Carboxylic Acid Evolution: Key Milestones in Industrial Applications

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carboxylic Acid History and Objectives

Carboxylic acids have played a pivotal role in industrial applications for centuries, with their history dating back to ancient times. The evolution of carboxylic acid utilization has been marked by significant milestones that have shaped various industries and technological advancements.

The journey of carboxylic acids began with the discovery of acetic acid in vinegar by ancient civilizations. This early recognition of the compound's properties laid the foundation for future explorations. The 18th century saw a surge in scientific interest, with Carl Wilhelm Scheele isolating several organic acids, including tartaric, citric, and lactic acids.

The 19th century brought about a revolution in carboxylic acid research and applications. In 1814, Michel Eugène Chevreul's work on fatty acids paved the way for the development of soaps and detergents. This period also witnessed the synthesis of salicylic acid by Hermann Kolbe in 1859, leading to the creation of aspirin in 1897 by Felix Hoffmann.

The early 20th century marked the beginning of industrial-scale production of carboxylic acids. The development of petrochemical processes enabled the large-scale synthesis of acetic acid, propanoic acid, and other important compounds. This era also saw the emergence of carboxylic acids as key intermediates in the production of plastics, pharmaceuticals, and food additives.

Post-World War II, the focus shifted towards developing more efficient and environmentally friendly production methods. The introduction of catalytic processes, such as the Monsanto process for acetic acid production in the 1960s, revolutionized the industry. These advancements significantly reduced production costs and improved yields.

In recent decades, the objectives of carboxylic acid research and development have evolved to address global challenges. Sustainability has become a key driver, with efforts directed towards bio-based production methods and green chemistry principles. The search for renewable feedstocks and the development of biodegradable materials have gained prominence.

Current objectives in the field include enhancing the efficiency of existing processes, exploring novel applications in emerging technologies, and developing carboxylic acid derivatives with improved properties. There is also a growing emphasis on the circular economy, with research focused on recycling and upcycling carboxylic acid-based products.

Looking ahead, the carboxylic acid industry aims to further integrate with biotechnology and nanotechnology. The development of smart materials, advanced drug delivery systems, and sustainable packaging solutions are among the key areas of focus. Additionally, there is a push towards utilizing carboxylic acids in energy storage applications and as building blocks for next-generation materials.

The journey of carboxylic acids began with the discovery of acetic acid in vinegar by ancient civilizations. This early recognition of the compound's properties laid the foundation for future explorations. The 18th century saw a surge in scientific interest, with Carl Wilhelm Scheele isolating several organic acids, including tartaric, citric, and lactic acids.

The 19th century brought about a revolution in carboxylic acid research and applications. In 1814, Michel Eugène Chevreul's work on fatty acids paved the way for the development of soaps and detergents. This period also witnessed the synthesis of salicylic acid by Hermann Kolbe in 1859, leading to the creation of aspirin in 1897 by Felix Hoffmann.

The early 20th century marked the beginning of industrial-scale production of carboxylic acids. The development of petrochemical processes enabled the large-scale synthesis of acetic acid, propanoic acid, and other important compounds. This era also saw the emergence of carboxylic acids as key intermediates in the production of plastics, pharmaceuticals, and food additives.

Post-World War II, the focus shifted towards developing more efficient and environmentally friendly production methods. The introduction of catalytic processes, such as the Monsanto process for acetic acid production in the 1960s, revolutionized the industry. These advancements significantly reduced production costs and improved yields.

In recent decades, the objectives of carboxylic acid research and development have evolved to address global challenges. Sustainability has become a key driver, with efforts directed towards bio-based production methods and green chemistry principles. The search for renewable feedstocks and the development of biodegradable materials have gained prominence.

Current objectives in the field include enhancing the efficiency of existing processes, exploring novel applications in emerging technologies, and developing carboxylic acid derivatives with improved properties. There is also a growing emphasis on the circular economy, with research focused on recycling and upcycling carboxylic acid-based products.

Looking ahead, the carboxylic acid industry aims to further integrate with biotechnology and nanotechnology. The development of smart materials, advanced drug delivery systems, and sustainable packaging solutions are among the key areas of focus. Additionally, there is a push towards utilizing carboxylic acids in energy storage applications and as building blocks for next-generation materials.

