How to Minimize Side Reactions in Carboxylic Acid Chemistry?

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carboxylic Acid Chemistry Background and Objectives

Carboxylic acids are fundamental organic compounds with a wide range of applications in chemistry and industry. The carboxyl group (-COOH) is a versatile functional group that can participate in numerous reactions, making it a crucial building block in organic synthesis. However, the reactivity of carboxylic acids often leads to undesired side reactions, which can significantly impact the efficiency and selectivity of chemical processes.

The evolution of carboxylic acid chemistry has been marked by continuous efforts to enhance reaction control and minimize unwanted side products. From the early days of organic synthesis to modern green chemistry approaches, researchers have been developing strategies to optimize carboxylic acid reactions. These advancements have been driven by the need for more efficient and sustainable chemical processes in various industries, including pharmaceuticals, materials science, and agrochemicals.

The primary objective in minimizing side reactions in carboxylic acid chemistry is to improve reaction yields, reduce waste generation, and enhance product purity. This goal aligns with the principles of green chemistry and sustainable manufacturing, which are becoming increasingly important in the face of environmental concerns and regulatory pressures. By achieving better control over carboxylic acid reactions, chemists can develop more efficient synthetic routes, reduce production costs, and minimize environmental impact.

Key technological trends in this field include the development of novel catalysts, the use of alternative reaction media, and the application of flow chemistry techniques. These innovations aim to provide better selectivity, milder reaction conditions, and improved overall efficiency in carboxylic acid transformations. Additionally, computational chemistry and high-throughput screening methods are being employed to predict and optimize reaction conditions, further advancing the field.

The challenges in minimizing side reactions stem from the inherent reactivity of the carboxyl group and its susceptibility to various competing pathways. Common side reactions include decarboxylation, esterification, and condensation reactions, which can lead to complex mixtures and reduced yields of desired products. Overcoming these challenges requires a deep understanding of reaction mechanisms, careful control of reaction parameters, and innovative approaches to reaction design.

As research in this area progresses, the focus is shifting towards developing more selective and efficient methodologies that can be applied on an industrial scale. This includes exploring new protecting group strategies, designing smarter catalytic systems, and leveraging the power of biocatalysis. The ultimate goal is to establish robust and versatile protocols that can be widely adopted in both academic and industrial settings, paving the way for more sustainable and economically viable chemical processes.

The evolution of carboxylic acid chemistry has been marked by continuous efforts to enhance reaction control and minimize unwanted side products. From the early days of organic synthesis to modern green chemistry approaches, researchers have been developing strategies to optimize carboxylic acid reactions. These advancements have been driven by the need for more efficient and sustainable chemical processes in various industries, including pharmaceuticals, materials science, and agrochemicals.

The primary objective in minimizing side reactions in carboxylic acid chemistry is to improve reaction yields, reduce waste generation, and enhance product purity. This goal aligns with the principles of green chemistry and sustainable manufacturing, which are becoming increasingly important in the face of environmental concerns and regulatory pressures. By achieving better control over carboxylic acid reactions, chemists can develop more efficient synthetic routes, reduce production costs, and minimize environmental impact.

Key technological trends in this field include the development of novel catalysts, the use of alternative reaction media, and the application of flow chemistry techniques. These innovations aim to provide better selectivity, milder reaction conditions, and improved overall efficiency in carboxylic acid transformations. Additionally, computational chemistry and high-throughput screening methods are being employed to predict and optimize reaction conditions, further advancing the field.

The challenges in minimizing side reactions stem from the inherent reactivity of the carboxyl group and its susceptibility to various competing pathways. Common side reactions include decarboxylation, esterification, and condensation reactions, which can lead to complex mixtures and reduced yields of desired products. Overcoming these challenges requires a deep understanding of reaction mechanisms, careful control of reaction parameters, and innovative approaches to reaction design.

As research in this area progresses, the focus is shifting towards developing more selective and efficient methodologies that can be applied on an industrial scale. This includes exploring new protecting group strategies, designing smarter catalytic systems, and leveraging the power of biocatalysis. The ultimate goal is to establish robust and versatile protocols that can be widely adopted in both academic and industrial settings, paving the way for more sustainable and economically viable chemical processes.

