Graphene Oxide: Key Applications in Catalysis Innovations

Graphene Oxide Catalysis: Background and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of catalysis, marking a significant milestone in the evolution of advanced materials science. This two-dimensional carbon-based nanomaterial, derived from the oxidation of graphene, has garnered immense attention due to its unique structural and chemical properties. The journey of GO in catalysis began with its discovery in the early 2000s, following the groundbreaking isolation of graphene in 2004.

The development of GO catalysis has been driven by the growing demand for more efficient, sustainable, and cost-effective catalytic processes across various industries. As global concerns about environmental sustainability and energy efficiency intensify, GO presents a promising solution due to its large surface area, abundant functional groups, and tunable electronic properties. These characteristics make GO an ideal candidate for catalytic applications, potentially revolutionizing chemical synthesis, energy conversion, and environmental remediation.

The evolution of GO catalysis has been marked by several key trends. Initially, research focused on understanding the fundamental properties of GO and its potential as a support material for traditional metal catalysts. As the field progressed, scientists began exploring GO as a metal-free catalyst, leveraging its intrinsic catalytic activity. Recent years have seen a shift towards the development of GO-based hybrid catalysts, combining the advantages of GO with other nanomaterials to achieve synergistic effects.

The primary objective of GO catalysis research is to harness the material's unique properties to develop highly efficient, selective, and stable catalysts. Researchers aim to optimize GO's performance in various catalytic reactions, including oxidation, reduction, and coupling reactions. Additionally, there is a strong focus on enhancing GO's recyclability and durability, addressing key challenges in industrial applications.

Another crucial goal is to elucidate the precise mechanisms of GO's catalytic activity. Understanding the role of oxygen-containing functional groups, defects, and electronic structure in catalytic processes is essential for rational catalyst design. This knowledge will enable the tailoring of GO properties to specific catalytic applications, potentially leading to breakthroughs in reaction efficiency and selectivity.

Furthermore, the field aims to expand the scope of GO catalysis to new reaction types and industrial processes. This includes exploring GO's potential in photocatalysis, electrocatalysis, and biocatalysis, opening up possibilities for clean energy production, environmental remediation, and pharmaceutical synthesis. The ultimate objective is to transition GO-based catalysts from laboratory success to large-scale industrial implementation, addressing challenges in scalability, cost-effectiveness, and long-term stability.

Market Demand Analysis for Graphene Oxide Catalysts

The market demand for graphene oxide catalysts has been experiencing significant growth in recent years, driven by the increasing need for more efficient and sustainable catalytic processes across various industries. The unique properties of graphene oxide, including its high surface area, excellent electron mobility, and tunable surface chemistry, make it an attractive material for catalytic applications.

In the energy sector, graphene oxide catalysts are gaining traction in fuel cell technologies, particularly for hydrogen production and oxygen reduction reactions. The automotive industry is showing keen interest in these catalysts for improving the efficiency of emission control systems and enhancing the performance of electric vehicle batteries. This demand is further bolstered by stringent environmental regulations worldwide, pushing manufacturers to adopt cleaner technologies.

The chemical industry represents another major market for graphene oxide catalysts. These materials are being increasingly utilized in organic synthesis, petrochemical processing, and fine chemical production. Their ability to facilitate reactions under milder conditions and with higher selectivity is driving adoption in pharmaceutical manufacturing and agrochemical production.

Environmental applications form a rapidly growing segment for graphene oxide catalysts. Water treatment and air purification systems are incorporating these materials to enhance the degradation of pollutants and improve overall efficiency. The rising global focus on addressing water scarcity and air pollution is expected to further propel this market segment.

The electronics industry is also contributing to the market demand, with graphene oxide catalysts finding applications in the production of advanced electronic materials and in the development of next-generation sensors and devices. The ongoing miniaturization trend in electronics is likely to sustain this demand in the coming years.

Geographically, Asia-Pacific is emerging as a key market for graphene oxide catalysts, driven by rapid industrialization and increasing environmental concerns in countries like China and India. North America and Europe continue to be significant markets, primarily due to their strong focus on research and development in advanced materials and sustainable technologies.

Despite the growing demand, challenges such as high production costs and scalability issues persist. However, ongoing research efforts and technological advancements are expected to address these barriers, potentially leading to wider adoption across industries. The market is also witnessing increased collaborations between academic institutions and industrial players, aimed at developing novel applications and improving the performance of graphene oxide catalysts.

Current State and Challenges in Graphene Oxide Catalysis

Graphene oxide (GO) has emerged as a promising material in catalysis innovations, with significant advancements in recent years. However, the current state of GO catalysis faces several challenges that hinder its widespread application and commercialization.

