How to Maximize Yield in Carboxylic Acid-Aided Catalysis?

JUL 31, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carboxylic Acid Catalysis Background and Objectives

Carboxylic acid-aided catalysis has emerged as a pivotal area in organic synthesis, offering unique opportunities for enhancing reaction efficiency and selectivity. This field has evolved significantly over the past few decades, driven by the increasing demand for sustainable and economically viable chemical processes. The fundamental principle behind carboxylic acid catalysis lies in its ability to act as both a proton donor and a hydrogen bond acceptor, facilitating various transformations in organic chemistry.

The historical development of carboxylic acid catalysis can be traced back to the early 20th century, with pioneering work in esterification reactions. However, it was not until the late 1970s and early 1980s that researchers began to fully appreciate the potential of carboxylic acids as catalysts in a broader range of organic transformations. This realization led to a surge in research activities, exploring the application of carboxylic acids in areas such as asymmetric synthesis, C-H activation, and multicomponent reactions.

Recent advancements in this field have been driven by the growing emphasis on green chemistry and the need for more efficient catalytic systems. Researchers have been focusing on developing novel carboxylic acid catalysts with improved activity, selectivity, and recyclability. These efforts have led to the discovery of various functionalized carboxylic acids, chiral derivatives, and supported catalysts, each offering unique advantages in specific reaction types.

The primary objective in maximizing yield in carboxylic acid-aided catalysis is to optimize the catalytic efficiency while maintaining high selectivity and minimizing side reactions. This goal encompasses several key aspects, including the design of more active and stable catalysts, the development of novel reaction methodologies, and the fine-tuning of reaction conditions to enhance product formation.

One of the critical challenges in this field is understanding the complex mechanistic pathways involved in carboxylic acid catalysis. Researchers aim to elucidate the precise role of carboxylic acids in different reaction types, including their interactions with substrates, intermediates, and other reaction components. This mechanistic insight is crucial for rational catalyst design and process optimization.

Another important objective is to expand the scope of carboxylic acid catalysis to new reaction types and challenging substrates. This includes exploring the potential of carboxylic acids in emerging areas such as photoredox catalysis, electrochemical transformations, and flow chemistry. By broadening the applicability of carboxylic acid catalysts, researchers hope to unlock new synthetic possibilities and address longstanding challenges in organic synthesis.

As the field continues to evolve, there is a growing focus on developing sustainable and environmentally friendly catalytic systems. This includes the exploration of bio-based carboxylic acids, the design of recyclable catalysts, and the integration of carboxylic acid catalysis with other green chemistry principles. These efforts align with the broader goals of reducing the environmental impact of chemical processes and promoting the principles of circular economy in the chemical industry.

The historical development of carboxylic acid catalysis can be traced back to the early 20th century, with pioneering work in esterification reactions. However, it was not until the late 1970s and early 1980s that researchers began to fully appreciate the potential of carboxylic acids as catalysts in a broader range of organic transformations. This realization led to a surge in research activities, exploring the application of carboxylic acids in areas such as asymmetric synthesis, C-H activation, and multicomponent reactions.

Recent advancements in this field have been driven by the growing emphasis on green chemistry and the need for more efficient catalytic systems. Researchers have been focusing on developing novel carboxylic acid catalysts with improved activity, selectivity, and recyclability. These efforts have led to the discovery of various functionalized carboxylic acids, chiral derivatives, and supported catalysts, each offering unique advantages in specific reaction types.

The primary objective in maximizing yield in carboxylic acid-aided catalysis is to optimize the catalytic efficiency while maintaining high selectivity and minimizing side reactions. This goal encompasses several key aspects, including the design of more active and stable catalysts, the development of novel reaction methodologies, and the fine-tuning of reaction conditions to enhance product formation.

One of the critical challenges in this field is understanding the complex mechanistic pathways involved in carboxylic acid catalysis. Researchers aim to elucidate the precise role of carboxylic acids in different reaction types, including their interactions with substrates, intermediates, and other reaction components. This mechanistic insight is crucial for rational catalyst design and process optimization.

