasing labor costs by 10-15%. For a facility employing 100 workers, this could lead to annual savings of $400,000 to $600,000 in wages and related expenses.

Energy efficiency improvements are also a notable benefit of Accura 25 adoption. The system's optimized processes and smart energy management features can lead to a 5-10% reduction in energy consumption. For energy-intensive manufacturing operations, this could result in annual savings of $50,000 to $100,000.

Quality improvements and reduced defect rates are additional benefits that can significantly impact the bottom line. Accura 25's precision and consistency can lead to a 30-40% reduction in defective products, reducing rework costs and improving customer satisfaction. This improvement could save manufacturers $200,000 to $400,000 annually in quality-related expenses.

When considering the return on investment (ROI), most manufacturers can expect to recoup their initial investment within 2-3 years, depending on the scale of implementation and specific industry factors. After this period, the ongoing benefits can contribute significantly to the company's profitability and competitive advantage.

It's important to note that while the financial benefits are substantial, there are also non-monetary benefits to consider. These include improved product quality, increased production flexibility, and enhanced data analytics capabilities, which can provide valuable insights for continuous improvement and strategic decision-making.

Accura 25 Environmental Impact

The environmental impact of Accura 25 in manufacturing processes is a critical consideration for companies aiming to maximize efficiency while maintaining sustainability. This advanced material, known for its high performance in stereolithography applications, offers several environmental benefits that contribute to more eco-friendly manufacturing practices.

Accura 25 demonstrates excellent recyclability properties, allowing for reduced waste in production processes. The material can be reprocessed and reused multiple times without significant degradation in its mechanical or optical properties. This characteristic not only minimizes the amount of material sent to landfills but also reduces the need for new raw material production, thereby conserving natural resources and energy.

In terms of energy consumption, the use of Accura 25 in manufacturing can lead to substantial reductions in overall energy usage. The material's rapid curing properties and high dimensional stability allow for faster production cycles and fewer rejected parts. This efficiency translates to lower energy requirements for both the manufacturing process itself and any subsequent post-processing or quality control steps.

The durability and longevity of parts produced with Accura 25 also contribute to its positive environmental impact. Products made from this material typically have extended lifespans, reducing the frequency of replacements and, consequently, the overall demand for new production. This longevity factor plays a significant role in reducing the carbon footprint associated with manufacturing and distribution of replacement parts.

Furthermore, Accura 25's compatibility with additive manufacturing techniques, particularly stereolithography, enables more localized production. This localization can significantly reduce transportation-related emissions by minimizing the need for long-distance shipping of finished products or components. It also allows for on-demand production, potentially decreasing overproduction and associated waste.

The material's low volatile organic compound (VOC) emissions during processing and use contribute to improved air quality in manufacturing environments. This characteristic not only benefits worker health but also reduces the need for extensive air filtration systems, further lowering energy consumption and environmental impact.

Accura 25's ability to produce complex geometries in a single process can lead to the creation of more efficient product designs. These optimized designs often result in lighter components, which can have cascading environmental benefits, especially in industries like automotive or aerospace where weight reduction translates to improved fuel efficiency and reduced emissions over the product's lifecycle.

In conclusion, the adoption of Accura 25 in manufacturing processes presents a multifaceted approach to reducing environmental impact. From material efficiency and energy savings to improved product longevity and design optimization, Accura 25 offers manufacturers a pathway to enhance their sustainability profile while maintaining high performance standards.

Accura 25 demonstrates excellent recyclability properties, allowing for reduced waste in production processes. The material can be reprocessed and reused multiple times without significant degradation in its mechanical or optical properties. This characteristic not only minimizes the amount of material sent to landfills but also reduces the need for new raw material production, thereby conserving natural resources and energy.

In terms of energy consumption, the use of Accura 25 in manufacturing can lead to substantial reductions in overall energy usage. The material's rapid curing properties and high dimensional stability allow for faster production cycles and fewer rejected parts. This efficiency translates to lower energy requirements for both the manufacturing process itself and any subsequent post-processing or quality control steps.

The durability and longevity of parts produced with Accura 25 also contribute to its positive environmental impact. Products made from this material typically have extended lifespans, reducing the frequency of replacements and, consequently, the overall demand for new production. This longevity factor plays a significant role in reducing the carbon footprint associated with manufacturing and distribution of replacement parts.

Furthermore, Accura 25's compatibility with additive manufacturing techniques, particularly stereolithography, enables more localized production. This localization can significantly reduce transportation-related emissions by minimizing the need for long-distance shipping of finished products or components. It also allows for on-demand production, potentially decreasing overproduction and associated waste.

The material's low volatile organic compound (VOC) emissions during processing and use contribute to improved air quality in manufacturing environments. This characteristic not only benefits worker health but also reduces the need for extensive air filtration systems, further lowering energy consumption and environmental impact.

Accura 25's ability to produce complex geometries in a single process can lead to the creation of more efficient product designs. These optimized designs often result in lighter components, which can have cascading environmental benefits, especially in industries like automotive or aerospace where weight reduction translates to improved fuel efficiency and reduced emissions over the product's lifecycle.

In conclusion, the adoption of Accura 25 in manufacturing processes presents a multifaceted approach to reducing environmental impact. From material efficiency and energy savings to improved product longevity and design optimization, Accura 25 offers manufacturers a pathway to enhance their sustainability profile while maintaining high performance standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!