Fatigue Crack Propagation Analysis in 4140 Steel Sprockets

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fatigue Crack Propagation Background and Objectives

Fatigue crack propagation in 4140 steel sprockets represents a critical area of study in materials science and mechanical engineering. This phenomenon has garnered significant attention due to its profound impact on the reliability and longevity of mechanical components in various industries, including automotive, aerospace, and heavy machinery.

The historical context of fatigue crack propagation research dates back to the mid-19th century, with pioneering work by August Wöhler on railway axles. Since then, the field has evolved dramatically, incorporating advanced analytical techniques and computational models. The study of fatigue in 4140 steel, a high-strength chromium-molybdenum alloy, has become particularly relevant due to its widespread use in critical applications where cyclic loading is prevalent.

The primary objective of fatigue crack propagation analysis in 4140 steel sprockets is to understand and predict the behavior of cracks under cyclic loading conditions. This involves examining the initiation, growth, and eventual failure of components, with the ultimate goal of enhancing design methodologies and improving the overall performance and safety of mechanical systems.

Key areas of focus include the investigation of microstructural influences on crack propagation, the role of stress intensity factors, and the impact of environmental conditions on fatigue life. Researchers aim to develop more accurate predictive models that can account for the complex interplay between material properties, loading conditions, and geometric factors specific to sprocket design.

Another crucial objective is to establish reliable fatigue life estimation techniques for 4140 steel sprockets. This involves the integration of experimental data with theoretical models to create practical tools for engineers and designers. Such tools are essential for optimizing component design, scheduling maintenance intervals, and preventing catastrophic failures in service.

The advancement of non-destructive testing methods for early crack detection in 4140 steel sprockets is also a significant goal. This includes the development and refinement of techniques such as acoustic emission, ultrasonic testing, and eddy current inspection, tailored specifically for sprocket geometries and operating conditions.

Furthermore, researchers are exploring innovative surface treatment and manufacturing processes to enhance the fatigue resistance of 4140 steel sprockets. This encompasses studies on shot peening, nitriding, and advanced heat treatment protocols, all aimed at inducing beneficial residual stresses and optimizing microstructure for improved fatigue performance.

As the field progresses, there is an increasing emphasis on understanding the influence of complex loading scenarios, such as those encountered in real-world applications of sprockets. This includes the analysis of multiaxial fatigue, variable amplitude loading, and the effects of overloads on crack propagation behavior in 4140 steel.

The historical context of fatigue crack propagation research dates back to the mid-19th century, with pioneering work by August Wöhler on railway axles. Since then, the field has evolved dramatically, incorporating advanced analytical techniques and computational models. The study of fatigue in 4140 steel, a high-strength chromium-molybdenum alloy, has become particularly relevant due to its widespread use in critical applications where cyclic loading is prevalent.

The primary objective of fatigue crack propagation analysis in 4140 steel sprockets is to understand and predict the behavior of cracks under cyclic loading conditions. This involves examining the initiation, growth, and eventual failure of components, with the ultimate goal of enhancing design methodologies and improving the overall performance and safety of mechanical systems.

Key areas of focus include the investigation of microstructural influences on crack propagation, the role of stress intensity factors, and the impact of environmental conditions on fatigue life. Researchers aim to develop more accurate predictive models that can account for the complex interplay between material properties, loading conditions, and geometric factors specific to sprocket design.

Another crucial objective is to establish reliable fatigue life estimation techniques for 4140 steel sprockets. This involves the integration of experimental data with theoretical models to create practical tools for engineers and designers. Such tools are essential for optimizing component design, scheduling maintenance intervals, and preventing catastrophic failures in service.

The advancement of non-destructive testing methods for early crack detection in 4140 steel sprockets is also a significant goal. This includes the development and refinement of techniques such as acoustic emission, ultrasonic testing, and eddy current inspection, tailored specifically for sprocket geometries and operating conditions.

