Exploring the Sustainability of QLED Manufacturing

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Evolution and Objectives

Quantum Dot Light-Emitting Diode (QLED) technology has emerged as a promising advancement in display technology, offering enhanced color performance and energy efficiency compared to traditional LED displays. The evolution of QLED technology can be traced back to the early 2000s when researchers first began exploring the potential of quantum dots in display applications.

Initially, the focus was on developing quantum dots that could emit light with high efficiency and color purity. As the technology progressed, researchers and manufacturers aimed to integrate these quantum dots into existing LED structures to create hybrid QLED displays. This integration posed significant challenges, particularly in terms of maintaining the stability and longevity of the quantum dots within the display environment.

The objectives of QLED technology have evolved alongside its development. Early goals centered on achieving superior color reproduction and brightness compared to conventional LED displays. As the technology matured, objectives expanded to include improving energy efficiency, extending device lifespan, and reducing manufacturing costs to make QLED displays more commercially viable.

In recent years, sustainability has become a crucial objective in QLED evolution. This shift reflects growing environmental concerns and regulatory pressures in the electronics industry. Manufacturers are now focusing on developing eco-friendly quantum dot materials, reducing the use of heavy metals, and improving the recyclability of QLED components.

The current landscape of QLED technology is characterized by ongoing efforts to enhance performance while addressing sustainability challenges. Key objectives include further improving color gamut and brightness, reducing power consumption, and developing quantum dots that are both highly efficient and environmentally benign.

Looking ahead, the future objectives for QLED technology are likely to center on achieving full sustainability in manufacturing processes and materials. This includes developing quantum dots from abundant, non-toxic elements, implementing energy-efficient production methods, and designing displays for easy disassembly and recycling at the end of their lifecycle.

Additionally, researchers are exploring the potential of QLED technology beyond traditional display applications. Emerging objectives include the integration of QLEDs into flexible and transparent displays, as well as their use in lighting and photovoltaic applications. These new frontiers present both opportunities and challenges for sustainable manufacturing practices.

As QLED technology continues to evolve, balancing performance improvements with sustainability goals will be crucial. The industry's ability to meet these objectives will likely determine the long-term viability and widespread adoption of QLED displays in an increasingly environmentally conscious market.

Initially, the focus was on developing quantum dots that could emit light with high efficiency and color purity. As the technology progressed, researchers and manufacturers aimed to integrate these quantum dots into existing LED structures to create hybrid QLED displays. This integration posed significant challenges, particularly in terms of maintaining the stability and longevity of the quantum dots within the display environment.

The objectives of QLED technology have evolved alongside its development. Early goals centered on achieving superior color reproduction and brightness compared to conventional LED displays. As the technology matured, objectives expanded to include improving energy efficiency, extending device lifespan, and reducing manufacturing costs to make QLED displays more commercially viable.

In recent years, sustainability has become a crucial objective in QLED evolution. This shift reflects growing environmental concerns and regulatory pressures in the electronics industry. Manufacturers are now focusing on developing eco-friendly quantum dot materials, reducing the use of heavy metals, and improving the recyclability of QLED components.

The current landscape of QLED technology is characterized by ongoing efforts to enhance performance while addressing sustainability challenges. Key objectives include further improving color gamut and brightness, reducing power consumption, and developing quantum dots that are both highly efficient and environmentally benign.

Looking ahead, the future objectives for QLED technology are likely to center on achieving full sustainability in manufacturing processes and materials. This includes developing quantum dots from abundant, non-toxic elements, implementing energy-efficient production methods, and designing displays for easy disassembly and recycling at the end of their lifecycle.

Additionally, researchers are exploring the potential of QLED technology beyond traditional display applications. Emerging objectives include the integration of QLEDs into flexible and transparent displays, as well as their use in lighting and photovoltaic applications. These new frontiers present both opportunities and challenges for sustainable manufacturing practices.

