Exploring High-Performance Polypropylene in Composite Aerostructures

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Composites in Aerospace: Background and Objectives

Polypropylene composites have emerged as a promising material in the aerospace industry, offering a unique combination of lightweight properties and high performance. The evolution of these composites in aerospace applications can be traced back to the early 2000s when researchers began exploring alternatives to traditional materials like aluminum and titanium. The primary objective of this technological advancement was to reduce aircraft weight, thereby improving fuel efficiency and reducing environmental impact.

The development of polypropylene composites for aerospace structures has been driven by the industry's constant pursuit of materials that can withstand extreme conditions while maintaining structural integrity. Over the past two decades, significant progress has been made in enhancing the mechanical properties, thermal stability, and chemical resistance of polypropylene-based composites, making them increasingly suitable for aerospace applications.

One of the key technological trends in this field has been the incorporation of various reinforcing agents, such as carbon fibers, glass fibers, and nanoparticles, into the polypropylene matrix. These additives have dramatically improved the strength-to-weight ratio of the composites, addressing one of the primary concerns in aerospace engineering. Additionally, advancements in polymer science have led to the development of specialized grades of polypropylene with enhanced thermal and oxidative stability, crucial for withstanding the harsh conditions encountered during flight.

The aerospace industry's shift towards more sustainable and cost-effective materials has further accelerated research into polypropylene composites. As environmental regulations become more stringent, the ability of these composites to be recycled and their lower carbon footprint compared to traditional aerospace materials have become significant advantages. This aligns well with the industry's long-term goals of reducing overall environmental impact and operating costs.

Current technological objectives in the field of polypropylene composites for aerospace applications include further improving their mechanical properties, particularly in terms of impact resistance and fatigue performance. Researchers are also focusing on enhancing the fire retardancy of these materials, a critical safety aspect in aircraft design. Additionally, there is ongoing work to develop more efficient manufacturing processes for large-scale production of polypropylene composite aerostructures, including advanced molding techniques and 3D printing technologies.

The integration of smart materials and nanotechnology with polypropylene composites represents another frontier in this field. The aim is to create multifunctional composites that can not only provide structural support but also offer capabilities such as self-healing, de-icing, and real-time structural health monitoring. These advancements are expected to revolutionize aircraft design and maintenance practices in the coming years.

The development of polypropylene composites for aerospace structures has been driven by the industry's constant pursuit of materials that can withstand extreme conditions while maintaining structural integrity. Over the past two decades, significant progress has been made in enhancing the mechanical properties, thermal stability, and chemical resistance of polypropylene-based composites, making them increasingly suitable for aerospace applications.

One of the key technological trends in this field has been the incorporation of various reinforcing agents, such as carbon fibers, glass fibers, and nanoparticles, into the polypropylene matrix. These additives have dramatically improved the strength-to-weight ratio of the composites, addressing one of the primary concerns in aerospace engineering. Additionally, advancements in polymer science have led to the development of specialized grades of polypropylene with enhanced thermal and oxidative stability, crucial for withstanding the harsh conditions encountered during flight.

The aerospace industry's shift towards more sustainable and cost-effective materials has further accelerated research into polypropylene composites. As environmental regulations become more stringent, the ability of these composites to be recycled and their lower carbon footprint compared to traditional aerospace materials have become significant advantages. This aligns well with the industry's long-term goals of reducing overall environmental impact and operating costs.

Current technological objectives in the field of polypropylene composites for aerospace applications include further improving their mechanical properties, particularly in terms of impact resistance and fatigue performance. Researchers are also focusing on enhancing the fire retardancy of these materials, a critical safety aspect in aircraft design. Additionally, there is ongoing work to develop more efficient manufacturing processes for large-scale production of polypropylene composite aerostructures, including advanced molding techniques and 3D printing technologies.

The integration of smart materials and nanotechnology with polypropylene composites represents another frontier in this field. The aim is to create multifunctional composites that can not only provide structural support but also offer capabilities such as self-healing, de-icing, and real-time structural health monitoring. These advancements are expected to revolutionize aircraft design and maintenance practices in the coming years.

Market Analysis for Lightweight Aerostructure Materials

The market for lightweight aerostructure materials has experienced significant growth in recent years, driven by the aerospace industry's continuous pursuit of fuel efficiency and improved performance. Polypropylene, particularly high-performance variants, has emerged as a promising material for composite aerostructures due to its excellent strength-to-weight ratio, chemical resistance, and cost-effectiveness.

