Graphene Oxide: Increasing Efficiency of Electrochemical Devices

Graphene Oxide Background and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of electrochemistry, offering unprecedented potential for enhancing the efficiency of electrochemical devices. This two-dimensional carbon-based nanomaterial, derived from the oxidation of graphite, has garnered significant attention due to its unique properties and versatile applications.

The journey of graphene oxide began with the discovery of graphene in 2004 by Andre Geim and Konstantin Novoselov, which earned them the Nobel Prize in Physics in 2010. Since then, researchers have been exploring various forms and derivatives of graphene, with graphene oxide standing out for its exceptional characteristics and ease of production.

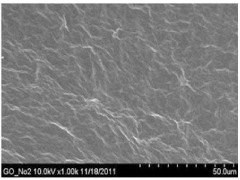

Graphene oxide's structure consists of a single layer of carbon atoms arranged in a hexagonal lattice, interspersed with oxygen-containing functional groups. This unique composition endows GO with remarkable properties, including high surface area, excellent electrical conductivity, and superior mechanical strength. These attributes make it an ideal candidate for improving the performance of electrochemical devices across various sectors.

The primary objective of research into graphene oxide for electrochemical applications is to harness its extraordinary properties to enhance device efficiency, stability, and functionality. Researchers aim to optimize GO's synthesis methods, tailor its properties through chemical modifications, and develop innovative integration techniques to fully exploit its potential in electrochemical systems.

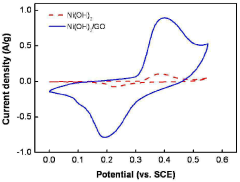

One of the key goals is to leverage GO's high surface area and conductivity to improve electrode performance in energy storage devices such as supercapacitors and batteries. By incorporating GO into electrode materials, scientists seek to increase charge storage capacity, enhance charge transfer kinetics, and improve overall device efficiency.

Another critical objective is to utilize GO's unique structure and properties to develop advanced sensors and biosensors with improved sensitivity and selectivity. The material's large surface area and abundant functional groups provide an excellent platform for immobilizing various biomolecules and catalysts, enabling the creation of highly efficient electrochemical sensing devices.

Furthermore, researchers are exploring GO's potential in electrocatalysis, aiming to develop more efficient and cost-effective catalysts for various electrochemical reactions, including water splitting, fuel cells, and CO2 reduction. The ultimate goal is to address global energy and environmental challenges by creating more sustainable and efficient electrochemical technologies.

As the field progresses, the focus is shifting towards understanding the fundamental mechanisms of GO's interaction with electrochemical systems, optimizing its properties for specific applications, and scaling up production methods for commercial viability. The ongoing research and development in this area hold promise for revolutionizing various industries, from energy storage and conversion to environmental remediation and biomedical applications.

Market Analysis for Graphene Oxide Applications

The market for graphene oxide applications in electrochemical devices is experiencing significant growth, driven by the material's unique properties and the increasing demand for more efficient energy storage and conversion technologies. Graphene oxide, a derivative of graphene, offers exceptional electrical conductivity, high surface area, and excellent mechanical strength, making it an ideal candidate for enhancing the performance of various electrochemical devices.

In the energy storage sector, graphene oxide is being extensively researched for its potential to improve the efficiency of batteries and supercapacitors. The global lithium-ion battery market, a key area where graphene oxide can make a substantial impact, is projected to grow rapidly in the coming years. This growth is primarily fueled by the rising adoption of electric vehicles and the increasing need for renewable energy storage solutions.

The fuel cell market is another area where graphene oxide applications are gaining traction. Graphene oxide-based materials are being explored as catalysts and electrode materials in fuel cells, potentially improving their efficiency and durability. As countries worldwide push for cleaner energy solutions, the demand for more efficient fuel cells is expected to rise, creating opportunities for graphene oxide applications.