As QLED technology continues to evolve, balancing performance improvements with sustainability goals will be crucial. The industry's ability to meet these objectives will likely determine the long-term viability and widespread adoption of QLED displays in an increasingly environmentally conscious market.

QLED Market Dynamics

The QLED (Quantum Dot Light-Emitting Diode) market has experienced significant growth and transformation in recent years, driven by advancements in display technology and increasing consumer demand for high-quality visual experiences. This emerging technology has rapidly gained traction in the consumer electronics sector, particularly in the television and monitor segments.

The global QLED market has shown robust expansion, with major players like Samsung, TCL, and Hisense leading the charge. Samsung, in particular, has been at the forefront of QLED technology development and commercialization, capturing a substantial market share. The technology's ability to deliver superior color accuracy, brightness, and energy efficiency compared to traditional LED displays has been a key factor in its market success.

Consumer preferences have shifted towards larger screen sizes and higher resolution displays, which has further fueled the demand for QLED technology. The growing popularity of 4K and 8K content has created a need for displays capable of rendering these high-resolution images with exceptional clarity and color fidelity, a niche that QLED technology effectively fills.

The QLED market has also benefited from the increasing adoption of smart TVs and the integration of advanced features such as AI-enhanced picture quality, voice control, and seamless connectivity with other smart home devices. These value-added features have contributed to the premium positioning of QLED products in the market.

In terms of regional dynamics, North America and Asia-Pacific have emerged as the leading markets for QLED technology. The high disposable income and tech-savvy consumer base in these regions have driven early adoption. However, Europe and other developing markets are also showing promising growth potential as awareness and availability of QLED products increase.

The competitive landscape of the QLED market is characterized by intense rivalry among major electronics manufacturers. While Samsung maintains a dominant position, other players are rapidly developing their QLED offerings to capture market share. This competition has led to accelerated innovation and a gradual reduction in prices, making QLED technology more accessible to a broader consumer base.

Looking ahead, the QLED market is poised for continued growth, with projections indicating a steady increase in market size over the next several years. Factors such as technological advancements, expanding applications beyond televisions (e.g., in automotive displays and signage), and increasing consumer awareness are expected to drive this growth. However, challenges such as high manufacturing costs and competition from other display technologies like OLED remain factors that could influence the market's trajectory.

The global QLED market has shown robust expansion, with major players like Samsung, TCL, and Hisense leading the charge. Samsung, in particular, has been at the forefront of QLED technology development and commercialization, capturing a substantial market share. The technology's ability to deliver superior color accuracy, brightness, and energy efficiency compared to traditional LED displays has been a key factor in its market success.

Consumer preferences have shifted towards larger screen sizes and higher resolution displays, which has further fueled the demand for QLED technology. The growing popularity of 4K and 8K content has created a need for displays capable of rendering these high-resolution images with exceptional clarity and color fidelity, a niche that QLED technology effectively fills.

The QLED market has also benefited from the increasing adoption of smart TVs and the integration of advanced features such as AI-enhanced picture quality, voice control, and seamless connectivity with other smart home devices. These value-added features have contributed to the premium positioning of QLED products in the market.

In terms of regional dynamics, North America and Asia-Pacific have emerged as the leading markets for QLED technology. The high disposable income and tech-savvy consumer base in these regions have driven early adoption. However, Europe and other developing markets are also showing promising growth potential as awareness and availability of QLED products increase.

The competitive landscape of the QLED market is characterized by intense rivalry among major electronics manufacturers. While Samsung maintains a dominant position, other players are rapidly developing their QLED offerings to capture market share. This competition has led to accelerated innovation and a gradual reduction in prices, making QLED technology more accessible to a broader consumer base.

Looking ahead, the QLED market is poised for continued growth, with projections indicating a steady increase in market size over the next several years. Factors such as technological advancements, expanding applications beyond televisions (e.g., in automotive displays and signage), and increasing consumer awareness are expected to drive this growth. However, challenges such as high manufacturing costs and competition from other display technologies like OLED remain factors that could influence the market's trajectory.