Furthermore, researchers are exploring innovative surface treatment and manufacturing processes to enhance the fatigue resistance of 4140 steel sprockets. This encompasses studies on shot peening, nitriding, and advanced heat treatment protocols, all aimed at inducing beneficial residual stresses and optimizing microstructure for improved fatigue performance.

As the field progresses, there is an increasing emphasis on understanding the influence of complex loading scenarios, such as those encountered in real-world applications of sprockets. This includes the analysis of multiaxial fatigue, variable amplitude loading, and the effects of overloads on crack propagation behavior in 4140 steel.

Market Demand for Durable 4140 Steel Sprockets

The market demand for durable 4140 steel sprockets has been steadily increasing in recent years, driven by the growing need for high-performance components in various industrial sectors. The automotive industry, in particular, has shown a significant appetite for these robust sprockets, as manufacturers seek to enhance the longevity and reliability of their vehicles' drivetrain systems. This demand is further fueled by the trend towards more powerful engines and increased torque requirements in modern automobiles.

In the heavy machinery and construction equipment sector, the demand for 4140 steel sprockets has also seen a notable uptick. The superior strength and wear resistance of these components make them ideal for use in harsh operating environments, where equipment reliability is paramount. Mining operations, earthmoving machinery, and industrial conveyor systems are among the key applications driving this demand.

The aerospace industry represents another growing market for durable 4140 steel sprockets. As aircraft manufacturers strive to improve fuel efficiency and reduce maintenance costs, the use of high-strength, fatigue-resistant components becomes increasingly critical. The ability of 4140 steel sprockets to withstand extreme temperatures and high-stress conditions makes them particularly attractive for aerospace applications.

Market analysis indicates that the global demand for 4140 steel sprockets is expected to grow at a compound annual growth rate (CAGR) of several percentage points over the next five years. This growth is attributed to the expanding industrial base in emerging economies, as well as the ongoing modernization of manufacturing facilities in developed nations.

The oil and gas industry also contributes significantly to the market demand for durable 4140 steel sprockets. As exploration and production activities extend into more challenging environments, the need for robust and reliable equipment increases. The corrosion resistance and high tensile strength of 4140 steel make it an excellent choice for sprockets used in offshore drilling rigs and subsea applications.

Furthermore, the renewable energy sector, particularly wind power generation, has emerged as a promising market for 4140 steel sprockets. The gearboxes in wind turbines require components that can withstand high loads and variable speeds, making durable sprockets essential for long-term operational efficiency.

As industries continue to prioritize equipment longevity and reduced downtime, the market for 4140 steel sprockets is expected to remain strong. Manufacturers are increasingly focusing on developing sprockets with enhanced fatigue resistance and improved crack propagation characteristics to meet the evolving demands of various sectors. This trend is likely to drive further innovation in materials science and manufacturing processes related to 4140 steel components.

In the heavy machinery and construction equipment sector, the demand for 4140 steel sprockets has also seen a notable uptick. The superior strength and wear resistance of these components make them ideal for use in harsh operating environments, where equipment reliability is paramount. Mining operations, earthmoving machinery, and industrial conveyor systems are among the key applications driving this demand.

The aerospace industry represents another growing market for durable 4140 steel sprockets. As aircraft manufacturers strive to improve fuel efficiency and reduce maintenance costs, the use of high-strength, fatigue-resistant components becomes increasingly critical. The ability of 4140 steel sprockets to withstand extreme temperatures and high-stress conditions makes them particularly attractive for aerospace applications.

Market analysis indicates that the global demand for 4140 steel sprockets is expected to grow at a compound annual growth rate (CAGR) of several percentage points over the next five years. This growth is attributed to the expanding industrial base in emerging economies, as well as the ongoing modernization of manufacturing facilities in developed nations.

The oil and gas industry also contributes significantly to the market demand for durable 4140 steel sprockets. As exploration and production activities extend into more challenging environments, the need for robust and reliable equipment increases. The corrosion resistance and high tensile strength of 4140 steel make it an excellent choice for sprockets used in offshore drilling rigs and subsea applications.

