Exploring High-Modulus Polypropylene in Sports Equipment

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Modulus PP Evolution

High-modulus polypropylene (HMPP) has undergone significant evolution since its inception in the 1960s. Initially developed as a modification of standard polypropylene, HMPP has seen continuous improvements in its molecular structure and production processes, leading to enhanced mechanical properties and performance characteristics.

In the early stages, researchers focused on increasing the crystallinity and orientation of polypropylene chains to achieve higher modulus and strength. This was primarily accomplished through various drawing techniques and the introduction of nucleating agents. The 1980s saw a breakthrough with the development of self-reinforced polypropylene composites, which utilized highly oriented HMPP fibers within a polypropylene matrix.

The 1990s marked a significant milestone with the introduction of metallocene catalysts, enabling better control over polymer architecture and molecular weight distribution. This advancement led to the production of HMPP with improved stiffness and impact resistance, making it increasingly attractive for sports equipment applications.

The turn of the millennium brought about innovations in nanotechnology, allowing for the incorporation of nanofillers such as carbon nanotubes and nanoclays into HMPP. These nanocomposites exhibited exceptional mechanical properties, further expanding the potential of HMPP in high-performance sports gear.

In recent years, the focus has shifted towards sustainability and recyclability. Researchers have been developing bio-based alternatives and exploring ways to enhance the recyclability of HMPP without compromising its high-modulus characteristics. This has led to the emergence of eco-friendly HMPP variants that maintain excellent mechanical properties while reducing environmental impact.

The evolution of HMPP processing techniques has also played a crucial role in its advancement. Improved extrusion and injection molding technologies have allowed for better control over the orientation and crystallization of polymer chains, resulting in HMPP products with superior mechanical properties and consistency.

Furthermore, the integration of computational modeling and simulation tools has accelerated the development of tailored HMPP formulations for specific sports equipment applications. These advancements have enabled manufacturers to optimize material properties and predict performance characteristics with greater accuracy, leading to more efficient product development cycles.

As we look to the future, the evolution of HMPP in sports equipment continues to be driven by the demand for lighter, stronger, and more durable materials. Ongoing research focuses on further enhancing the balance between stiffness and impact resistance, as well as improving the long-term durability and environmental sustainability of HMPP-based products.

In the early stages, researchers focused on increasing the crystallinity and orientation of polypropylene chains to achieve higher modulus and strength. This was primarily accomplished through various drawing techniques and the introduction of nucleating agents. The 1980s saw a breakthrough with the development of self-reinforced polypropylene composites, which utilized highly oriented HMPP fibers within a polypropylene matrix.

The 1990s marked a significant milestone with the introduction of metallocene catalysts, enabling better control over polymer architecture and molecular weight distribution. This advancement led to the production of HMPP with improved stiffness and impact resistance, making it increasingly attractive for sports equipment applications.

The turn of the millennium brought about innovations in nanotechnology, allowing for the incorporation of nanofillers such as carbon nanotubes and nanoclays into HMPP. These nanocomposites exhibited exceptional mechanical properties, further expanding the potential of HMPP in high-performance sports gear.

In recent years, the focus has shifted towards sustainability and recyclability. Researchers have been developing bio-based alternatives and exploring ways to enhance the recyclability of HMPP without compromising its high-modulus characteristics. This has led to the emergence of eco-friendly HMPP variants that maintain excellent mechanical properties while reducing environmental impact.

The evolution of HMPP processing techniques has also played a crucial role in its advancement. Improved extrusion and injection molding technologies have allowed for better control over the orientation and crystallization of polymer chains, resulting in HMPP products with superior mechanical properties and consistency.

Furthermore, the integration of computational modeling and simulation tools has accelerated the development of tailored HMPP formulations for specific sports equipment applications. These advancements have enabled manufacturers to optimize material properties and predict performance characteristics with greater accuracy, leading to more efficient product development cycles.

As we look to the future, the evolution of HMPP in sports equipment continues to be driven by the demand for lighter, stronger, and more durable materials. Ongoing research focuses on further enhancing the balance between stiffness and impact resistance, as well as improving the long-term durability and environmental sustainability of HMPP-based products.

Sports Equipment Market Trends

The sports equipment market has been experiencing significant growth and transformation in recent years, driven by factors such as increasing health consciousness, rising disposable incomes, and technological advancements in material science. The global sports equipment market size was valued at approximately $126 billion in 2021 and is projected to reach $178 billion by 2026, growing at a CAGR of 7.2% during the forecast period.

