Future of Carboxylic Acid in Biodegradable Polymer Production

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carboxylic Acid in Biopolymers: Background and Objectives

Carboxylic acids have played a pivotal role in the development of biodegradable polymers, marking a significant shift towards sustainable materials in various industries. The journey of carboxylic acids in biopolymer production can be traced back to the early 1990s when environmental concerns began to drive research into alternatives to traditional petroleum-based plastics. This technological evolution has been driven by the growing need for materials that can decompose naturally, reducing the environmental impact of plastic waste.

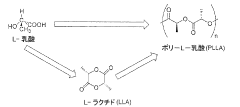

The primary objective in utilizing carboxylic acids for biodegradable polymer production is to create materials that maintain the desirable properties of conventional plastics while offering enhanced biodegradability. Carboxylic acids, with their unique chemical structure and reactivity, serve as essential building blocks in the synthesis of various biopolymers. They contribute to the formation of ester linkages, which are crucial for the biodegradability of the resulting polymers.

Over the years, research has focused on optimizing the use of carboxylic acids derived from renewable resources, such as plant-based feedstocks. This aligns with the broader goal of developing sustainable production methods and reducing reliance on fossil fuels. The integration of carboxylic acids into biopolymer synthesis has opened up new possibilities for tailoring material properties, including mechanical strength, thermal stability, and degradation rates.

The technological landscape has seen significant advancements in the methods of incorporating carboxylic acids into polymer structures. From simple condensation reactions to more complex catalytic processes, researchers have continually refined techniques to improve efficiency and expand the range of achievable polymer properties. This progress has been driven by interdisciplinary collaborations, combining expertise from chemistry, materials science, and biotechnology.

Looking ahead, the future of carboxylic acids in biodegradable polymer production holds great promise. Emerging trends point towards the development of more sophisticated biopolymers with enhanced functionalities, such as stimuli-responsive degradation or improved barrier properties. There is also a growing interest in exploring novel sources of carboxylic acids, including those derived from waste streams or produced through microbial fermentation.

As we move forward, the objectives for carboxylic acid utilization in biopolymer production are becoming increasingly ambitious. These include achieving cost-competitiveness with traditional plastics, expanding the range of applications for biodegradable polymers, and further reducing the environmental footprint of production processes. The ultimate goal is to establish carboxylic acid-based biopolymers as a mainstream alternative to conventional plastics across various sectors, from packaging to medical devices.

The primary objective in utilizing carboxylic acids for biodegradable polymer production is to create materials that maintain the desirable properties of conventional plastics while offering enhanced biodegradability. Carboxylic acids, with their unique chemical structure and reactivity, serve as essential building blocks in the synthesis of various biopolymers. They contribute to the formation of ester linkages, which are crucial for the biodegradability of the resulting polymers.

Over the years, research has focused on optimizing the use of carboxylic acids derived from renewable resources, such as plant-based feedstocks. This aligns with the broader goal of developing sustainable production methods and reducing reliance on fossil fuels. The integration of carboxylic acids into biopolymer synthesis has opened up new possibilities for tailoring material properties, including mechanical strength, thermal stability, and degradation rates.

The technological landscape has seen significant advancements in the methods of incorporating carboxylic acids into polymer structures. From simple condensation reactions to more complex catalytic processes, researchers have continually refined techniques to improve efficiency and expand the range of achievable polymer properties. This progress has been driven by interdisciplinary collaborations, combining expertise from chemistry, materials science, and biotechnology.

Looking ahead, the future of carboxylic acids in biodegradable polymer production holds great promise. Emerging trends point towards the development of more sophisticated biopolymers with enhanced functionalities, such as stimuli-responsive degradation or improved barrier properties. There is also a growing interest in exploring novel sources of carboxylic acids, including those derived from waste streams or produced through microbial fermentation.

As we move forward, the objectives for carboxylic acid utilization in biopolymer production are becoming increasingly ambitious. These include achieving cost-competitiveness with traditional plastics, expanding the range of applications for biodegradable polymers, and further reducing the environmental footprint of production processes. The ultimate goal is to establish carboxylic acid-based biopolymers as a mainstream alternative to conventional plastics across various sectors, from packaging to medical devices.

Market Analysis for Biodegradable Polymers

The biodegradable polymers market has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. This market segment is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed 15% over the next five years.