The global aerospace composites market, which includes lightweight materials for aerostructures, was valued at approximately $32 billion in 2020 and is projected to reach $53 billion by 2026, growing at a CAGR of 8.5%. This growth is primarily attributed to the increasing demand for fuel-efficient aircraft and the rising adoption of composite materials in both commercial and military aerospace applications.

Within this market, thermoplastic composites, including high-performance polypropylene, are gaining traction. The thermoplastic composites segment is expected to witness the highest growth rate among all composite types in the aerospace industry, with a CAGR of over 10% during the forecast period.

The demand for lightweight aerostructure materials is particularly strong in regions with established aerospace industries, such as North America and Europe. These regions account for the largest market share, with North America holding approximately 40% of the global market. However, the Asia-Pacific region is emerging as a significant market, driven by the growing aviation sector in countries like China and India.

Key factors influencing the market for lightweight aerostructure materials include:

1. Stringent fuel efficiency regulations: Governments worldwide are implementing stricter fuel efficiency standards for aircraft, driving the adoption of lightweight materials.

2. Increasing air passenger traffic: The growing number of air travelers is leading to higher demand for new aircraft, consequently boosting the market for lightweight materials.

3. Technological advancements: Ongoing research and development in material science are enhancing the properties of lightweight materials, including high-performance polypropylene, making them more suitable for aerospace applications.

4. Cost considerations: As the aerospace industry seeks to reduce manufacturing and operational costs, materials like high-performance polypropylene offer an attractive balance between performance and affordability.

The market for high-performance polypropylene in composite aerostructures is expected to grow significantly, with potential applications in interior components, secondary structures, and even primary structures in the future. However, challenges such as high initial investment costs and the need for specialized manufacturing processes may impact market growth.

The global aerospace composites market, which includes lightweight materials for aerostructures, was valued at approximately $32 billion in 2020 and is projected to reach $53 billion by 2026, growing at a CAGR of 8.5%. This growth is primarily attributed to the increasing demand for fuel-efficient aircraft and the rising adoption of composite materials in both commercial and military aerospace applications.

Within this market, thermoplastic composites, including high-performance polypropylene, are gaining traction. The thermoplastic composites segment is expected to witness the highest growth rate among all composite types in the aerospace industry, with a CAGR of over 10% during the forecast period.

The demand for lightweight aerostructure materials is particularly strong in regions with established aerospace industries, such as North America and Europe. These regions account for the largest market share, with North America holding approximately 40% of the global market. However, the Asia-Pacific region is emerging as a significant market, driven by the growing aviation sector in countries like China and India.

Key factors influencing the market for lightweight aerostructure materials include:

1. Stringent fuel efficiency regulations: Governments worldwide are implementing stricter fuel efficiency standards for aircraft, driving the adoption of lightweight materials.

2. Increasing air passenger traffic: The growing number of air travelers is leading to higher demand for new aircraft, consequently boosting the market for lightweight materials.

3. Technological advancements: Ongoing research and development in material science are enhancing the properties of lightweight materials, including high-performance polypropylene, making them more suitable for aerospace applications.

4. Cost considerations: As the aerospace industry seeks to reduce manufacturing and operational costs, materials like high-performance polypropylene offer an attractive balance between performance and affordability.

The market for high-performance polypropylene in composite aerostructures is expected to grow significantly, with potential applications in interior components, secondary structures, and even primary structures in the future. However, challenges such as high initial investment costs and the need for specialized manufacturing processes may impact market growth.

Current Challenges in High-Performance Polypropylene Composites

The integration of high-performance polypropylene in composite aerostructures faces several significant challenges that hinder its widespread adoption in the aerospace industry. One of the primary obstacles is the inherent low stiffness and strength of polypropylene compared to traditional aerospace materials like carbon fiber-reinforced epoxy composites. This limitation necessitates innovative approaches to enhance the mechanical properties of polypropylene-based composites without compromising their lightweight characteristics.

Another critical challenge lies in the thermal stability of polypropylene at elevated temperatures. Aerospace applications often involve exposure to extreme temperature fluctuations, and polypropylene's relatively low melting point and thermal degradation susceptibility pose concerns for long-term durability and performance. Researchers are actively exploring methods to improve the thermal resistance of polypropylene composites, such as incorporating nanofillers or developing novel copolymer formulations.

