Exploring Nano-Mechanical Properties of Microporous Polypropylene

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microporous PP Nano-Mechanics: Background and Objectives

Microporous polypropylene (PP) has emerged as a significant material in various industries due to its unique structural and mechanical properties. The exploration of nano-mechanical properties of microporous PP represents a cutting-edge research area that combines materials science, nanotechnology, and polymer engineering. This field has evolved rapidly over the past few decades, driven by the increasing demand for high-performance materials in applications ranging from filtration and separation to energy storage and biomedical devices.

The development of microporous PP can be traced back to the 1960s when researchers first discovered methods to create controlled pore structures in polymeric materials. Since then, advancements in polymer processing techniques and characterization methods have led to a deeper understanding of the relationship between microstructure and mechanical properties at the nanoscale.

The primary objective of exploring nano-mechanical properties of microporous PP is to elucidate the fundamental mechanisms that govern its behavior under various conditions. This includes investigating the influence of pore size, distribution, and interconnectivity on the material's overall mechanical performance. By understanding these relationships, researchers aim to develop tailored microporous PP structures with enhanced properties for specific applications.

One of the key technological trends in this field is the development of advanced characterization techniques that allow for in-situ observation of nano-mechanical behavior. Atomic force microscopy (AFM), nanoindentation, and nanoscale tensile testing have become invaluable tools for probing the local mechanical properties of microporous PP at unprecedented resolution.

Another significant trend is the integration of computational modeling with experimental studies. Molecular dynamics simulations and finite element analysis are increasingly being used to predict and interpret the nano-mechanical behavior of microporous PP, providing insights that are difficult to obtain through experimental methods alone.

The exploration of nano-mechanical properties also extends to the investigation of surface interactions and interfacial phenomena in microporous PP. This is particularly relevant for applications involving fluid transport or selective permeation, where surface properties play a crucial role in determining overall performance.

As research in this area progresses, there is a growing focus on developing multifunctional microporous PP materials that combine enhanced mechanical properties with other desirable characteristics such as thermal stability, chemical resistance, or biocompatibility. This holistic approach to material design is expected to open up new avenues for innovation and expand the potential applications of microporous PP in advanced technologies.

The development of microporous PP can be traced back to the 1960s when researchers first discovered methods to create controlled pore structures in polymeric materials. Since then, advancements in polymer processing techniques and characterization methods have led to a deeper understanding of the relationship between microstructure and mechanical properties at the nanoscale.

The primary objective of exploring nano-mechanical properties of microporous PP is to elucidate the fundamental mechanisms that govern its behavior under various conditions. This includes investigating the influence of pore size, distribution, and interconnectivity on the material's overall mechanical performance. By understanding these relationships, researchers aim to develop tailored microporous PP structures with enhanced properties for specific applications.

One of the key technological trends in this field is the development of advanced characterization techniques that allow for in-situ observation of nano-mechanical behavior. Atomic force microscopy (AFM), nanoindentation, and nanoscale tensile testing have become invaluable tools for probing the local mechanical properties of microporous PP at unprecedented resolution.

Another significant trend is the integration of computational modeling with experimental studies. Molecular dynamics simulations and finite element analysis are increasingly being used to predict and interpret the nano-mechanical behavior of microporous PP, providing insights that are difficult to obtain through experimental methods alone.

The exploration of nano-mechanical properties also extends to the investigation of surface interactions and interfacial phenomena in microporous PP. This is particularly relevant for applications involving fluid transport or selective permeation, where surface properties play a crucial role in determining overall performance.

As research in this area progresses, there is a growing focus on developing multifunctional microporous PP materials that combine enhanced mechanical properties with other desirable characteristics such as thermal stability, chemical resistance, or biocompatibility. This holistic approach to material design is expected to open up new avenues for innovation and expand the potential applications of microporous PP in advanced technologies.

Market Demand for Advanced Microporous Materials

The market demand for advanced microporous materials, particularly microporous polypropylene, has been steadily increasing across various industries. This growth is primarily driven by the unique properties these materials offer, such as high porosity, excellent mechanical strength, and chemical resistance. In the automotive sector, microporous polypropylene membranes are gaining traction for use in battery separators, fuel cells, and air filtration systems. The electric vehicle market, in particular, is creating a significant demand surge for high-performance battery separators, where microporous polypropylene plays a crucial role in enhancing battery efficiency and safety.