Industrial Demand Analysis

The industrial demand for carboxylic acids has experienced significant growth over the past decades, driven by their versatile applications across various sectors. The global market for carboxylic acids is projected to reach substantial figures, with a compound annual growth rate (CAGR) indicating steady expansion in the coming years. This growth is primarily attributed to the increasing demand from end-use industries such as food and beverages, pharmaceuticals, personal care, and agriculture.

In the food and beverage industry, carboxylic acids play a crucial role as preservatives, flavor enhancers, and acidulants. The rising consumer preference for processed and convenience foods has led to a surge in demand for these acids, particularly acetic acid, citric acid, and lactic acid. The pharmaceutical sector also heavily relies on carboxylic acids for the synthesis of various drugs and active pharmaceutical ingredients (APIs), contributing significantly to market growth.

The personal care and cosmetics industry has emerged as a key driver for carboxylic acid demand, particularly for fatty acids used in the production of soaps, detergents, and skincare products. The growing consumer awareness regarding personal hygiene and the increasing disposable income in developing economies have fueled this sector's expansion, consequently boosting the demand for carboxylic acids.

Agriculture represents another vital market for carboxylic acids, with applications in pesticides, herbicides, and plant growth regulators. The global push for increased agricultural productivity and sustainable farming practices has led to a rise in the use of these chemicals, further propelling market growth.

Regionally, Asia-Pacific has emerged as the largest consumer of carboxylic acids, driven by rapid industrialization, population growth, and increasing disposable income. China and India, in particular, have witnessed substantial growth in demand across various industries. North America and Europe follow closely, with mature markets characterized by high consumption in established industries and ongoing research and development activities.

The market landscape for carboxylic acids is characterized by intense competition among key players, leading to continuous innovation and product development. Manufacturers are increasingly focusing on developing bio-based carboxylic acids to cater to the growing demand for sustainable and eco-friendly products. This trend is expected to shape the future of the carboxylic acid market, potentially opening new avenues for growth and application.

In the food and beverage industry, carboxylic acids play a crucial role as preservatives, flavor enhancers, and acidulants. The rising consumer preference for processed and convenience foods has led to a surge in demand for these acids, particularly acetic acid, citric acid, and lactic acid. The pharmaceutical sector also heavily relies on carboxylic acids for the synthesis of various drugs and active pharmaceutical ingredients (APIs), contributing significantly to market growth.

The personal care and cosmetics industry has emerged as a key driver for carboxylic acid demand, particularly for fatty acids used in the production of soaps, detergents, and skincare products. The growing consumer awareness regarding personal hygiene and the increasing disposable income in developing economies have fueled this sector's expansion, consequently boosting the demand for carboxylic acids.

Agriculture represents another vital market for carboxylic acids, with applications in pesticides, herbicides, and plant growth regulators. The global push for increased agricultural productivity and sustainable farming practices has led to a rise in the use of these chemicals, further propelling market growth.

Regionally, Asia-Pacific has emerged as the largest consumer of carboxylic acids, driven by rapid industrialization, population growth, and increasing disposable income. China and India, in particular, have witnessed substantial growth in demand across various industries. North America and Europe follow closely, with mature markets characterized by high consumption in established industries and ongoing research and development activities.

The market landscape for carboxylic acids is characterized by intense competition among key players, leading to continuous innovation and product development. Manufacturers are increasingly focusing on developing bio-based carboxylic acids to cater to the growing demand for sustainable and eco-friendly products. This trend is expected to shape the future of the carboxylic acid market, potentially opening new avenues for growth and application.

Current Challenges in Carboxylic Acid Production

Despite significant advancements in carboxylic acid production, several challenges persist in industrial applications. One of the primary issues is the high energy consumption associated with traditional production methods. Many processes require elevated temperatures and pressures, leading to substantial operational costs and environmental concerns.

Raw material availability and cost fluctuations pose another significant challenge. The production of carboxylic acids often relies on petroleum-based feedstocks, which are subject to price volatility and supply chain disruptions. This dependency on non-renewable resources also raises sustainability concerns in an increasingly environmentally conscious market.

Yield optimization remains a critical challenge in carboxylic acid production. Current processes often suffer from low selectivity, resulting in the formation of unwanted by-products. This not only reduces the overall efficiency but also necessitates complex and costly separation and purification steps, further impacting the economic viability of production.