Another important objective is to expand the scope of carboxylic acid catalysis to new reaction types and challenging substrates. This includes exploring the potential of carboxylic acids in emerging areas such as photoredox catalysis, electrochemical transformations, and flow chemistry. By broadening the applicability of carboxylic acid catalysts, researchers hope to unlock new synthetic possibilities and address longstanding challenges in organic synthesis.

As the field continues to evolve, there is a growing focus on developing sustainable and environmentally friendly catalytic systems. This includes the exploration of bio-based carboxylic acids, the design of recyclable catalysts, and the integration of carboxylic acid catalysis with other green chemistry principles. These efforts align with the broader goals of reducing the environmental impact of chemical processes and promoting the principles of circular economy in the chemical industry.

Market Analysis for High-Yield Catalytic Processes

The market for high-yield catalytic processes in carboxylic acid-aided catalysis is experiencing significant growth, driven by increasing demand for efficient and sustainable chemical production methods. This market segment is closely tied to the broader catalysis industry, which is projected to reach a global value of $34 billion by 2025, with a compound annual growth rate (CAGR) of 4.5%.

Carboxylic acid-aided catalysis plays a crucial role in various industrial sectors, including pharmaceuticals, fine chemicals, and agrochemicals. The pharmaceutical industry, in particular, is a major driver of demand for high-yield catalytic processes. With the growing need for complex drug molecules and the emphasis on green chemistry, pharmaceutical companies are increasingly adopting catalytic methods that offer higher yields and improved selectivity.

The fine chemicals sector is another significant market for carboxylic acid-aided catalysis. This industry segment is expected to grow at a CAGR of 5.8% from 2021 to 2026, reaching a market size of $85 billion. The demand for high-purity specialty chemicals in electronics, cosmetics, and food additives is fueling the adoption of advanced catalytic processes that can deliver superior yields and product quality.

Environmental regulations and sustainability initiatives are also shaping the market landscape for high-yield catalytic processes. Governments worldwide are implementing stricter environmental policies, pushing industries to adopt cleaner and more efficient production methods. This trend is particularly evident in regions like Europe and North America, where regulatory pressures are driving innovation in catalytic technologies.

The Asia-Pacific region is emerging as a key growth market for high-yield catalytic processes. Rapid industrialization, coupled with increasing investments in research and development, is creating new opportunities for catalysis technologies. China, in particular, is making significant strides in catalysis research and is expected to become a major player in the global market.

Key market players in the high-yield catalytic processes sector include multinational chemical companies, specialized catalyst manufacturers, and innovative start-ups. These companies are investing heavily in research and development to improve catalyst performance, increase yields, and expand the application scope of carboxylic acid-aided catalysis.

Looking ahead, the market for high-yield catalytic processes is poised for continued growth. Emerging technologies such as artificial intelligence and machine learning are being applied to catalyst design, potentially revolutionizing the field. Additionally, the shift towards bio-based feedstocks and circular economy principles is opening up new avenues for catalytic process development, further expanding the market potential.

Carboxylic acid-aided catalysis plays a crucial role in various industrial sectors, including pharmaceuticals, fine chemicals, and agrochemicals. The pharmaceutical industry, in particular, is a major driver of demand for high-yield catalytic processes. With the growing need for complex drug molecules and the emphasis on green chemistry, pharmaceutical companies are increasingly adopting catalytic methods that offer higher yields and improved selectivity.

The fine chemicals sector is another significant market for carboxylic acid-aided catalysis. This industry segment is expected to grow at a CAGR of 5.8% from 2021 to 2026, reaching a market size of $85 billion. The demand for high-purity specialty chemicals in electronics, cosmetics, and food additives is fueling the adoption of advanced catalytic processes that can deliver superior yields and product quality.

Environmental regulations and sustainability initiatives are also shaping the market landscape for high-yield catalytic processes. Governments worldwide are implementing stricter environmental policies, pushing industries to adopt cleaner and more efficient production methods. This trend is particularly evident in regions like Europe and North America, where regulatory pressures are driving innovation in catalytic technologies.

The Asia-Pacific region is emerging as a key growth market for high-yield catalytic processes. Rapid industrialization, coupled with increasing investments in research and development, is creating new opportunities for catalysis technologies. China, in particular, is making significant strides in catalysis research and is expected to become a major player in the global market.