In the healthcare industry, microporous polypropylene finds applications in medical filtration, drug delivery systems, and wound dressings. The ongoing global health concerns have further accelerated the demand for advanced filtration materials in medical devices and personal protective equipment. The water treatment industry is another key market driver, with microporous polypropylene membranes being increasingly used in water purification and desalination processes due to their excellent fouling resistance and durability.

The packaging industry is also contributing to the growing demand for microporous polypropylene. These materials are being utilized in breathable packaging solutions, which help in extending the shelf life of perishable goods while maintaining product quality. This application is particularly relevant in the food and pharmaceutical sectors, where packaging integrity and product preservation are paramount.

In the electronics industry, the miniaturization trend and the need for high-performance materials in semiconductor manufacturing have led to increased interest in microporous polypropylene. Its use in clean room environments and as a component in advanced electronic devices showcases the material's versatility and importance in high-tech applications.

The construction sector is another area where microporous polypropylene is gaining ground. Its application in building materials for improved insulation and moisture management is driving demand, especially in regions focusing on energy-efficient construction practices. The material's lightweight nature and durability make it an attractive option for modern construction techniques.

As environmental concerns continue to shape market trends, the recyclability and potential biodegradability of microporous polypropylene are becoming increasingly important factors. Research and development efforts are focused on enhancing these aspects, which is likely to further boost market demand in environmentally conscious industries.

The global market for microporous materials, including polypropylene, is expected to continue its growth trajectory in the coming years. This growth is underpinned by ongoing technological advancements, expanding applications across diverse industries, and the increasing focus on sustainable and high-performance materials in various sectors.

In the healthcare industry, microporous polypropylene finds applications in medical filtration, drug delivery systems, and wound dressings. The ongoing global health concerns have further accelerated the demand for advanced filtration materials in medical devices and personal protective equipment. The water treatment industry is another key market driver, with microporous polypropylene membranes being increasingly used in water purification and desalination processes due to their excellent fouling resistance and durability.

The packaging industry is also contributing to the growing demand for microporous polypropylene. These materials are being utilized in breathable packaging solutions, which help in extending the shelf life of perishable goods while maintaining product quality. This application is particularly relevant in the food and pharmaceutical sectors, where packaging integrity and product preservation are paramount.

In the electronics industry, the miniaturization trend and the need for high-performance materials in semiconductor manufacturing have led to increased interest in microporous polypropylene. Its use in clean room environments and as a component in advanced electronic devices showcases the material's versatility and importance in high-tech applications.

The construction sector is another area where microporous polypropylene is gaining ground. Its application in building materials for improved insulation and moisture management is driving demand, especially in regions focusing on energy-efficient construction practices. The material's lightweight nature and durability make it an attractive option for modern construction techniques.

As environmental concerns continue to shape market trends, the recyclability and potential biodegradability of microporous polypropylene are becoming increasingly important factors. Research and development efforts are focused on enhancing these aspects, which is likely to further boost market demand in environmentally conscious industries.

The global market for microporous materials, including polypropylene, is expected to continue its growth trajectory in the coming years. This growth is underpinned by ongoing technological advancements, expanding applications across diverse industries, and the increasing focus on sustainable and high-performance materials in various sectors.

Current Challenges in Nano-Mechanical Characterization

The nano-mechanical characterization of microporous polypropylene presents several significant challenges that researchers and engineers must overcome to gain a comprehensive understanding of this material's properties at the nanoscale. One of the primary difficulties lies in the complex structure of microporous polypropylene, which consists of interconnected pores and a network of polymer chains. This intricate architecture makes it challenging to isolate and measure individual components' mechanical properties accurately.

Sample preparation is another critical challenge in nano-mechanical characterization. Microporous polypropylene's porous nature makes it susceptible to deformation and damage during sample preparation, potentially altering its mechanical properties. Researchers must develop specialized techniques to prepare samples that maintain the material's original structure and properties while allowing for precise measurements at the nanoscale.

The heterogeneity of microporous polypropylene further complicates nano-mechanical characterization. The material's properties can vary significantly across different regions due to variations in pore size, distribution, and polymer chain orientation. This heterogeneity necessitates multiple measurements at various locations to obtain a representative understanding of the material's overall nano-mechanical behavior.