The interfacial adhesion between polypropylene matrices and reinforcing fibers presents a significant hurdle in achieving optimal composite performance. The non-polar nature of polypropylene results in poor wettability and weak bonding with many common reinforcing materials, leading to reduced mechanical properties and potential delamination issues. Overcoming this challenge requires the development of effective surface treatment techniques or compatibilizing agents to enhance fiber-matrix adhesion.

Processing and manufacturing high-performance polypropylene composites for aerospace applications also pose technical difficulties. The high viscosity of polypropylene melts can lead to challenges in achieving uniform fiber distribution and void-free laminates. Additionally, the relatively high processing temperatures required for polypropylene can cause degradation of temperature-sensitive reinforcing fibers or additives.

Environmental concerns and sustainability requirements in the aerospace industry present another set of challenges for polypropylene composites. While polypropylene itself is recyclable, the incorporation of various additives and reinforcing materials can complicate the recycling process. Developing eco-friendly formulations and establishing efficient recycling methods for end-of-life composite components are crucial areas of ongoing research.

Lastly, the aerospace industry's stringent certification and qualification processes pose a significant barrier to the adoption of new materials like high-performance polypropylene composites. Extensive testing and validation are required to demonstrate long-term reliability, fire resistance, and compliance with safety regulations. Overcoming these regulatory hurdles and establishing a track record of successful applications will be essential for the widespread acceptance of polypropylene-based composites in aerospace structures.

Another critical challenge lies in the thermal stability of polypropylene at elevated temperatures. Aerospace applications often involve exposure to extreme temperature fluctuations, and polypropylene's relatively low melting point and thermal degradation susceptibility pose concerns for long-term durability and performance. Researchers are actively exploring methods to improve the thermal resistance of polypropylene composites, such as incorporating nanofillers or developing novel copolymer formulations.

The interfacial adhesion between polypropylene matrices and reinforcing fibers presents a significant hurdle in achieving optimal composite performance. The non-polar nature of polypropylene results in poor wettability and weak bonding with many common reinforcing materials, leading to reduced mechanical properties and potential delamination issues. Overcoming this challenge requires the development of effective surface treatment techniques or compatibilizing agents to enhance fiber-matrix adhesion.

Processing and manufacturing high-performance polypropylene composites for aerospace applications also pose technical difficulties. The high viscosity of polypropylene melts can lead to challenges in achieving uniform fiber distribution and void-free laminates. Additionally, the relatively high processing temperatures required for polypropylene can cause degradation of temperature-sensitive reinforcing fibers or additives.

Environmental concerns and sustainability requirements in the aerospace industry present another set of challenges for polypropylene composites. While polypropylene itself is recyclable, the incorporation of various additives and reinforcing materials can complicate the recycling process. Developing eco-friendly formulations and establishing efficient recycling methods for end-of-life composite components are crucial areas of ongoing research.

Lastly, the aerospace industry's stringent certification and qualification processes pose a significant barrier to the adoption of new materials like high-performance polypropylene composites. Extensive testing and validation are required to demonstrate long-term reliability, fire resistance, and compliance with safety regulations. Overcoming these regulatory hurdles and establishing a track record of successful applications will be essential for the widespread acceptance of polypropylene-based composites in aerospace structures.

Existing Solutions for Enhancing Polypropylene Performance

01 Composition and preparation of high-performance polypropylene

High-performance polypropylene compositions are developed by incorporating specific additives, modifiers, or through novel preparation methods. These compositions often include nucleating agents, reinforcing materials, or specialized catalysts to enhance the polymer's properties such as strength, stiffness, and heat resistance.- Composition and preparation of high-performance polypropylene: High-performance polypropylene compositions are developed by incorporating specific additives, modifiers, or through novel preparation methods. These compositions often include nucleating agents, reinforcing materials, or specialized catalysts to enhance the polymer's properties such as strength, stiffness, and heat resistance.

- Modification techniques for improved polypropylene properties: Various modification techniques are employed to enhance polypropylene properties. These may include chemical modification, blending with other polymers, or the use of specific processing conditions. Such modifications can lead to improvements in impact strength, thermal stability, or barrier properties of the resulting high-performance polypropylene materials.

- Application-specific high-performance polypropylene formulations: Tailored polypropylene formulations are developed for specific applications such as automotive parts, packaging materials, or industrial components. These formulations often involve optimizing the polymer structure, molecular weight distribution, or incorporating specific additives to meet the performance requirements of the intended application.