Industrial Applications and Market Demand

Carboxylic acid chemistry plays a crucial role in various industrial sectors, driving significant market demand for efficient and selective reactions. The minimization of side reactions in carboxylic acid chemistry is of paramount importance across multiple industries, including pharmaceuticals, agrochemicals, polymers, and fine chemicals.

In the pharmaceutical industry, carboxylic acids serve as key building blocks for numerous active pharmaceutical ingredients (APIs). The ability to control side reactions is essential for improving product yield, purity, and cost-effectiveness in drug manufacturing processes. Many blockbuster drugs, such as aspirin, ibuprofen, and statins, rely on carboxylic acid chemistry. The global pharmaceutical market, valued at over $1.4 trillion, continues to grow, creating a substantial demand for advanced carboxylic acid reaction technologies.

The agrochemical sector also heavily relies on carboxylic acid chemistry for the production of herbicides, pesticides, and plant growth regulators. Minimizing side reactions in these processes is crucial for developing more environmentally friendly and effective agricultural products. As the global population increases and arable land becomes scarcer, the demand for high-performance agrochemicals is expected to rise, further emphasizing the need for improved carboxylic acid reaction control.

In the polymer industry, carboxylic acids are essential precursors for various materials, including polyesters, polyamides, and acrylic polymers. The global polymer market, projected to reach $750 billion by 2025, requires increasingly sophisticated carboxylic acid chemistry to develop advanced materials with enhanced properties. Minimizing side reactions in polymer synthesis can lead to improved product quality, reduced waste, and more efficient production processes.

The fine chemicals industry, which produces specialty chemicals for diverse applications, also benefits significantly from advancements in carboxylic acid chemistry. Flavors, fragrances, dyes, and other high-value chemicals often involve carboxylic acid intermediates. The ability to minimize side reactions in these processes can lead to higher-quality products and more economical production methods.

Furthermore, the growing emphasis on green chemistry and sustainable manufacturing practices across industries has intensified the focus on reaction selectivity and efficiency. Minimizing side reactions in carboxylic acid chemistry aligns with these goals by reducing waste, lowering energy consumption, and improving atom economy. This trend is particularly evident in the increasing adoption of biocatalysis and flow chemistry techniques in industrial processes.

The market demand for technologies and methodologies that can effectively minimize side reactions in carboxylic acid chemistry is expected to grow as industries strive for higher efficiency, sustainability, and product quality. This demand drives ongoing research and development efforts in academia and industry, fostering innovation in catalysis, reaction engineering, and process optimization.

In the pharmaceutical industry, carboxylic acids serve as key building blocks for numerous active pharmaceutical ingredients (APIs). The ability to control side reactions is essential for improving product yield, purity, and cost-effectiveness in drug manufacturing processes. Many blockbuster drugs, such as aspirin, ibuprofen, and statins, rely on carboxylic acid chemistry. The global pharmaceutical market, valued at over $1.4 trillion, continues to grow, creating a substantial demand for advanced carboxylic acid reaction technologies.

The agrochemical sector also heavily relies on carboxylic acid chemistry for the production of herbicides, pesticides, and plant growth regulators. Minimizing side reactions in these processes is crucial for developing more environmentally friendly and effective agricultural products. As the global population increases and arable land becomes scarcer, the demand for high-performance agrochemicals is expected to rise, further emphasizing the need for improved carboxylic acid reaction control.

In the polymer industry, carboxylic acids are essential precursors for various materials, including polyesters, polyamides, and acrylic polymers. The global polymer market, projected to reach $750 billion by 2025, requires increasingly sophisticated carboxylic acid chemistry to develop advanced materials with enhanced properties. Minimizing side reactions in polymer synthesis can lead to improved product quality, reduced waste, and more efficient production processes.