Another challenge is the development and application of appropriate testing methodologies. Traditional macro-scale testing techniques may not be suitable for characterizing nano-mechanical properties, as they often lack the necessary resolution and sensitivity. Researchers must adapt existing techniques or develop new ones specifically tailored to microporous polypropylene's unique structure and properties at the nanoscale.

The influence of environmental factors on nano-mechanical properties poses an additional challenge. Factors such as temperature, humidity, and mechanical stress can significantly affect the material's behavior at the nanoscale. Controlling and accounting for these variables during testing is crucial for obtaining accurate and reproducible results.

Data interpretation and analysis present further challenges in nano-mechanical characterization. The complex interplay between the material's porous structure and polymer chains can lead to non-linear and time-dependent mechanical responses. Developing robust models and analytical techniques to interpret this data and extract meaningful information about the material's nano-mechanical properties is an ongoing area of research.

Finally, the integration of nano-mechanical characterization results with other material properties and performance metrics remains a significant challenge. Establishing clear relationships between nano-scale mechanical properties and macro-scale performance is crucial for translating research findings into practical applications and improvements in microporous polypropylene-based products.

Sample preparation is another critical challenge in nano-mechanical characterization. Microporous polypropylene's porous nature makes it susceptible to deformation and damage during sample preparation, potentially altering its mechanical properties. Researchers must develop specialized techniques to prepare samples that maintain the material's original structure and properties while allowing for precise measurements at the nanoscale.

The heterogeneity of microporous polypropylene further complicates nano-mechanical characterization. The material's properties can vary significantly across different regions due to variations in pore size, distribution, and polymer chain orientation. This heterogeneity necessitates multiple measurements at various locations to obtain a representative understanding of the material's overall nano-mechanical behavior.

Another challenge is the development and application of appropriate testing methodologies. Traditional macro-scale testing techniques may not be suitable for characterizing nano-mechanical properties, as they often lack the necessary resolution and sensitivity. Researchers must adapt existing techniques or develop new ones specifically tailored to microporous polypropylene's unique structure and properties at the nanoscale.

The influence of environmental factors on nano-mechanical properties poses an additional challenge. Factors such as temperature, humidity, and mechanical stress can significantly affect the material's behavior at the nanoscale. Controlling and accounting for these variables during testing is crucial for obtaining accurate and reproducible results.

Data interpretation and analysis present further challenges in nano-mechanical characterization. The complex interplay between the material's porous structure and polymer chains can lead to non-linear and time-dependent mechanical responses. Developing robust models and analytical techniques to interpret this data and extract meaningful information about the material's nano-mechanical properties is an ongoing area of research.

Finally, the integration of nano-mechanical characterization results with other material properties and performance metrics remains a significant challenge. Establishing clear relationships between nano-scale mechanical properties and macro-scale performance is crucial for translating research findings into practical applications and improvements in microporous polypropylene-based products.

Existing Methods for Nano-Mechanical Property Analysis

01 Fabrication methods for microporous polypropylene

Various techniques are employed to create microporous polypropylene structures, including phase separation, stretching, and template-based methods. These processes control pore size, distribution, and overall porosity, which directly influence the nano-mechanical properties of the material.- Fabrication methods for microporous polypropylene: Various techniques are employed to create microporous polypropylene structures, including phase separation, stretching, and template-assisted methods. These processes control pore size, distribution, and overall porosity, which directly influence the nano-mechanical properties of the material.

- Surface modification of microporous polypropylene: Surface treatments and modifications are applied to microporous polypropylene to enhance its mechanical properties at the nanoscale. These modifications can include plasma treatment, chemical grafting, or nanoparticle incorporation, leading to improved strength, elasticity, and durability.

- Characterization techniques for nano-mechanical properties: Advanced characterization methods are used to assess the nano-mechanical properties of microporous polypropylene. These include nanoindentation, atomic force microscopy, and nanoscale tensile testing, which provide insights into the material's stiffness, hardness, and deformation behavior at the nanoscale.

- Influence of pore structure on nano-mechanical properties: The pore size, shape, and interconnectivity in microporous polypropylene significantly affect its nano-mechanical properties. Research focuses on optimizing these structural features to achieve desired mechanical characteristics, such as enhanced flexibility or improved tensile strength at the nanoscale.