- Processing methods for high-performance polypropylene: Advanced processing methods are utilized to produce high-performance polypropylene products. These may include specialized extrusion techniques, injection molding processes, or post-processing treatments. The focus is on optimizing processing conditions to achieve desired mechanical, thermal, or optical properties in the final product.

- Characterization and testing of high-performance polypropylene: Various characterization and testing methods are employed to evaluate the properties and performance of high-performance polypropylene materials. These may include mechanical testing, thermal analysis, rheological measurements, or accelerated aging tests. The results of these tests are used to validate the enhanced properties and ensure the material meets the required specifications for high-performance applications.

02 Modification techniques for improved polypropylene properties

Various modification techniques are employed to enhance polypropylene properties. These may include chemical modification, blending with other polymers, or the use of specific processing conditions. Such modifications can result in improved mechanical properties, thermal stability, or specific functional characteristics.Expand Specific Solutions03 Polypropylene composites for enhanced performance

High-performance polypropylene composites are developed by incorporating fillers, fibers, or nanoparticles. These composites often exhibit superior mechanical properties, improved barrier characteristics, or enhanced thermal and electrical conductivity compared to unmodified polypropylene.Expand Specific Solutions04 Specialized polypropylene grades for specific applications

Tailored polypropylene grades are developed for specific high-performance applications. These may include grades with improved impact resistance, high melt strength, or enhanced processability for use in automotive parts, packaging, or industrial applications.Expand Specific Solutions05 Sustainable and eco-friendly high-performance polypropylene

Research focuses on developing high-performance polypropylene that is more sustainable and environmentally friendly. This includes the use of bio-based additives, recycled content, or the development of easily recyclable polypropylene composites without compromising on performance.Expand Specific Solutions

Key Players in Aerospace Composite Materials Industry

The high-performance polypropylene market for composite aerostructures is in a growth phase, driven by increasing demand for lightweight materials in aerospace applications. The market size is expanding as manufacturers seek to improve fuel efficiency and reduce emissions. Technologically, the field is advancing rapidly, with companies like Borealis AG, Kingfa Sci. & Tech., and SABIC Global Technologies leading innovation. These firms are developing enhanced polypropylene formulations with improved strength-to-weight ratios and thermal stability. Collaboration between material suppliers like Prime Polymer Co. and aerospace manufacturers such as Spirit AeroSystems and Boeing is accelerating the adoption of these advanced materials in aircraft components, indicating a maturing technology landscape with significant potential for further growth and refinement.

Borealis AG

Technical Solution: Borealis AG has developed a high-performance polypropylene (PP) composite solution for aerostructures, focusing on lightweight and durable materials. Their technology involves the use of long glass fiber-reinforced PP (LGF-PP) compounds, which offer a superior strength-to-weight ratio compared to traditional materials [1]. The company has implemented a proprietary fiber impregnation technology that ensures uniform distribution of glass fibers within the PP matrix, resulting in enhanced mechanical properties and improved impact resistance [2]. Additionally, Borealis has developed a specialized surface treatment process for the glass fibers, which enhances the interfacial adhesion between the fibers and the PP matrix, leading to better load transfer and overall composite performance [3].

Strengths: Excellent strength-to-weight ratio, improved impact resistance, and enhanced interfacial adhesion. Weaknesses: Potentially higher production costs compared to traditional materials and limited high-temperature performance compared to some thermoset composites.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a range of high-performance polypropylene composites specifically tailored for aerostructure applications. Their technology focuses on the development of nano-reinforced PP composites, incorporating graphene and carbon nanotubes to enhance mechanical properties and thermal stability [1]. SABIC's proprietary processing technique allows for the uniform dispersion of nanoparticles within the PP matrix, resulting in significant improvements in tensile strength, modulus, and impact resistance [2]. The company has also developed a novel compatibilization method to improve the interfacial adhesion between the PP matrix and reinforcing fibers, leading to enhanced load transfer and overall composite performance [3]. Furthermore, SABIC has implemented a specialized surface treatment for their PP composites, improving their resistance to environmental factors and enhancing their long-term durability in aerospace applications [4].

Strengths: Enhanced mechanical properties, improved thermal stability, and increased durability. Weaknesses: Potential challenges in large-scale production of nano-reinforced composites and higher material costs compared to conventional PP.