Catalyst performance and longevity present ongoing challenges. Many carboxylic acid production processes rely on heterogeneous catalysts, which can suffer from deactivation, fouling, and limited selectivity. Developing more robust, efficient, and selective catalysts is crucial for improving process economics and sustainability.

Environmental concerns and stringent regulations pose additional challenges. The production of carboxylic acids often generates significant amounts of waste and emissions. Meeting increasingly strict environmental standards while maintaining cost-effectiveness requires innovative approaches to waste reduction, recycling, and emission control.

Scale-up and process intensification remain challenging for newer, more sustainable production methods. While promising alternatives such as bio-based production and electrochemical synthesis have emerged, translating these technologies from laboratory scale to industrial production presents significant engineering and economic hurdles.

Lastly, product quality and consistency are ongoing concerns, particularly for high-purity applications in pharmaceuticals and electronics. Achieving and maintaining the required purity levels across large-scale production batches demands sophisticated process control and analytical techniques, adding complexity and cost to production operations.

Raw material availability and cost fluctuations pose another significant challenge. The production of carboxylic acids often relies on petroleum-based feedstocks, which are subject to price volatility and supply chain disruptions. This dependency on non-renewable resources also raises sustainability concerns in an increasingly environmentally conscious market.

Yield optimization remains a critical challenge in carboxylic acid production. Current processes often suffer from low selectivity, resulting in the formation of unwanted by-products. This not only reduces the overall efficiency but also necessitates complex and costly separation and purification steps, further impacting the economic viability of production.

Catalyst performance and longevity present ongoing challenges. Many carboxylic acid production processes rely on heterogeneous catalysts, which can suffer from deactivation, fouling, and limited selectivity. Developing more robust, efficient, and selective catalysts is crucial for improving process economics and sustainability.

Environmental concerns and stringent regulations pose additional challenges. The production of carboxylic acids often generates significant amounts of waste and emissions. Meeting increasingly strict environmental standards while maintaining cost-effectiveness requires innovative approaches to waste reduction, recycling, and emission control.

Scale-up and process intensification remain challenging for newer, more sustainable production methods. While promising alternatives such as bio-based production and electrochemical synthesis have emerged, translating these technologies from laboratory scale to industrial production presents significant engineering and economic hurdles.

Lastly, product quality and consistency are ongoing concerns, particularly for high-purity applications in pharmaceuticals and electronics. Achieving and maintaining the required purity levels across large-scale production batches demands sophisticated process control and analytical techniques, adding complexity and cost to production operations.

Modern Synthesis Methods

01 Synthesis of carboxylic acids

Various methods for synthesizing carboxylic acids are described, including oxidation of primary alcohols or aldehydes, hydrolysis of nitriles, and carbonylation reactions. These processes often involve catalysts and specific reaction conditions to achieve high yields and selectivity.- Synthesis of carboxylic acids: Various methods for synthesizing carboxylic acids are described, including oxidation of primary alcohols or aldehydes, hydrolysis of nitriles, and carbonylation reactions. These processes often involve catalysts and specific reaction conditions to achieve high yields and selectivity.

- Derivatives and applications of carboxylic acids: Carboxylic acids serve as precursors for various derivatives such as esters, amides, and anhydrides. These compounds find applications in pharmaceuticals, polymers, and industrial chemicals. The synthesis and properties of these derivatives are explored in several patents.

- Purification and separation techniques: Methods for purifying and separating carboxylic acids from reaction mixtures or natural sources are described. These include crystallization, distillation, extraction, and chromatographic techniques, often tailored to specific carboxylic acids or industrial processes.

- Carboxylic acids in polymer chemistry: The use of carboxylic acids in polymer synthesis and modification is explored. This includes their role as monomers, chain terminators, and functional groups for post-polymerization modifications. Applications in adhesives, coatings, and biodegradable materials are also discussed.

- Industrial production and scale-up: Patents related to the industrial-scale production of carboxylic acids are presented. These cover reactor designs, continuous processes, and strategies for improving yield and energy efficiency in large-scale manufacturing of important carboxylic acids.