The fine chemicals industry, which produces specialty chemicals for diverse applications, also benefits significantly from advancements in carboxylic acid chemistry. Flavors, fragrances, dyes, and other high-value chemicals often involve carboxylic acid intermediates. The ability to minimize side reactions in these processes can lead to higher-quality products and more economical production methods.

Furthermore, the growing emphasis on green chemistry and sustainable manufacturing practices across industries has intensified the focus on reaction selectivity and efficiency. Minimizing side reactions in carboxylic acid chemistry aligns with these goals by reducing waste, lowering energy consumption, and improving atom economy. This trend is particularly evident in the increasing adoption of biocatalysis and flow chemistry techniques in industrial processes.

The market demand for technologies and methodologies that can effectively minimize side reactions in carboxylic acid chemistry is expected to grow as industries strive for higher efficiency, sustainability, and product quality. This demand drives ongoing research and development efforts in academia and industry, fostering innovation in catalysis, reaction engineering, and process optimization.

Current Challenges in Side Reaction Control

Controlling side reactions in carboxylic acid chemistry remains a significant challenge for researchers and industry professionals. The high reactivity of carboxylic acids and their derivatives often leads to undesired secondary reactions, impacting product yield, purity, and overall process efficiency. One of the primary challenges is the nucleophilic nature of carboxylic acids, which can lead to self-condensation or reaction with other nucleophiles present in the reaction mixture.

The presence of multiple functional groups in carboxylic acid molecules further complicates the control of side reactions. For instance, in α-substituted carboxylic acids, the α-carbon can undergo undesired reactions, leading to racemization or epimerization. This is particularly problematic in the synthesis of chiral compounds, where maintaining stereochemical integrity is crucial.

Another significant challenge is the control of esterification side reactions. In the presence of alcohols or other hydroxyl-containing compounds, carboxylic acids can readily form esters, even under mild conditions. This can be especially problematic in multi-step syntheses or in reactions where both carboxylic acids and alcohols are present as reactants or solvents.

The formation of anhydrides is another common side reaction that poses challenges in carboxylic acid chemistry. Under certain conditions, two carboxylic acid molecules can condense to form an anhydride, reducing the yield of the desired product and potentially altering the reaction pathway. This is particularly problematic in dehydration reactions or when working with activated carboxylic acid derivatives.

Oxidation and reduction side reactions also present significant challenges. Carboxylic acids can undergo oxidation to form peroxy acids or decarboxylation products, especially in the presence of strong oxidizing agents or at elevated temperatures. Conversely, reduction of carboxylic acids to aldehydes or alcohols can occur unintentionally, particularly when using strong reducing agents or in the presence of catalytic hydrogenation conditions.

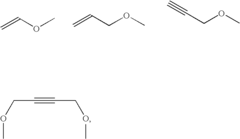

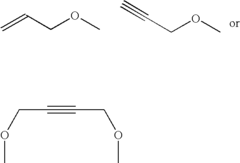

The control of polymerization side reactions is another area of concern, especially when working with unsaturated carboxylic acids. These compounds can undergo spontaneous polymerization, leading to the formation of unwanted oligomers or polymers, which can significantly impact product purity and reaction efficiency.

Addressing these challenges requires a multifaceted approach, combining careful reaction design, precise control of reaction conditions, and the development of novel catalysts and reagents. Researchers are continually exploring new strategies to minimize side reactions, such as the use of protective groups, selective catalysts, and innovative reaction media. However, the complexity of carboxylic acid chemistry ensures that the control of side reactions remains an ongoing area of research and development in both academic and industrial settings.

The presence of multiple functional groups in carboxylic acid molecules further complicates the control of side reactions. For instance, in α-substituted carboxylic acids, the α-carbon can undergo undesired reactions, leading to racemization or epimerization. This is particularly problematic in the synthesis of chiral compounds, where maintaining stereochemical integrity is crucial.

Another significant challenge is the control of esterification side reactions. In the presence of alcohols or other hydroxyl-containing compounds, carboxylic acids can readily form esters, even under mild conditions. This can be especially problematic in multi-step syntheses or in reactions where both carboxylic acids and alcohols are present as reactants or solvents.

