Graphene Oxide: Novel Approaches in Thermal Interface Materials

Graphene Oxide TIM Evolution and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of thermal interface materials (TIMs), marking a significant milestone in the evolution of heat management solutions. The journey of GO in TIMs began with the discovery of graphene's exceptional thermal properties, which prompted researchers to explore its potential in thermal management applications.

The development of GO-based TIMs has been driven by the increasing demand for more efficient heat dissipation in electronic devices. As electronic components become smaller and more powerful, the need for effective thermal management has become critical. Traditional TIMs, such as thermal greases and metal-based compounds, have reached their performance limits, creating a pressing need for innovative solutions.

GO's unique structure, consisting of a single layer of carbon atoms with oxygen-containing functional groups, offers a combination of high thermal conductivity and flexibility. This makes it an ideal candidate for TIMs, as it can conform to surface irregularities and provide excellent thermal contact between heat-generating components and heat sinks.

The evolution of GO-based TIMs has seen several key stages. Initially, researchers focused on incorporating GO into existing TIM matrices to enhance their thermal conductivity. This approach led to significant improvements but also revealed challenges related to GO dispersion and interface resistance. Subsequent efforts concentrated on developing novel synthesis methods to create GO with tailored properties for TIM applications.

Recent advancements have focused on creating hybrid GO-based TIMs, combining GO with other materials such as metals, ceramics, or polymers to achieve synergistic effects. These hybrid materials aim to address the limitations of pure GO, such as its tendency to agglomerate and its relatively low through-plane thermal conductivity.

The primary objectives in the development of GO-based TIMs are multifaceted. Researchers aim to maximize thermal conductivity while maintaining flexibility and ease of application. Enhancing the stability and long-term performance of GO-based TIMs under various environmental conditions is another crucial goal. Additionally, efforts are being made to develop scalable and cost-effective production methods to facilitate the widespread adoption of GO-based TIMs in commercial applications.

Looking ahead, the field of GO-based TIMs is poised for further innovation. Objectives include developing GO-based TIMs with self-healing properties, creating smart TIMs that can adapt to changing thermal loads, and exploring the potential of 3D-printed GO structures for customized thermal management solutions. As research progresses, the integration of GO-based TIMs with emerging technologies such as flexible electronics and wearable devices is expected to open new avenues for thermal management in next-generation electronic systems.

Market Demand for Advanced Thermal Management

The market demand for advanced thermal management solutions has been steadily increasing, driven by the rapid evolution of electronic devices and systems. As components become smaller, more powerful, and more densely packed, the need for efficient heat dissipation has become critical. This trend is particularly evident in industries such as consumer electronics, automotive, aerospace, and data centers.

In the consumer electronics sector, the push for thinner, lighter, and more powerful devices has led to a surge in demand for high-performance thermal interface materials (TIMs). Smartphones, tablets, and laptops require increasingly sophisticated thermal management solutions to maintain optimal performance and prevent overheating. The global smartphone market alone, which shipped over 1.2 billion units in 2022, represents a significant driver for advanced TIMs.

The automotive industry is another major contributor to the growing demand for thermal management solutions. With the rise of electric vehicles (EVs) and the increasing integration of electronics in conventional vehicles, thermal management has become a crucial factor in vehicle design and performance. The EV market, in particular, requires advanced TIMs for battery thermal management systems to ensure safety, longevity, and optimal performance of battery packs.

Data centers, which form the backbone of our digital infrastructure, are also fueling the demand for advanced thermal management solutions. As data processing and storage requirements continue to grow exponentially, the need for efficient cooling systems becomes paramount. The global data center market, valued at over $200 billion in 2021, is expected to maintain strong growth, driving demand for innovative TIMs that can handle high heat loads and improve overall energy efficiency.

The aerospace and defense sectors present another significant market for advanced thermal management solutions. High-performance aircraft, satellites, and military equipment operate in extreme conditions and require sophisticated thermal control systems. The increasing use of composite materials in aerospace applications has further emphasized the need for advanced TIMs that can effectively bridge thermal gaps between different materials.