02 Derivatives and applications of carboxylic acids

Carboxylic acids serve as precursors for various derivatives such as esters, amides, and anhydrides. These compounds find applications in pharmaceuticals, polymers, and industrial processes. The synthesis and properties of these derivatives are explored in several patents.Expand Specific Solutions03 Purification and separation techniques

Methods for purifying and separating carboxylic acids from reaction mixtures or natural sources are described. These techniques include crystallization, distillation, extraction, and chromatography, aimed at obtaining high-purity carboxylic acids for various applications.Expand Specific Solutions04 Carboxylic acids in polymer chemistry

The use of carboxylic acids in polymer synthesis and modification is explored. This includes their role as monomers, chain terminators, and functional groups for post-polymerization modifications. Applications in adhesives, coatings, and biodegradable materials are also discussed.Expand Specific Solutions05 Green chemistry approaches for carboxylic acids

Environmentally friendly methods for producing and using carboxylic acids are presented. These include bio-based production routes, catalytic processes with improved atom economy, and the use of renewable feedstocks. The focus is on reducing environmental impact while maintaining industrial viability.Expand Specific Solutions

Major Industrial Players

The carboxylic acid industry is in a mature stage, characterized by established applications across various sectors and a stable market size. The global market for carboxylic acids is estimated to be in the billions of dollars, with steady growth projected. Technologically, the field is well-developed, with ongoing innovations focused on improving production efficiency and exploring new applications. Key players like Eastman Chemical, Dow Global Technologies, and Evonik Operations are driving advancements in industrial-scale production and application development. Academic institutions such as ETH Zurich and the University of Science & Technology of China are contributing to fundamental research, while companies like ExxonMobil Chemical and DSM IP Assets are actively patenting new technologies, indicating a competitive and innovation-driven landscape.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has been at the forefront of carboxylic acid technology, particularly in the development of specialty acids for high-value applications. Their proprietary oxidation technology for producing 2-ethylhexanoic acid has set industry standards for efficiency and quality[4]. Eastman has also made breakthroughs in the synthesis of long-chain fatty acids from renewable resources, addressing the growing demand for sustainable chemical production[5]. Their research extends to the application of carboxylic acids in advanced polymer systems, including biodegradable plastics and high-performance coatings[6].

Strengths: Expertise in specialty acids, strong focus on renewable resources, and diverse application portfolio. Weaknesses: Higher production costs for some specialty acids, market volatility for certain niche products.

Dow Global Technologies LLC

Technical Solution: Dow has made significant strides in carboxylic acid evolution for industrial applications. They have developed innovative processes for producing acrylic and methacrylic acids, which are crucial in various industries. Their patented technology involves a two-step oxidation process of propylene or isobutylene, resulting in higher yields and improved product purity[1]. Dow has also focused on sustainable production methods, incorporating bio-based feedstocks and catalytic processes to reduce environmental impact[2]. Their research extends to novel applications of carboxylic acids in advanced materials, such as superabsorbent polymers and specialty coatings[3].

Strengths: Advanced catalytic processes, high product purity, and focus on sustainability. Weaknesses: Dependence on petrochemical feedstocks for some processes, potential high energy requirements.

Key Patents in Carboxylic Acid Synthesis

Process for the alkoxycarbonylation of diisobutene and a C4 to C7 olefin and subsequent hydrolysis

PatentPendingUS20250026706A1

Innovation

- A process involving the simultaneous alkoxycarbonylation of diisobutene and C4 to C7 olefins with an alcohol and carbon monoxide in a common reaction zone, using a homogeneous catalyst system, followed by hydrolysis or saponification to produce carboxylic acids or their salts, allowing for more resource-efficient operation and flexible production.

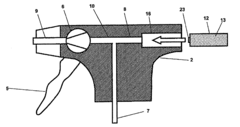

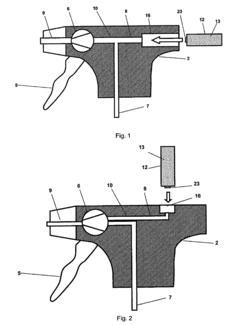

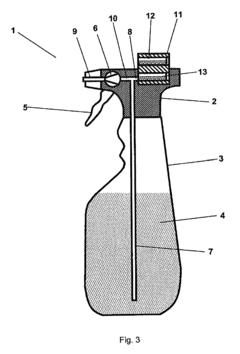

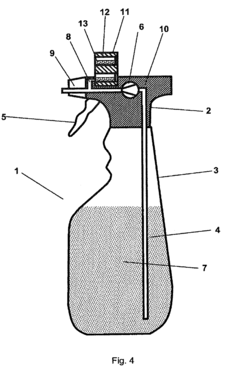

Dispensing device for dispensing a plurality of different preparations

PatentInactiveUS20090277928A1

Innovation

- A dispensing device with a receiving element for portion cartridges that can be detachably coupled, allowing users to select and mix different additive substances, such as fragrances and cleaning agents, without requiring design changes to single-chambered bottles, using a delivery element like a pump or aerosol package to dispense preparations from separate cartridges.