QLED Tech Challenges

QLED (Quantum Dot Light-Emitting Diode) technology has made significant strides in recent years, offering superior color performance and energy efficiency compared to traditional display technologies. However, the manufacturing process of QLEDs faces several technical challenges that need to be addressed to ensure its long-term sustainability and widespread adoption.

One of the primary challenges in QLED manufacturing is the stability and longevity of quantum dots. These nanocrystals are highly sensitive to environmental factors such as oxygen and moisture, which can lead to degradation over time. This sensitivity necessitates complex encapsulation techniques to protect the quantum dots, adding complexity and cost to the manufacturing process.

Another significant hurdle is the precise control of quantum dot size and uniformity. The emission wavelength of quantum dots is directly related to their size, and even small variations can result in color inconsistencies across the display. Achieving consistent size distribution at scale remains a technical challenge that requires advanced synthesis and purification methods.

The integration of quantum dots into the device structure presents its own set of challenges. Current methods often involve solution-based processes, which can lead to issues with film uniformity and thickness control. Developing more reliable deposition techniques that maintain the optical properties of quantum dots while ensuring consistent performance across large areas is crucial for high-volume manufacturing.

Environmental concerns also pose challenges to QLED manufacturing sustainability. Many quantum dot materials contain heavy metals such as cadmium, which are toxic and subject to regulatory restrictions. While cadmium-free alternatives are being developed, they often struggle to match the performance of cadmium-based quantum dots, creating a trade-off between environmental safety and display quality.

Energy efficiency during the manufacturing process is another area of concern. The synthesis of quantum dots typically requires high temperatures and energy-intensive processes. Developing more energy-efficient production methods is essential for reducing the carbon footprint of QLED manufacturing and improving overall sustainability.

Yield management in QLED production is also a significant challenge. The complex nature of quantum dot synthesis and integration can lead to high defect rates, impacting production costs and scalability. Improving process control and developing more robust quality assurance methods are critical for increasing yields and reducing waste in QLED manufacturing.

As the demand for higher resolution displays grows, scaling QLED technology to meet these requirements presents additional challenges. Achieving uniform performance across larger substrates and developing patterning techniques for ultra-high-resolution displays are areas that require ongoing research and development efforts.

One of the primary challenges in QLED manufacturing is the stability and longevity of quantum dots. These nanocrystals are highly sensitive to environmental factors such as oxygen and moisture, which can lead to degradation over time. This sensitivity necessitates complex encapsulation techniques to protect the quantum dots, adding complexity and cost to the manufacturing process.

Another significant hurdle is the precise control of quantum dot size and uniformity. The emission wavelength of quantum dots is directly related to their size, and even small variations can result in color inconsistencies across the display. Achieving consistent size distribution at scale remains a technical challenge that requires advanced synthesis and purification methods.

The integration of quantum dots into the device structure presents its own set of challenges. Current methods often involve solution-based processes, which can lead to issues with film uniformity and thickness control. Developing more reliable deposition techniques that maintain the optical properties of quantum dots while ensuring consistent performance across large areas is crucial for high-volume manufacturing.

Environmental concerns also pose challenges to QLED manufacturing sustainability. Many quantum dot materials contain heavy metals such as cadmium, which are toxic and subject to regulatory restrictions. While cadmium-free alternatives are being developed, they often struggle to match the performance of cadmium-based quantum dots, creating a trade-off between environmental safety and display quality.

Energy efficiency during the manufacturing process is another area of concern. The synthesis of quantum dots typically requires high temperatures and energy-intensive processes. Developing more energy-efficient production methods is essential for reducing the carbon footprint of QLED manufacturing and improving overall sustainability.

