Graphene Oxide: Innovating Modern Communication Devices

Graphene Oxide Evolution

Graphene oxide has undergone a remarkable evolution since its initial discovery, transforming from a novel material to a key component in modern communication devices. The journey began with the isolation of graphene in 2004, which sparked intense research into its derivatives, including graphene oxide. Initially, graphene oxide was primarily studied for its unique structural and chemical properties, with researchers focusing on understanding its synthesis methods and basic characteristics.

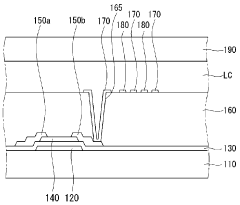

As research progressed, the potential applications of graphene oxide in electronics and communication technologies became increasingly apparent. The material's exceptional electrical and thermal conductivity, coupled with its flexibility and strength, made it an attractive candidate for next-generation electronic components. Early experiments demonstrated its potential in creating transparent conductive films, a crucial element in touchscreens and display technologies.

The evolution of graphene oxide in communication devices gained momentum with the development of more sophisticated synthesis and functionalization techniques. These advancements allowed for better control over the material's properties, enabling researchers to tailor graphene oxide for specific applications. For instance, the ability to precisely control the oxygen content in graphene oxide opened up new possibilities for creating tunable electronic properties, essential for various communication device components.

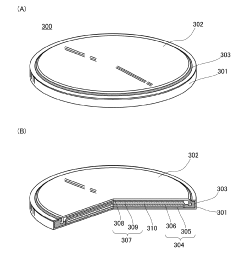

A significant milestone in the evolution of graphene oxide was its integration into flexible and wearable electronics. As the demand for more versatile and compact communication devices grew, graphene oxide's flexibility and strength positioned it as an ideal material for creating bendable displays, flexible antennas, and wearable sensors. This shift marked a turning point in the material's application, moving from theoretical potential to practical implementation in consumer electronics.

Recent years have seen graphene oxide evolving into a multifunctional material in communication devices. Its use has expanded beyond simple conductive elements to more complex applications such as electromagnetic interference shielding, high-frequency transistors, and energy storage components for mobile devices. The material's ability to enhance the performance of batteries and supercapacitors has made it particularly valuable in addressing the power consumption challenges of modern communication devices.

The ongoing evolution of graphene oxide in communication technologies is now focused on overcoming scaling challenges and improving manufacturing processes. Researchers and industry players are working on developing cost-effective and scalable production methods to enable widespread adoption of graphene oxide-based components in commercial devices. This phase of evolution is crucial for transitioning graphene oxide from a laboratory marvel to a standard material in the communication industry.

Market Demand Analysis

The market demand for graphene oxide in modern communication devices has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for high-performance, lightweight, and flexible electronic components in the rapidly evolving telecommunications industry. Graphene oxide's unique properties, including exceptional electrical conductivity, thermal management capabilities, and mechanical strength, make it an ideal candidate for various applications in communication devices.

In the smartphone market, graphene oxide is gaining traction as a potential material for next-generation displays, touch sensors, and batteries. The global smartphone market, valued at over $400 billion, is constantly seeking innovative materials to enhance device performance and user experience. Graphene oxide's transparency and flexibility open up possibilities for foldable and bendable displays, addressing the growing consumer demand for more versatile and durable devices.

The wearable technology sector, including smartwatches and fitness trackers, is another area where graphene oxide shows promise. This market segment is projected to reach $100 billion by 2025, with a compound annual growth rate of over 20%. Graphene oxide's ability to create ultra-thin, flexible, and highly conductive components aligns perfectly with the requirements of wearable devices, potentially revolutionizing their design and functionality.

In the realm of 5G and future 6G networks, graphene oxide is poised to play a crucial role. The global 5G infrastructure market is expected to exceed $50 billion by 2025, with a strong emphasis on high-frequency communication and improved energy efficiency. Graphene oxide's exceptional electromagnetic properties make it an excellent candidate for developing high-frequency antennas, filters, and other components essential for advanced wireless communication systems.

The Internet of Things (IoT) sector presents another significant market opportunity for graphene oxide. With billions of connected devices projected to be in use by 2025, there is a growing demand for materials that can enhance the performance and energy efficiency of IoT sensors and communication modules. Graphene oxide's properties align well with these requirements, potentially driving its adoption in this rapidly expanding market.

However, it's important to note that while the potential market for graphene oxide in communication devices is vast, there are still challenges to overcome. These include scaling up production to meet industrial demands, ensuring consistent quality, and addressing potential environmental and health concerns. As these challenges are addressed, the market demand for graphene oxide in communication devices is expected to continue its upward trajectory, reshaping the landscape of modern telecommunications technology.

