Exploring Carboxylic Acid Coatings for Corrosion Prevention

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Corrosion Prevention Background and Objectives

Corrosion prevention has been a critical concern in various industries for decades, with significant economic and safety implications. The evolution of corrosion prevention techniques has been driven by the need to protect valuable assets, infrastructure, and equipment from degradation caused by environmental factors. As industries continue to expand and face more challenging operational environments, the demand for advanced corrosion prevention solutions has grown exponentially.

The field of corrosion prevention has witnessed substantial progress, from simple protective coatings to sophisticated electrochemical methods. However, despite these advancements, corrosion remains a persistent problem, costing industries billions of dollars annually in maintenance, repairs, and replacements. This ongoing challenge has led to a renewed focus on innovative approaches to corrosion prevention, with particular interest in sustainable and environmentally friendly solutions.

One promising area of research in corrosion prevention is the exploration of carboxylic acid coatings. These organic compounds have shown potential in forming protective layers on metal surfaces, offering a unique combination of corrosion resistance and environmental compatibility. The interest in carboxylic acid coatings stems from their ability to form strong chemical bonds with metal substrates, creating a barrier against corrosive agents while being less toxic than traditional corrosion inhibitors.

The primary objective of exploring carboxylic acid coatings for corrosion prevention is to develop a new generation of protective solutions that can outperform existing technologies in terms of effectiveness, durability, and environmental impact. Researchers aim to understand the fundamental mechanisms by which carboxylic acids interact with metal surfaces and how these interactions can be optimized to enhance corrosion resistance.

Additionally, there is a focus on investigating the long-term stability of carboxylic acid coatings under various environmental conditions, including exposure to different pH levels, temperatures, and corrosive media. The goal is to create coatings that can provide reliable protection in diverse industrial settings, from marine environments to chemical processing plants.

Another key objective is to explore the potential for combining carboxylic acid coatings with other corrosion prevention techniques, such as cathodic protection or inhibitor additives, to create synergistic effects that offer superior protection. This multifaceted approach aims to address the complex nature of corrosion processes and provide comprehensive solutions for different types of corrosion challenges.

As the research in this field progresses, there is also an emphasis on developing scalable and cost-effective methods for applying carboxylic acid coatings in industrial settings. This includes investigating various application techniques, optimizing coating formulations, and assessing the feasibility of large-scale production and implementation.

The field of corrosion prevention has witnessed substantial progress, from simple protective coatings to sophisticated electrochemical methods. However, despite these advancements, corrosion remains a persistent problem, costing industries billions of dollars annually in maintenance, repairs, and replacements. This ongoing challenge has led to a renewed focus on innovative approaches to corrosion prevention, with particular interest in sustainable and environmentally friendly solutions.

One promising area of research in corrosion prevention is the exploration of carboxylic acid coatings. These organic compounds have shown potential in forming protective layers on metal surfaces, offering a unique combination of corrosion resistance and environmental compatibility. The interest in carboxylic acid coatings stems from their ability to form strong chemical bonds with metal substrates, creating a barrier against corrosive agents while being less toxic than traditional corrosion inhibitors.

The primary objective of exploring carboxylic acid coatings for corrosion prevention is to develop a new generation of protective solutions that can outperform existing technologies in terms of effectiveness, durability, and environmental impact. Researchers aim to understand the fundamental mechanisms by which carboxylic acids interact with metal surfaces and how these interactions can be optimized to enhance corrosion resistance.

Additionally, there is a focus on investigating the long-term stability of carboxylic acid coatings under various environmental conditions, including exposure to different pH levels, temperatures, and corrosive media. The goal is to create coatings that can provide reliable protection in diverse industrial settings, from marine environments to chemical processing plants.

Another key objective is to explore the potential for combining carboxylic acid coatings with other corrosion prevention techniques, such as cathodic protection or inhibitor additives, to create synergistic effects that offer superior protection. This multifaceted approach aims to address the complex nature of corrosion processes and provide comprehensive solutions for different types of corrosion challenges.

As the research in this field progresses, there is also an emphasis on developing scalable and cost-effective methods for applying carboxylic acid coatings in industrial settings. This includes investigating various application techniques, optimizing coating formulations, and assessing the feasibility of large-scale production and implementation.

Market Analysis for Corrosion-Resistant Coatings

The global market for corrosion-resistant coatings has been experiencing steady growth, driven by increasing industrial activities and infrastructure development across various sectors. The demand for effective corrosion prevention solutions, particularly in harsh environments, has led to a surge in research and development of advanced coating technologies, including carboxylic acid-based coatings.

