Exploring Polypropylene Suture Material Longevity in Healthcare

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Suture Evolution and Objectives

Polypropylene sutures have undergone significant evolution since their introduction in the 1960s. Initially developed as a non-absorbable synthetic material, polypropylene quickly gained popularity in healthcare due to its excellent tensile strength, minimal tissue reactivity, and resistance to bacterial colonization. The journey of polypropylene sutures reflects the broader advancements in medical technology and surgical techniques over the past six decades.

In the early stages, polypropylene sutures were primarily used in cardiovascular surgeries, where their strength and inertness proved invaluable. As manufacturing processes improved, the material's applications expanded to include general surgery, orthopedics, and plastic surgery. The 1980s and 1990s saw significant improvements in the monofilament structure of polypropylene sutures, enhancing their handling characteristics and knot security.

The turn of the millennium brought about a focus on reducing surgical site infections, leading to the development of antimicrobial-coated polypropylene sutures. This innovation aimed to combine the material's inherent benefits with active infection prevention properties. Concurrently, research into surface modifications of polypropylene sutures intensified, seeking to improve tissue integration and reduce long-term complications associated with permanent sutures.

Recent years have witnessed a growing interest in the long-term performance of polypropylene sutures, particularly in applications where the material remains in the body for extended periods. This focus has been driven by observations of suture degradation and potential complications in some patients years after implantation. As a result, the current objectives in polypropylene suture research and development are multifaceted.

Primarily, there is a push to enhance the long-term stability of polypropylene sutures without compromising their beneficial properties. This involves exploring new polymer formulations and manufacturing techniques to improve resistance to oxidation and hydrolysis, which are believed to be key factors in long-term degradation. Another objective is to develop methods for accurately predicting the lifespan of polypropylene sutures in various physiological environments, enabling better-informed decisions in surgical planning.

Furthermore, research is underway to create "smart" polypropylene sutures that can adapt to changing tissue conditions over time or even promote healing processes. This includes investigating bioactive coatings that could release growth factors or other therapeutic agents gradually. The ultimate goal is to develop a new generation of polypropylene sutures that not only maintain their structural integrity for decades but also actively contribute to long-term patient outcomes.

In the early stages, polypropylene sutures were primarily used in cardiovascular surgeries, where their strength and inertness proved invaluable. As manufacturing processes improved, the material's applications expanded to include general surgery, orthopedics, and plastic surgery. The 1980s and 1990s saw significant improvements in the monofilament structure of polypropylene sutures, enhancing their handling characteristics and knot security.

The turn of the millennium brought about a focus on reducing surgical site infections, leading to the development of antimicrobial-coated polypropylene sutures. This innovation aimed to combine the material's inherent benefits with active infection prevention properties. Concurrently, research into surface modifications of polypropylene sutures intensified, seeking to improve tissue integration and reduce long-term complications associated with permanent sutures.

Recent years have witnessed a growing interest in the long-term performance of polypropylene sutures, particularly in applications where the material remains in the body for extended periods. This focus has been driven by observations of suture degradation and potential complications in some patients years after implantation. As a result, the current objectives in polypropylene suture research and development are multifaceted.

Primarily, there is a push to enhance the long-term stability of polypropylene sutures without compromising their beneficial properties. This involves exploring new polymer formulations and manufacturing techniques to improve resistance to oxidation and hydrolysis, which are believed to be key factors in long-term degradation. Another objective is to develop methods for accurately predicting the lifespan of polypropylene sutures in various physiological environments, enabling better-informed decisions in surgical planning.

Furthermore, research is underway to create "smart" polypropylene sutures that can adapt to changing tissue conditions over time or even promote healing processes. This includes investigating bioactive coatings that could release growth factors or other therapeutic agents gradually. The ultimate goal is to develop a new generation of polypropylene sutures that not only maintain their structural integrity for decades but also actively contribute to long-term patient outcomes.

Healthcare Market Demand for Durable Sutures

The healthcare industry has witnessed a growing demand for durable sutures, particularly polypropylene sutures, due to their superior longevity and performance in various medical procedures. This demand is driven by several factors, including the increasing number of surgical procedures, advancements in medical technology, and the need for improved patient outcomes.