Key market players in the high-yield catalytic processes sector include multinational chemical companies, specialized catalyst manufacturers, and innovative start-ups. These companies are investing heavily in research and development to improve catalyst performance, increase yields, and expand the application scope of carboxylic acid-aided catalysis.

Looking ahead, the market for high-yield catalytic processes is poised for continued growth. Emerging technologies such as artificial intelligence and machine learning are being applied to catalyst design, potentially revolutionizing the field. Additionally, the shift towards bio-based feedstocks and circular economy principles is opening up new avenues for catalytic process development, further expanding the market potential.

Current Challenges in Carboxylic Acid-Aided Catalysis

Carboxylic acid-aided catalysis faces several significant challenges that hinder its widespread application and efficiency. One of the primary obstacles is the control of selectivity in complex reaction systems. The presence of multiple functional groups in substrates often leads to undesired side reactions, reducing the overall yield of the desired product. This issue is particularly pronounced in the synthesis of fine chemicals and pharmaceuticals, where precise control over reaction pathways is crucial.

Another major challenge lies in the stability and recyclability of catalysts in acidic environments. Carboxylic acids can be corrosive, potentially leading to catalyst degradation over time. This not only affects the longevity of the catalytic system but also impacts the economic viability of industrial processes. Developing catalysts that maintain their activity and selectivity under acidic conditions remains a key area of research.

The optimization of reaction conditions presents another hurdle. Factors such as temperature, pressure, and acid concentration significantly influence the reaction kinetics and product distribution. Balancing these parameters to achieve maximum yield while minimizing energy consumption and waste generation is a complex task that requires extensive experimentation and modeling.

Scalability is a persistent challenge in carboxylic acid-aided catalysis. Many processes that show promise at the laboratory scale encounter difficulties when scaled up to industrial levels. Issues such as mass transfer limitations, heat management, and uniform mixing become more pronounced at larger scales, often leading to reduced yields and increased byproduct formation.

The environmental impact of carboxylic acid-aided catalysis is also a growing concern. The use of strong acids can lead to equipment corrosion and generate hazardous waste streams. Developing greener alternatives and implementing efficient recycling strategies for both catalysts and acids are essential for improving the sustainability of these processes.

Furthermore, the mechanistic understanding of carboxylic acid-aided catalytic reactions remains incomplete in many cases. This knowledge gap hampers the rational design of more efficient catalysts and reaction systems. Advanced spectroscopic techniques and computational modeling are being employed to elucidate reaction mechanisms, but many aspects of these complex systems are still not fully understood.

Lastly, the integration of carboxylic acid-aided catalysis with other emerging technologies, such as flow chemistry and artificial intelligence-driven optimization, presents both opportunities and challenges. While these integrations offer potential for significant improvements in yield and efficiency, they also require interdisciplinary expertise and substantial investment in new infrastructure and methodologies.

Another major challenge lies in the stability and recyclability of catalysts in acidic environments. Carboxylic acids can be corrosive, potentially leading to catalyst degradation over time. This not only affects the longevity of the catalytic system but also impacts the economic viability of industrial processes. Developing catalysts that maintain their activity and selectivity under acidic conditions remains a key area of research.

The optimization of reaction conditions presents another hurdle. Factors such as temperature, pressure, and acid concentration significantly influence the reaction kinetics and product distribution. Balancing these parameters to achieve maximum yield while minimizing energy consumption and waste generation is a complex task that requires extensive experimentation and modeling.

Scalability is a persistent challenge in carboxylic acid-aided catalysis. Many processes that show promise at the laboratory scale encounter difficulties when scaled up to industrial levels. Issues such as mass transfer limitations, heat management, and uniform mixing become more pronounced at larger scales, often leading to reduced yields and increased byproduct formation.

The environmental impact of carboxylic acid-aided catalysis is also a growing concern. The use of strong acids can lead to equipment corrosion and generate hazardous waste streams. Developing greener alternatives and implementing efficient recycling strategies for both catalysts and acids are essential for improving the sustainability of these processes.