The corrosion-resistant coatings market is primarily segmented into epoxy, polyurethane, acrylic, alkyd, zinc, and other types. Among these, carboxylic acid coatings are gaining traction due to their superior performance in protecting metal surfaces from corrosion. The market for these coatings is expected to grow significantly in the coming years, as industries seek more environmentally friendly and cost-effective solutions.

Key industries driving the demand for corrosion-resistant coatings include oil and gas, marine, automotive, aerospace, and construction. The oil and gas sector, in particular, presents a substantial opportunity for carboxylic acid coatings due to the harsh operating conditions and the critical need for equipment protection. The marine industry also shows promising growth potential, as ships and offshore structures require robust corrosion protection against saltwater exposure.

Geographically, Asia-Pacific leads the market for corrosion-resistant coatings, followed by North America and Europe. The rapid industrialization and infrastructure development in countries like China and India are major contributors to this regional dominance. However, stringent environmental regulations in developed regions are pushing for the adoption of more sustainable coating solutions, which could benefit carboxylic acid-based products.

The market is characterized by intense competition among key players, including PPG Industries, AkzoNobel, Sherwin-Williams, and Hempel. These companies are investing heavily in research and development to improve coating performance and expand their product portfolios. The entry of new players specializing in carboxylic acid coatings is expected to further intensify market competition and drive innovation.

Factors such as increasing awareness about the economic impact of corrosion, growing emphasis on asset protection, and the need for extended maintenance intervals are fueling market growth. However, challenges such as volatile raw material prices and the need for skilled application techniques may hinder market expansion to some extent.

In conclusion, the market analysis for corrosion-resistant coatings, particularly carboxylic acid-based solutions, indicates a positive growth trajectory. The increasing demand across various industries, coupled with the push for more sustainable and efficient coating technologies, presents significant opportunities for market players to innovate and capture market share in this evolving sector.

The corrosion-resistant coatings market is primarily segmented into epoxy, polyurethane, acrylic, alkyd, zinc, and other types. Among these, carboxylic acid coatings are gaining traction due to their superior performance in protecting metal surfaces from corrosion. The market for these coatings is expected to grow significantly in the coming years, as industries seek more environmentally friendly and cost-effective solutions.

Key industries driving the demand for corrosion-resistant coatings include oil and gas, marine, automotive, aerospace, and construction. The oil and gas sector, in particular, presents a substantial opportunity for carboxylic acid coatings due to the harsh operating conditions and the critical need for equipment protection. The marine industry also shows promising growth potential, as ships and offshore structures require robust corrosion protection against saltwater exposure.

Geographically, Asia-Pacific leads the market for corrosion-resistant coatings, followed by North America and Europe. The rapid industrialization and infrastructure development in countries like China and India are major contributors to this regional dominance. However, stringent environmental regulations in developed regions are pushing for the adoption of more sustainable coating solutions, which could benefit carboxylic acid-based products.

The market is characterized by intense competition among key players, including PPG Industries, AkzoNobel, Sherwin-Williams, and Hempel. These companies are investing heavily in research and development to improve coating performance and expand their product portfolios. The entry of new players specializing in carboxylic acid coatings is expected to further intensify market competition and drive innovation.

Factors such as increasing awareness about the economic impact of corrosion, growing emphasis on asset protection, and the need for extended maintenance intervals are fueling market growth. However, challenges such as volatile raw material prices and the need for skilled application techniques may hinder market expansion to some extent.

In conclusion, the market analysis for corrosion-resistant coatings, particularly carboxylic acid-based solutions, indicates a positive growth trajectory. The increasing demand across various industries, coupled with the push for more sustainable and efficient coating technologies, presents significant opportunities for market players to innovate and capture market share in this evolving sector.

Current Challenges in Carboxylic Acid Coating Technology

Despite the promising potential of carboxylic acid coatings for corrosion prevention, several significant challenges persist in their development and application. One of the primary issues is the limited stability of these coatings under harsh environmental conditions. Carboxylic acid coatings can degrade or detach from metal surfaces when exposed to extreme temperatures, pH levels, or mechanical stress, reducing their long-term effectiveness in corrosion protection.