- Composite systems incorporating microporous polypropylene: Microporous polypropylene is often combined with other materials to create composite systems with enhanced nano-mechanical properties. These composites may include nanofillers, reinforcing fibers, or polymer blends, resulting in materials with improved strength, toughness, and dimensional stability at the nanoscale.

02 Influence of additives on nano-mechanical properties

The incorporation of additives such as nanoparticles, compatibilizers, or other polymers can significantly alter the nano-mechanical properties of microporous polypropylene. These additives can enhance strength, flexibility, or thermal stability of the material.Expand Specific Solutions03 Characterization techniques for nano-mechanical properties

Advanced characterization methods are used to assess the nano-mechanical properties of microporous polypropylene. These include nanoindentation, atomic force microscopy, and nano-tensile testing, which provide insights into modulus, hardness, and deformation behavior at the nanoscale.Expand Specific Solutions04 Relationship between microstructure and nano-mechanical properties

The nano-mechanical properties of microporous polypropylene are strongly influenced by its microstructure, including pore size, shape, and interconnectivity. Understanding this relationship allows for tailoring of the material's properties for specific applications.Expand Specific Solutions05 Applications exploiting nano-mechanical properties

The unique nano-mechanical properties of microporous polypropylene are utilized in various applications, including filtration membranes, battery separators, and biomedical scaffolds. These applications leverage the material's strength, porosity, and surface characteristics at the nanoscale.Expand Specific Solutions

Key Players in Microporous Polymer Research

The exploration of nano-mechanical properties of microporous polypropylene is in a developing stage, with a growing market driven by increasing applications in various industries. The technology's maturity is advancing, with key players like Toray Industries, Shanghai PRET Composites, and Celgard LLC leading research and development efforts. These companies are investing in innovative techniques to enhance material performance and expand applications. The competitive landscape is characterized by a mix of established chemical companies and specialized materials firms, each contributing unique expertise to the field. As the technology progresses, collaborations between industry and academic institutions, such as Drexel University and the University of Minnesota, are becoming increasingly important in pushing the boundaries of microporous polypropylene research and applications.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed advanced microporous polypropylene membranes with enhanced nano-mechanical properties. Their approach involves a controlled stretching process that creates a unique pore structure, resulting in improved tensile strength and elongation[1]. The company utilizes a proprietary blend of polypropylene resins and additives to optimize the membrane's performance. Toray's membranes exhibit excellent chemical resistance and thermal stability, making them suitable for various applications including filtration, separation, and battery separators[3]. The company has also implemented a surface modification technique to enhance the membrane's hydrophilicity or hydrophobicity depending on the specific application requirements[5].

Strengths: High tensile strength, excellent chemical resistance, and versatility in applications. Weaknesses: Potentially higher production costs due to specialized processes and materials.

Celgard LLC

Technical Solution: Celgard LLC specializes in developing microporous polypropylene membranes with advanced nano-mechanical properties for battery separator applications. Their technology focuses on creating a highly uniform pore structure through a proprietary dry-stretch process[2]. This results in membranes with exceptional mechanical strength and thermal stability. Celgard's membranes feature a unique tri-layer design, combining different polymer layers to optimize performance[4]. The company has also developed a ceramic coating technology that enhances the membrane's thermal and mechanical properties, making it particularly suitable for high-performance lithium-ion batteries[6].

Strengths: Excellent mechanical strength, thermal stability, and specialized for battery applications. Weaknesses: Limited versatility outside of battery separators.

Innovative Approaches in Nano-Mechanical Characterization

Polypropylene for use in microporous films

PatentWO2014065331A1

Innovation

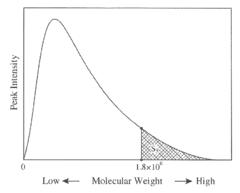

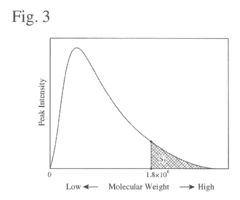

- Development of polypropylene with specific molecular weight ranges (100,000 to 800,000) and mesopentad fractions (95.5% or more) for microporous films, produced through a dry method involving cold-stretching and warm-stretching processes, to enhance molecular orientation and uniformity, thereby improving air permeability and strength while avoiding the use of fillers and plasticizers.