Surgical procedures across various medical specialties, such as cardiovascular, orthopedic, and general surgery, have been on the rise globally. This trend is attributed to the aging population, increased prevalence of chronic diseases, and improved access to healthcare services. As a result, the demand for high-quality suture materials that can withstand the rigors of these procedures has significantly increased.

Polypropylene sutures have gained popularity among healthcare professionals due to their exceptional durability and minimal tissue reactivity. These sutures maintain their strength over extended periods, making them ideal for procedures that require long-term wound support. The healthcare market has recognized the value of polypropylene sutures in reducing the risk of wound dehiscence and improving overall patient outcomes.

The demand for durable sutures is also driven by the growing emphasis on cost-effectiveness in healthcare. While polypropylene sutures may have a higher initial cost compared to some alternatives, their longevity and reduced risk of complications can lead to significant cost savings in the long run. Healthcare providers are increasingly considering the total cost of care, including potential readmissions and follow-up procedures, when selecting suture materials.

Advancements in minimally invasive surgical techniques have further fueled the demand for high-performance sutures. These procedures require sutures that can maintain their integrity in confined spaces and withstand the stresses of endoscopic manipulation. Polypropylene sutures, with their excellent handling characteristics and knot security, have become a preferred choice for many minimally invasive applications.

The increasing focus on infection prevention in healthcare settings has also contributed to the demand for durable sutures. Polypropylene sutures have demonstrated lower infection rates compared to some other suture materials, making them particularly attractive in high-risk surgical scenarios. This property aligns with the healthcare industry's efforts to reduce healthcare-associated infections and improve patient safety.

Market research indicates that the global suture market is expected to experience steady growth in the coming years, with a significant portion attributed to synthetic non-absorbable sutures like polypropylene. The Asia-Pacific region, in particular, is projected to show rapid growth in demand for advanced suture materials, driven by improving healthcare infrastructure and increasing surgical volumes.

Surgical procedures across various medical specialties, such as cardiovascular, orthopedic, and general surgery, have been on the rise globally. This trend is attributed to the aging population, increased prevalence of chronic diseases, and improved access to healthcare services. As a result, the demand for high-quality suture materials that can withstand the rigors of these procedures has significantly increased.

Polypropylene sutures have gained popularity among healthcare professionals due to their exceptional durability and minimal tissue reactivity. These sutures maintain their strength over extended periods, making them ideal for procedures that require long-term wound support. The healthcare market has recognized the value of polypropylene sutures in reducing the risk of wound dehiscence and improving overall patient outcomes.

The demand for durable sutures is also driven by the growing emphasis on cost-effectiveness in healthcare. While polypropylene sutures may have a higher initial cost compared to some alternatives, their longevity and reduced risk of complications can lead to significant cost savings in the long run. Healthcare providers are increasingly considering the total cost of care, including potential readmissions and follow-up procedures, when selecting suture materials.

Advancements in minimally invasive surgical techniques have further fueled the demand for high-performance sutures. These procedures require sutures that can maintain their integrity in confined spaces and withstand the stresses of endoscopic manipulation. Polypropylene sutures, with their excellent handling characteristics and knot security, have become a preferred choice for many minimally invasive applications.

The increasing focus on infection prevention in healthcare settings has also contributed to the demand for durable sutures. Polypropylene sutures have demonstrated lower infection rates compared to some other suture materials, making them particularly attractive in high-risk surgical scenarios. This property aligns with the healthcare industry's efforts to reduce healthcare-associated infections and improve patient safety.

Market research indicates that the global suture market is expected to experience steady growth in the coming years, with a significant portion attributed to synthetic non-absorbable sutures like polypropylene. The Asia-Pacific region, in particular, is projected to show rapid growth in demand for advanced suture materials, driven by improving healthcare infrastructure and increasing surgical volumes.

Current Challenges in Suture Longevity

Despite significant advancements in suture materials, the longevity of polypropylene sutures in healthcare settings remains a critical challenge. One of the primary issues is the degradation of suture strength over time, particularly in environments with high moisture or exposure to bodily fluids. This degradation can lead to premature suture failure, potentially compromising wound closure integrity and patient outcomes.

Another challenge is the biocompatibility of polypropylene sutures over extended periods. While generally considered inert, long-term implantation can sometimes trigger foreign body reactions or chronic inflammation in some patients. This can result in delayed healing, increased scarring, or even the need for suture removal, negating the benefits of a non-absorbable material.