In the field of water treatment and desalination, graphene oxide membranes are showing promise for their ability to efficiently filter water and remove contaminants. The global water treatment market is expanding due to increasing water scarcity and stricter environmental regulations, presenting a significant opportunity for graphene oxide-based solutions.

The electronics industry is also exploring graphene oxide applications, particularly in the development of flexible and wearable electronics. As consumer demand for more advanced and versatile electronic devices grows, the market for graphene oxide in this sector is expected to expand.

Despite the promising outlook, challenges remain in scaling up production and reducing costs associated with graphene oxide manufacturing. However, ongoing research and development efforts are focused on addressing these issues, which could lead to wider adoption across various industries.

Overall, the market for graphene oxide applications in electrochemical devices is poised for substantial growth. As research progresses and manufacturing processes improve, graphene oxide is likely to play an increasingly important role in enhancing the efficiency and performance of a wide range of electrochemical devices across multiple industries.

Current Challenges in Graphene Oxide Integration

Despite the promising potential of graphene oxide (GO) in enhancing the efficiency of electrochemical devices, several significant challenges persist in its integration. One of the primary obstacles is the scalable production of high-quality GO with consistent properties. Current synthesis methods often result in variations in the oxidation degree, sheet size, and defect density, which can significantly impact the performance of electrochemical devices.

Another critical challenge lies in the control of GO's surface chemistry. The presence of oxygen-containing functional groups on GO's surface, while beneficial for certain applications, can hinder electron transfer in electrochemical processes. Achieving a balance between conductivity and reactivity through precise control of these functional groups remains a complex task.

The stability of GO in electrochemical environments poses another significant hurdle. Under prolonged exposure to electrolytes or during repeated charge-discharge cycles, GO may undergo structural changes or degradation, leading to a decrease in device performance over time. This instability can result in reduced conductivity, decreased active surface area, and potential delamination from electrode surfaces.

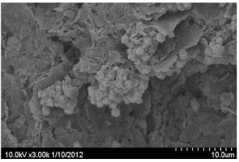

Furthermore, the integration of GO into existing electrode materials and device architectures presents technical difficulties. Ensuring uniform dispersion and strong interfacial interactions between GO and other components is crucial for optimal performance but often challenging to achieve consistently at scale.

The environmental impact and potential toxicity of GO also raise concerns. While GO itself is generally considered less toxic than pristine graphene, its long-term effects on human health and the environment are not fully understood. This uncertainty can hinder widespread adoption in certain applications, particularly those involving direct human contact or potential environmental release.

Lastly, the cost-effectiveness of GO integration remains a significant challenge. While the raw materials for GO production are relatively inexpensive, the complex processing steps and the need for high-purity precursors can drive up costs. Balancing the enhanced performance with the increased production expenses is crucial for commercial viability.

Addressing these challenges requires interdisciplinary efforts combining materials science, electrochemistry, and engineering. Advances in synthesis techniques, surface modification strategies, and device fabrication methods are needed to fully harness the potential of GO in electrochemical devices. Additionally, comprehensive studies on long-term stability, environmental impact, and cost-effective production methods are essential to overcome the current limitations and pave the way for widespread adoption of GO in next-generation electrochemical technologies.

Existing Graphene Oxide Enhancement Methods

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide with improved efficiency are described. These methods include chemical exfoliation, thermal reduction, and electrochemical approaches. The focus is on developing scalable and cost-effective production techniques that yield high-quality graphene oxide with enhanced properties.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide with improved efficiency are described. These methods aim to enhance the quality and yield of graphene oxide, making it more suitable for various applications. Techniques may include modified Hummers' method, electrochemical exfoliation, or chemical vapor deposition.

- Applications in energy storage devices: Graphene oxide's efficiency is explored in energy storage applications, particularly in batteries and supercapacitors. Its high surface area and excellent electrical properties make it an attractive material for improving the performance of these devices, including increased capacity and faster charging rates.