Another challenge lies in achieving uniform and consistent coating thickness across complex geometries. Irregular surfaces or intricate shapes can lead to uneven distribution of the carboxylic acid coating, resulting in areas with inadequate protection. This non-uniformity can create weak points where corrosion may initiate and propagate more rapidly.

The adhesion strength between carboxylic acid coatings and various metal substrates remains a concern. While these coatings generally form strong bonds with certain metals, their adhesion to others may be insufficient for long-term protection. Improving the bonding mechanisms across a wider range of metal surfaces is crucial for expanding the applicability of these coatings.

Scalability and cost-effectiveness present additional hurdles in the widespread adoption of carboxylic acid coatings. Current production methods may not be suitable for large-scale industrial applications, and the cost of raw materials and processing can be prohibitive for some sectors. Developing more efficient and economical manufacturing techniques is essential for broader implementation.

The environmental impact of carboxylic acid coatings is another area of concern. While generally considered more environmentally friendly than traditional corrosion prevention methods, there are still questions about the long-term effects of these coatings on ecosystems, particularly in marine environments. Ensuring the biodegradability and non-toxicity of coating components without compromising their protective properties is an ongoing challenge.

Compatibility with existing coating systems and surface treatments poses yet another obstacle. Integrating carboxylic acid coatings into established corrosion prevention protocols may require significant modifications to current practices, potentially leading to resistance from industries with well-established procedures.

Lastly, the lack of standardized testing and performance metrics specific to carboxylic acid coatings hinders their widespread acceptance. Developing comprehensive, industry-accepted standards for evaluating the effectiveness and durability of these coatings is crucial for building confidence among potential users and regulators.

Another challenge lies in achieving uniform and consistent coating thickness across complex geometries. Irregular surfaces or intricate shapes can lead to uneven distribution of the carboxylic acid coating, resulting in areas with inadequate protection. This non-uniformity can create weak points where corrosion may initiate and propagate more rapidly.

The adhesion strength between carboxylic acid coatings and various metal substrates remains a concern. While these coatings generally form strong bonds with certain metals, their adhesion to others may be insufficient for long-term protection. Improving the bonding mechanisms across a wider range of metal surfaces is crucial for expanding the applicability of these coatings.

Scalability and cost-effectiveness present additional hurdles in the widespread adoption of carboxylic acid coatings. Current production methods may not be suitable for large-scale industrial applications, and the cost of raw materials and processing can be prohibitive for some sectors. Developing more efficient and economical manufacturing techniques is essential for broader implementation.

The environmental impact of carboxylic acid coatings is another area of concern. While generally considered more environmentally friendly than traditional corrosion prevention methods, there are still questions about the long-term effects of these coatings on ecosystems, particularly in marine environments. Ensuring the biodegradability and non-toxicity of coating components without compromising their protective properties is an ongoing challenge.

Compatibility with existing coating systems and surface treatments poses yet another obstacle. Integrating carboxylic acid coatings into established corrosion prevention protocols may require significant modifications to current practices, potentially leading to resistance from industries with well-established procedures.

Lastly, the lack of standardized testing and performance metrics specific to carboxylic acid coatings hinders their widespread acceptance. Developing comprehensive, industry-accepted standards for evaluating the effectiveness and durability of these coatings is crucial for building confidence among potential users and regulators.

Existing Carboxylic Acid Coating Solutions

01 Carboxylic acid-based corrosion inhibitors

Carboxylic acids and their derivatives are used as effective corrosion inhibitors in various coatings and treatments. These compounds form protective films on metal surfaces, preventing or reducing corrosion. They can be incorporated into coating formulations or used as standalone treatments for corrosion protection.- Carboxylic acid-based corrosion inhibitors: Carboxylic acids and their derivatives are used as effective corrosion inhibitors in various coatings and formulations. These compounds form protective films on metal surfaces, preventing corrosion by creating a barrier against aggressive environmental factors. The effectiveness of these inhibitors can be enhanced by optimizing their molecular structure and concentration.

- Carboxylic acid-containing polymer coatings: Polymer coatings incorporating carboxylic acid functionalities provide corrosion protection for metal substrates. These coatings form strong adhesion to the metal surface and create a durable barrier against corrosive agents. The carboxylic acid groups in the polymer structure contribute to improved coating performance and longevity.

- Synergistic combinations with other corrosion inhibitors:

- Application methods for carboxylic acid coatings: Various application methods are employed for carboxylic acid-based coatings to enhance corrosion protection. These include spray coating, dip coating, and electrodeposition techniques. The choice of application method affects the coating thickness, uniformity, and overall performance in corrosion prevention.