The formation of biofilms on polypropylene sutures presents a significant hurdle in maintaining long-term suture effectiveness. These microbial communities can adhere to the suture surface, potentially leading to localized infections or acting as a nidus for systemic infections. The difficulty in eradicating established biofilms often necessitates complete suture removal, which can be invasive and disruptive to the healing process.

Suture knot security is another area of concern, especially in dynamic tissue environments. Over time, the knots in polypropylene sutures may loosen or slip, compromising wound closure. This is particularly problematic in areas subject to constant movement or tension, such as in orthopedic or cardiovascular applications.

The interaction between polypropylene sutures and surrounding tissues over extended periods can lead to tissue erosion or suture extrusion. This is especially challenging in delicate tissues or in areas where the suture is close to the skin surface. Such complications can necessitate additional medical interventions and negatively impact patient comfort and satisfaction.

Environmental factors, such as exposure to UV radiation or certain chemicals used in medical settings, can potentially accelerate the degradation of polypropylene sutures. This poses challenges in maintaining suture integrity in various clinical scenarios, particularly in long-term implantation or in exposed wound closures.

Lastly, the difficulty in accurately predicting the long-term behavior of polypropylene sutures in diverse physiological environments remains a significant challenge. Individual patient factors, such as metabolism, immune response, and tissue characteristics, can greatly influence suture longevity, making standardized predictions and recommendations challenging for healthcare providers.

Another challenge is the biocompatibility of polypropylene sutures over extended periods. While generally considered inert, long-term implantation can sometimes trigger foreign body reactions or chronic inflammation in some patients. This can result in delayed healing, increased scarring, or even the need for suture removal, negating the benefits of a non-absorbable material.

The formation of biofilms on polypropylene sutures presents a significant hurdle in maintaining long-term suture effectiveness. These microbial communities can adhere to the suture surface, potentially leading to localized infections or acting as a nidus for systemic infections. The difficulty in eradicating established biofilms often necessitates complete suture removal, which can be invasive and disruptive to the healing process.

Suture knot security is another area of concern, especially in dynamic tissue environments. Over time, the knots in polypropylene sutures may loosen or slip, compromising wound closure. This is particularly problematic in areas subject to constant movement or tension, such as in orthopedic or cardiovascular applications.

The interaction between polypropylene sutures and surrounding tissues over extended periods can lead to tissue erosion or suture extrusion. This is especially challenging in delicate tissues or in areas where the suture is close to the skin surface. Such complications can necessitate additional medical interventions and negatively impact patient comfort and satisfaction.

Environmental factors, such as exposure to UV radiation or certain chemicals used in medical settings, can potentially accelerate the degradation of polypropylene sutures. This poses challenges in maintaining suture integrity in various clinical scenarios, particularly in long-term implantation or in exposed wound closures.

Lastly, the difficulty in accurately predicting the long-term behavior of polypropylene sutures in diverse physiological environments remains a significant challenge. Individual patient factors, such as metabolism, immune response, and tissue characteristics, can greatly influence suture longevity, making standardized predictions and recommendations challenging for healthcare providers.

Existing Longevity Enhancement Solutions

01 Polypropylene suture material composition

Polypropylene sutures are made from synthetic polymer materials, offering high tensile strength and longevity. The composition can be modified to enhance durability and biocompatibility, improving the overall performance and lifespan of the suture material.- Polypropylene suture material composition: Polypropylene sutures are made from synthetic polymer materials, offering high tensile strength and longevity. The composition of these sutures can be optimized to enhance their durability and performance in various surgical applications. Modifications to the polypropylene structure or the addition of other materials can improve the suture's longevity and overall effectiveness.

- Surface treatment for improved longevity: Surface treatments can be applied to polypropylene sutures to enhance their longevity. These treatments may include coatings or modifications that improve the suture's resistance to degradation, reduce friction during use, and enhance its overall performance over time. Such treatments can significantly extend the functional lifespan of the suture material in the body.

- Packaging and storage methods: The longevity of polypropylene suture materials can be influenced by their packaging and storage methods. Proper packaging techniques and storage conditions can help maintain the suture's integrity and prevent degradation before use. This includes protection from environmental factors such as light, humidity, and temperature fluctuations.

- Sterilization techniques for longevity: Various sterilization techniques can be employed to ensure the longevity of polypropylene suture materials. These methods must effectively sterilize the sutures without compromising their structural integrity or long-term performance. Appropriate sterilization processes can contribute to the overall durability and shelf-life of the suture material.