The demand for biodegradable polymers is particularly strong in packaging applications, which account for the largest share of the market. Food packaging, disposable cutlery, and shopping bags are among the most popular products utilizing these materials. The agriculture sector is also emerging as a key consumer, with biodegradable mulch films and plant pots gaining traction.

Geographically, Europe leads the biodegradable polymers market, followed closely by North America. These regions have implemented stringent regulations on single-use plastics, fostering the adoption of eco-friendly alternatives. Asia-Pacific is expected to witness the fastest growth, driven by increasing environmental awareness and government initiatives in countries like China and India.

Key players in the biodegradable polymers market include NatureWorks LLC, BASF SE, Novamont S.p.A., and Total Corbion PLA. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of their products, with a focus on enhancing the role of carboxylic acids in polymer production.

The integration of carboxylic acids in biodegradable polymer production is gaining attention due to their potential to improve material properties and expand application possibilities. Carboxylic acids can enhance the degradation rate, mechanical strength, and thermal stability of biodegradable polymers, making them more suitable for a wider range of applications.

Market trends indicate a growing demand for bio-based carboxylic acids as raw materials for biodegradable polymers. This shift is driven by the desire to reduce reliance on petroleum-based feedstocks and create fully sustainable products. Succinic acid, adipic acid, and lactic acid are among the most promising carboxylic acids in this context.

The future of carboxylic acids in biodegradable polymer production is closely tied to advancements in biotechnology and green chemistry. Innovations in fermentation processes and catalytic conversions are expected to lower production costs and increase the availability of bio-based carboxylic acids, further driving market growth.

The demand for biodegradable polymers is particularly strong in packaging applications, which account for the largest share of the market. Food packaging, disposable cutlery, and shopping bags are among the most popular products utilizing these materials. The agriculture sector is also emerging as a key consumer, with biodegradable mulch films and plant pots gaining traction.

Geographically, Europe leads the biodegradable polymers market, followed closely by North America. These regions have implemented stringent regulations on single-use plastics, fostering the adoption of eco-friendly alternatives. Asia-Pacific is expected to witness the fastest growth, driven by increasing environmental awareness and government initiatives in countries like China and India.

Key players in the biodegradable polymers market include NatureWorks LLC, BASF SE, Novamont S.p.A., and Total Corbion PLA. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of their products, with a focus on enhancing the role of carboxylic acids in polymer production.

The integration of carboxylic acids in biodegradable polymer production is gaining attention due to their potential to improve material properties and expand application possibilities. Carboxylic acids can enhance the degradation rate, mechanical strength, and thermal stability of biodegradable polymers, making them more suitable for a wider range of applications.

Market trends indicate a growing demand for bio-based carboxylic acids as raw materials for biodegradable polymers. This shift is driven by the desire to reduce reliance on petroleum-based feedstocks and create fully sustainable products. Succinic acid, adipic acid, and lactic acid are among the most promising carboxylic acids in this context.

The future of carboxylic acids in biodegradable polymer production is closely tied to advancements in biotechnology and green chemistry. Innovations in fermentation processes and catalytic conversions are expected to lower production costs and increase the availability of bio-based carboxylic acids, further driving market growth.

Current Challenges in Carboxylic Acid-Based Biopolymers

The development of carboxylic acid-based biopolymers faces several significant challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is the high production cost compared to conventional petroleum-based polymers. The synthesis of carboxylic acid monomers from renewable resources often involves complex and energy-intensive processes, leading to increased manufacturing expenses.

Another major challenge is the limited availability of suitable carboxylic acid monomers derived from renewable sources. While some bio-based carboxylic acids, such as lactic acid and succinic acid, are readily available, others remain scarce or difficult to produce at scale. This scarcity restricts the diversity of biopolymers that can be developed and limits their potential applications.

The mechanical properties of carboxylic acid-based biopolymers also present challenges. Many of these materials exhibit lower strength, durability, and thermal stability compared to their petroleum-based counterparts. This limitation restricts their use in applications that require high-performance materials, such as automotive parts or durable consumer goods.

Processability is another significant hurdle in the production of carboxylic acid-based biopolymers. Some of these materials have narrow processing windows, making them difficult to mold, extrude, or thermoform using conventional polymer processing equipment. This challenge often necessitates the development of specialized processing techniques or the modification of existing machinery, further increasing production costs.

The biodegradability of these polymers, while generally considered an advantage, can also pose challenges in certain applications. Controlling the rate of degradation to match the intended product lifespan is crucial but often difficult to achieve. Additionally, ensuring consistent biodegradation across various environmental conditions remains a complex task.