One of the key trends shaping the sports equipment market is the growing demand for high-performance, lightweight materials that enhance athletic performance. This trend has led to increased interest in advanced polymers, such as high-modulus polypropylene, which offers superior strength-to-weight ratios compared to traditional materials. The adoption of these innovative materials is particularly evident in sectors like cycling, skiing, and racquet sports.

Another notable trend is the rising popularity of outdoor and adventure sports, which has fueled demand for specialized equipment. This trend has been further accelerated by the COVID-19 pandemic, as more people seek outdoor recreational activities. Consequently, there has been a surge in sales of camping gear, hiking equipment, and water sports accessories.

The integration of smart technology into sports equipment is also reshaping the market landscape. Wearable devices, smart fabrics, and connected equipment are gaining traction among both professional athletes and fitness enthusiasts. This trend is driving collaborations between sports equipment manufacturers and technology companies to develop innovative products that offer real-time performance tracking and analysis.

Sustainability has emerged as a critical factor influencing consumer choices in the sports equipment market. There is a growing demand for eco-friendly products made from recycled or biodegradable materials. This shift is prompting manufacturers to invest in sustainable production processes and explore alternative materials, including bio-based polymers and recycled plastics.

The e-commerce channel has become increasingly important for sports equipment sales, with online retail experiencing double-digit growth in recent years. This trend has been accelerated by the pandemic, leading to a significant shift in consumer purchasing behavior. As a result, sports equipment brands are investing heavily in their digital presence and direct-to-consumer strategies.

Customization and personalization are gaining prominence in the sports equipment market, with consumers seeking products tailored to their specific needs and preferences. This trend is driving innovations in manufacturing processes, such as 3D printing, which allows for the production of customized equipment components.

One of the key trends shaping the sports equipment market is the growing demand for high-performance, lightweight materials that enhance athletic performance. This trend has led to increased interest in advanced polymers, such as high-modulus polypropylene, which offers superior strength-to-weight ratios compared to traditional materials. The adoption of these innovative materials is particularly evident in sectors like cycling, skiing, and racquet sports.

Another notable trend is the rising popularity of outdoor and adventure sports, which has fueled demand for specialized equipment. This trend has been further accelerated by the COVID-19 pandemic, as more people seek outdoor recreational activities. Consequently, there has been a surge in sales of camping gear, hiking equipment, and water sports accessories.

The integration of smart technology into sports equipment is also reshaping the market landscape. Wearable devices, smart fabrics, and connected equipment are gaining traction among both professional athletes and fitness enthusiasts. This trend is driving collaborations between sports equipment manufacturers and technology companies to develop innovative products that offer real-time performance tracking and analysis.

Sustainability has emerged as a critical factor influencing consumer choices in the sports equipment market. There is a growing demand for eco-friendly products made from recycled or biodegradable materials. This shift is prompting manufacturers to invest in sustainable production processes and explore alternative materials, including bio-based polymers and recycled plastics.

The e-commerce channel has become increasingly important for sports equipment sales, with online retail experiencing double-digit growth in recent years. This trend has been accelerated by the pandemic, leading to a significant shift in consumer purchasing behavior. As a result, sports equipment brands are investing heavily in their digital presence and direct-to-consumer strategies.

Customization and personalization are gaining prominence in the sports equipment market, with consumers seeking products tailored to their specific needs and preferences. This trend is driving innovations in manufacturing processes, such as 3D printing, which allows for the production of customized equipment components.

Technical Challenges in HMPP

High-Modulus Polypropylene (HMPP) represents a significant advancement in polymer science, offering enhanced mechanical properties compared to conventional polypropylene. However, its application in sports equipment faces several technical challenges that researchers and manufacturers must overcome to fully harness its potential.

One of the primary challenges lies in achieving consistent and uniform molecular orientation during the manufacturing process. HMPP's superior properties stem from its highly aligned molecular structure, but maintaining this alignment throughout complex shapes and varying thicknesses typical in sports equipment can be problematic. Inconsistencies in molecular orientation can lead to unpredictable performance and potential weak points in the final product.

The processing temperature window for HMPP is relatively narrow, making it challenging to integrate with other materials commonly used in sports equipment. This limitation can complicate the manufacturing of composite structures, where HMPP needs to be combined with fibers, foams, or other polymers to achieve desired performance characteristics. Developing effective bonding techniques and compatible processing conditions for multi-material systems remains an ongoing challenge.