The formation of anhydrides is another common side reaction that poses challenges in carboxylic acid chemistry. Under certain conditions, two carboxylic acid molecules can condense to form an anhydride, reducing the yield of the desired product and potentially altering the reaction pathway. This is particularly problematic in dehydration reactions or when working with activated carboxylic acid derivatives.

Oxidation and reduction side reactions also present significant challenges. Carboxylic acids can undergo oxidation to form peroxy acids or decarboxylation products, especially in the presence of strong oxidizing agents or at elevated temperatures. Conversely, reduction of carboxylic acids to aldehydes or alcohols can occur unintentionally, particularly when using strong reducing agents or in the presence of catalytic hydrogenation conditions.

The control of polymerization side reactions is another area of concern, especially when working with unsaturated carboxylic acids. These compounds can undergo spontaneous polymerization, leading to the formation of unwanted oligomers or polymers, which can significantly impact product purity and reaction efficiency.

Addressing these challenges requires a multifaceted approach, combining careful reaction design, precise control of reaction conditions, and the development of novel catalysts and reagents. Researchers are continually exploring new strategies to minimize side reactions, such as the use of protective groups, selective catalysts, and innovative reaction media. However, the complexity of carboxylic acid chemistry ensures that the control of side reactions remains an ongoing area of research and development in both academic and industrial settings.

Existing Strategies for Side Reaction Minimization

01 Decarboxylation reactions

Decarboxylation is a common side reaction in carboxylic acid chemistry, where the carboxyl group is removed as carbon dioxide. This reaction can occur under various conditions, such as heat or in the presence of certain catalysts. Understanding and controlling decarboxylation is crucial in many organic synthesis processes.- Esterification side reactions: Carboxylic acids can undergo esterification reactions as a common side reaction. This occurs when the carboxylic acid reacts with an alcohol, forming an ester and water. The reaction can be catalyzed by acids or bases and is often reversible. Understanding and controlling esterification is crucial in many organic synthesis processes.

- Decarboxylation reactions: Decarboxylation is a side reaction where carboxylic acids lose carbon dioxide, resulting in the formation of a new compound with one less carbon atom. This reaction can occur spontaneously at high temperatures or in the presence of certain catalysts. Decarboxylation can be both beneficial and detrimental depending on the desired outcome of a chemical process.

- Oxidation and reduction reactions: Carboxylic acids can undergo oxidation or reduction reactions as side processes. Oxidation may lead to the formation of more complex molecules or degradation products, while reduction can result in the formation of aldehydes or alcohols. These reactions are important considerations in organic synthesis and can affect the purity and yield of desired products.

- Halogenation side reactions: Halogenation can occur as a side reaction in carboxylic acid chemistry, particularly in the presence of halogenating agents. This can lead to the formation of α-halogenated carboxylic acids or acyl halides. Understanding and controlling halogenation is important in various industrial processes and in the synthesis of pharmaceuticals and other organic compounds.

- Condensation and polymerization reactions: Carboxylic acids can participate in condensation reactions, leading to the formation of anhydrides, amides, or polymers. These side reactions can occur between two carboxylic acid molecules or between a carboxylic acid and another functional group. Controlling these reactions is crucial in polymer chemistry and in the synthesis of various organic compounds.

02 Esterification and transesterification

Esterification is a side reaction where carboxylic acids react with alcohols to form esters. Transesterification involves the exchange of alkoxy groups between an ester and an alcohol. These reactions can be both beneficial and problematic in organic synthesis, depending on the desired outcome.Expand Specific Solutions03 Oxidation and reduction of carboxylic acids

Carboxylic acids can undergo oxidation or reduction reactions as side processes. Oxidation may lead to the formation of higher oxidation state compounds, while reduction can result in the formation of aldehydes or alcohols. These reactions can impact the purity and yield of desired products in organic synthesis.Expand Specific Solutions04 Halogenation of carboxylic acids

Halogenation can occur as a side reaction in carboxylic acid chemistry, leading to the formation of acyl halides or α-halogenated carboxylic acids. These reactions can be influenced by factors such as temperature, catalysts, and the presence of halogenating agents. Control of halogenation is important in maintaining product selectivity.Expand Specific Solutions05 Condensation reactions