Technical Challenges

Despite the promising potential of graphene oxide in modern communication devices, several significant technical challenges persist in its development and application. One of the primary obstacles is the scalable production of high-quality graphene oxide. Current manufacturing processes often result in inconsistent quality and limited yield, hindering large-scale industrial applications. The challenge lies in developing efficient and cost-effective methods to produce graphene oxide with consistent properties and minimal defects.

Another critical challenge is the precise control of graphene oxide's electrical properties. While graphene oxide's unique structure offers excellent conductivity, its performance can be highly sensitive to environmental factors and processing conditions. Achieving consistent and tunable electrical characteristics across different batches and applications remains a significant hurdle for researchers and engineers.

The integration of graphene oxide into existing communication device architectures presents another set of challenges. Compatibility issues with traditional semiconductor materials and manufacturing processes can arise, requiring innovative approaches to seamlessly incorporate graphene oxide into current technologies. This integration challenge extends to ensuring long-term stability and reliability of graphene oxide-based components in diverse operating conditions.

Thermal management is a crucial concern in the application of graphene oxide in communication devices. While graphene oxide exhibits excellent thermal conductivity, effectively dissipating heat in compact device designs can be challenging. Developing efficient heat dissipation strategies that maintain the performance and longevity of graphene oxide-based components is essential for their practical implementation.

Furthermore, the environmental stability of graphene oxide poses a significant challenge. Its susceptibility to degradation under certain conditions, such as exposure to moisture or specific chemicals, can impact the long-term reliability of devices. Developing effective encapsulation techniques and protective measures to enhance the durability of graphene oxide in various environmental conditions is crucial for its widespread adoption in communication technologies.

Lastly, the challenge of standardization and quality control in graphene oxide production and application cannot be overlooked. The lack of universally accepted standards for characterization and performance metrics hampers the consistent evaluation and comparison of graphene oxide-based solutions across different research and industrial settings. Establishing robust quality control measures and industry-wide standards is essential for accelerating the commercialization and widespread adoption of graphene oxide in communication devices.

Current GO Solutions

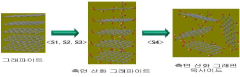

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in electronics and energy storage: Graphene oxide is utilized in electronic devices and energy storage systems due to its unique electrical and thermal properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.

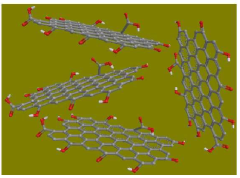

- Functionalization and modification of graphene oxide: Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its reactivity, dispersibility, and compatibility with other materials.

- Graphene oxide-based composites and nanocomposites: The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with polymers, metals, or other nanomaterials. These composites exhibit enhanced mechanical, thermal, and electrical properties for various applications.

- Characterization and analysis techniques for graphene oxide: Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical approaches to determine the structure, composition, and properties of graphene oxide materials.

02 Applications of graphene oxide in electronics and energy storage

Graphene oxide is utilized in electronic devices and energy storage systems due to its unique properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its performance in various fields.Expand Specific Solutions04 Graphene oxide-based composites and materials

The development of graphene oxide-based composites and materials is described, combining graphene oxide with other substances to create novel materials with enhanced properties for applications in areas such as structural materials, coatings, and filters.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various methods and techniques for characterizing and analyzing graphene oxide are presented, including spectroscopic, microscopic, and electrochemical approaches. These techniques help in understanding the structure, properties, and quality of graphene oxide samples.Expand Specific Solutions

Key Industry Players

The graphene oxide market for modern communication devices is in a growth phase, driven by increasing demand for high-performance electronics. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, graphene oxide is advancing from early-stage research to commercial applications, with varying levels of maturity across different use cases. Companies like Semiconductor Energy Laboratory Co., Ltd., Global Graphene Group, Inc., and LG Display Co., Ltd. are at the forefront of developing graphene oxide-based technologies for communication devices. Research institutions such as Northwestern University and Zhejiang University are contributing to fundamental advancements, while industry players like SK Innovation Co., Ltd. and Thomson Licensing SAS are focusing on practical applications and product development.

Semiconductor Energy Laboratory Co., Ltd.

Centre National de la Recherche Scientifique

Core GO Innovations

- The use of graphene oxide with a specific carbon-to-oxygen ratio (2.5 to 4) as a conductive additive in the positive electrode active material layer, which is uniformly dispersed and reduced to form a network with high electrical conductivity, enhancing the dispersibility and conductivity of the electrode.