HMPP's inherent stiffness, while beneficial for certain applications, can lead to brittleness and reduced impact resistance. This characteristic is particularly problematic in sports equipment that requires a balance of strength and flexibility. Engineers must find ways to modify HMPP or create composite structures that maintain its high modulus while improving toughness and energy absorption capabilities.

Another significant challenge is the long-term durability of HMPP in sports equipment. Exposure to UV radiation, moisture, and repeated stress can potentially degrade the polymer's structure over time, leading to a loss of mechanical properties. Developing effective stabilization techniques and protective coatings that do not compromise HMPP's performance is crucial for ensuring the longevity of sports equipment.

The recyclability of HMPP-based sports equipment presents another technical hurdle. While polypropylene is generally recyclable, the additives and modifications used to achieve high modulus can complicate the recycling process. Creating HMPP formulations that maintain recyclability without sacrificing performance is essential for meeting increasing environmental sustainability demands in the sports industry.

Lastly, scaling up the production of HMPP for widespread use in sports equipment while maintaining cost-effectiveness poses a significant challenge. The specialized processing techniques required for HMPP can increase manufacturing costs, potentially limiting its adoption in price-sensitive market segments. Developing more efficient production methods and exploring ways to reduce raw material costs are critical for the broader implementation of HMPP in sports equipment.

One of the primary challenges lies in achieving consistent and uniform molecular orientation during the manufacturing process. HMPP's superior properties stem from its highly aligned molecular structure, but maintaining this alignment throughout complex shapes and varying thicknesses typical in sports equipment can be problematic. Inconsistencies in molecular orientation can lead to unpredictable performance and potential weak points in the final product.

The processing temperature window for HMPP is relatively narrow, making it challenging to integrate with other materials commonly used in sports equipment. This limitation can complicate the manufacturing of composite structures, where HMPP needs to be combined with fibers, foams, or other polymers to achieve desired performance characteristics. Developing effective bonding techniques and compatible processing conditions for multi-material systems remains an ongoing challenge.

HMPP's inherent stiffness, while beneficial for certain applications, can lead to brittleness and reduced impact resistance. This characteristic is particularly problematic in sports equipment that requires a balance of strength and flexibility. Engineers must find ways to modify HMPP or create composite structures that maintain its high modulus while improving toughness and energy absorption capabilities.

Another significant challenge is the long-term durability of HMPP in sports equipment. Exposure to UV radiation, moisture, and repeated stress can potentially degrade the polymer's structure over time, leading to a loss of mechanical properties. Developing effective stabilization techniques and protective coatings that do not compromise HMPP's performance is crucial for ensuring the longevity of sports equipment.

The recyclability of HMPP-based sports equipment presents another technical hurdle. While polypropylene is generally recyclable, the additives and modifications used to achieve high modulus can complicate the recycling process. Creating HMPP formulations that maintain recyclability without sacrificing performance is essential for meeting increasing environmental sustainability demands in the sports industry.

Lastly, scaling up the production of HMPP for widespread use in sports equipment while maintaining cost-effectiveness poses a significant challenge. The specialized processing techniques required for HMPP can increase manufacturing costs, potentially limiting its adoption in price-sensitive market segments. Developing more efficient production methods and exploring ways to reduce raw material costs are critical for the broader implementation of HMPP in sports equipment.

Current HMPP Applications

01 Composition and manufacturing of high-modulus polypropylene

High-modulus polypropylene is developed through specific compositions and manufacturing processes. This involves the use of particular additives, catalysts, and processing conditions to enhance the modulus of the polypropylene. The resulting material exhibits improved mechanical properties, including higher stiffness and strength.- Composition and manufacturing of high-modulus polypropylene: High-modulus polypropylene is developed through specific compositions and manufacturing processes. These may include the use of particular catalysts, additives, or processing techniques to enhance the modulus of the polypropylene. The resulting material exhibits improved mechanical properties, particularly in terms of stiffness and strength.

- Fiber and filament applications: High-modulus polypropylene is utilized in the production of fibers and filaments. These materials find applications in various industries, including textiles, ropes, and industrial fabrics. The high modulus properties contribute to improved tensile strength and dimensional stability in the final products.

- Blending and composite materials: High-modulus polypropylene is often blended with other polymers or materials to create composite materials with enhanced properties. These blends can result in materials with a combination of high modulus, impact resistance, and other desirable characteristics, suitable for various applications in automotive, construction, and consumer goods industries.