Carboxylic acids can participate in various condensation reactions as side processes, including aldol condensation, Claisen condensation, and self-condensation. These reactions can lead to the formation of complex molecules and may compete with desired transformations in organic synthesis. Understanding and controlling these condensation reactions is crucial for optimizing reaction outcomes.Expand Specific Solutions

Key Players in Carboxylic Acid Research and Production

The competitive landscape for minimizing side reactions in carboxylic acid chemistry is characterized by a mature market with established players and ongoing research. Major companies like BASF, Daicel, and Eastman Chemical are at the forefront, leveraging their extensive R&D capabilities and industry experience. The market size is substantial, driven by applications in pharmaceuticals, agrochemicals, and industrial processes. Technological advancements focus on improving selectivity and yield, with research institutions like AIST and Nanjing Tech University contributing to innovation. Emerging players such as Astex Therapeutics and SK Innovation are also making strides, indicating a dynamic and evolving field.

BASF Corp.

Technical Solution: BASF has developed innovative strategies to minimize side reactions in carboxylic acid chemistry. They employ selective catalysts and optimized reaction conditions to enhance desired product formation. Their approach includes using metal-organic frameworks (MOFs) as heterogeneous catalysts, which provide high selectivity and recyclability[1]. BASF also utilizes continuous flow chemistry techniques, allowing for precise control of reaction parameters and reducing unwanted side reactions[2]. Additionally, they have implemented advanced purification methods, such as membrane separation technology, to efficiently remove byproducts and increase overall yield[3].

Strengths: Extensive R&D capabilities, diverse product portfolio, and global presence. Weaknesses: High operational costs and potential environmental concerns associated with chemical production.

Bayer Intellectual Property GmbH

Technical Solution: Bayer has developed sophisticated strategies to minimize side reactions in carboxylic acid chemistry, particularly in pharmaceutical applications. They employ chiral catalysts and asymmetric synthesis techniques to achieve high stereoselectivity, reducing unwanted isomer formation[10]. Bayer has also implemented advanced computational modeling and high-throughput experimentation to optimize reaction conditions and predict potential side reactions[11]. Their approach includes the use of protective group chemistry to shield reactive functional groups and prevent undesired reactions[12]. Additionally, Bayer utilizes flow chemistry and microreactor technology to precisely control reaction parameters, enhancing selectivity and reducing side product formation in complex organic syntheses involving carboxylic acids.

Strengths: Strong R&D capabilities, extensive patent portfolio, and expertise in pharmaceutical chemistry. Weaknesses: High regulatory scrutiny in the pharmaceutical industry and potential public perception issues related to certain products.

Innovative Approaches in Reaction Selectivity

Process for preparing organosilicon compounds

PatentInactiveUS20050137412A1

Innovation

- A process involving the use of cyclic ethers in the presence of carbinol groups and Si-bonded hydrogen-containing organosilicon compounds, which allows for a homogeneous reaction without the need for insoluble additives, reducing side reactions and operational costs.

Process for reacting a low molecular weight hydroxy compound with a carboxylic acid halide

PatentInactiveEP0513055A1

Innovation

- Reversing the addition process by initially adding the carboxylic acid halide in excess and gradually introducing the hydroxy compound, allowing for controlled reaction conditions and minimizing heat absorption by ensuring HCl gas is released early, thus avoiding unwanted side reactions.

Green Chemistry Considerations

Green chemistry principles play a crucial role in minimizing side reactions in carboxylic acid chemistry. The focus on environmentally friendly and sustainable practices aligns with the goal of reducing unwanted by-products and improving overall reaction efficiency. One key consideration is the use of catalysts that promote selectivity and reduce energy requirements. Enzyme-catalyzed reactions, for instance, offer high specificity and can operate under mild conditions, minimizing the formation of side products.