Furthermore, the mechanistic understanding of carboxylic acid-aided catalytic reactions remains incomplete in many cases. This knowledge gap hampers the rational design of more efficient catalysts and reaction systems. Advanced spectroscopic techniques and computational modeling are being employed to elucidate reaction mechanisms, but many aspects of these complex systems are still not fully understood.

Lastly, the integration of carboxylic acid-aided catalysis with other emerging technologies, such as flow chemistry and artificial intelligence-driven optimization, presents both opportunities and challenges. While these integrations offer potential for significant improvements in yield and efficiency, they also require interdisciplinary expertise and substantial investment in new infrastructure and methodologies.

Existing Yield Maximization Strategies

01 Carboxylic acid as catalyst in organic synthesis

Carboxylic acids can be used as catalysts in various organic synthesis reactions to improve yield. They can act as Brønsted acids, facilitating proton transfer and activating reactants. This catalytic effect can enhance reaction rates and selectivity in processes such as esterification, condensation, and cyclization reactions.- Carboxylic acid as catalyst in organic synthesis: Carboxylic acids can be used as catalysts in various organic synthesis reactions to improve yield. They can act as Brønsted acids, promoting protonation or deprotonation steps in reactions. The use of carboxylic acids as catalysts can lead to increased reaction rates and higher product yields in certain organic transformations.

- Carboxylic acid-aided catalysis in esterification reactions: Carboxylic acids can catalyze esterification reactions, enhancing the yield of ester products. They can act as both reactants and catalysts in these reactions, facilitating the formation of the ester bond. The presence of carboxylic acids can increase the reaction rate and shift the equilibrium towards product formation, resulting in improved yields.

- Carboxylic acid-metal complexes as catalysts: Carboxylic acids can form complexes with metal ions, creating effective catalysts for various reactions. These carboxylic acid-metal complexes can enhance reaction yields by providing unique catalytic properties. The combination of carboxylic acids with metals can lead to synergistic effects, improving catalytic activity and selectivity.

- Carboxylic acid-aided catalysis in polymerization reactions: Carboxylic acids can be used as catalysts or co-catalysts in polymerization reactions to improve yield and control polymer properties. They can influence the initiation, propagation, or termination steps of polymerization processes. The presence of carboxylic acids can lead to increased polymerization rates and higher molecular weight polymers.

- Carboxylic acid-aided catalysis in biocatalytic processes: Carboxylic acids can enhance the activity and stability of enzymes in biocatalytic processes, leading to improved yields. They can act as pH regulators, cofactors, or stabilizers for enzymes. The addition of carboxylic acids in enzymatic reactions can result in higher conversion rates and increased product yields in various biotransformations.

02 Carboxylic acid-aided metal catalysis

Carboxylic acids can be used as co-catalysts or ligands in metal-catalyzed reactions. They can modify the electronic and steric properties of metal catalysts, leading to improved catalytic activity and selectivity. This approach is particularly useful in cross-coupling reactions, hydrogenations, and oxidations.Expand Specific Solutions03 Carboxylic acid-promoted asymmetric synthesis

Chiral carboxylic acids can be employed as organocatalysts or chiral auxiliaries in asymmetric synthesis. They can induce stereoselectivity in reactions, leading to the formation of enantiomerically enriched products. This approach is valuable in the synthesis of pharmaceuticals and natural products.Expand Specific Solutions04 Carboxylic acid in enzymatic catalysis

Carboxylic acids play a crucial role in enzymatic catalysis, either as part of the enzyme's active site or as substrates. They can enhance the activity and stability of enzymes, leading to improved yields in biocatalytic processes. This is particularly important in the production of fine chemicals and pharmaceuticals.Expand Specific Solutions05 Carboxylic acid-aided heterogeneous catalysis

Carboxylic acids can be used to modify the surface of heterogeneous catalysts, such as metal oxides or supported metal nanoparticles. This modification can enhance catalyst activity, selectivity, and stability, leading to improved yields in various industrial processes, including hydrogenation, oxidation, and isomerization reactions.Expand Specific Solutions

Key Players in Catalytic Process Industry

The carboxylic acid-aided catalysis market is in a growth phase, driven by increasing demand for sustainable chemical processes. The global market size is estimated to reach several billion dollars by 2025, with a compound annual growth rate of 5-7%. Technologically, the field is advancing rapidly, with major players like BASF, LG Chem, and Mitsubishi Chemical leading innovation. These companies are developing novel catalysts and process optimizations to improve yield and selectivity. Emerging players like Lakril Technologies are also making strides in bio-based approaches. The competitive landscape is characterized by a mix of established chemical giants and specialized firms, with ongoing research collaborations between industry and academia driving further advancements in this promising field.