Innovations in High-Performance Polypropylene Composites

Polypropylene composite

PatentInactiveEP0888883A2

Innovation

- A polypropylene composite comprising a polypropylene sheet with a freely selectable basis weight, coated with a non-crosslinked polypropylene foam and a multi-component polypropylene non-woven fabric, using an olefinic adhesive for bonding, which is flame retardant, hydrophilic, and anti-corrosive, and designed for thermal processing and recycling.

Polypropylene composite, and preparation method therefor and use thereof

PatentWO2025112331A1

Innovation

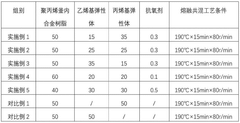

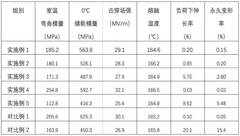

- The polypropylene-based alloy resin is used as the matrix, and the vinyl elastomer and acrylic elastomer are combined to prepare polypropylene composite materials through a melt blending process. Combining the performance advantages of vinyl elastomer and acrylic elastomer, the mechanical toughness and electrical properties of the polypropylene composite materials are balanced.

Environmental Impact and Sustainability Considerations

The integration of high-performance polypropylene in composite aerostructures presents significant environmental and sustainability considerations. As the aerospace industry increasingly focuses on reducing its carbon footprint, the choice of materials plays a crucial role in achieving sustainability goals. Polypropylene, being a thermoplastic polymer, offers several advantages in this regard.

Firstly, polypropylene is recyclable, which aligns with the circular economy principles. Unlike thermoset composites that are challenging to recycle, polypropylene-based composites can be melted down and reformed, potentially reducing waste and conserving resources. This recyclability factor contributes to the overall lifecycle sustainability of aircraft components.

The production of polypropylene also tends to have a lower environmental impact compared to some traditional aerospace materials. It requires less energy to manufacture and process, resulting in reduced greenhouse gas emissions during the production phase. Additionally, the lightweight nature of polypropylene composites contributes to fuel efficiency in aircraft, leading to decreased emissions over the operational life of the aircraft.

However, it is essential to consider the sourcing of polypropylene. Currently, most polypropylene is derived from fossil fuels, which raises concerns about long-term sustainability. The aerospace industry must explore and invest in bio-based or recycled sources of polypropylene to enhance its environmental credentials further.

The durability and resistance to environmental factors of high-performance polypropylene composites also contribute to sustainability. Longer-lasting components reduce the need for frequent replacements, minimizing waste generation and resource consumption over time. This aspect is particularly relevant in the aerospace sector, where component longevity is crucial for safety and operational efficiency.

When evaluating the environmental impact, it's crucial to conduct comprehensive life cycle assessments (LCA) of polypropylene composites in aerostructures. These assessments should compare the environmental footprint of polypropylene-based components with traditional materials across all stages - from raw material extraction to end-of-life disposal or recycling.

Lastly, the adoption of high-performance polypropylene in aerostructures may drive innovation in sustainable manufacturing processes. This could include the development of more energy-efficient production techniques, advanced recycling technologies, and the integration of renewable energy sources in manufacturing facilities.

Firstly, polypropylene is recyclable, which aligns with the circular economy principles. Unlike thermoset composites that are challenging to recycle, polypropylene-based composites can be melted down and reformed, potentially reducing waste and conserving resources. This recyclability factor contributes to the overall lifecycle sustainability of aircraft components.

The production of polypropylene also tends to have a lower environmental impact compared to some traditional aerospace materials. It requires less energy to manufacture and process, resulting in reduced greenhouse gas emissions during the production phase. Additionally, the lightweight nature of polypropylene composites contributes to fuel efficiency in aircraft, leading to decreased emissions over the operational life of the aircraft.

However, it is essential to consider the sourcing of polypropylene. Currently, most polypropylene is derived from fossil fuels, which raises concerns about long-term sustainability. The aerospace industry must explore and invest in bio-based or recycled sources of polypropylene to enhance its environmental credentials further.

The durability and resistance to environmental factors of high-performance polypropylene composites also contribute to sustainability. Longer-lasting components reduce the need for frequent replacements, minimizing waste generation and resource consumption over time. This aspect is particularly relevant in the aerospace sector, where component longevity is crucial for safety and operational efficiency.

When evaluating the environmental impact, it's crucial to conduct comprehensive life cycle assessments (LCA) of polypropylene composites in aerostructures. These assessments should compare the environmental footprint of polypropylene-based components with traditional materials across all stages - from raw material extraction to end-of-life disposal or recycling.