The selection of solvents is another critical aspect of green chemistry in carboxylic acid reactions. Water-based systems or bio-derived solvents can replace traditional organic solvents, reducing environmental impact and potentially suppressing side reactions. Ionic liquids have also gained attention as green alternatives, offering unique properties that can enhance reaction control and product selectivity.

Process intensification techniques, such as microreactor technology, contribute to greener carboxylic acid chemistry. These systems allow for precise control of reaction parameters, leading to improved selectivity and reduced waste generation. Continuous flow processes, in particular, can optimize reaction conditions and minimize the formation of unwanted by-products.

The application of alternative energy sources aligns with green chemistry principles while addressing side reaction challenges. Microwave-assisted reactions, for example, can provide rapid and selective heating, potentially reducing reaction times and limiting the occurrence of side reactions. Similarly, photochemical processes offer a way to initiate reactions under mild conditions, often with high selectivity.

Atom economy is a fundamental concept in green chemistry that directly relates to minimizing side reactions. Designing synthetic routes that incorporate a higher percentage of reactants into the final product naturally reduces the potential for side product formation. This approach often involves rethinking traditional synthetic pathways and exploring novel reaction mechanisms.

The use of renewable feedstocks in carboxylic acid chemistry not only promotes sustainability but can also lead to more selective reactions. Biomass-derived starting materials often possess inherent functionalities that can be exploited to achieve desired transformations with fewer side reactions. This approach aligns with the broader goals of green chemistry while addressing the specific challenge of side reaction minimization.

In conclusion, integrating green chemistry considerations into carboxylic acid chemistry offers multiple avenues for minimizing side reactions. From catalyst design and solvent selection to process optimization and alternative energy sources, these principles provide a comprehensive framework for developing more efficient and environmentally friendly synthetic processes.

The selection of solvents is another critical aspect of green chemistry in carboxylic acid reactions. Water-based systems or bio-derived solvents can replace traditional organic solvents, reducing environmental impact and potentially suppressing side reactions. Ionic liquids have also gained attention as green alternatives, offering unique properties that can enhance reaction control and product selectivity.

Process intensification techniques, such as microreactor technology, contribute to greener carboxylic acid chemistry. These systems allow for precise control of reaction parameters, leading to improved selectivity and reduced waste generation. Continuous flow processes, in particular, can optimize reaction conditions and minimize the formation of unwanted by-products.

The application of alternative energy sources aligns with green chemistry principles while addressing side reaction challenges. Microwave-assisted reactions, for example, can provide rapid and selective heating, potentially reducing reaction times and limiting the occurrence of side reactions. Similarly, photochemical processes offer a way to initiate reactions under mild conditions, often with high selectivity.

Atom economy is a fundamental concept in green chemistry that directly relates to minimizing side reactions. Designing synthetic routes that incorporate a higher percentage of reactants into the final product naturally reduces the potential for side product formation. This approach often involves rethinking traditional synthetic pathways and exploring novel reaction mechanisms.

The use of renewable feedstocks in carboxylic acid chemistry not only promotes sustainability but can also lead to more selective reactions. Biomass-derived starting materials often possess inherent functionalities that can be exploited to achieve desired transformations with fewer side reactions. This approach aligns with the broader goals of green chemistry while addressing the specific challenge of side reaction minimization.

In conclusion, integrating green chemistry considerations into carboxylic acid chemistry offers multiple avenues for minimizing side reactions. From catalyst design and solvent selection to process optimization and alternative energy sources, these principles provide a comprehensive framework for developing more efficient and environmentally friendly synthetic processes.

Analytical Techniques for Side Product Detection

Analytical techniques for side product detection play a crucial role in minimizing side reactions in carboxylic acid chemistry. These methods enable researchers to identify and quantify unwanted byproducts, providing valuable insights into reaction mechanisms and optimization strategies.

High-performance liquid chromatography (HPLC) is a widely used technique for separating and detecting side products in carboxylic acid reactions. HPLC offers high resolution and sensitivity, allowing for the identification of trace amounts of impurities. Reversed-phase HPLC is particularly effective for analyzing polar compounds, such as carboxylic acids and their derivatives. By optimizing mobile phase composition and column selection, researchers can achieve excellent separation of target compounds and side products.