Scalability is a persistent issue in the production of carboxylic acid-based biopolymers. Many promising materials developed in laboratory settings face significant obstacles when transitioning to industrial-scale production. Factors such as reaction kinetics, heat transfer, and mixing efficiency can differ dramatically between small-scale and large-scale operations, necessitating extensive process optimization.

Lastly, regulatory hurdles and market acceptance present non-technical challenges. The approval process for new materials, especially those intended for food contact or medical applications, can be lengthy and costly. Moreover, changing consumer perceptions and established supply chains to favor these new materials requires significant effort and investment in marketing and education.

Addressing these challenges requires a multidisciplinary approach, combining advances in chemistry, materials science, and engineering. Ongoing research focuses on developing more efficient synthesis routes, improving material properties through copolymerization or blending, and optimizing processing techniques. As these challenges are gradually overcome, carboxylic acid-based biopolymers are poised to play an increasingly important role in the transition towards more sustainable and environmentally friendly materials.

Another major challenge is the limited availability of suitable carboxylic acid monomers derived from renewable sources. While some bio-based carboxylic acids, such as lactic acid and succinic acid, are readily available, others remain scarce or difficult to produce at scale. This scarcity restricts the diversity of biopolymers that can be developed and limits their potential applications.

The mechanical properties of carboxylic acid-based biopolymers also present challenges. Many of these materials exhibit lower strength, durability, and thermal stability compared to their petroleum-based counterparts. This limitation restricts their use in applications that require high-performance materials, such as automotive parts or durable consumer goods.

Processability is another significant hurdle in the production of carboxylic acid-based biopolymers. Some of these materials have narrow processing windows, making them difficult to mold, extrude, or thermoform using conventional polymer processing equipment. This challenge often necessitates the development of specialized processing techniques or the modification of existing machinery, further increasing production costs.

The biodegradability of these polymers, while generally considered an advantage, can also pose challenges in certain applications. Controlling the rate of degradation to match the intended product lifespan is crucial but often difficult to achieve. Additionally, ensuring consistent biodegradation across various environmental conditions remains a complex task.

Scalability is a persistent issue in the production of carboxylic acid-based biopolymers. Many promising materials developed in laboratory settings face significant obstacles when transitioning to industrial-scale production. Factors such as reaction kinetics, heat transfer, and mixing efficiency can differ dramatically between small-scale and large-scale operations, necessitating extensive process optimization.

Lastly, regulatory hurdles and market acceptance present non-technical challenges. The approval process for new materials, especially those intended for food contact or medical applications, can be lengthy and costly. Moreover, changing consumer perceptions and established supply chains to favor these new materials requires significant effort and investment in marketing and education.

Addressing these challenges requires a multidisciplinary approach, combining advances in chemistry, materials science, and engineering. Ongoing research focuses on developing more efficient synthesis routes, improving material properties through copolymerization or blending, and optimizing processing techniques. As these challenges are gradually overcome, carboxylic acid-based biopolymers are poised to play an increasingly important role in the transition towards more sustainable and environmentally friendly materials.

Existing Carboxylic Acid-Based Biopolymer Solutions

01 Synthesis of carboxylic acids

Various methods for synthesizing carboxylic acids are described, including oxidation of primary alcohols or aldehydes, hydrolysis of nitriles, and carbonylation reactions. These processes often involve catalysts and specific reaction conditions to achieve high yields and selectivity.- Synthesis of carboxylic acids: Various methods for synthesizing carboxylic acids are described, including oxidation of primary alcohols or aldehydes, hydrolysis of nitriles, and carbonylation reactions. These processes often involve catalysts and specific reaction conditions to achieve high yields and selectivity.

- Derivatives and applications of carboxylic acids: Carboxylic acids serve as precursors for various derivatives such as esters, amides, and anhydrides. These compounds find applications in pharmaceuticals, polymers, and industrial chemicals. The synthesis and properties of these derivatives are explored in several patents.

- Purification and separation techniques: Methods for purifying and separating carboxylic acids from reaction mixtures or natural sources are described. These techniques include crystallization, distillation, extraction, and chromatography, often tailored to specific carboxylic acids or industrial processes.

- Carboxylic acids in polymer chemistry: Carboxylic acids play a crucial role in polymer chemistry, serving as monomers or modifiers in various polymerization processes. Patents describe their use in producing polyesters, polyamides, and other functional polymers with specific properties.