- Processing techniques for modulus enhancement: Various processing techniques are employed to increase the modulus of polypropylene. These may include orientation processes, heat treatments, or specific extrusion methods. The goal is to align the polymer chains and increase crystallinity, resulting in higher modulus values and improved mechanical properties.

- Applications in packaging and films: High-modulus polypropylene finds extensive use in packaging and film applications. The increased stiffness and strength allow for the production of thinner, yet stronger packaging materials and films. This results in reduced material usage while maintaining or improving performance in areas such as barrier properties and mechanical strength.

02 Fiber and filament applications

High-modulus polypropylene is utilized in the production of fibers and filaments. These materials find applications in various industries, including textiles, automotive, and construction. The high modulus properties contribute to improved tensile strength and dimensional stability in the final products.Expand Specific Solutions03 Blending and composite materials

High-modulus polypropylene is often blended with other polymers or materials to create composite materials with enhanced properties. These blends can result in materials with improved impact resistance, heat resistance, or specific functional characteristics tailored for particular applications.Expand Specific Solutions04 Surface modification and treatment

Various surface modification techniques are applied to high-modulus polypropylene to improve its compatibility with other materials or enhance specific surface properties. These treatments can include plasma treatment, chemical modification, or the application of coatings to achieve desired characteristics such as improved adhesion or barrier properties.Expand Specific Solutions05 Recycling and sustainability

Research and development efforts focus on improving the recyclability and sustainability of high-modulus polypropylene. This includes developing methods for efficient recycling, incorporating recycled content into new products, and exploring bio-based alternatives to enhance the material's environmental profile.Expand Specific Solutions

Key Players in HMPP Industry

The high-modulus polypropylene market in sports equipment is in a growth phase, driven by increasing demand for lightweight, durable materials. The global market size is estimated to be in the hundreds of millions of dollars, with steady expansion projected. Technologically, high-modulus polypropylene is advancing rapidly, with key players like ExxonMobil, Borealis, and LG Chem leading innovation. Companies such as Toyobo, DSM, and Kaneka are also making significant contributions, particularly in fiber and composite applications for sports gear. The technology's maturity varies across different sports segments, with more established use in products like golf club shafts and tennis rackets, while newer applications are still emerging.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed Achieve™ Advanced PP, a high-modulus polypropylene (HMPP) specifically designed for sports equipment applications. This innovative material utilizes proprietary catalyst and process technology to create a unique molecular structure with enhanced stiffness and impact resistance. The HMPP offers a density reduction of up to 20% compared to traditional materials, while maintaining or improving mechanical properties[1]. ExxonMobil's technology allows for the fine-tuning of the polymer chain architecture, resulting in a balance of high modulus and good processability. The company has also implemented a controlled rheology process to optimize melt flow characteristics, enabling easier molding of complex sports equipment shapes[2].

Strengths: Superior stiffness-to-weight ratio, excellent impact resistance, and improved processability. Weaknesses: Potentially higher cost compared to standard PP, may require specialized processing equipment for optimal results.

Borealis AG

Technical Solution: Borealis has introduced Fibremod™, a family of high-modulus polypropylene compounds tailored for sports equipment applications. This technology combines short glass fiber reinforcement with specially designed PP matrices to achieve exceptional stiffness and impact strength. Fibremod™ grades offer up to 50% weight reduction compared to traditional materials like ABS or PA[3]. Borealis utilizes a proprietary compounding process that ensures uniform fiber distribution and optimal fiber-matrix adhesion, resulting in consistent mechanical properties throughout the molded part. The company has also developed a surface treatment technology for the glass fibers, enhancing the interfacial bonding with the PP matrix and improving overall performance[4].

Strengths: Significant weight reduction potential, excellent mechanical properties, and good dimensional stability. Weaknesses: Higher material cost, potential for fiber breakage during processing, and limited color options due to glass fiber content.