Furthermore, the renewable energy sector, particularly wind power generation, has emerged as a promising market for 4140 steel sprockets. The gearboxes in wind turbines require components that can withstand high loads and variable speeds, making durable sprockets essential for long-term operational efficiency.

As industries continue to prioritize equipment longevity and reduced downtime, the market for 4140 steel sprockets is expected to remain strong. Manufacturers are increasingly focusing on developing sprockets with enhanced fatigue resistance and improved crack propagation characteristics to meet the evolving demands of various sectors. This trend is likely to drive further innovation in materials science and manufacturing processes related to 4140 steel components.

Current Challenges in Fatigue Crack Analysis

Fatigue crack analysis in 4140 steel sprockets faces several significant challenges that hinder accurate prediction and prevention of failure. One of the primary obstacles is the complex geometry of sprockets, which creates stress concentrations and makes it difficult to apply traditional fracture mechanics models. The tooth profile, root fillet, and pitch line all contribute to non-uniform stress distributions, complicating the analysis of crack initiation and propagation.

Another major challenge lies in the variable loading conditions experienced by sprockets during operation. The cyclic nature of tooth engagement, combined with potential overloads and impact forces, creates a complex stress state that is not easily captured by conventional fatigue models. This variability in loading makes it challenging to accurately predict crack growth rates and fatigue life.

The microstructure of 4140 steel adds another layer of complexity to fatigue crack analysis. The heat treatment process used to achieve desired mechanical properties can result in variations in grain structure and residual stresses across the sprocket. These microstructural inhomogeneities can significantly influence crack initiation and propagation behavior, making it difficult to develop universally applicable predictive models.

Environmental factors also pose significant challenges in fatigue crack analysis of sprockets. Exposure to corrosive environments, lubricants, and temperature fluctuations can accelerate crack growth and alter material properties. Accounting for these environmental effects in analytical models remains a considerable challenge, particularly in predicting long-term fatigue behavior.

The detection and monitoring of fatigue cracks in sprockets present additional difficulties. Non-destructive testing methods often struggle to identify small cracks in complex geometries, especially in hard-to-reach areas of the sprocket. This limitation can lead to underestimation of crack presence and growth, potentially resulting in unexpected failures.

Furthermore, the interaction between multiple cracks and their influence on overall fatigue behavior is not well understood. Sprockets may develop multiple crack initiation sites, and the coalescence of these cracks can lead to accelerated failure. Current analytical methods often struggle to account for these complex crack interaction phenomena.

Lastly, the development of reliable and efficient computational models for fatigue crack analysis in sprockets remains an ongoing challenge. While finite element analysis (FEA) and other numerical methods have made significant strides, the computational cost of accurately modeling crack propagation in complex geometries under variable loading conditions is still prohibitively high for many practical applications.

Another major challenge lies in the variable loading conditions experienced by sprockets during operation. The cyclic nature of tooth engagement, combined with potential overloads and impact forces, creates a complex stress state that is not easily captured by conventional fatigue models. This variability in loading makes it challenging to accurately predict crack growth rates and fatigue life.

The microstructure of 4140 steel adds another layer of complexity to fatigue crack analysis. The heat treatment process used to achieve desired mechanical properties can result in variations in grain structure and residual stresses across the sprocket. These microstructural inhomogeneities can significantly influence crack initiation and propagation behavior, making it difficult to develop universally applicable predictive models.

Environmental factors also pose significant challenges in fatigue crack analysis of sprockets. Exposure to corrosive environments, lubricants, and temperature fluctuations can accelerate crack growth and alter material properties. Accounting for these environmental effects in analytical models remains a considerable challenge, particularly in predicting long-term fatigue behavior.