One of the primary obstacles is the lack of standardization in GO synthesis and characterization methods. The variability in production techniques leads to inconsistent material properties, making it difficult to reproduce experimental results and scale up production. This inconsistency also affects the catalytic performance of GO-based materials, as the oxygen-containing functional groups on the GO surface play a crucial role in catalytic activity.

Another challenge lies in the stability of GO under catalytic conditions. The reduction of GO during catalytic reactions can alter its structure and properties, potentially leading to decreased catalytic efficiency over time. This instability poses a significant hurdle for long-term applications and industrial-scale implementation of GO-based catalysts.

The high production cost of high-quality GO remains a limiting factor for its widespread adoption in catalysis. Current synthesis methods often involve expensive precursors and complex purification processes, making GO-based catalysts less economically viable compared to traditional alternatives.

Furthermore, the environmental impact of GO production and disposal is a growing concern. The use of strong oxidizing agents and acids in GO synthesis raises questions about the sustainability and eco-friendliness of these materials, necessitating the development of greener production methods.

In terms of catalytic performance, while GO has shown promise in various reactions, there is still a need for improvement in selectivity and efficiency. The complex surface chemistry of GO can lead to undesired side reactions, and optimizing the balance between catalytic activity and selectivity remains a challenge for researchers.

The scalability of GO-based catalysts from laboratory to industrial scale is another significant hurdle. Many successful demonstrations of GO catalysis have been limited to small-scale experiments, and translating these results to large-scale applications presents numerous engineering and process challenges.

Lastly, the fundamental understanding of the catalytic mechanisms involving GO is still evolving. The complex interplay between GO's structure, functional groups, and catalytic activity is not fully elucidated, hindering the rational design of more efficient GO-based catalysts.

Despite these challenges, ongoing research efforts are addressing these issues through innovative approaches, including the development of new synthesis methods, surface modification techniques, and hybrid materials. As these challenges are gradually overcome, GO is poised to play an increasingly important role in catalysis innovations across various industries.

Existing Graphene Oxide Catalytic Solutions

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in electronics and energy storage: Graphene oxide is utilized in electronic devices and energy storage systems due to its unique electrical and thermal properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.

- Functionalization and modification of graphene oxide: Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its reactivity, dispersibility, and compatibility with other materials.

- Graphene oxide-based composites and nanocomposites: The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with polymers, metals, or other nanomaterials. These composites exhibit enhanced mechanical, thermal, and electrical properties for various applications.

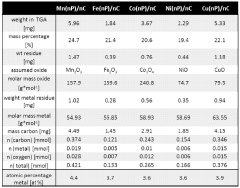

- Characterization and analysis techniques for graphene oxide: Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical tools to determine the structure, composition, and properties of graphene oxide materials.

02 Applications of graphene oxide in energy storage devices

Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and composite formation with other materials.Expand Specific Solutions04 Graphene oxide in environmental applications

Graphene oxide is used in environmental applications such as water purification, pollutant removal, and environmental sensing. Its high adsorption capacity and chemical properties make it effective for removing contaminants from water and air.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to determine the quality, composition, and performance of graphene oxide materials.Expand Specific Solutions

Key Players in Graphene Oxide Catalyst Development

The field of graphene oxide catalysis innovations is in a rapidly evolving stage, with significant market growth potential. The global market for graphene-based catalysts is expanding, driven by increasing demand in various industries. Technologically, graphene oxide catalysis is advancing quickly, with research institutions and companies at different stages of development. Leading players like Centre National de la Recherche Scientifique, Rice University, and King Abdullah University of Science & Technology are pushing the boundaries of graphene oxide applications in catalysis. Companies such as SABIC Global Technologies BV and NEC Corp. are also actively involved, indicating a growing industrial interest. The technology's maturity varies across different applications, with some areas nearing commercialization while others remain in early research phases.

Corning, Inc.

China Petroleum & Chemical Corp.

Core Innovations in Graphene Oxide Catalysis

- A method involving the dissolution of nanographite intercalation compounds in aprotic organic solvents, followed by reaction with metal salts or complexes without a reducing agent, to form nanographene-supported metal or metal oxide nanoparticles, allowing for controlled size and distribution of nanoparticles on the graphene surface.