Environmental Impact Assessment

The environmental impact of carboxylic acid production and applications has become increasingly significant as industrial use has expanded over the decades. The evolution of carboxylic acid synthesis and utilization has brought both benefits and challenges to environmental sustainability.

Early production methods often involved energy-intensive processes and the use of toxic precursors, leading to concerns about air and water pollution. The oxidation of hydrocarbons, a common industrial route, generated substantial greenhouse gas emissions and required extensive waste treatment. However, advancements in catalytic processes and green chemistry principles have gradually improved the environmental profile of carboxylic acid production.

The introduction of biotechnological approaches, such as fermentation and enzymatic conversions, has offered more environmentally friendly alternatives. These methods often operate under milder conditions, consume less energy, and produce fewer harmful by-products. For instance, the production of citric acid through fermentation has largely replaced chemical synthesis, significantly reducing the carbon footprint of this widely used carboxylic acid.

Water pollution has been a persistent issue in carboxylic acid manufacturing. The high water solubility of many carboxylic acids poses challenges for wastewater treatment and can lead to aquatic ecosystem disruption if not properly managed. Industries have responded by implementing advanced effluent treatment technologies and closed-loop systems to minimize water contamination and reduce overall water consumption.

The use of carboxylic acids in various applications has also had mixed environmental impacts. In agriculture, the widespread use of acetic acid as a herbicide has reduced reliance on more persistent and toxic pesticides. However, the overuse of certain carboxylic acid-based fertilizers has contributed to soil acidification and nutrient runoff, affecting biodiversity and water quality in surrounding ecosystems.

In the polymer industry, the development of bio-based carboxylic acids for plastics production has offered potential alternatives to petroleum-derived materials. These bio-based polymers often have lower carbon footprints and improved biodegradability, addressing concerns about plastic pollution and fossil fuel dependence. However, the scalability and land-use implications of producing bio-based feedstocks remain subjects of ongoing environmental assessment.

The pharmaceutical sector's use of carboxylic acids has generally led to positive environmental outcomes. Many carboxylic acid-based drugs are more readily metabolized by the human body, resulting in lower levels of active pharmaceutical ingredients in wastewater. This reduces the potential for ecological disruption and the development of antibiotic-resistant bacteria in aquatic environments.

As environmental regulations have become more stringent, industries have been compelled to innovate in their carboxylic acid-related processes. This has driven research into cleaner production methods, more efficient catalysts, and improved recycling techniques. The adoption of life cycle assessment methodologies has also helped identify and mitigate environmental hotspots in carboxylic acid value chains.

Early production methods often involved energy-intensive processes and the use of toxic precursors, leading to concerns about air and water pollution. The oxidation of hydrocarbons, a common industrial route, generated substantial greenhouse gas emissions and required extensive waste treatment. However, advancements in catalytic processes and green chemistry principles have gradually improved the environmental profile of carboxylic acid production.

The introduction of biotechnological approaches, such as fermentation and enzymatic conversions, has offered more environmentally friendly alternatives. These methods often operate under milder conditions, consume less energy, and produce fewer harmful by-products. For instance, the production of citric acid through fermentation has largely replaced chemical synthesis, significantly reducing the carbon footprint of this widely used carboxylic acid.

Water pollution has been a persistent issue in carboxylic acid manufacturing. The high water solubility of many carboxylic acids poses challenges for wastewater treatment and can lead to aquatic ecosystem disruption if not properly managed. Industries have responded by implementing advanced effluent treatment technologies and closed-loop systems to minimize water contamination and reduce overall water consumption.

The use of carboxylic acids in various applications has also had mixed environmental impacts. In agriculture, the widespread use of acetic acid as a herbicide has reduced reliance on more persistent and toxic pesticides. However, the overuse of certain carboxylic acid-based fertilizers has contributed to soil acidification and nutrient runoff, affecting biodiversity and water quality in surrounding ecosystems.