- Environmental and regulatory considerations: The development of carboxylic acid coatings for corrosion protection takes into account environmental and regulatory requirements. Efforts are made to formulate coatings with reduced volatile organic compounds (VOCs) and improved biodegradability while maintaining effective corrosion resistance properties.

02 Polymer coatings with carboxylic acid functionalities

Polymers containing carboxylic acid groups are utilized in protective coatings to enhance corrosion resistance. These polymers can form strong bonds with metal surfaces and create barrier layers against corrosive agents. The carboxylic acid functionalities contribute to improved adhesion and corrosion protection properties of the coatings.Expand Specific Solutions03 Carboxylic acid-modified surface treatments

Surface treatments involving carboxylic acids or their derivatives are employed to enhance corrosion resistance of metals. These treatments can include conversion coatings, passivation processes, or surface modifications that incorporate carboxylic acid compounds to form protective layers on the metal surface.Expand Specific Solutions04 Synergistic combinations with carboxylic acids

Carboxylic acids are often combined with other corrosion inhibitors or additives to create synergistic effects in corrosion protection. These combinations can enhance the overall performance of coatings or treatments, providing improved corrosion resistance compared to individual components alone.Expand Specific Solutions05 Environmentally friendly carboxylic acid-based solutions

Development of eco-friendly corrosion protection solutions using carboxylic acids and their derivatives. These formulations aim to replace traditional, potentially harmful corrosion inhibitors with more sustainable alternatives while maintaining effective corrosion protection properties.Expand Specific Solutions

Key Players in Carboxylic Acid Coating Industry

The field of carboxylic acid coatings for corrosion prevention is in a growth phase, with increasing market demand driven by the need for more effective and environmentally friendly anti-corrosion solutions. The global market for these coatings is expanding, particularly in industries such as automotive, aerospace, and marine. Companies like BASF Corp., Akzo Nobel Chemicals International BV, and Kansai Paint Co., Ltd. are at the forefront of developing advanced carboxylic acid-based coatings. The technology is maturing rapidly, with ongoing research at institutions like École Polytechnique Fédérale de Lausanne and Wuhan University of Technology contributing to improvements in coating performance and durability. As the industry evolves, collaborations between academic institutions and major chemical companies are likely to accelerate innovation and market adoption.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced carboxylic acid-based coatings for corrosion prevention. Their approach involves using long-chain carboxylic acids as self-assembled monolayers (SAMs) on metal surfaces[1]. These SAMs form a dense, hydrophobic barrier that significantly reduces corrosion rates. BASF's technology also incorporates nanoparticles into the coating matrix, enhancing its durability and scratch resistance[3]. The company has further improved the coating's performance by developing a two-step application process: first, a primer layer rich in carboxylic acid groups is applied, followed by a topcoat that cross-links with the primer, creating a robust protective layer[5].

Strengths: Excellent barrier properties, enhanced durability due to nanoparticle incorporation, and strong adhesion to metal surfaces. Weaknesses: May require careful surface preparation and controlled application conditions for optimal performance.

Akzo Nobel Chemicals International BV

Technical Solution: Akzo Nobel has pioneered a novel approach to carboxylic acid coatings for corrosion prevention. Their technology utilizes a combination of short and long-chain carboxylic acids to create a multi-layered protective coating[2]. The short-chain acids provide excellent adhesion to the metal substrate, while the long-chain acids form a hydrophobic outer layer. Akzo Nobel has also developed a proprietary cross-linking agent that reacts with the carboxylic acid groups, forming a highly cross-linked network that significantly enhances the coating's barrier properties[4]. Additionally, the company has incorporated corrosion inhibitors into the coating formulation, providing active protection against aggressive ions[6].

Strengths: Multi-layered protection, excellent adhesion, and active corrosion inhibition. Weaknesses: May be more complex and costly to produce compared to simpler coating systems.

Innovative Carboxylic Acid Coating Formulations

Releasable corrosion inhibitor compositions

PatentInactiveEP1880041A1

Innovation

- Development of surface-modified aluminum oxyhydroxide particles with chemically anchored organic corrosion inhibitors that are released upon hydroxide ion disruption, triggered by corrosion conditions, allowing for targeted and sustained release of inhibitors without degrading coating properties.