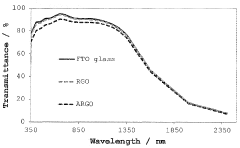

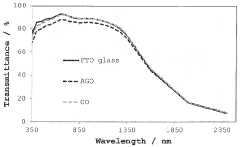

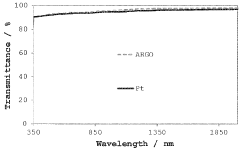

- A method involving the preparation of structured graphene platelets with controlled reduction, oxygen-containing functional groups, and surface lattice defects, applied as thin films over a transparent conductive oxide substrate, optimizing thickness, size, and treatment conditions to achieve high transparency and electrocatalytic activity.

Environmental Impact of Graphene Oxide Catalysts

The environmental impact of graphene oxide catalysts is a critical consideration in their development and application. These catalysts offer significant potential for enhancing chemical reactions and processes, but their widespread use necessitates a thorough examination of their ecological footprint.

One of the primary environmental benefits of graphene oxide catalysts is their potential to improve the efficiency of various industrial processes. By accelerating reaction rates and reducing energy requirements, these catalysts can contribute to a decrease in overall energy consumption and greenhouse gas emissions. This is particularly relevant in sectors such as petrochemicals, fine chemicals, and environmental remediation, where catalytic processes play a crucial role.

However, the production of graphene oxide itself raises environmental concerns. The synthesis of graphene oxide typically involves the use of strong oxidizing agents and acids, which can generate hazardous waste and contribute to water pollution if not properly managed. Additionally, the energy-intensive nature of graphene oxide production may offset some of the environmental gains achieved through its catalytic applications.

The potential release of graphene oxide nanoparticles into the environment during catalyst use or disposal is another area of concern. While research is ongoing, there are indications that these nanoparticles could have adverse effects on aquatic ecosystems and soil microorganisms. The long-term persistence of graphene oxide in the environment and its potential for bioaccumulation in food chains are subjects that require further investigation.

On the positive side, graphene oxide catalysts have shown promise in environmental remediation applications. They have demonstrated effectiveness in the degradation of pollutants such as organic dyes, pharmaceutical compounds, and heavy metals in wastewater treatment processes. This ability to address existing environmental challenges could partially offset the potential negative impacts associated with their production and use.

The recyclability of graphene oxide catalysts is another factor that influences their environmental impact. Many studies have shown that these catalysts can be recovered and reused multiple times without significant loss of activity. This characteristic reduces the need for frequent catalyst replacement, thereby minimizing waste generation and resource consumption.

As research in this field progresses, efforts are being made to develop more environmentally friendly methods for graphene oxide synthesis and to optimize catalyst formulations for enhanced stability and recyclability. These advancements are crucial for improving the overall environmental profile of graphene oxide catalysts and ensuring their sustainable integration into various industrial applications.

Scalability and Industrial Implementation Strategies

The scalability and industrial implementation of graphene oxide (GO) in catalysis innovations present both significant opportunities and challenges. As research progresses, the focus is shifting towards large-scale production and practical applications in industrial settings.

One of the primary challenges in scaling up GO production is maintaining consistent quality and properties across batches. Current methods, such as modified Hummers' method, face limitations in terms of yield and environmental impact. To address this, researchers are exploring continuous flow processes and green synthesis routes that can potentially increase production efficiency while reducing environmental footprint.

Industrial implementation strategies for GO-based catalysts are evolving to meet the demands of various sectors, including petrochemicals, fine chemicals, and environmental remediation. The development of robust and stable GO-based catalysts that can withstand harsh industrial conditions is a key focus area. This includes enhancing the thermal and chemical stability of GO materials through functionalization and composite formation.

Another critical aspect of industrial implementation is the integration of GO-based catalysts into existing manufacturing processes. This requires careful consideration of reactor design, catalyst recovery, and process optimization. Researchers are investigating various reactor configurations, such as fixed-bed and fluidized-bed reactors, to maximize the catalytic performance of GO materials in large-scale operations.

Cost-effectiveness remains a crucial factor in the industrial adoption of GO-based catalysts. While GO offers superior catalytic properties, its production cost needs to be competitive with traditional catalysts to ensure widespread adoption. Efforts are underway to develop more economical production methods and to explore the use of waste materials as precursors for GO synthesis.

The recyclability and regeneration of GO-based catalysts are also essential considerations for industrial implementation. Developing efficient methods for catalyst recovery and regeneration can significantly improve the economic viability of GO-based catalytic processes. This includes exploring magnetic separation techniques and in-situ regeneration methods to extend catalyst lifetime and reduce operational costs.

As the field advances, there is a growing emphasis on collaborative efforts between academia and industry to bridge the gap between laboratory-scale discoveries and industrial-scale applications. These partnerships are crucial for addressing practical challenges and accelerating the commercialization of GO-based catalytic technologies.