- Industrial production and scale-up: Patents focus on industrial-scale production of carboxylic acids, addressing challenges in reactor design, process optimization, and continuous manufacturing. These innovations aim to improve yield, reduce costs, and enhance sustainability in large-scale carboxylic acid production.

02 Derivatives and applications of carboxylic acids

Carboxylic acids serve as precursors for various derivatives such as esters, amides, and anhydrides. These compounds find applications in pharmaceuticals, polymers, and industrial processes. The synthesis and properties of these derivatives are explored in several patents.Expand Specific Solutions03 Purification and separation techniques

Methods for purifying and separating carboxylic acids from reaction mixtures or natural sources are described. These techniques include crystallization, distillation, extraction, and chromatography, aimed at obtaining high-purity carboxylic acids for various applications.Expand Specific Solutions04 Carboxylic acids in polymer chemistry

The use of carboxylic acids in polymer synthesis and modification is explored. This includes their role as monomers, chain terminators, and functional groups for post-polymerization modifications. Applications in adhesives, coatings, and biodegradable materials are discussed.Expand Specific Solutions05 Green chemistry approaches for carboxylic acids

Environmentally friendly methods for producing and using carboxylic acids are presented. These include bio-based production routes, catalytic processes with reduced waste, and the use of renewable feedstocks. The focus is on sustainable practices in the synthesis and application of carboxylic acids.Expand Specific Solutions

Key Players in Biodegradable Polymer Industry

The future of carboxylic acid in biodegradable polymer production is characterized by a competitive landscape in its growth phase. The market is expanding due to increasing demand for sustainable materials, with a projected significant market size growth. Technologically, the field is advancing rapidly, with companies like Takeda Pharmaceutical, Kureha Corp., and Toray Plastics (America) leading innovation. Academic institutions such as Boston University and Cornell University are contributing to research advancements. The involvement of major chemical companies like Eastman Chemical and DuPont de Nemours indicates the industry's maturation, while specialized firms like Zhangjiagang Oasis New Material Technology are focusing on niche applications, demonstrating the sector's diversification and technological progression.

Kureha Corp.

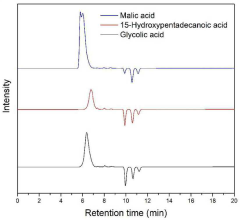

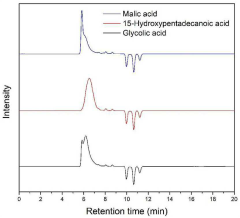

Technical Solution: Kureha Corporation has developed an innovative approach to biodegradable polymer production using carboxylic acids, focusing on polyglycolic acid (PGA). Their proprietary process involves the ring-opening polymerization of glycolide, which is derived from glycolic acid. Kureha has optimized the polymerization conditions to produce high-molecular-weight PGA with excellent mechanical properties and rapid biodegradability[12]. The company has also developed advanced purification techniques to remove impurities from the glycolide monomer, resulting in improved polymer quality and consistency[13]. Additionally, Kureha has explored copolymerization of glycolide with other monomers to create biodegradable polymers with tailored properties for specific applications, such as medical devices and packaging materials[14].

Strengths: Specialized expertise in PGA production, high-quality polymer output, and diverse application potential. Weaknesses: Limited raw material sources and potential high production costs.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed a groundbreaking approach to biodegradable polymer production using carboxylic acids. Their focus is on the synthesis of polybutylene adipate terephthalate (PBAT), a versatile biodegradable polyester. Asahi Kasei's proprietary process involves the copolymerization of adipic acid, terephthalic acid, and 1,4-butanediol using a novel catalyst system that enhances the polymer's biodegradability while maintaining excellent mechanical properties[6]. The company has also pioneered the use of bio-based adipic acid derived from renewable resources, further improving the sustainability profile of their PBAT products[7]. Additionally, Asahi Kasei has developed advanced processing techniques to produce PBAT films with superior barrier properties, making them suitable for food packaging applications[8].

Strengths: Innovative catalyst system, integration of bio-based monomers, and advanced processing techniques. Weaknesses: Potential challenges in competing with established non-biodegradable plastics in certain markets.

Innovations in Carboxylic Acid Biopolymer Synthesis

Production method of biodegradable polymer using organic acid as catalyst and initiator

PatentInactiveKR1020220152127A

Innovation

- A method using an organic acid with both a carboxyl and hydroxyl group as both catalyst and initiator for lactone-based monomer polymerization, introducing a carboxyl group during synthesis without additional processing, simplifying the process and enhancing biocompatibility.