In the polymer industry, the development of bio-based carboxylic acids for plastics production has offered potential alternatives to petroleum-derived materials. These bio-based polymers often have lower carbon footprints and improved biodegradability, addressing concerns about plastic pollution and fossil fuel dependence. However, the scalability and land-use implications of producing bio-based feedstocks remain subjects of ongoing environmental assessment.

The pharmaceutical sector's use of carboxylic acids has generally led to positive environmental outcomes. Many carboxylic acid-based drugs are more readily metabolized by the human body, resulting in lower levels of active pharmaceutical ingredients in wastewater. This reduces the potential for ecological disruption and the development of antibiotic-resistant bacteria in aquatic environments.

As environmental regulations have become more stringent, industries have been compelled to innovate in their carboxylic acid-related processes. This has driven research into cleaner production methods, more efficient catalysts, and improved recycling techniques. The adoption of life cycle assessment methodologies has also helped identify and mitigate environmental hotspots in carboxylic acid value chains.

Regulatory Framework for Carboxylic Acids

The regulatory framework for carboxylic acids has evolved significantly over the years, reflecting the growing importance of these compounds in various industrial applications. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating carboxylic acids used in food, pharmaceuticals, and cosmetics. The FDA's Generally Recognized as Safe (GRAS) list includes several carboxylic acids, such as acetic acid and citric acid, which are widely used in food production.

The Environmental Protection Agency (EPA) oversees the use of carboxylic acids in industrial processes and their potential environmental impact. Under the Toxic Substances Control Act (TSCA), manufacturers must report new chemical substances, including novel carboxylic acids, to the EPA for review before production or importation. This ensures that potential risks to human health and the environment are assessed and mitigated.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of carboxylic acids in various industries. REACH requires companies to register chemical substances, including carboxylic acids, and provide safety data to the European Chemicals Agency (ECHA). This comprehensive approach aims to protect human health and the environment while promoting innovation in the chemical industry.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been widely adopted internationally, providing a standardized approach to communicating chemical hazards. Many carboxylic acids are classified under GHS, with specific hazard statements and precautionary measures required on labels and safety data sheets.

In the pharmaceutical industry, regulatory bodies such as the FDA and the European Medicines Agency (EMA) have established guidelines for the use of carboxylic acids in drug manufacturing. These guidelines cover aspects such as impurity limits, stability testing, and good manufacturing practices (GMP) to ensure the safety and efficacy of pharmaceutical products containing carboxylic acids.

As the industrial applications of carboxylic acids continue to expand, regulatory frameworks are adapting to address emerging concerns. For instance, the increasing use of bio-based carboxylic acids has led to discussions on how to regulate these sustainable alternatives within existing frameworks. Additionally, the growing focus on circular economy principles is influencing regulations related to the recycling and reuse of carboxylic acids in industrial processes.

The Environmental Protection Agency (EPA) oversees the use of carboxylic acids in industrial processes and their potential environmental impact. Under the Toxic Substances Control Act (TSCA), manufacturers must report new chemical substances, including novel carboxylic acids, to the EPA for review before production or importation. This ensures that potential risks to human health and the environment are assessed and mitigated.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of carboxylic acids in various industries. REACH requires companies to register chemical substances, including carboxylic acids, and provide safety data to the European Chemicals Agency (ECHA). This comprehensive approach aims to protect human health and the environment while promoting innovation in the chemical industry.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been widely adopted internationally, providing a standardized approach to communicating chemical hazards. Many carboxylic acids are classified under GHS, with specific hazard statements and precautionary measures required on labels and safety data sheets.

In the pharmaceutical industry, regulatory bodies such as the FDA and the European Medicines Agency (EMA) have established guidelines for the use of carboxylic acids in drug manufacturing. These guidelines cover aspects such as impurity limits, stability testing, and good manufacturing practices (GMP) to ensure the safety and efficacy of pharmaceutical products containing carboxylic acids.

As the industrial applications of carboxylic acids continue to expand, regulatory frameworks are adapting to address emerging concerns. For instance, the increasing use of bio-based carboxylic acids has led to discussions on how to regulate these sustainable alternatives within existing frameworks. Additionally, the growing focus on circular economy principles is influencing regulations related to the recycling and reuse of carboxylic acids in industrial processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!