The detection and monitoring of fatigue cracks in sprockets present additional difficulties. Non-destructive testing methods often struggle to identify small cracks in complex geometries, especially in hard-to-reach areas of the sprocket. This limitation can lead to underestimation of crack presence and growth, potentially resulting in unexpected failures.

Furthermore, the interaction between multiple cracks and their influence on overall fatigue behavior is not well understood. Sprockets may develop multiple crack initiation sites, and the coalescence of these cracks can lead to accelerated failure. Current analytical methods often struggle to account for these complex crack interaction phenomena.

Lastly, the development of reliable and efficient computational models for fatigue crack analysis in sprockets remains an ongoing challenge. While finite element analysis (FEA) and other numerical methods have made significant strides, the computational cost of accurately modeling crack propagation in complex geometries under variable loading conditions is still prohibitively high for many practical applications.

Existing Fatigue Crack Propagation Models

01 Material properties and composition of 4140 steel

4140 steel is a medium carbon alloy steel known for its high strength and toughness. Its composition and heat treatment significantly influence its fatigue resistance and crack propagation behavior in sprocket applications. Understanding the material's microstructure and mechanical properties is crucial for predicting and mitigating fatigue crack growth in 4140 steel sprockets.- Fatigue crack propagation analysis in 4140 steel sprockets: Advanced techniques are employed to analyze fatigue crack propagation in 4140 steel sprockets. These methods involve studying the microstructure, stress distribution, and crack growth patterns to predict and prevent failure. Computational models and experimental tests are used to assess the fatigue life and identify critical areas prone to crack initiation and propagation.

- Heat treatment optimization for 4140 steel sprockets: Optimizing heat treatment processes for 4140 steel sprockets can significantly improve their fatigue resistance. Techniques such as quenching, tempering, and surface hardening are tailored to enhance the material's microstructure, resulting in improved fatigue strength and crack propagation resistance. The heat treatment parameters are carefully controlled to achieve the desired balance of hardness, toughness, and ductility.

- Surface treatment methods to enhance fatigue resistance: Various surface treatment methods are applied to 4140 steel sprockets to enhance their fatigue resistance and slow crack propagation. These techniques include shot peening, nitriding, and carburizing, which introduce compressive residual stresses in the surface layer. This helps to impede crack initiation and retard crack growth, thereby extending the fatigue life of the sprockets.

- Design optimization for stress distribution in sprockets: The design of 4140 steel sprockets is optimized to improve stress distribution and minimize areas of high stress concentration. This involves using advanced CAD/CAE tools to analyze and modify tooth profiles, root fillet geometry, and overall sprocket dimensions. By reducing stress concentrations, the likelihood of fatigue crack initiation and propagation is decreased, leading to improved sprocket durability.

- Non-destructive testing methods for crack detection: Non-destructive testing (NDT) methods are employed to detect and monitor fatigue cracks in 4140 steel sprockets. Techniques such as ultrasonic testing, magnetic particle inspection, and eddy current testing are used to identify surface and subsurface cracks at early stages. This allows for timely maintenance and replacement of affected components, preventing catastrophic failures due to fatigue crack propagation.

02 Fatigue crack initiation and propagation mechanisms

Fatigue crack propagation in 4140 steel sprockets involves complex mechanisms influenced by cyclic loading, stress concentrations, and environmental factors. Identifying the primary crack initiation sites and understanding the crack growth behavior is essential for developing effective strategies to enhance the fatigue life of sprockets. This includes analyzing the roles of microstructural features, residual stresses, and loading conditions on crack propagation rates.Expand Specific Solutions03 Surface treatment and manufacturing processes

Various surface treatments and manufacturing processes can significantly impact the fatigue resistance of 4140 steel sprockets. Techniques such as shot peening, carburizing, and nitriding can induce beneficial compressive residual stresses and improve surface hardness, thereby enhancing resistance to crack initiation and propagation. Optimizing these processes is crucial for extending the fatigue life of sprockets in demanding applications.Expand Specific Solutions04 Stress analysis and design optimization