Method for producing biodegradable polymer

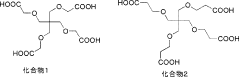

PatentInactiveJPWO2009087910A1

Innovation

- A method involving direct dehydration polycondensation of difunctional hydroxycarboxylic acids with trifunctional or higher carboxylic acids using an organic onium salt catalyst to produce branched or crosslinked biodegradable polymers, which can be reused and stable in aqueous environments.

Environmental Impact Assessment

The environmental impact assessment of carboxylic acid in biodegradable polymer production is a critical aspect of evaluating the sustainability and ecological footprint of this emerging technology. Carboxylic acids play a crucial role in the synthesis of biodegradable polymers, offering a promising alternative to conventional plastics. However, their production and use in polymer manufacturing processes require careful consideration of potential environmental consequences.

One of the primary environmental benefits of using carboxylic acids in biodegradable polymer production is the reduction of plastic waste accumulation in ecosystems. These polymers can decompose naturally under specific conditions, significantly decreasing the long-term environmental burden associated with traditional plastics. This characteristic aligns with global efforts to mitigate plastic pollution and its detrimental effects on marine and terrestrial ecosystems.

The production of carboxylic acids for biodegradable polymers often involves renewable resources, such as plant-based feedstocks. This shift from petroleum-based raw materials to bio-based alternatives contributes to reducing greenhouse gas emissions and dependence on fossil fuels. However, the environmental impact of large-scale cultivation of these feedstocks, including land use changes and potential competition with food crops, must be carefully assessed and managed.

Water consumption and quality are important considerations in the environmental impact assessment. The production processes for carboxylic acids and their subsequent use in polymer synthesis may require significant water resources. Ensuring efficient water management practices and implementing effective wastewater treatment systems are essential to minimize the impact on local water supplies and aquatic ecosystems.

Energy consumption during the production and processing of carboxylic acids for biodegradable polymers is another crucial factor. While these processes may be less energy-intensive compared to traditional plastic production, there is still room for improvement in energy efficiency. Implementing renewable energy sources and optimizing production processes can further reduce the carbon footprint associated with biodegradable polymer manufacturing.

The end-of-life management of biodegradable polymers derived from carboxylic acids presents both opportunities and challenges. While these materials can decompose more readily than conventional plastics, proper disposal and composting infrastructure are necessary to realize their full environmental benefits. Educating consumers and establishing appropriate waste management systems are essential steps in maximizing the positive environmental impact of these materials.

Lifecycle assessment (LCA) studies are crucial for comprehensively evaluating the environmental impact of carboxylic acid-based biodegradable polymers. These assessments consider all stages of the product lifecycle, from raw material extraction to disposal, providing valuable insights into the overall sustainability of these materials compared to traditional plastics and other alternatives.

One of the primary environmental benefits of using carboxylic acids in biodegradable polymer production is the reduction of plastic waste accumulation in ecosystems. These polymers can decompose naturally under specific conditions, significantly decreasing the long-term environmental burden associated with traditional plastics. This characteristic aligns with global efforts to mitigate plastic pollution and its detrimental effects on marine and terrestrial ecosystems.

The production of carboxylic acids for biodegradable polymers often involves renewable resources, such as plant-based feedstocks. This shift from petroleum-based raw materials to bio-based alternatives contributes to reducing greenhouse gas emissions and dependence on fossil fuels. However, the environmental impact of large-scale cultivation of these feedstocks, including land use changes and potential competition with food crops, must be carefully assessed and managed.

Water consumption and quality are important considerations in the environmental impact assessment. The production processes for carboxylic acids and their subsequent use in polymer synthesis may require significant water resources. Ensuring efficient water management practices and implementing effective wastewater treatment systems are essential to minimize the impact on local water supplies and aquatic ecosystems.

Energy consumption during the production and processing of carboxylic acids for biodegradable polymers is another crucial factor. While these processes may be less energy-intensive compared to traditional plastic production, there is still room for improvement in energy efficiency. Implementing renewable energy sources and optimizing production processes can further reduce the carbon footprint associated with biodegradable polymer manufacturing.