The demand for graphene oxide-based TIMs is particularly promising within this broader market context. Graphene oxide's exceptional thermal conductivity, coupled with its ability to form stable dispersions and its potential for functionalization, makes it an attractive candidate for next-generation thermal interface materials. Industries are actively seeking TIMs that can offer superior thermal performance while also addressing challenges such as long-term reliability, ease of application, and compatibility with various substrate materials.

As the global focus on energy efficiency and sustainability intensifies, there is a growing interest in thermal management solutions that can contribute to overall system efficiency and reduced energy consumption. This trend aligns well with the potential benefits of graphene oxide-based TIMs, which could offer improved thermal performance with potentially lower material usage and environmental impact compared to traditional solutions.

Current Challenges in Graphene Oxide TIM Development

Despite the promising potential of graphene oxide (GO) in thermal interface materials (TIMs), several significant challenges hinder its widespread adoption and optimal performance. One of the primary obstacles is the difficulty in achieving uniform dispersion of GO within the matrix material. The tendency of GO sheets to agglomerate due to strong van der Waals forces between layers can lead to inconsistent thermal conductivity throughout the TIM, reducing its overall effectiveness.

Another critical challenge lies in the interface thermal resistance between GO and the matrix material. The poor adhesion and weak bonding at this interface can create thermal barriers, limiting the heat transfer efficiency of the composite. Researchers are actively exploring surface functionalization techniques to enhance the compatibility and bonding between GO and various matrix materials, but finding the optimal balance between improved interfacial interactions and preserved thermal properties of GO remains a complex task.

The scalability of GO-based TIM production presents another significant hurdle. While laboratory-scale synthesis of high-quality GO is well-established, translating these processes to industrial-scale production while maintaining consistent quality and properties is challenging. The cost-effectiveness of large-scale GO production and its integration into TIMs is a crucial factor that needs to be addressed for commercial viability.

Stability and long-term reliability of GO-based TIMs under various operating conditions pose additional challenges. Exposure to high temperatures, humidity, and mechanical stress can potentially degrade the GO structure or alter its properties over time. Ensuring the consistent performance of GO-TIMs throughout the lifespan of electronic devices is essential for their practical implementation.

Furthermore, the environmental impact and potential health risks associated with GO production and use in TIMs need careful consideration. While GO is generally considered less toxic than pristine graphene, concerns about its long-term effects on human health and the environment persist. Developing eco-friendly synthesis methods and establishing comprehensive safety protocols for handling and disposal of GO-based materials are crucial steps in addressing these concerns.

Lastly, the optimization of GO content in TIMs presents a delicate balance. While increasing GO concentration can enhance thermal conductivity, it may also lead to increased brittleness and reduced mechanical stability of the composite. Finding the optimal GO loading that maximizes thermal performance without compromising other essential properties of the TIM remains an ongoing challenge for researchers and engineers in this field.

Existing Graphene Oxide TIM Solutions

01 Graphene oxide-based thermal interface materials

Graphene oxide is used as a key component in thermal interface materials due to its excellent thermal conductivity and large surface area. These materials are designed to enhance heat dissipation in electronic devices, improving their overall performance and lifespan. The graphene oxide can be functionalized or combined with other materials to optimize its thermal properties and compatibility with various substrates.- Graphene oxide-based thermal interface materials: Graphene oxide is used as a key component in thermal interface materials due to its excellent thermal conductivity and large surface area. These materials are designed to enhance heat dissipation in electronic devices, improving their overall performance and lifespan. The graphene oxide can be functionalized or combined with other materials to optimize its thermal properties and compatibility with various substrates.

- Preparation methods for graphene oxide thermal interfaces: Various methods are employed to prepare graphene oxide-based thermal interface materials. These may include chemical vapor deposition, solution-based processes, or mechanical exfoliation. The preparation techniques aim to control the thickness, size, and orientation of graphene oxide sheets to maximize their thermal conductivity and ensure uniform distribution within the interface material.