Advanced stress analysis techniques, including finite element analysis (FEA) and fracture mechanics approaches, are essential for optimizing the design of 4140 steel sprockets to minimize fatigue crack propagation. These methods help identify critical stress concentration areas and guide design modifications to redistribute loads more effectively. Incorporating factors such as tooth profile, root fillet geometry, and overall sprocket dimensions can significantly improve fatigue performance.Expand Specific Solutions05 Monitoring and predictive maintenance strategies

Implementing effective monitoring and predictive maintenance strategies is crucial for managing fatigue crack propagation in 4140 steel sprockets. This includes the use of non-destructive testing techniques, such as ultrasonic inspection and acoustic emission monitoring, to detect early-stage cracks. Additionally, developing predictive models based on operational data and material behavior can help forecast potential failures and optimize maintenance schedules, thereby extending the service life of sprockets in critical applications.Expand Specific Solutions

Key Players in Steel Sprocket Manufacturing

The fatigue crack propagation analysis in 4140 steel sprockets is in a mature stage of development, with a substantial market size due to its critical applications in various industries. The technology's maturity is evident from the involvement of established players across different sectors. Companies like NIPPON STEEL CORP., JFE Steel Corp., and POSCO Holdings, Inc. are at the forefront of steel production and research, likely contributing to material advancements. Academic institutions such as Zhejiang University and Louisiana State University are actively involved in research, indicating ongoing efforts to refine and improve the technology. The presence of industrial giants like General Electric Company and The Timken Co. suggests practical applications in manufacturing and machinery, further demonstrating the technology's established position in the market.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced analytical techniques for fatigue crack propagation in 4140 steel sprockets. Their approach combines finite element analysis (FEA) with fracture mechanics principles to accurately predict crack growth rates and fatigue life. The company utilizes a proprietary microstructure-based model that accounts for the specific heat treatment and manufacturing processes of 4140 steel[1]. This model incorporates factors such as grain size, phase distribution, and residual stresses to provide more accurate predictions than traditional methods. NIPPON STEEL also employs advanced non-destructive testing techniques, including phased array ultrasonic testing (PAUT) and acoustic emission monitoring, to validate their analytical models and detect early-stage fatigue cracks in sprockets[3].

Strengths: Highly accurate prediction of fatigue life, integration of material microstructure effects, and advanced non-destructive testing capabilities. Weaknesses: Potentially higher computational costs and the need for extensive material characterization data.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has developed a comprehensive approach to fatigue crack propagation analysis in 4140 steel sprockets, focusing on the integration of experimental and computational methods. Their technique involves high-resolution digital image correlation (DIC) to measure strain fields around crack tips during cyclic loading[2]. This data is then fed into a machine learning algorithm that predicts crack growth rates based on local stress intensity factors and material properties. JFE Steel has also implemented a novel heat treatment process for 4140 steel that enhances its fatigue resistance by optimizing the distribution of carbides and refining the grain structure[4]. Additionally, they have developed a surface treatment method using shot peening with controlled residual stress profiles to further improve fatigue performance of sprockets[5].

Strengths: Integration of advanced experimental techniques with computational methods, innovative heat treatment process, and surface enhancement technologies. Weaknesses: Potential complexity in implementing the full suite of techniques in production environments and the need for specialized equipment.

Advanced Techniques in Crack Growth Prediction

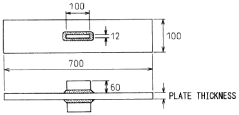

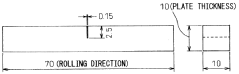

A steel plate superior in fatigue crack propagation resistance and a method of production of the same

PatentInactiveIN5142DELNP2006A

Innovation

- A steel plate with a lamellar structure comprising ferrite as the matrix phase and elongated martensite as the second phase, with specific hardness, area fraction, aspect ratio, and interlayer distance, along with controlled alloying elements, to achieve a fatigue crack propagation speed of not more than 10^-8 m/cycle and enhanced fatigue life.