The end-of-life management of biodegradable polymers derived from carboxylic acids presents both opportunities and challenges. While these materials can decompose more readily than conventional plastics, proper disposal and composting infrastructure are necessary to realize their full environmental benefits. Educating consumers and establishing appropriate waste management systems are essential steps in maximizing the positive environmental impact of these materials.

Lifecycle assessment (LCA) studies are crucial for comprehensively evaluating the environmental impact of carboxylic acid-based biodegradable polymers. These assessments consider all stages of the product lifecycle, from raw material extraction to disposal, providing valuable insights into the overall sustainability of these materials compared to traditional plastics and other alternatives.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials is evolving rapidly as governments and international organizations recognize the importance of sustainable alternatives to traditional plastics. In the context of carboxylic acid-based biodegradable polymers, several key regulations and standards are shaping the industry landscape.

The European Union has taken a leading role in establishing comprehensive guidelines for biodegradable materials. The EN 13432 standard, which specifies requirements for packaging recoverable through composting and biodegradation, has become a benchmark for many countries. This standard requires that at least 90% of the organic material be converted into CO2 within six months in industrial composting conditions.

In the United States, the ASTM D6400 standard provides similar specifications for labeling of plastics designed to be aerobically composted in municipal or industrial facilities. The Federal Trade Commission's Green Guides also offer guidelines on environmental marketing claims, including those related to biodegradability and compostability.

Japan has implemented the GreenPla certification system, which evaluates the biodegradability, compostability, and absence of harmful substances in plastic products. This system has been influential in promoting the development and adoption of biodegradable materials in the Asian market.

Globally, the ISO 17088 standard provides specifications for compostable plastics, including those derived from carboxylic acids. This international standard helps harmonize requirements across different regions and facilitates global trade in biodegradable materials.

Emerging regulations are focusing on the end-of-life management of biodegradable polymers. For instance, the EU's Single-Use Plastics Directive, while primarily targeting conventional plastics, also impacts biodegradable alternatives by setting collection and recycling targets.

As the use of carboxylic acid-based biodegradable polymers expands, regulators are increasingly considering their environmental impact throughout the entire lifecycle. This includes assessing the sourcing of raw materials, production processes, and potential effects on soil and marine ecosystems upon degradation.

Looking ahead, regulatory frameworks are likely to become more stringent and comprehensive. There is a growing push for standardized testing methods to verify claims of biodegradability under various environmental conditions. Additionally, regulations may evolve to address concerns about microplastic formation during the degradation process of some biodegradable polymers.

The future regulatory landscape will likely emphasize a circular economy approach, encouraging the development of biodegradable materials that not only break down safely but also contribute to nutrient cycles or can be efficiently recycled into new products.

The European Union has taken a leading role in establishing comprehensive guidelines for biodegradable materials. The EN 13432 standard, which specifies requirements for packaging recoverable through composting and biodegradation, has become a benchmark for many countries. This standard requires that at least 90% of the organic material be converted into CO2 within six months in industrial composting conditions.

In the United States, the ASTM D6400 standard provides similar specifications for labeling of plastics designed to be aerobically composted in municipal or industrial facilities. The Federal Trade Commission's Green Guides also offer guidelines on environmental marketing claims, including those related to biodegradability and compostability.

Japan has implemented the GreenPla certification system, which evaluates the biodegradability, compostability, and absence of harmful substances in plastic products. This system has been influential in promoting the development and adoption of biodegradable materials in the Asian market.

Globally, the ISO 17088 standard provides specifications for compostable plastics, including those derived from carboxylic acids. This international standard helps harmonize requirements across different regions and facilitates global trade in biodegradable materials.

Emerging regulations are focusing on the end-of-life management of biodegradable polymers. For instance, the EU's Single-Use Plastics Directive, while primarily targeting conventional plastics, also impacts biodegradable alternatives by setting collection and recycling targets.

As the use of carboxylic acid-based biodegradable polymers expands, regulators are increasingly considering their environmental impact throughout the entire lifecycle. This includes assessing the sourcing of raw materials, production processes, and potential effects on soil and marine ecosystems upon degradation.

Looking ahead, regulatory frameworks are likely to become more stringent and comprehensive. There is a growing push for standardized testing methods to verify claims of biodegradability under various environmental conditions. Additionally, regulations may evolve to address concerns about microplastic formation during the degradation process of some biodegradable polymers.

The future regulatory landscape will likely emphasize a circular economy approach, encouraging the development of biodegradable materials that not only break down safely but also contribute to nutrient cycles or can be efficiently recycled into new products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!