- Water purification and environmental applications: The efficiency of graphene oxide in water purification and environmental remediation is investigated. Its ability to adsorb contaminants and pollutants makes it a promising material for water treatment technologies, including the removal of heavy metals and organic pollutants from water sources.

- Functionalization and modification techniques: Various methods for functionalizing and modifying graphene oxide are explored to enhance its efficiency for specific applications. These techniques may include chemical modifications, doping, or creating composites with other materials to tailor its properties for improved performance in various fields.

- Characterization and quality control methods: Techniques for characterizing and ensuring the quality of graphene oxide are developed to improve its efficiency in various applications. These methods may include spectroscopic analysis, microscopy techniques, and other analytical tools to assess the purity, structure, and properties of graphene oxide.

02 Applications in energy storage devices

Graphene oxide's efficiency is explored in energy storage applications, particularly in batteries and supercapacitors. The material's high surface area and excellent electrical properties contribute to improved energy density, faster charging rates, and longer cycle life in these devices.Expand Specific Solutions03 Environmental remediation and water treatment

The efficiency of graphene oxide in environmental applications is investigated, focusing on water purification and contaminant removal. Its high adsorption capacity and selectivity make it an effective material for removing pollutants, heavy metals, and organic compounds from water and wastewater.Expand Specific Solutions04 Functionalization and composite materials

Methods for functionalizing graphene oxide and incorporating it into composite materials are explored to enhance its efficiency in various applications. These modifications improve the material's compatibility, dispersion, and performance in areas such as polymer reinforcement, coatings, and sensors.Expand Specific Solutions05 Characterization and quality control techniques

Advanced characterization methods and quality control techniques are developed to assess the efficiency and properties of graphene oxide. These include spectroscopic, microscopic, and electrochemical analysis methods to evaluate the material's structure, composition, and performance in various applications.Expand Specific Solutions

Key Players in Graphene Oxide Research

The graphene oxide market for enhancing electrochemical device efficiency is in a growth phase, with increasing market size driven by demand for improved energy storage and conversion technologies. The technology's maturity is advancing rapidly, with companies like The Sixth Element Materials Technology and Nantong Xisheng New Material Technology leading in production capabilities. Research institutions such as King Fahd University of Petroleum & Minerals and the Sichuan Institute of Graphene Industrial Technology are pushing boundaries in application development. Major players like SK Innovation, LG Chem, and Toray Industries are investing heavily in R&D, indicating a competitive landscape with both specialized manufacturers and large conglomerates vying for market share in this promising field.

The Sixth Element (Changzhou) Materials Technology Co., Ltd.

SK Innovation Co., Ltd.

Breakthrough Graphene Oxide Innovations

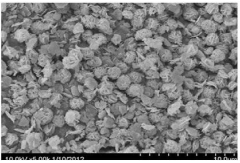

- A method involving ultrasonic treatment is used to intercalate nickel hydroxide between graphene oxide layers to form a graphene oxide composite, which enhances electrical properties and simplifies the production process.

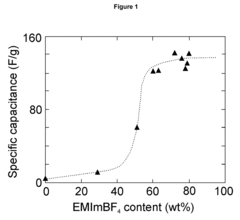

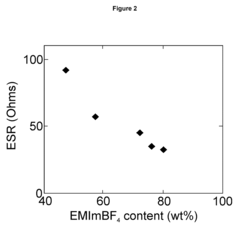

- A method of creating graphene-ionic liquid composites by combining a graphene source with at least one ionic liquid and heating the mixture at a temperature of at least 130°C, which is then coated onto a substrate, forming electrodes for energy storage devices.

Environmental Impact of Graphene Oxide Production

The production of graphene oxide, while promising for enhancing electrochemical devices, raises significant environmental concerns. The primary method of synthesis, the modified Hummers' method, involves the use of strong oxidizing agents and acids, which can lead to the generation of hazardous waste and toxic by-products.