Organic corrosion inhibitors

PatentWO2021097532A1

Innovation

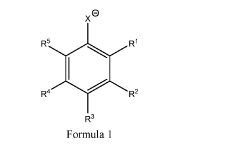

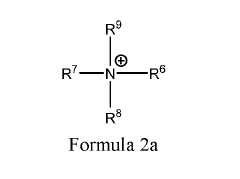

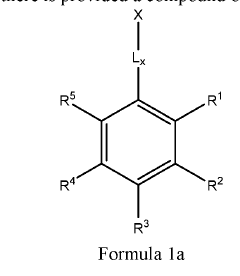

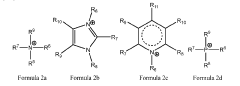

- The use of organic corrosion inhibitors comprising onium cations and aromatic carboxylate anions, which form ionic compounds that create a protective film on metal surfaces, inhibiting corrosion and offering additional antimicrobial properties.

Environmental Impact of Carboxylic Acid Coatings

The environmental impact of carboxylic acid coatings for corrosion prevention is a crucial aspect to consider in their application and development. These coatings offer significant benefits in terms of corrosion protection, but their potential effects on the environment must be carefully evaluated.

One of the primary environmental advantages of carboxylic acid coatings is their biodegradability. Many carboxylic acids are naturally occurring compounds that can be broken down by microorganisms in the environment. This characteristic reduces the long-term accumulation of these substances in ecosystems, minimizing their potential for persistent environmental contamination.

However, the release of carboxylic acids into aquatic environments can have short-term effects on local pH levels. Depending on the concentration and specific acid used, this could potentially impact aquatic life in the immediate vicinity of treated surfaces. It is essential to consider the buffering capacity of the receiving water bodies and the dilution factors to assess the actual risk.

The production process of carboxylic acid coatings also warrants attention from an environmental perspective. Some synthesis methods may involve the use of organic solvents or other chemicals that could pose environmental risks if not properly managed. Manufacturers are increasingly adopting green chemistry principles to minimize the use of harmful substances and reduce waste generation during production.

In terms of air quality, carboxylic acid coatings generally have lower volatile organic compound (VOC) emissions compared to traditional solvent-based coatings. This characteristic contributes to reduced air pollution and aligns with increasingly stringent environmental regulations in many regions.

The disposal of materials treated with carboxylic acid coatings is another environmental consideration. While the coatings themselves may be biodegradable, the substrates they protect often are not. Proper end-of-life management of coated products is necessary to prevent the release of potentially harmful substances into the environment.

Life cycle assessments (LCAs) of carboxylic acid coatings have shown that their overall environmental impact is generally lower than that of conventional corrosion prevention methods. The extended lifespan of protected materials reduces the need for frequent replacements, thereby conserving resources and energy in the long term.

Research into the ecotoxicological effects of specific carboxylic acid coatings is ongoing. Studies are examining their potential impacts on various organisms and ecosystems to ensure their safe use in different applications. This research is crucial for developing guidelines and best practices for the responsible use of these coatings.

One of the primary environmental advantages of carboxylic acid coatings is their biodegradability. Many carboxylic acids are naturally occurring compounds that can be broken down by microorganisms in the environment. This characteristic reduces the long-term accumulation of these substances in ecosystems, minimizing their potential for persistent environmental contamination.

However, the release of carboxylic acids into aquatic environments can have short-term effects on local pH levels. Depending on the concentration and specific acid used, this could potentially impact aquatic life in the immediate vicinity of treated surfaces. It is essential to consider the buffering capacity of the receiving water bodies and the dilution factors to assess the actual risk.

The production process of carboxylic acid coatings also warrants attention from an environmental perspective. Some synthesis methods may involve the use of organic solvents or other chemicals that could pose environmental risks if not properly managed. Manufacturers are increasingly adopting green chemistry principles to minimize the use of harmful substances and reduce waste generation during production.

In terms of air quality, carboxylic acid coatings generally have lower volatile organic compound (VOC) emissions compared to traditional solvent-based coatings. This characteristic contributes to reduced air pollution and aligns with increasingly stringent environmental regulations in many regions.

The disposal of materials treated with carboxylic acid coatings is another environmental consideration. While the coatings themselves may be biodegradable, the substrates they protect often are not. Proper end-of-life management of coated products is necessary to prevent the release of potentially harmful substances into the environment.