Lastly, the adoption of high-performance polypropylene in aerostructures may drive innovation in sustainable manufacturing processes. This could include the development of more energy-efficient production techniques, advanced recycling technologies, and the integration of renewable energy sources in manufacturing facilities.

Certification and Regulatory Requirements for Aerospace Materials

The certification and regulatory requirements for aerospace materials are critical aspects of the development and implementation of high-performance polypropylene in composite aerostructures. These requirements ensure the safety, reliability, and performance of materials used in aircraft construction.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies overseeing the certification of aerospace materials. These organizations have established stringent standards and protocols that must be met before any material can be approved for use in aircraft structures.

For high-performance polypropylene composites, the certification process typically begins with material qualification. This involves extensive testing to characterize the material's mechanical properties, environmental resistance, and long-term durability. The tests include tensile strength, compressive strength, shear strength, fatigue resistance, and impact resistance under various environmental conditions.

Fire safety is a paramount concern in aerospace applications. Polypropylene composites must meet strict flammability requirements, including flame resistance and smoke toxicity standards. The FAA's FAR 25.853 and EASA's CS-25 regulations outline specific tests for interior materials, which may also apply to structural composites depending on their location within the aircraft.

Environmental factors play a significant role in material certification. Polypropylene composites must demonstrate resistance to moisture absorption, UV radiation, and temperature extremes encountered during flight. The material's performance under these conditions must be thoroughly documented and validated through accelerated aging tests and simulated service conditions.

Consistency in manufacturing processes is crucial for certification. Manufacturers must establish and document quality control procedures to ensure that each batch of polypropylene composite material meets the specified requirements. This includes process controls, material traceability, and regular testing of production samples.

The certification process also involves evaluating the material's compatibility with other aircraft components and systems. This includes assessing potential galvanic corrosion issues, electromagnetic interference, and the effectiveness of bonding and repair techniques.

Regulatory bodies require extensive documentation throughout the certification process. This includes detailed test reports, material specifications, process controls, and quality assurance procedures. The documentation must demonstrate compliance with all applicable regulations and standards.

Once certified, the material is subject to ongoing surveillance and periodic re-evaluation to ensure continued compliance with regulatory requirements. Any significant changes to the material composition or manufacturing process may require recertification.

In conclusion, the certification and regulatory requirements for high-performance polypropylene in composite aerostructures are comprehensive and rigorous. Meeting these standards is essential for ensuring the safety and reliability of aircraft components, and it represents a significant milestone in the adoption of new materials in the aerospace industry.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies overseeing the certification of aerospace materials. These organizations have established stringent standards and protocols that must be met before any material can be approved for use in aircraft structures.

For high-performance polypropylene composites, the certification process typically begins with material qualification. This involves extensive testing to characterize the material's mechanical properties, environmental resistance, and long-term durability. The tests include tensile strength, compressive strength, shear strength, fatigue resistance, and impact resistance under various environmental conditions.

Fire safety is a paramount concern in aerospace applications. Polypropylene composites must meet strict flammability requirements, including flame resistance and smoke toxicity standards. The FAA's FAR 25.853 and EASA's CS-25 regulations outline specific tests for interior materials, which may also apply to structural composites depending on their location within the aircraft.

Environmental factors play a significant role in material certification. Polypropylene composites must demonstrate resistance to moisture absorption, UV radiation, and temperature extremes encountered during flight. The material's performance under these conditions must be thoroughly documented and validated through accelerated aging tests and simulated service conditions.

Consistency in manufacturing processes is crucial for certification. Manufacturers must establish and document quality control procedures to ensure that each batch of polypropylene composite material meets the specified requirements. This includes process controls, material traceability, and regular testing of production samples.

The certification process also involves evaluating the material's compatibility with other aircraft components and systems. This includes assessing potential galvanic corrosion issues, electromagnetic interference, and the effectiveness of bonding and repair techniques.

Regulatory bodies require extensive documentation throughout the certification process. This includes detailed test reports, material specifications, process controls, and quality assurance procedures. The documentation must demonstrate compliance with all applicable regulations and standards.

Once certified, the material is subject to ongoing surveillance and periodic re-evaluation to ensure continued compliance with regulatory requirements. Any significant changes to the material composition or manufacturing process may require recertification.

In conclusion, the certification and regulatory requirements for high-performance polypropylene in composite aerostructures are comprehensive and rigorous. Meeting these standards is essential for ensuring the safety and reliability of aircraft components, and it represents a significant milestone in the adoption of new materials in the aerospace industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!