Material Science Advancements for 4140 Steel

Recent advancements in material science have significantly improved the properties and performance of 4140 steel, particularly in applications requiring high strength and fatigue resistance. One of the key developments has been the refinement of heat treatment processes, which has led to enhanced microstructural control. By optimizing the tempering temperature and duration, researchers have achieved a more uniform distribution of carbides, resulting in improved toughness without sacrificing strength.

Surface engineering techniques have also played a crucial role in enhancing the fatigue resistance of 4140 steel. Innovations in nitriding processes, such as plasma nitriding and gas nitriding, have enabled the creation of harder, more wear-resistant surface layers while maintaining the core toughness of the material. These surface treatments have shown particular promise in increasing the fatigue life of components subjected to cyclic loading, such as sprockets.

Advancements in alloying techniques have further expanded the capabilities of 4140 steel. The introduction of nano-scale precipitates through careful control of alloying elements and heat treatment has led to significant improvements in both strength and ductility. This has been particularly beneficial in applications where high fatigue resistance is required, as the enhanced microstructure can more effectively resist crack initiation and propagation.

Computational modeling and simulation tools have revolutionized the design and optimization of 4140 steel components. Finite element analysis (FEA) coupled with advanced material models now allows engineers to predict fatigue behavior with greater accuracy, enabling the development of more efficient and durable designs. These tools have been instrumental in optimizing the geometry and stress distribution in critical components like sprockets, leading to improved fatigue life and performance.

The integration of non-destructive testing (NDT) methods has also contributed to the advancement of 4140 steel applications. Techniques such as ultrasonic testing, eddy current inspection, and acoustic emission monitoring have been refined to detect early signs of fatigue damage in steel components. This has enabled more proactive maintenance strategies and has significantly reduced the risk of catastrophic failure in critical applications.

Surface engineering techniques have also played a crucial role in enhancing the fatigue resistance of 4140 steel. Innovations in nitriding processes, such as plasma nitriding and gas nitriding, have enabled the creation of harder, more wear-resistant surface layers while maintaining the core toughness of the material. These surface treatments have shown particular promise in increasing the fatigue life of components subjected to cyclic loading, such as sprockets.

Advancements in alloying techniques have further expanded the capabilities of 4140 steel. The introduction of nano-scale precipitates through careful control of alloying elements and heat treatment has led to significant improvements in both strength and ductility. This has been particularly beneficial in applications where high fatigue resistance is required, as the enhanced microstructure can more effectively resist crack initiation and propagation.

Computational modeling and simulation tools have revolutionized the design and optimization of 4140 steel components. Finite element analysis (FEA) coupled with advanced material models now allows engineers to predict fatigue behavior with greater accuracy, enabling the development of more efficient and durable designs. These tools have been instrumental in optimizing the geometry and stress distribution in critical components like sprockets, leading to improved fatigue life and performance.

The integration of non-destructive testing (NDT) methods has also contributed to the advancement of 4140 steel applications. Techniques such as ultrasonic testing, eddy current inspection, and acoustic emission monitoring have been refined to detect early signs of fatigue damage in steel components. This has enabled more proactive maintenance strategies and has significantly reduced the risk of catastrophic failure in critical applications.

Regulatory Standards for Sprocket Durability

Regulatory standards for sprocket durability play a crucial role in ensuring the safety and reliability of mechanical systems across various industries. These standards are typically established by regulatory bodies and industry associations to provide guidelines for the design, manufacturing, and testing of sprockets. In the context of fatigue crack propagation analysis in 4140 steel sprockets, several key regulatory standards are particularly relevant.

The Society of Automotive Engineers (SAE) has developed specific standards for sprocket durability, including SAE J1575 for chain drive sprockets and SAE J498 for sprocket tooth strength. These standards outline the minimum requirements for sprocket design, material selection, and performance testing. They also provide guidelines for calculating the load-carrying capacity and fatigue life of sprockets, which are essential considerations in fatigue crack propagation analysis.