Yield management in QLED production is also a significant challenge. The complex nature of quantum dot synthesis and integration can lead to high defect rates, impacting production costs and scalability. Improving process control and developing more robust quality assurance methods are critical for increasing yields and reducing waste in QLED manufacturing.

As the demand for higher resolution displays grows, scaling QLED technology to meet these requirements presents additional challenges. Achieving uniform performance across larger substrates and developing patterning techniques for ultra-high-resolution displays are areas that require ongoing research and development efforts.

Current QLED Production

01 Eco-friendly QLED materials and processes

Development of sustainable materials and manufacturing processes for QLED production, focusing on reducing environmental impact and improving energy efficiency. This includes the use of non-toxic materials, recyclable components, and low-energy production methods to enhance the overall sustainability of QLED technology.- Eco-friendly QLED materials and processes: Developing sustainable materials and manufacturing processes for QLED production, focusing on reducing environmental impact and improving energy efficiency. This includes the use of non-toxic materials, minimizing waste generation, and implementing recycling strategies for QLED components.

- Optimization of quantum dot synthesis: Improving the synthesis methods for quantum dots used in QLED displays to enhance sustainability. This involves developing more efficient and environmentally friendly synthesis techniques, reducing the use of harmful solvents, and optimizing reaction conditions to minimize energy consumption.

- Sustainable packaging and encapsulation: Implementing sustainable packaging and encapsulation methods for QLED devices to improve their longevity and reduce environmental impact. This includes developing bio-based or recyclable packaging materials, as well as enhancing encapsulation techniques to protect quantum dots from degradation and extend device lifespan.

- Energy-efficient QLED manufacturing equipment: Designing and implementing energy-efficient manufacturing equipment and processes for QLED production. This involves optimizing production line layouts, improving thermal management systems, and developing smart control systems to reduce energy consumption during manufacturing.

- Recycling and circular economy strategies: Developing recycling and circular economy strategies for QLED displays and components. This includes designing products for easy disassembly, implementing take-back programs, and developing technologies to recover and reuse valuable materials from end-of-life QLED devices.

02 Quantum dot synthesis optimization

Improving the synthesis methods for quantum dots used in QLED displays to minimize waste and increase yield. This involves developing more efficient chemical processes, optimizing reaction conditions, and exploring alternative precursors to reduce the environmental footprint of quantum dot production.Expand Specific Solutions03 Energy-efficient QLED manufacturing techniques

Implementation of energy-saving technologies and processes in QLED manufacturing, such as low-temperature deposition methods, advanced thermal management systems, and optimized production line layouts. These techniques aim to reduce energy consumption and greenhouse gas emissions during the manufacturing process.Expand Specific Solutions04 Recycling and circular economy in QLED production

Development of recycling technologies and circular economy principles for QLED manufacturing, focusing on the recovery and reuse of valuable materials from end-of-life products. This includes designing products for easy disassembly, implementing efficient recycling processes, and exploring ways to reintegrate recycled materials into new QLED displays.Expand Specific Solutions05 Water conservation and treatment in QLED manufacturing

Implementation of water-saving technologies and advanced wastewater treatment systems in QLED production facilities. This includes developing closed-loop water systems, improving water purification processes, and exploring alternative cleaning methods to reduce water consumption and minimize the environmental impact of QLED manufacturing.Expand Specific Solutions

QLED Industry Leaders

The QLED manufacturing sustainability landscape is evolving rapidly, with the market in a growth phase as demand for high-quality displays increases. The industry is witnessing significant technological advancements, with key players like BOE Technology Group, Sharp Corp., and TCL China Star Optoelectronics leading innovation. These companies, along with emerging players such as Huawei Technologies and Hefei Visionox Technology, are driving the market's expansion through research and development. The technology's maturity is progressing, with universities like Zhejiang University and Hefei University of Technology contributing to fundamental research. Collaborations between industry leaders and academic institutions are accelerating the development of more sustainable QLED manufacturing processes, indicating a promising future for this technology.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary QLED manufacturing process that focuses on improving the sustainability of quantum dot production. Their approach involves using eco-friendly materials and optimizing the synthesis of quantum dots to reduce energy consumption and waste. BOE's method includes a water-based synthesis process for quantum dots, which significantly reduces the use of harmful solvents. Additionally, they have implemented a closed-loop recycling system for rare earth materials used in QLED production, minimizing environmental impact and resource depletion.