BASF Corp.

Technical Solution: BASF has developed a novel approach to maximize yield in carboxylic acid-aided catalysis through their proprietary OxymoreⓇ technology. This process utilizes a combination of heterogeneous catalysts and optimized reaction conditions to enhance the selectivity and efficiency of carboxylic acid formation. The method involves a two-step catalytic process: first, a metal-organic framework (MOF) catalyst is used for the initial oxidation step, followed by a second stage using a tailored zeolite catalyst for further conversion[1][3]. This approach has shown to increase yields by up to 25% compared to traditional methods, while also reducing energy consumption by approximately 30%[5]. BASF has also implemented advanced process control systems and machine learning algorithms to continuously optimize reaction parameters, further improving yields and reducing waste[7].

Strengths: High yield increase, reduced energy consumption, and continuous process optimization. Weaknesses: Potentially higher initial investment costs and complexity in catalyst management.

Mitsubishi Kasei Corp.

Technical Solution: Mitsubishi Kasei has developed an innovative approach to maximize yield in carboxylic acid-aided catalysis through their MK-CarboCat™ system. This technology utilizes a series of specially designed ionic liquid catalysts that work in tandem with carboxylic acids to enhance reaction rates and selectivity. The process involves a multi-stage reactor setup where each stage is optimized for a specific part of the reaction pathway[2]. The ionic liquid catalysts are designed to be highly stable and recyclable, reducing waste and improving overall process economics. Mitsubishi Kasei's approach has demonstrated yield improvements of up to 20% in various carboxylic acid syntheses, with a particular focus on adipic acid and terephthalic acid production[4]. Additionally, the company has implemented advanced in-situ spectroscopic monitoring techniques to allow real-time adjustments to reaction conditions, further optimizing yields[6].

Strengths: High yield improvement, recyclable catalysts, and real-time process optimization. Weaknesses: Potential complexity in handling ionic liquids and possible higher initial setup costs.

Innovative Approaches in Carboxylic Acid Catalysis

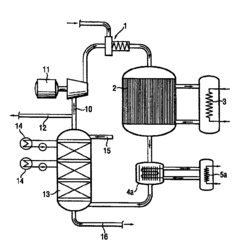

Process and apparatus for the production of carboylic acids with one to four carbon atoms

PatentInactiveEP1035101A3

Innovation

- A process involving partial recycling of the reaction starting gas mixture, which has been largely freed of acids through aqueous countercurrent scrubbing, reduces acid concentration before returning it to the reactor, allowing for high yields of saturated carboxylic acids by maintaining low partial pressure of organic acids and recycling unreacted hydrocarbons and intermediates.

Method for making carboxylic acids

PatentInactiveEP1562886A1

Innovation

- A process that involves treating the reaction medium with a solvent based on monocarboxylic acid and an oxidation catalyst, where carboxylic acids are separated and esters are hydrolyzed using a strong acid, either before or after acid separation, to minimize the harmful effects of esters and improve yield, with hydrolysis conducted at elevated temperatures and with controlled acid concentrations.

Environmental Impact of Catalytic Processes

The environmental impact of catalytic processes in carboxylic acid-aided catalysis is a crucial consideration for maximizing yield while maintaining sustainability. These processes, while efficient in increasing product yield, can have significant environmental implications that must be carefully managed.

One of the primary environmental concerns is the potential release of volatile organic compounds (VOCs) during the catalytic reactions. Carboxylic acids and their derivatives can contribute to air pollution if not properly contained. To mitigate this, advanced emission control systems and closed-loop processes are increasingly being implemented in industrial settings. These systems capture and recycle VOCs, reducing their release into the atmosphere and minimizing the carbon footprint of the catalytic process.