The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) have jointly established the ANSI/ASME B29.1 standard for precision roller chains, sprockets, and attachments. This standard includes specifications for sprocket materials, heat treatment processes, and dimensional tolerances, all of which can significantly impact the fatigue resistance of 4140 steel sprockets.

In the European Union, the EN 14587 standard addresses the fatigue strength of railway axles and wheels, which can be applied to sprockets used in railway applications. This standard provides guidance on fatigue testing methods and acceptance criteria, which can be adapted for sprocket durability assessment in other industries.

The International Organization for Standardization (ISO) has developed ISO 606, which specifies the dimensions and general requirements for short-pitch precision roller chains and associated chain wheels or sprockets. While not specifically focused on fatigue analysis, this standard provides important guidelines for sprocket design that can influence fatigue performance.

For the oil and gas industry, the American Petroleum Institute (API) has established standards such as API Specification 7F, which covers chain and sprockets for power transmission. This standard includes requirements for material properties, heat treatment, and quality control processes that are relevant to fatigue resistance in harsh operating environments.

In addition to these industry-specific standards, general materials testing standards such as ASTM E647 for measurement of fatigue crack growth rates and ASTM E466 for conducting force-controlled constant amplitude axial fatigue tests of metallic materials are often referenced in sprocket durability assessments. These standards provide standardized methods for evaluating the fatigue properties of 4140 steel and other materials used in sprocket manufacturing.

Compliance with these regulatory standards is essential for manufacturers and end-users of sprockets, as it ensures that the components meet minimum safety and performance requirements. Furthermore, adherence to these standards can provide a framework for conducting thorough fatigue crack propagation analysis in 4140 steel sprockets, ultimately leading to more reliable and durable mechanical systems.

The Society of Automotive Engineers (SAE) has developed specific standards for sprocket durability, including SAE J1575 for chain drive sprockets and SAE J498 for sprocket tooth strength. These standards outline the minimum requirements for sprocket design, material selection, and performance testing. They also provide guidelines for calculating the load-carrying capacity and fatigue life of sprockets, which are essential considerations in fatigue crack propagation analysis.

The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) have jointly established the ANSI/ASME B29.1 standard for precision roller chains, sprockets, and attachments. This standard includes specifications for sprocket materials, heat treatment processes, and dimensional tolerances, all of which can significantly impact the fatigue resistance of 4140 steel sprockets.

In the European Union, the EN 14587 standard addresses the fatigue strength of railway axles and wheels, which can be applied to sprockets used in railway applications. This standard provides guidance on fatigue testing methods and acceptance criteria, which can be adapted for sprocket durability assessment in other industries.

The International Organization for Standardization (ISO) has developed ISO 606, which specifies the dimensions and general requirements for short-pitch precision roller chains and associated chain wheels or sprockets. While not specifically focused on fatigue analysis, this standard provides important guidelines for sprocket design that can influence fatigue performance.

For the oil and gas industry, the American Petroleum Institute (API) has established standards such as API Specification 7F, which covers chain and sprockets for power transmission. This standard includes requirements for material properties, heat treatment, and quality control processes that are relevant to fatigue resistance in harsh operating environments.

In addition to these industry-specific standards, general materials testing standards such as ASTM E647 for measurement of fatigue crack growth rates and ASTM E466 for conducting force-controlled constant amplitude axial fatigue tests of metallic materials are often referenced in sprocket durability assessments. These standards provide standardized methods for evaluating the fatigue properties of 4140 steel and other materials used in sprocket manufacturing.

Compliance with these regulatory standards is essential for manufacturers and end-users of sprockets, as it ensures that the components meet minimum safety and performance requirements. Furthermore, adherence to these standards can provide a framework for conducting thorough fatigue crack propagation analysis in 4140 steel sprockets, ultimately leading to more reliable and durable mechanical systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!