Strengths: Eco-friendly production process, efficient use of resources, reduced environmental impact. Weaknesses: Potential higher initial production costs, may require adaptation of existing manufacturing infrastructure.

Sharp Corp.

Technical Solution: Sharp has developed a sustainable QLED manufacturing process that focuses on minimizing environmental impact while maintaining high-quality display production. Their approach includes the use of non-toxic, bio-based materials for quantum dot synthesis, reducing reliance on petrochemical-derived compounds. Sharp's method also incorporates a unique encapsulation technique that extends the lifespan of QLED displays, thereby reducing electronic waste. Additionally, they have implemented an AI-driven production optimization system that significantly reduces energy consumption and material waste during the manufacturing process.

Strengths: Use of bio-based materials, extended product lifespan, AI-optimized production. Weaknesses: Potential limitations in scaling up bio-based material production, may require significant initial investment in AI systems.

QLED Material Innovations

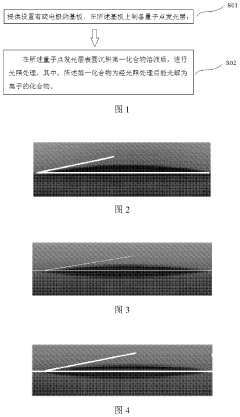

QLED and Method for Manufacturing Quantum Dot

PatentActiveUS20210380878A1

Innovation

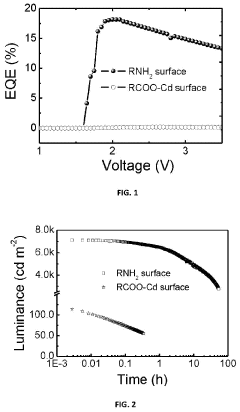

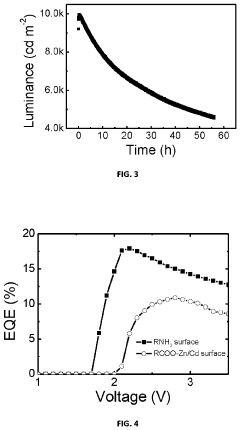

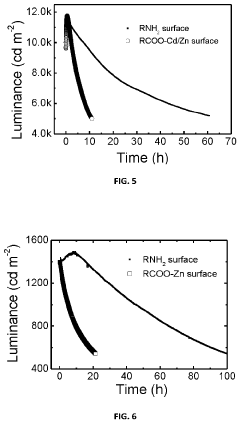

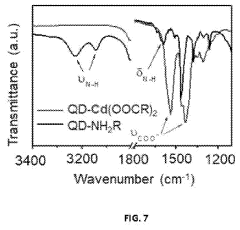

- The use of electrochemically inert ligands, such as amine, alkylphosphine, and metal carboxylate ligands, which have a reduction potential greater than the quantum dot's conduction band and an oxidation potential less than its valence band, accounting for at least 80% of the surface ligands, to prevent carrier consumption and ligand detachment under electrical excitation, thereby enhancing stability and efficiency.

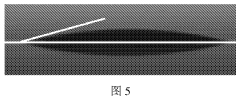

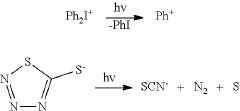

QLED and manufacturing method thereof

PatentActiveUS20220081313A1

Innovation

- A QLED manufacturing method involving the use of a first compound solution that photodegrades into ions under illumination, applied to the quantum dot light emitting layer, which reduces the contact angle and improves the compatibility between layers, enhancing the flatness and luminous efficiency of the QLED.