Gas chromatography-mass spectrometry (GC-MS) is another powerful tool for side product detection, especially for volatile and thermally stable compounds. This technique combines the separation capabilities of gas chromatography with the identification power of mass spectrometry. GC-MS can provide structural information on unknown side products, aiding in their characterization and elucidation of reaction pathways.

Nuclear magnetic resonance (NMR) spectroscopy offers valuable insights into the structure and composition of reaction mixtures. 1H and 13C NMR can reveal the presence of unexpected side products and provide information on their molecular structure. Two-dimensional NMR techniques, such as COSY and HSQC, enable more detailed structural analysis of complex mixtures.

Mass spectrometry (MS) techniques, including electrospray ionization (ESI) and matrix-assisted laser desorption/ionization (MALDI), are essential for analyzing non-volatile and thermally labile compounds. These methods can detect a wide range of side products with high sensitivity and provide accurate mass measurements for molecular formula determination.

Infrared (IR) spectroscopy is useful for identifying functional groups present in side products. This technique can help distinguish between different types of carboxylic acid derivatives and detect the formation of unexpected functional groups during reactions.

Thin-layer chromatography (TLC) serves as a rapid and cost-effective method for monitoring reaction progress and detecting side products. While not as sensitive as HPLC or GC-MS, TLC can provide valuable qualitative information on the presence of impurities and guide further analysis using more advanced techniques.

Capillary electrophoresis (CE) is emerging as a powerful technique for analyzing charged species in complex mixtures. CE offers high resolution and efficiency, making it suitable for separating and detecting ionic side products in carboxylic acid reactions.

By employing a combination of these analytical techniques, researchers can gain comprehensive insights into side product formation in carboxylic acid chemistry. This knowledge is essential for developing strategies to minimize unwanted reactions and optimize synthetic processes.

High-performance liquid chromatography (HPLC) is a widely used technique for separating and detecting side products in carboxylic acid reactions. HPLC offers high resolution and sensitivity, allowing for the identification of trace amounts of impurities. Reversed-phase HPLC is particularly effective for analyzing polar compounds, such as carboxylic acids and their derivatives. By optimizing mobile phase composition and column selection, researchers can achieve excellent separation of target compounds and side products.

Gas chromatography-mass spectrometry (GC-MS) is another powerful tool for side product detection, especially for volatile and thermally stable compounds. This technique combines the separation capabilities of gas chromatography with the identification power of mass spectrometry. GC-MS can provide structural information on unknown side products, aiding in their characterization and elucidation of reaction pathways.

Nuclear magnetic resonance (NMR) spectroscopy offers valuable insights into the structure and composition of reaction mixtures. 1H and 13C NMR can reveal the presence of unexpected side products and provide information on their molecular structure. Two-dimensional NMR techniques, such as COSY and HSQC, enable more detailed structural analysis of complex mixtures.

Mass spectrometry (MS) techniques, including electrospray ionization (ESI) and matrix-assisted laser desorption/ionization (MALDI), are essential for analyzing non-volatile and thermally labile compounds. These methods can detect a wide range of side products with high sensitivity and provide accurate mass measurements for molecular formula determination.

Infrared (IR) spectroscopy is useful for identifying functional groups present in side products. This technique can help distinguish between different types of carboxylic acid derivatives and detect the formation of unexpected functional groups during reactions.

Thin-layer chromatography (TLC) serves as a rapid and cost-effective method for monitoring reaction progress and detecting side products. While not as sensitive as HPLC or GC-MS, TLC can provide valuable qualitative information on the presence of impurities and guide further analysis using more advanced techniques.

Capillary electrophoresis (CE) is emerging as a powerful technique for analyzing charged species in complex mixtures. CE offers high resolution and efficiency, making it suitable for separating and detecting ionic side products in carboxylic acid reactions.

By employing a combination of these analytical techniques, researchers can gain comprehensive insights into side product formation in carboxylic acid chemistry. This knowledge is essential for developing strategies to minimize unwanted reactions and optimize synthetic processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!