One of the main environmental issues is the release of heavy metals and toxic chemicals during the production process. Potassium permanganate and sulfuric acid, key components in graphene oxide synthesis, can contaminate water sources if not properly managed. This contamination poses risks to aquatic ecosystems and human health, necessitating stringent waste treatment protocols.

Air pollution is another critical concern. The production of graphene oxide can release particulate matter and volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to air quality degradation and may have long-term impacts on respiratory health in surrounding communities.

Energy consumption in graphene oxide production is substantial, contributing to indirect environmental impacts through increased carbon emissions. The high-temperature processes and extensive purification steps required for high-quality graphene oxide synthesis demand significant energy inputs, often sourced from fossil fuels.

Water usage is also a notable environmental factor. The production and purification processes require large volumes of water, potentially straining local water resources, especially in water-scarce regions. The resulting wastewater, laden with chemical residues, requires extensive treatment before safe disposal.

The scalability of graphene oxide production presents a double-edged sword for environmental impact. While larger-scale production could potentially improve efficiency and reduce per-unit environmental costs, it also risks amplifying the overall environmental footprint if not managed sustainably.

Efforts to mitigate these environmental impacts are ongoing. Research into green synthesis methods, using less harmful reagents and more environmentally friendly processes, shows promise. Additionally, closed-loop production systems and advanced waste treatment technologies are being developed to minimize environmental discharge and maximize resource recovery.

As the demand for graphene oxide in electrochemical devices grows, balancing technological advancement with environmental stewardship becomes crucial. Implementing life cycle assessments and adopting circular economy principles in graphene oxide production will be essential for ensuring its sustainable integration into future technologies.

Scalability and Cost-effectiveness Analysis

The scalability and cost-effectiveness of graphene oxide (GO) in electrochemical devices are critical factors determining its widespread adoption and commercial viability. As production techniques for GO continue to evolve, significant progress has been made in scaling up manufacturing processes while simultaneously reducing costs.

Large-scale production of GO has been achieved through various methods, including modified Hummers' method and electrochemical exfoliation. These techniques have demonstrated the ability to produce GO in quantities suitable for industrial applications. However, challenges remain in maintaining consistent quality and properties across large batches, which is crucial for ensuring uniform performance in electrochemical devices.

Recent advancements in continuous flow production methods have shown promise in addressing scalability issues. These processes allow for the synthesis of GO in a more controlled and efficient manner, potentially reducing production time and costs. Additionally, the development of automated systems for GO production has further improved scalability by minimizing human intervention and increasing output consistency.

Cost-effectiveness analysis reveals that while the production of high-quality GO remains relatively expensive compared to traditional materials, the gap is narrowing. The primary cost drivers include raw materials, energy consumption, and purification processes. However, as production scales up, economies of scale are beginning to take effect, gradually reducing per-unit costs.

Efforts to improve cost-effectiveness have focused on optimizing raw material usage, developing more energy-efficient production methods, and streamlining purification processes. For instance, the use of cheaper graphite sources and the implementation of recycling strategies for chemical reagents have shown potential in reducing overall production costs.

The environmental impact of GO production is another crucial consideration in scalability and cost-effectiveness analysis. Sustainable production methods, such as those utilizing green solvents or electrochemical approaches, are being explored to minimize environmental footprint and associated costs. These eco-friendly processes may also lead to reduced regulatory compliance expenses in the long term.

As the technology matures, it is anticipated that the cost of GO will continue to decrease, making it more competitive with traditional materials used in electrochemical devices. This trend, coupled with the superior performance characteristics of GO, suggests a favorable outlook for its widespread adoption in various applications, including energy storage, sensors, and water treatment technologies.

In conclusion, while challenges in scalability and cost-effectiveness persist, ongoing research and development efforts are steadily improving the commercial viability of GO for electrochemical devices. The convergence of enhanced production techniques, cost reduction strategies, and increasing demand is likely to drive further improvements in these areas, paving the way for broader implementation of GO-based technologies in the near future.