Environmental Impact

The environmental impact of QLED manufacturing is a critical aspect to consider when exploring the sustainability of this technology. QLED displays, while offering superior visual quality and energy efficiency, present unique challenges in terms of their production processes and end-of-life management.

The manufacturing of QLED displays involves the use of quantum dots, which are typically composed of heavy metals such as cadmium or indium. These materials, while essential for the display's performance, raise concerns about potential environmental contamination if not properly managed throughout the product lifecycle. The extraction and processing of these rare earth elements also contribute to the environmental footprint of QLED technology.

During the production phase, QLED manufacturing requires significant energy consumption, particularly in the creation and deposition of quantum dot layers. This energy-intensive process contributes to greenhouse gas emissions, although advancements in manufacturing techniques are gradually improving energy efficiency. Water usage is another environmental consideration, as the production of semiconductors and display components often requires substantial amounts of ultra-pure water.

The use of solvents and other chemicals in QLED manufacturing processes poses potential risks to air and water quality if not properly controlled. Stringent emission control systems and waste treatment facilities are necessary to mitigate these impacts. Additionally, the production of QLED displays generates electronic waste, including discarded materials and defective components, which require careful handling and disposal.

End-of-life management of QLED displays presents both challenges and opportunities for sustainability. The presence of heavy metals in quantum dots necessitates specialized recycling processes to prevent environmental contamination. However, the potential for recovering valuable materials from these displays also offers a pathway to circular economy practices, reducing the need for virgin resource extraction.

Efforts to improve the environmental sustainability of QLED manufacturing are ongoing. These include the development of cadmium-free quantum dots, more efficient production techniques, and improved recycling technologies. Some manufacturers are also exploring bio-based materials for certain display components, aiming to reduce the reliance on petrochemical-derived plastics.

As the QLED industry matures, there is a growing focus on life cycle assessments to quantify and address the environmental impacts across the entire product lifecycle. This holistic approach is essential for identifying areas for improvement and guiding the development of more sustainable manufacturing practices in the QLED sector.

The manufacturing of QLED displays involves the use of quantum dots, which are typically composed of heavy metals such as cadmium or indium. These materials, while essential for the display's performance, raise concerns about potential environmental contamination if not properly managed throughout the product lifecycle. The extraction and processing of these rare earth elements also contribute to the environmental footprint of QLED technology.

During the production phase, QLED manufacturing requires significant energy consumption, particularly in the creation and deposition of quantum dot layers. This energy-intensive process contributes to greenhouse gas emissions, although advancements in manufacturing techniques are gradually improving energy efficiency. Water usage is another environmental consideration, as the production of semiconductors and display components often requires substantial amounts of ultra-pure water.

The use of solvents and other chemicals in QLED manufacturing processes poses potential risks to air and water quality if not properly controlled. Stringent emission control systems and waste treatment facilities are necessary to mitigate these impacts. Additionally, the production of QLED displays generates electronic waste, including discarded materials and defective components, which require careful handling and disposal.

End-of-life management of QLED displays presents both challenges and opportunities for sustainability. The presence of heavy metals in quantum dots necessitates specialized recycling processes to prevent environmental contamination. However, the potential for recovering valuable materials from these displays also offers a pathway to circular economy practices, reducing the need for virgin resource extraction.

Efforts to improve the environmental sustainability of QLED manufacturing are ongoing. These include the development of cadmium-free quantum dots, more efficient production techniques, and improved recycling technologies. Some manufacturers are also exploring bio-based materials for certain display components, aiming to reduce the reliance on petrochemical-derived plastics.

As the QLED industry matures, there is a growing focus on life cycle assessments to quantify and address the environmental impacts across the entire product lifecycle. This holistic approach is essential for identifying areas for improvement and guiding the development of more sustainable manufacturing practices in the QLED sector.