- In vivo performance and degradation studies: Research into the in vivo performance and degradation of polypropylene sutures is crucial for understanding and improving their longevity. Studies focusing on how these sutures behave in the body over extended periods can provide insights into their long-term effectiveness and potential areas for improvement. This research can lead to the development of more durable and biocompatible suture materials.

02 Surface treatment for improved longevity

Surface treatments can be applied to polypropylene sutures to enhance their longevity. These treatments may include coatings or modifications that improve resistance to degradation, reduce friction, and increase biocompatibility, thereby extending the functional lifespan of the suture material.Expand Specific Solutions03 Packaging and storage methods

Proper packaging and storage methods play a crucial role in maintaining the longevity of polypropylene suture materials. Specialized packaging techniques and storage conditions can protect the sutures from environmental factors that may compromise their integrity and performance over time.Expand Specific Solutions04 Sterilization techniques for extended shelf life

Various sterilization techniques can be employed to extend the shelf life of polypropylene suture materials. These methods ensure the sutures remain sterile and maintain their physical properties for extended periods, contributing to their overall longevity and usability in medical applications.Expand Specific Solutions05 In vivo degradation resistance

Polypropylene sutures are designed to resist degradation in vivo, contributing to their longevity. This resistance is achieved through material selection and manufacturing processes that enhance the suture's ability to withstand biological environments without significant loss of strength or integrity over time.Expand Specific Solutions

Key Players in Suture Material Industry

The exploration of polypropylene suture material longevity in healthcare is currently in a mature stage of industry development, with a significant market size due to its widespread use in medical procedures. The global suture market, including polypropylene materials, is estimated to be worth billions of dollars. Technologically, polypropylene sutures are well-established, with companies like Ethicon, Inc., Covidien Pte Ltd., and Arthrex GmbH leading in innovation and production. These firms, along with others such as Mitsui Chemicals, Inc. and DSM IP Assets BV, continue to refine the material's properties, focusing on improving longevity, biocompatibility, and overall performance in diverse surgical applications.

Arthrex GmbH

Technical Solution: Arthrex has developed innovative approaches to enhance polypropylene suture material longevity, particularly in orthopedic and sports medicine applications. Their FiberWire® suture, while not pure polypropylene, incorporates a unique blend of polyethylene and polypropylene to create a high-strength, low-stretch suture material[7]. This hybrid approach combines the beneficial properties of both polymers, resulting in improved tensile strength and knot security compared to traditional polypropylene sutures. Arthrex has also introduced the SutureTape technology, which utilizes a flat, braided design with polypropylene components to increase the suture-to-tissue interface, potentially improving long-term fixation and reducing the risk of suture cut-through[8]. These advancements demonstrate Arthrex's commitment to enhancing suture performance and longevity in challenging surgical environments.

Strengths: Specialized focus on orthopedic applications, innovative suture designs, strong presence in sports medicine. Weaknesses: Limited product range outside of orthopedics, potentially higher costs due to specialized materials.

DSM IP Assets BV

Technical Solution: DSM has made significant contributions to polypropylene suture material longevity through their advanced polymer science. Their Dyneema Purity® fiber, while not strictly polypropylene, represents a breakthrough in ultra-high molecular weight polyethylene (UHMWPE) that can be used in sutures and other medical devices[5]. This material offers exceptional strength-to-weight ratio and durability, potentially outperforming traditional polypropylene in certain applications. DSM has also developed specialized coating technologies that can be applied to polypropylene sutures to enhance their biocompatibility and reduce friction during tissue passage[6]. These innovations contribute to improved suture performance and longevity in healthcare settings, particularly in orthopedic and cardiovascular surgeries where long-term strength retention is critical.

Strengths: Cutting-edge material science, diverse applications beyond healthcare, strong focus on sustainability. Weaknesses: Higher material costs, may require specialized handling and surgical techniques.

Innovative Polypropylene Suture Developments

Filament having cellulose fibers with non resorbable features less radio pacifier

PatentInactiveUS20210353821A1

Innovation

- Development of biocompatible, non-resorbable filaments and suture strands made from a cellulose fiber thermoplastic composition with two dissimilar thermoplastic polymers, which are radiopaque without traditional radio pacifiers, providing improved resistance to hydrolysis and hydrophilicity for antibiotic coatings, and are processed to maintain fiber orientation and strength.