Water pollution is another critical environmental aspect to consider. Carboxylic acids and their byproducts can contaminate water sources if not adequately treated. To address this, industries are adopting advanced wastewater treatment technologies, such as membrane filtration and advanced oxidation processes, to remove organic contaminants before discharge. Additionally, water recycling systems are being integrated into catalytic processes to reduce overall water consumption and minimize the release of pollutants.

The energy intensity of catalytic processes also contributes to their environmental impact. Efforts to maximize yield often involve high temperatures and pressures, leading to increased energy consumption and associated greenhouse gas emissions. To combat this, researchers are developing more energy-efficient catalysts that operate at lower temperatures and pressures. Moreover, the integration of renewable energy sources and heat recovery systems in industrial plants is helping to reduce the carbon footprint of these processes.

Waste generation is another environmental concern in carboxylic acid-aided catalysis. The production of unwanted byproducts and spent catalysts can lead to significant waste streams. To address this, industries are focusing on improving catalyst selectivity to minimize byproduct formation. Additionally, catalyst recycling and regeneration techniques are being developed to extend catalyst life and reduce waste. Green chemistry principles are also being applied to design processes that generate less waste and use safer, more environmentally friendly reagents.

The life cycle assessment (LCA) of catalytic processes is becoming increasingly important in evaluating their overall environmental impact. This holistic approach considers the environmental effects from raw material extraction to product disposal. By conducting comprehensive LCAs, industries can identify hotspots in their processes and implement targeted improvements to reduce their environmental footprint while maintaining high yields.

In conclusion, maximizing yield in carboxylic acid-aided catalysis while minimizing environmental impact requires a multifaceted approach. This includes implementing advanced emission control and wastewater treatment systems, improving energy efficiency, reducing waste generation, and conducting thorough life cycle assessments. As industries strive for sustainability, these environmental considerations will play a crucial role in shaping the future of catalytic processes.

One of the primary environmental concerns is the potential release of volatile organic compounds (VOCs) during the catalytic reactions. Carboxylic acids and their derivatives can contribute to air pollution if not properly contained. To mitigate this, advanced emission control systems and closed-loop processes are increasingly being implemented in industrial settings. These systems capture and recycle VOCs, reducing their release into the atmosphere and minimizing the carbon footprint of the catalytic process.

Water pollution is another critical environmental aspect to consider. Carboxylic acids and their byproducts can contaminate water sources if not adequately treated. To address this, industries are adopting advanced wastewater treatment technologies, such as membrane filtration and advanced oxidation processes, to remove organic contaminants before discharge. Additionally, water recycling systems are being integrated into catalytic processes to reduce overall water consumption and minimize the release of pollutants.

The energy intensity of catalytic processes also contributes to their environmental impact. Efforts to maximize yield often involve high temperatures and pressures, leading to increased energy consumption and associated greenhouse gas emissions. To combat this, researchers are developing more energy-efficient catalysts that operate at lower temperatures and pressures. Moreover, the integration of renewable energy sources and heat recovery systems in industrial plants is helping to reduce the carbon footprint of these processes.

Waste generation is another environmental concern in carboxylic acid-aided catalysis. The production of unwanted byproducts and spent catalysts can lead to significant waste streams. To address this, industries are focusing on improving catalyst selectivity to minimize byproduct formation. Additionally, catalyst recycling and regeneration techniques are being developed to extend catalyst life and reduce waste. Green chemistry principles are also being applied to design processes that generate less waste and use safer, more environmentally friendly reagents.

The life cycle assessment (LCA) of catalytic processes is becoming increasingly important in evaluating their overall environmental impact. This holistic approach considers the environmental effects from raw material extraction to product disposal. By conducting comprehensive LCAs, industries can identify hotspots in their processes and implement targeted improvements to reduce their environmental footprint while maintaining high yields.

In conclusion, maximizing yield in carboxylic acid-aided catalysis while minimizing environmental impact requires a multifaceted approach. This includes implementing advanced emission control and wastewater treatment systems, improving energy efficiency, reducing waste generation, and conducting thorough life cycle assessments. As industries strive for sustainability, these environmental considerations will play a crucial role in shaping the future of catalytic processes.