Microporous polyolefin membrane, its production method, and battery separator

PatentActiveUS7700182B2

Innovation

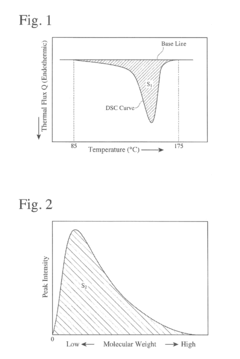

- A microporous polyolefin membrane composition comprising a polyethylene resin and polypropylene with a weight-average molecular weight of 6×105 or more and a heat of fusion of 90 J/g or more, where a fraction with a molecular weight of 1.8×106 or more is 10% or more by mass, is extruded, cooled to form a gel-like sheet, and then stretched and solvent removed in an arbitrary order to achieve balanced properties.

Environmental Impact of Microporous PP Production

The production of microporous polypropylene (PP) has significant environmental implications that warrant careful consideration. The manufacturing process involves energy-intensive steps and the use of various chemicals, which can contribute to greenhouse gas emissions and potential pollution if not properly managed. The primary environmental concerns stem from the raw material extraction, polymer synthesis, and the micropore formation processes.

During the production of microporous PP, the use of solvents and other chemical additives is a key environmental factor. These substances, if released into the environment, can lead to air and water pollution. Proper handling, recycling, and disposal of these chemicals are crucial to minimize their environmental impact. Additionally, the energy consumption during the manufacturing process, particularly in the extrusion and stretching phases, contributes to the carbon footprint of microporous PP production.

Water usage is another significant environmental aspect of microporous PP production. The process often requires substantial amounts of water for cooling and cleaning purposes. Implementing water recycling systems and improving water efficiency can help mitigate this impact. Furthermore, the potential release of microplastics during the production and use of microporous PP is an emerging environmental concern that requires attention and further research.

The disposal and end-of-life management of microporous PP products also present environmental challenges. While polypropylene is recyclable, the microporous structure and potential contamination from use can complicate the recycling process. Developing effective recycling methods specifically for microporous PP is essential to reduce waste and promote a circular economy approach.

On the positive side, the unique properties of microporous PP, such as its lightweight nature and durability, can contribute to environmental benefits in certain applications. For instance, when used in filtration systems, it can help improve water and air quality. In packaging applications, its lightweight properties can lead to reduced transportation-related emissions.

To address the environmental impacts, many manufacturers are adopting cleaner production techniques. These include using bio-based or recycled raw materials, implementing energy-efficient processes, and developing closed-loop systems for chemical and water recycling. Additionally, research into biodegradable alternatives and environmentally friendly micropore formation techniques is ongoing, aiming to reduce the overall environmental footprint of microporous PP production.

In conclusion, while the production of microporous PP poses several environmental challenges, ongoing technological advancements and sustainable practices are helping to mitigate these impacts. Balancing the unique benefits of microporous PP with environmental considerations remains a key focus for the industry, driving innovation towards more sustainable production methods and applications.

During the production of microporous PP, the use of solvents and other chemical additives is a key environmental factor. These substances, if released into the environment, can lead to air and water pollution. Proper handling, recycling, and disposal of these chemicals are crucial to minimize their environmental impact. Additionally, the energy consumption during the manufacturing process, particularly in the extrusion and stretching phases, contributes to the carbon footprint of microporous PP production.

Water usage is another significant environmental aspect of microporous PP production. The process often requires substantial amounts of water for cooling and cleaning purposes. Implementing water recycling systems and improving water efficiency can help mitigate this impact. Furthermore, the potential release of microplastics during the production and use of microporous PP is an emerging environmental concern that requires attention and further research.

The disposal and end-of-life management of microporous PP products also present environmental challenges. While polypropylene is recyclable, the microporous structure and potential contamination from use can complicate the recycling process. Developing effective recycling methods specifically for microporous PP is essential to reduce waste and promote a circular economy approach.

On the positive side, the unique properties of microporous PP, such as its lightweight nature and durability, can contribute to environmental benefits in certain applications. For instance, when used in filtration systems, it can help improve water and air quality. In packaging applications, its lightweight properties can lead to reduced transportation-related emissions.

To address the environmental impacts, many manufacturers are adopting cleaner production techniques. These include using bio-based or recycled raw materials, implementing energy-efficient processes, and developing closed-loop systems for chemical and water recycling. Additionally, research into biodegradable alternatives and environmentally friendly micropore formation techniques is ongoing, aiming to reduce the overall environmental footprint of microporous PP production.