Ultra-thin, high strength, drug-loaded sutures and coatings thereof

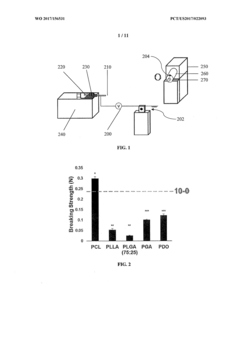

PatentWO2017156531A1

Innovation

- Development of ultra-thin, high-strength multifilament composite fibers made from twisted biocompatible polymeric nanofibers that maintain tensile strength even with drug loading, using techniques like electrospinning to create fibers that can be twisted into sutures or coatings for sustained drug release.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount when exploring polypropylene suture material longevity in healthcare applications. Polypropylene, a synthetic polymer, has been widely used in medical sutures due to its favorable properties, including high tensile strength, low tissue reactivity, and resistance to degradation.

The biocompatibility of polypropylene sutures is a critical factor in their long-term performance. These sutures demonstrate minimal tissue reaction, reducing the risk of inflammation and adverse immune responses. This characteristic is particularly important for procedures requiring extended healing periods or permanent suture placement. However, it is essential to note that while polypropylene exhibits excellent biocompatibility, individual patient factors may still influence the body's response to the material.

Safety considerations for polypropylene sutures extend beyond initial biocompatibility. Long-term studies have shown that these sutures maintain their structural integrity over extended periods, minimizing the risk of suture failure or breakdown. This durability contributes to the overall safety profile of polypropylene sutures, especially in applications where suture longevity is crucial for patient outcomes.

The non-absorbable nature of polypropylene sutures presents both advantages and potential safety concerns. On one hand, their persistence ensures continued wound support and reduces the risk of wound dehiscence. On the other hand, the permanent presence of foreign material in the body may lead to complications in some cases, such as suture extrusion or chronic irritation, particularly in superficial wound closures.

Sterilization processes play a vital role in ensuring the safety of polypropylene sutures. Common methods include ethylene oxide treatment and gamma irradiation. These processes must be carefully controlled to maintain the material's integrity while eliminating potential pathogens. Improper sterilization can compromise the suture's mechanical properties or introduce harmful residues, underscoring the importance of rigorous quality control measures.

The interaction between polypropylene sutures and the surrounding tissue environment over time is an area of ongoing research. While generally inert, there is evidence suggesting that prolonged exposure to certain biological factors may lead to subtle changes in the suture material. These changes could potentially affect the long-term performance and safety profile of the sutures, highlighting the need for continued surveillance and post-market studies.

In conclusion, the biocompatibility and safety considerations for polypropylene suture materials are generally favorable, supporting their widespread use in healthcare. However, ongoing vigilance and research are necessary to fully understand and mitigate any long-term risks associated with their use in diverse clinical scenarios.

The biocompatibility of polypropylene sutures is a critical factor in their long-term performance. These sutures demonstrate minimal tissue reaction, reducing the risk of inflammation and adverse immune responses. This characteristic is particularly important for procedures requiring extended healing periods or permanent suture placement. However, it is essential to note that while polypropylene exhibits excellent biocompatibility, individual patient factors may still influence the body's response to the material.

Safety considerations for polypropylene sutures extend beyond initial biocompatibility. Long-term studies have shown that these sutures maintain their structural integrity over extended periods, minimizing the risk of suture failure or breakdown. This durability contributes to the overall safety profile of polypropylene sutures, especially in applications where suture longevity is crucial for patient outcomes.

The non-absorbable nature of polypropylene sutures presents both advantages and potential safety concerns. On one hand, their persistence ensures continued wound support and reduces the risk of wound dehiscence. On the other hand, the permanent presence of foreign material in the body may lead to complications in some cases, such as suture extrusion or chronic irritation, particularly in superficial wound closures.

Sterilization processes play a vital role in ensuring the safety of polypropylene sutures. Common methods include ethylene oxide treatment and gamma irradiation. These processes must be carefully controlled to maintain the material's integrity while eliminating potential pathogens. Improper sterilization can compromise the suture's mechanical properties or introduce harmful residues, underscoring the importance of rigorous quality control measures.