HMPP Property Enhancements

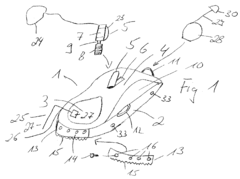

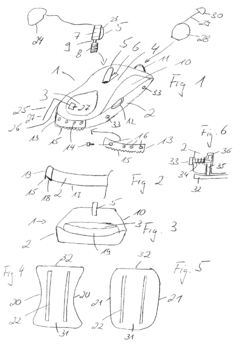

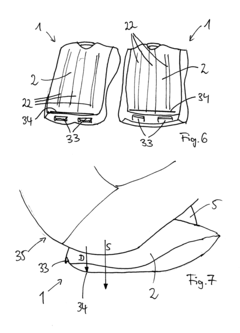

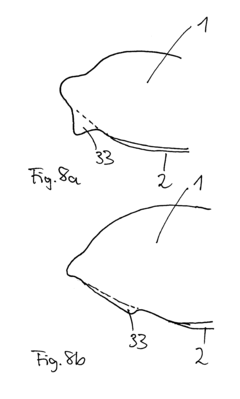

Sport apparatus

PatentInactiveEP1832494A2

Innovation

- The sports equipment features modular design with coupling elements for quick component changes, a foldable and breakable control handle, adjustable braking systems, vibration-damping seats, and materials like propylene and ethylene copolymers for enhanced gliding properties, along with interchangeable parts and buoyant capabilities.

Composition containing thermoplastic polyurethane and a copolymer having polyamide blocks and polyether blocks comprising amine chain ends

PatentWO2022223936A1

Innovation

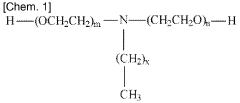

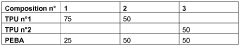

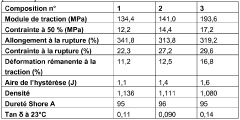

- A composition combining thermoplastic polyurethane with a copolymer having polyamide and polyether blocks with amine chain ends, where the copolymer is covalently bonded to the TPU via a urea function, achieving a specific molar ratio and concentration of functional groups to enhance compatibility and mechanical properties.

Environmental Impact of HMPP

The environmental impact of High-Modulus Polypropylene (HMPP) in sports equipment is a crucial consideration as the industry moves towards more sustainable practices. HMPP, while offering superior performance characteristics, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of HMPP is its potential for recyclability. As a thermoplastic, HMPP can be melted down and reformed multiple times without significant degradation of its properties. This characteristic allows for the possibility of closed-loop recycling systems within the sports equipment industry, potentially reducing waste and the need for virgin materials.

However, the recycling process for HMPP is not without its challenges. The high-performance additives and reinforcements used to enhance its properties can complicate the recycling process. Separation of these additives from the base polymer may require specialized techniques, which could increase the cost and energy requirements of recycling.

The production of HMPP also has environmental implications. While the manufacturing process is generally less energy-intensive compared to some other high-performance materials, it still requires significant energy input. The use of catalysts and other chemical additives in the production process may also have environmental impacts that need to be carefully managed.

In terms of durability, HMPP-based sports equipment tends to have a longer lifespan compared to traditional materials. This increased durability can lead to reduced consumption and waste over time, as products need to be replaced less frequently. However, this benefit may be offset if the improved performance characteristics of HMPP lead to more frequent upgrades by consumers seeking the latest technology.

The end-of-life disposal of HMPP sports equipment is another important consideration. While theoretically recyclable, the reality is that many HMPP products may end up in landfills due to lack of appropriate recycling infrastructure or consumer awareness. In landfill conditions, HMPP, like other plastics, can persist for hundreds of years.

Efforts are being made to address these environmental challenges. Some manufacturers are exploring bio-based alternatives to traditional HMPP, aiming to reduce reliance on fossil fuel-derived raw materials. Additionally, research is ongoing into more efficient recycling technologies specifically tailored for high-performance polymers like HMPP.

The sports equipment industry is also increasingly adopting life cycle assessment (LCA) approaches to evaluate the full environmental impact of HMPP products from cradle to grave. These assessments help in identifying hotspots for environmental improvement and guide the development of more sustainable product designs and manufacturing processes.

One of the primary environmental benefits of HMPP is its potential for recyclability. As a thermoplastic, HMPP can be melted down and reformed multiple times without significant degradation of its properties. This characteristic allows for the possibility of closed-loop recycling systems within the sports equipment industry, potentially reducing waste and the need for virgin materials.

However, the recycling process for HMPP is not without its challenges. The high-performance additives and reinforcements used to enhance its properties can complicate the recycling process. Separation of these additives from the base polymer may require specialized techniques, which could increase the cost and energy requirements of recycling.

The production of HMPP also has environmental implications. While the manufacturing process is generally less energy-intensive compared to some other high-performance materials, it still requires significant energy input. The use of catalysts and other chemical additives in the production process may also have environmental impacts that need to be carefully managed.