In conclusion, while the production of microporous PP poses several environmental challenges, ongoing technological advancements and sustainable practices are helping to mitigate these impacts. Balancing the unique benefits of microporous PP with environmental considerations remains a key focus for the industry, driving innovation towards more sustainable production methods and applications.

Standardization of Nano-Mechanical Testing Protocols

The standardization of nano-mechanical testing protocols for microporous polypropylene is crucial for ensuring consistent and reliable measurements across different research groups and industrial applications. Current testing methods often lack uniformity, leading to discrepancies in results and hindering the comparison of data from various sources.

To address this issue, a comprehensive set of standardized protocols must be developed. These protocols should cover sample preparation, testing conditions, and data analysis procedures. For sample preparation, guidelines should be established for cutting, mounting, and surface treatment of microporous polypropylene specimens. This includes specifying the optimal sample size, thickness, and surface roughness to ensure reproducibility.

Testing conditions play a vital role in obtaining accurate nano-mechanical properties. Standardized protocols should define the range of acceptable environmental conditions, such as temperature and humidity, during testing. Additionally, the type and specifications of nano-indentation equipment should be standardized, including the indenter geometry, loading rates, and maximum applied forces.

Data analysis procedures are equally important in ensuring consistent results. Standardized methods for calculating elastic modulus, hardness, and other relevant mechanical properties should be established. This includes specifying the appropriate models for data fitting and the statistical analysis required to assess the reliability of the measurements.

Interlaboratory studies should be conducted to validate the proposed standardized protocols. These studies would involve multiple research institutions and industrial laboratories performing tests on identical microporous polypropylene samples using the standardized methods. The results from these studies would help identify any remaining inconsistencies and refine the protocols accordingly.

The development of standardized nano-mechanical testing protocols for microporous polypropylene would greatly benefit both academic research and industrial applications. It would enable more accurate comparisons between different studies, facilitate the transfer of knowledge from research to industry, and improve quality control in manufacturing processes. Furthermore, these standardized protocols could serve as a foundation for developing similar standards for other microporous polymeric materials.

To ensure widespread adoption, the standardized protocols should be published in peer-reviewed journals and submitted to relevant standards organizations, such as ASTM International or ISO. Regular reviews and updates of these protocols would be necessary to incorporate advancements in nano-mechanical testing technologies and methodologies, ensuring their continued relevance and effectiveness in the field of microporous polypropylene characterization.

To address this issue, a comprehensive set of standardized protocols must be developed. These protocols should cover sample preparation, testing conditions, and data analysis procedures. For sample preparation, guidelines should be established for cutting, mounting, and surface treatment of microporous polypropylene specimens. This includes specifying the optimal sample size, thickness, and surface roughness to ensure reproducibility.

Testing conditions play a vital role in obtaining accurate nano-mechanical properties. Standardized protocols should define the range of acceptable environmental conditions, such as temperature and humidity, during testing. Additionally, the type and specifications of nano-indentation equipment should be standardized, including the indenter geometry, loading rates, and maximum applied forces.

Data analysis procedures are equally important in ensuring consistent results. Standardized methods for calculating elastic modulus, hardness, and other relevant mechanical properties should be established. This includes specifying the appropriate models for data fitting and the statistical analysis required to assess the reliability of the measurements.

Interlaboratory studies should be conducted to validate the proposed standardized protocols. These studies would involve multiple research institutions and industrial laboratories performing tests on identical microporous polypropylene samples using the standardized methods. The results from these studies would help identify any remaining inconsistencies and refine the protocols accordingly.

The development of standardized nano-mechanical testing protocols for microporous polypropylene would greatly benefit both academic research and industrial applications. It would enable more accurate comparisons between different studies, facilitate the transfer of knowledge from research to industry, and improve quality control in manufacturing processes. Furthermore, these standardized protocols could serve as a foundation for developing similar standards for other microporous polymeric materials.

To ensure widespread adoption, the standardized protocols should be published in peer-reviewed journals and submitted to relevant standards organizations, such as ASTM International or ISO. Regular reviews and updates of these protocols would be necessary to incorporate advancements in nano-mechanical testing technologies and methodologies, ensuring their continued relevance and effectiveness in the field of microporous polypropylene characterization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!