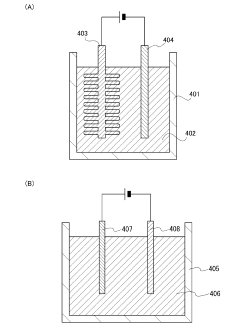

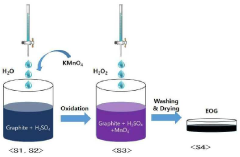

- A method involving the controlled oxidation of graphite edges using diluted sulfuric acid and potassium permanganate, followed by hydrogen peroxide termination and exfoliation, to produce graphene oxide with oxidized edges.

GO Manufacturing Process

The manufacturing process of graphene oxide (GO) is a critical aspect of its application in modern communication devices. The most common method for producing GO is the modified Hummers' method, which involves the oxidation of graphite using strong oxidizing agents. This process begins with the treatment of graphite flakes with a mixture of concentrated sulfuric acid, sodium nitrate, and potassium permanganate. The resulting mixture is then stirred and maintained at a controlled temperature for several hours to ensure thorough oxidation.

Following the oxidation step, the mixture is diluted with water and treated with hydrogen peroxide to reduce the residual permanganate and manganese dioxide to colorless soluble manganese sulfate. The graphite oxide slurry is then purified by washing with water, hydrochloric acid, and ethanol to remove metal ions and other impurities. The purified graphite oxide is subsequently exfoliated into graphene oxide sheets through sonication or mechanical stirring.

An alternative method for GO production is the Tour method, which eliminates the use of sodium nitrate, thus preventing the generation of toxic gases. This method employs a mixture of sulfuric acid and phosphoric acid with potassium permanganate as the oxidizing agent. The Tour method offers improved efficiency and environmental friendliness compared to the traditional Hummers' method.

Recent advancements in GO manufacturing have focused on scaling up production while maintaining quality and consistency. Continuous flow reactors have been developed to enable large-scale production of GO, offering better control over reaction conditions and improved product uniformity. Additionally, researchers are exploring greener synthesis routes, such as electrochemical exfoliation and microwave-assisted synthesis, to reduce the environmental impact of GO production.

The quality control of GO is crucial for its application in communication devices. Characterization techniques such as Raman spectroscopy, X-ray diffraction, and atomic force microscopy are employed to assess the structural and chemical properties of the produced GO. These methods help ensure the consistency and reliability of GO for use in advanced electronic applications.

As the demand for GO in communication devices continues to grow, researchers are also investigating methods to tailor the properties of GO during the manufacturing process. This includes controlling the degree of oxidation, the size of GO sheets, and the introduction of specific functional groups to enhance its performance in specific applications such as electromagnetic shielding, flexible electronics, and high-frequency communication devices.

Environmental Impact

The environmental impact of graphene oxide in modern communication devices is a critical consideration as this innovative material gains prominence in the tech industry. Graphene oxide's production process involves chemical treatments that can potentially release harmful substances into the environment if not properly managed. However, the material's unique properties also offer opportunities for reducing the overall environmental footprint of communication devices.

One of the primary environmental concerns is the energy-intensive nature of graphene oxide production. The synthesis process typically requires high temperatures and strong oxidizing agents, which can lead to significant energy consumption and greenhouse gas emissions. As the demand for graphene oxide increases in the communication device sector, addressing these production-related environmental issues becomes paramount.

Water pollution is another potential risk associated with graphene oxide manufacturing. The chemical processes involved may generate wastewater containing toxic compounds, necessitating careful treatment and disposal protocols to prevent contamination of water bodies. Additionally, the potential release of graphene oxide nanoparticles into aquatic ecosystems raises concerns about their impact on marine life and water quality.

On the positive side, the incorporation of graphene oxide in communication devices can lead to improved energy efficiency and extended product lifespans. The material's excellent conductivity and thermal properties allow for the development of more energy-efficient components, potentially reducing the overall power consumption of devices. This, in turn, can contribute to lower carbon emissions associated with device usage over time.

Furthermore, graphene oxide's durability and strength can enhance the longevity of communication devices, potentially reducing electronic waste. By extending the useful life of products, the demand for new devices and the associated environmental impacts of manufacturing and disposal may be mitigated. This aligns with the growing emphasis on sustainable product design and circular economy principles in the tech industry.

The recyclability of graphene oxide-based components is an area of ongoing research and development. While the material itself is potentially recyclable, the complex integration with other materials in communication devices presents challenges for end-of-life recovery and reuse. Advancements in recycling technologies specific to graphene oxide could significantly improve the environmental profile of devices incorporating this material.

As the adoption of graphene oxide in communication devices continues to grow, it is crucial to conduct comprehensive life cycle assessments to fully understand and quantify its environmental impacts. This holistic approach will enable manufacturers and policymakers to make informed decisions about the material's use and implement appropriate mitigation strategies where necessary.