The interaction between polypropylene sutures and the surrounding tissue environment over time is an area of ongoing research. While generally inert, there is evidence suggesting that prolonged exposure to certain biological factors may lead to subtle changes in the suture material. These changes could potentially affect the long-term performance and safety profile of the sutures, highlighting the need for continued surveillance and post-market studies.

In conclusion, the biocompatibility and safety considerations for polypropylene suture materials are generally favorable, supporting their widespread use in healthcare. However, ongoing vigilance and research are necessary to fully understand and mitigate any long-term risks associated with their use in diverse clinical scenarios.

Cost-Effectiveness Analysis

Cost-effectiveness analysis of polypropylene suture material in healthcare settings reveals significant economic benefits compared to alternative materials. The longevity of polypropylene sutures contributes to reduced replacement frequency, resulting in lower overall costs for healthcare providers and patients.

Initial procurement costs for polypropylene sutures are generally higher than some alternatives. However, their extended lifespan offsets this initial investment over time. Studies have shown that polypropylene sutures can maintain their tensile strength and structural integrity for prolonged periods, often outlasting other suture materials in similar applications.

The durability of polypropylene sutures leads to fewer complications and reduced need for follow-up procedures. This translates to cost savings in terms of reduced hospital readmissions, shorter hospital stays, and decreased demand for additional medical interventions. Furthermore, the lower incidence of suture-related infections associated with polypropylene materials contributes to reduced antibiotic usage and associated costs.

In surgical settings, the use of polypropylene sutures has been linked to improved wound healing outcomes. This results in faster patient recovery times, potentially reducing the overall cost of care by shortening hospital stays and minimizing post-operative complications. The economic impact extends beyond direct medical costs to include indirect savings from reduced patient downtime and faster return to productive activities.

Long-term cost projections demonstrate that healthcare facilities adopting polypropylene sutures can achieve substantial savings over extended periods. These projections account for factors such as reduced inventory management costs, decreased waste from expired sutures, and lower frequency of suture-related adverse events.

When considering the environmental impact, polypropylene sutures present a favorable profile. Their longevity reduces the frequency of disposal, potentially lowering the environmental costs associated with medical waste management. This aspect aligns with growing initiatives for sustainable healthcare practices and may contribute to cost savings in waste disposal and regulatory compliance.

In conclusion, the cost-effectiveness analysis strongly supports the adoption of polypropylene suture materials in healthcare settings. While initial costs may be higher, the long-term economic benefits, improved patient outcomes, and potential environmental advantages make polypropylene sutures a financially sound choice for healthcare providers aiming to optimize their resources and improve overall care quality.

Initial procurement costs for polypropylene sutures are generally higher than some alternatives. However, their extended lifespan offsets this initial investment over time. Studies have shown that polypropylene sutures can maintain their tensile strength and structural integrity for prolonged periods, often outlasting other suture materials in similar applications.

The durability of polypropylene sutures leads to fewer complications and reduced need for follow-up procedures. This translates to cost savings in terms of reduced hospital readmissions, shorter hospital stays, and decreased demand for additional medical interventions. Furthermore, the lower incidence of suture-related infections associated with polypropylene materials contributes to reduced antibiotic usage and associated costs.

In surgical settings, the use of polypropylene sutures has been linked to improved wound healing outcomes. This results in faster patient recovery times, potentially reducing the overall cost of care by shortening hospital stays and minimizing post-operative complications. The economic impact extends beyond direct medical costs to include indirect savings from reduced patient downtime and faster return to productive activities.

Long-term cost projections demonstrate that healthcare facilities adopting polypropylene sutures can achieve substantial savings over extended periods. These projections account for factors such as reduced inventory management costs, decreased waste from expired sutures, and lower frequency of suture-related adverse events.

When considering the environmental impact, polypropylene sutures present a favorable profile. Their longevity reduces the frequency of disposal, potentially lowering the environmental costs associated with medical waste management. This aspect aligns with growing initiatives for sustainable healthcare practices and may contribute to cost savings in waste disposal and regulatory compliance.

In conclusion, the cost-effectiveness analysis strongly supports the adoption of polypropylene suture materials in healthcare settings. While initial costs may be higher, the long-term economic benefits, improved patient outcomes, and potential environmental advantages make polypropylene sutures a financially sound choice for healthcare providers aiming to optimize their resources and improve overall care quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!