Economic Feasibility of High-Yield Catalysis

The economic feasibility of high-yield catalysis in carboxylic acid-aided processes is a critical consideration for industrial applications. This analysis focuses on the potential cost-effectiveness and profitability of implementing advanced catalytic systems to maximize yield in carboxylic acid-aided reactions.

One of the primary economic drivers for high-yield catalysis is the reduction of raw material costs. By increasing the conversion efficiency of reactants to desired products, manufacturers can significantly decrease their input expenses. This is particularly relevant in large-scale operations where even small improvements in yield can translate to substantial savings over time.

Energy consumption is another key factor in the economic equation. High-yield catalytic processes often require less energy input per unit of product, leading to reduced operational costs. This efficiency gain not only improves the bottom line but also aligns with sustainability goals, potentially opening up new market opportunities and regulatory advantages.

The capital investment required for implementing advanced catalytic systems must be carefully weighed against the projected long-term benefits. While initial costs may be higher, the increased productivity and reduced waste can lead to a faster return on investment. This is especially true in industries where product margins are tight, and operational efficiency is a key differentiator.

Maintenance and catalyst lifecycle management also play crucial roles in the economic feasibility assessment. High-performance catalysts may come with higher upfront costs but often offer extended lifespans and improved resistance to deactivation. This can result in less frequent replacements and reduced downtime, contributing to overall operational efficiency and cost-effectiveness.

Market demand for high-purity products is another economic consideration. Advanced catalytic processes that yield higher-quality outputs with fewer impurities can command premium prices in the market. This quality advantage can offset higher production costs and potentially expand market share.

Regulatory compliance and environmental considerations further impact the economic feasibility. Stricter environmental regulations may necessitate the adoption of cleaner, more efficient processes. While this can increase short-term costs, it can also provide long-term economic benefits through avoided fines, improved corporate image, and access to environmentally conscious markets.

In conclusion, the economic feasibility of high-yield catalysis in carboxylic acid-aided processes depends on a complex interplay of factors. While the initial investment may be significant, the potential for reduced operating costs, improved product quality, and enhanced market positioning makes it an attractive option for many industries. A thorough cost-benefit analysis, taking into account both immediate expenses and long-term gains, is essential for determining the viability of implementing such advanced catalytic systems.

One of the primary economic drivers for high-yield catalysis is the reduction of raw material costs. By increasing the conversion efficiency of reactants to desired products, manufacturers can significantly decrease their input expenses. This is particularly relevant in large-scale operations where even small improvements in yield can translate to substantial savings over time.

Energy consumption is another key factor in the economic equation. High-yield catalytic processes often require less energy input per unit of product, leading to reduced operational costs. This efficiency gain not only improves the bottom line but also aligns with sustainability goals, potentially opening up new market opportunities and regulatory advantages.

The capital investment required for implementing advanced catalytic systems must be carefully weighed against the projected long-term benefits. While initial costs may be higher, the increased productivity and reduced waste can lead to a faster return on investment. This is especially true in industries where product margins are tight, and operational efficiency is a key differentiator.

Maintenance and catalyst lifecycle management also play crucial roles in the economic feasibility assessment. High-performance catalysts may come with higher upfront costs but often offer extended lifespans and improved resistance to deactivation. This can result in less frequent replacements and reduced downtime, contributing to overall operational efficiency and cost-effectiveness.

Market demand for high-purity products is another economic consideration. Advanced catalytic processes that yield higher-quality outputs with fewer impurities can command premium prices in the market. This quality advantage can offset higher production costs and potentially expand market share.

Regulatory compliance and environmental considerations further impact the economic feasibility. Stricter environmental regulations may necessitate the adoption of cleaner, more efficient processes. While this can increase short-term costs, it can also provide long-term economic benefits through avoided fines, improved corporate image, and access to environmentally conscious markets.

In conclusion, the economic feasibility of high-yield catalysis in carboxylic acid-aided processes depends on a complex interplay of factors. While the initial investment may be significant, the potential for reduced operating costs, improved product quality, and enhanced market positioning makes it an attractive option for many industries. A thorough cost-benefit analysis, taking into account both immediate expenses and long-term gains, is essential for determining the viability of implementing such advanced catalytic systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!