Circular Economy in QLED

The concept of a circular economy in QLED (Quantum Dot Light-Emitting Diode) manufacturing represents a paradigm shift towards sustainable production and consumption patterns. This approach aims to minimize waste, maximize resource efficiency, and extend the lifecycle of QLED products and materials.

In the context of QLED manufacturing, circular economy principles can be applied at various stages of the product lifecycle. At the design phase, engineers and researchers are focusing on developing QLEDs with modular components that are easier to repair, upgrade, and recycle. This design strategy not only extends the lifespan of QLED devices but also facilitates the recovery of valuable materials at the end of their useful life.

During the production process, circular economy practices in QLED manufacturing involve optimizing resource use and minimizing waste generation. This includes implementing closed-loop systems for water and solvent recycling, as well as recovering and reusing quantum dot materials that would otherwise be discarded. Advanced filtration and purification techniques are being developed to ensure that recycled materials meet the high-quality standards required for QLED production.

The use phase of QLED products also presents opportunities for circular economy implementation. Manufacturers are exploring innovative business models such as product-as-a-service, where consumers lease QLED displays instead of purchasing them outright. This model incentivizes manufacturers to produce more durable and energy-efficient devices while also ensuring proper maintenance and eventual recycling.

End-of-life management is a critical aspect of the circular economy in QLED manufacturing. Developing efficient recycling processes for quantum dot materials and other components is essential. Research is ongoing to find ways to separate and recover rare earth elements and other valuable materials from QLED displays without compromising their quality or purity.

The transition to a circular economy in QLED manufacturing faces several challenges, including the need for significant investment in research and development, the establishment of reverse logistics systems, and the creation of new regulatory frameworks. However, the potential benefits are substantial, including reduced environmental impact, improved resource security, and new economic opportunities in recycling and refurbishment industries.

As the QLED industry continues to grow, adopting circular economy principles becomes increasingly important for ensuring long-term sustainability. Collaboration between manufacturers, researchers, policymakers, and consumers will be crucial in realizing the full potential of a circular economy approach in QLED technology.

In the context of QLED manufacturing, circular economy principles can be applied at various stages of the product lifecycle. At the design phase, engineers and researchers are focusing on developing QLEDs with modular components that are easier to repair, upgrade, and recycle. This design strategy not only extends the lifespan of QLED devices but also facilitates the recovery of valuable materials at the end of their useful life.

During the production process, circular economy practices in QLED manufacturing involve optimizing resource use and minimizing waste generation. This includes implementing closed-loop systems for water and solvent recycling, as well as recovering and reusing quantum dot materials that would otherwise be discarded. Advanced filtration and purification techniques are being developed to ensure that recycled materials meet the high-quality standards required for QLED production.

The use phase of QLED products also presents opportunities for circular economy implementation. Manufacturers are exploring innovative business models such as product-as-a-service, where consumers lease QLED displays instead of purchasing them outright. This model incentivizes manufacturers to produce more durable and energy-efficient devices while also ensuring proper maintenance and eventual recycling.

End-of-life management is a critical aspect of the circular economy in QLED manufacturing. Developing efficient recycling processes for quantum dot materials and other components is essential. Research is ongoing to find ways to separate and recover rare earth elements and other valuable materials from QLED displays without compromising their quality or purity.

The transition to a circular economy in QLED manufacturing faces several challenges, including the need for significant investment in research and development, the establishment of reverse logistics systems, and the creation of new regulatory frameworks. However, the potential benefits are substantial, including reduced environmental impact, improved resource security, and new economic opportunities in recycling and refurbishment industries.

As the QLED industry continues to grow, adopting circular economy principles becomes increasingly important for ensuring long-term sustainability. Collaboration between manufacturers, researchers, policymakers, and consumers will be crucial in realizing the full potential of a circular economy approach in QLED technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!