Life cycle assessments (LCAs) of carboxylic acid coatings have shown that their overall environmental impact is generally lower than that of conventional corrosion prevention methods. The extended lifespan of protected materials reduces the need for frequent replacements, thereby conserving resources and energy in the long term.

Research into the ecotoxicological effects of specific carboxylic acid coatings is ongoing. Studies are examining their potential impacts on various organisms and ecosystems to ensure their safe use in different applications. This research is crucial for developing guidelines and best practices for the responsible use of these coatings.

Cost-Benefit Analysis of Carboxylic Acid Coatings

The cost-benefit analysis of carboxylic acid coatings for corrosion prevention reveals a complex interplay of economic factors and performance advantages. Initial implementation costs for these coatings are generally higher than traditional anti-corrosion methods, primarily due to the specialized materials and application processes required. However, the long-term economic benefits often outweigh these upfront expenses.

One of the primary advantages of carboxylic acid coatings is their extended durability. These coatings typically offer a longer service life compared to conventional alternatives, reducing the frequency of reapplication and associated maintenance costs. This longevity translates into significant savings over time, particularly in industries where equipment downtime is costly.

The superior corrosion resistance provided by carboxylic acid coatings contributes to asset preservation, extending the lifespan of treated surfaces and equipment. This reduction in material degradation leads to decreased replacement costs and improved operational efficiency. In industries such as marine, oil and gas, and chemical processing, where corrosion-related failures can result in substantial financial losses, the protective properties of these coatings offer a compelling economic argument.

Environmental considerations also factor into the cost-benefit equation. Carboxylic acid coatings often have lower volatile organic compound (VOC) emissions compared to some traditional coatings, potentially reducing environmental compliance costs and aligning with increasingly stringent regulations. This eco-friendly aspect can enhance a company's sustainability profile, potentially leading to improved stakeholder relations and market positioning.

However, the cost-effectiveness of carboxylic acid coatings can vary depending on the specific application environment. In highly corrosive settings, the enhanced protection may justify the higher initial investment more readily than in less aggressive conditions. Additionally, the complexity of application may require specialized training or equipment, potentially increasing implementation costs.

The scalability of carboxylic acid coating solutions also impacts their economic viability. For large-scale industrial applications, economies of scale may help offset initial costs, making them more competitive with traditional methods. Conversely, for smaller or one-off applications, the cost-benefit ratio may be less favorable.

In conclusion, while carboxylic acid coatings generally present higher upfront costs, their long-term economic benefits in terms of extended asset life, reduced maintenance, and potential environmental advantages often result in a favorable return on investment. However, a thorough assessment of specific application requirements and operational contexts is crucial to determine the optimal cost-benefit balance for each implementation scenario.

One of the primary advantages of carboxylic acid coatings is their extended durability. These coatings typically offer a longer service life compared to conventional alternatives, reducing the frequency of reapplication and associated maintenance costs. This longevity translates into significant savings over time, particularly in industries where equipment downtime is costly.

The superior corrosion resistance provided by carboxylic acid coatings contributes to asset preservation, extending the lifespan of treated surfaces and equipment. This reduction in material degradation leads to decreased replacement costs and improved operational efficiency. In industries such as marine, oil and gas, and chemical processing, where corrosion-related failures can result in substantial financial losses, the protective properties of these coatings offer a compelling economic argument.

Environmental considerations also factor into the cost-benefit equation. Carboxylic acid coatings often have lower volatile organic compound (VOC) emissions compared to some traditional coatings, potentially reducing environmental compliance costs and aligning with increasingly stringent regulations. This eco-friendly aspect can enhance a company's sustainability profile, potentially leading to improved stakeholder relations and market positioning.

However, the cost-effectiveness of carboxylic acid coatings can vary depending on the specific application environment. In highly corrosive settings, the enhanced protection may justify the higher initial investment more readily than in less aggressive conditions. Additionally, the complexity of application may require specialized training or equipment, potentially increasing implementation costs.

The scalability of carboxylic acid coating solutions also impacts their economic viability. For large-scale industrial applications, economies of scale may help offset initial costs, making them more competitive with traditional methods. Conversely, for smaller or one-off applications, the cost-benefit ratio may be less favorable.

In conclusion, while carboxylic acid coatings generally present higher upfront costs, their long-term economic benefits in terms of extended asset life, reduced maintenance, and potential environmental advantages often result in a favorable return on investment. However, a thorough assessment of specific application requirements and operational contexts is crucial to determine the optimal cost-benefit balance for each implementation scenario.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!