In terms of durability, HMPP-based sports equipment tends to have a longer lifespan compared to traditional materials. This increased durability can lead to reduced consumption and waste over time, as products need to be replaced less frequently. However, this benefit may be offset if the improved performance characteristics of HMPP lead to more frequent upgrades by consumers seeking the latest technology.

The end-of-life disposal of HMPP sports equipment is another important consideration. While theoretically recyclable, the reality is that many HMPP products may end up in landfills due to lack of appropriate recycling infrastructure or consumer awareness. In landfill conditions, HMPP, like other plastics, can persist for hundreds of years.

Efforts are being made to address these environmental challenges. Some manufacturers are exploring bio-based alternatives to traditional HMPP, aiming to reduce reliance on fossil fuel-derived raw materials. Additionally, research is ongoing into more efficient recycling technologies specifically tailored for high-performance polymers like HMPP.

The sports equipment industry is also increasingly adopting life cycle assessment (LCA) approaches to evaluate the full environmental impact of HMPP products from cradle to grave. These assessments help in identifying hotspots for environmental improvement and guide the development of more sustainable product designs and manufacturing processes.

HMPP Manufacturing Processes

The manufacturing processes for High-Modulus Polypropylene (HMPP) are critical in determining the final properties and performance of sports equipment. The primary method for producing HMPP involves a multi-stage process that begins with the polymerization of propylene monomers using specialized catalysts. This initial step is crucial in achieving the desired molecular weight and isotacticity, which are key factors in the material's high modulus.

Following polymerization, the HMPP undergoes a series of orientation and drawing processes. The first stage typically involves melt extrusion, where the polymer is heated and forced through a die to create a continuous filament or sheet. This extruded material is then rapidly cooled to preserve its molecular structure.

The next critical step is the drawing process, which is often performed in multiple stages. The initial drawing occurs at temperatures slightly above the glass transition temperature of the polymer. This step aligns the molecular chains along the drawing direction, significantly enhancing the material's strength and stiffness. Subsequent drawing stages may be performed at progressively higher temperatures to further improve the molecular orientation and crystallinity.

Heat treatment is another crucial aspect of HMPP manufacturing. Controlled heating and cooling cycles are employed to optimize the crystalline structure of the polymer. This process, known as annealing, helps to relieve internal stresses and further enhance the material's mechanical properties.

For sports equipment applications, additional processing steps may be incorporated. These can include the addition of reinforcing fibers or nanoparticles to create composite materials with even higher strength-to-weight ratios. Surface treatments or coatings may also be applied to improve wear resistance or provide specific surface properties relevant to the intended sport.

The final stages of HMPP manufacturing for sports equipment often involve shaping and molding processes. Techniques such as injection molding, compression molding, or thermoforming are used to create the desired product geometries. These processes must be carefully controlled to maintain the enhanced properties achieved through the earlier manufacturing stages.

Quality control is an integral part of HMPP manufacturing, with continuous monitoring and testing throughout the production process. This ensures consistency in the material's properties and performance, which is crucial for high-performance sports equipment.

Following polymerization, the HMPP undergoes a series of orientation and drawing processes. The first stage typically involves melt extrusion, where the polymer is heated and forced through a die to create a continuous filament or sheet. This extruded material is then rapidly cooled to preserve its molecular structure.

The next critical step is the drawing process, which is often performed in multiple stages. The initial drawing occurs at temperatures slightly above the glass transition temperature of the polymer. This step aligns the molecular chains along the drawing direction, significantly enhancing the material's strength and stiffness. Subsequent drawing stages may be performed at progressively higher temperatures to further improve the molecular orientation and crystallinity.

Heat treatment is another crucial aspect of HMPP manufacturing. Controlled heating and cooling cycles are employed to optimize the crystalline structure of the polymer. This process, known as annealing, helps to relieve internal stresses and further enhance the material's mechanical properties.

For sports equipment applications, additional processing steps may be incorporated. These can include the addition of reinforcing fibers or nanoparticles to create composite materials with even higher strength-to-weight ratios. Surface treatments or coatings may also be applied to improve wear resistance or provide specific surface properties relevant to the intended sport.

The final stages of HMPP manufacturing for sports equipment often involve shaping and molding processes. Techniques such as injection molding, compression molding, or thermoforming are used to create the desired product geometries. These processes must be carefully controlled to maintain the enhanced properties achieved through the earlier manufacturing stages.

Quality control is an integral part of HMPP manufacturing, with continuous monitoring and testing throughout the production process. This ensures consistency in the material's properties and performance, which is crucial for high-performance sports equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!