- Composite materials incorporating graphene oxide for thermal management: Graphene oxide is often combined with other materials such as polymers, metals, or ceramics to create composite thermal interface materials. These composites leverage the high thermal conductivity of graphene oxide while addressing challenges like mechanical stability, adhesion, and compatibility with different surfaces. The resulting materials offer improved thermal performance compared to traditional thermal interface materials.

- Application of graphene oxide thermal interfaces in electronic devices: Graphene oxide-based thermal interface materials find applications in various electronic devices, including smartphones, computers, and power electronics. They are used to efficiently transfer heat from heat-generating components to heat sinks or cooling systems, thereby preventing overheating and improving device reliability. The thin nature of graphene oxide allows for its integration into compact and high-performance electronic designs.

- Functionalization and modification of graphene oxide for enhanced thermal properties: Researchers explore various methods to functionalize or modify graphene oxide to enhance its thermal properties and compatibility with different materials. This may involve chemical treatments, surface modifications, or the introduction of additional compounds. These modifications aim to improve the thermal conductivity, reduce thermal resistance at interfaces, and enhance the overall performance of graphene oxide-based thermal interface materials.

02 Graphene oxide composites for thermal management

Composite materials incorporating graphene oxide are developed for thermal management applications. These composites often combine graphene oxide with polymers, metals, or ceramics to create materials with enhanced thermal conductivity and mechanical properties. The resulting composites can be used in various forms such as films, coatings, or bulk materials for efficient heat dissipation in electronic devices and other thermal management systems.Expand Specific Solutions03 Graphene oxide-based heat spreaders

Heat spreaders utilizing graphene oxide are designed to efficiently distribute and dissipate heat in electronic devices. These heat spreaders can be in the form of thin films or coatings applied directly to heat-generating components or integrated into the device's structure. The high thermal conductivity and flexibility of graphene oxide allow for effective heat management in compact and complex electronic designs.Expand Specific Solutions04 Functionalization of graphene oxide for thermal applications

Various methods are developed to functionalize graphene oxide, enhancing its thermal properties and compatibility with different materials. Functionalization can involve chemical modifications, surface treatments, or the addition of nanoparticles. These processes aim to improve the thermal conductivity, stability, and interfacial properties of graphene oxide, making it more effective in thermal management applications.Expand Specific Solutions05 Manufacturing processes for graphene oxide thermal interface materials

Various manufacturing processes are developed to produce graphene oxide-based thermal interface materials at scale. These processes focus on achieving uniform dispersion of graphene oxide in the matrix material, controlling the thickness and density of the resulting material, and ensuring consistent quality. Advanced techniques such as solution processing, in-situ reduction, and layer-by-layer assembly are employed to optimize the thermal and mechanical properties of the final product.Expand Specific Solutions

Key Players in Graphene Oxide TIM Industry

The graphene oxide market for thermal interface materials is in a growth phase, with increasing demand driven by the electronics and automotive industries. The market size is expanding rapidly, projected to reach several billion dollars by 2030. Technologically, graphene oxide-based thermal interface materials are advancing, but still face challenges in large-scale production and integration. Companies like Paragraf Ltd., Global Graphene Group, and SHT Smart High-Tech AB are at the forefront of commercialization efforts. Academic institutions such as Zhejiang University and the University of California are contributing significant research to improve material properties and manufacturing processes. While the technology shows promise, further development is needed to achieve widespread industrial adoption and cost-effectiveness.

Paragraf Ltd.

Global Graphene Group, Inc.

Core Innovations in Graphene Oxide TIM

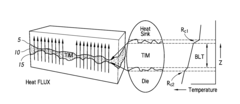

- The development of a thermal interface material comprising a matrix with graphene and multilayer graphene fillers, where the graphene and multilayer graphene are dispersed within the matrix, offering improved thermal conductivity enhancement with reduced filler loading, and the use of metallic fillers like silver in combination with epoxy or thermal greases to achieve high thermal conductivity across a range of temperatures.

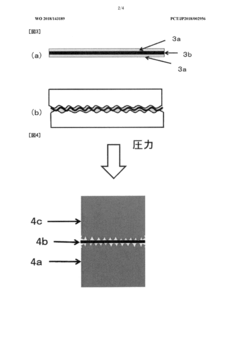

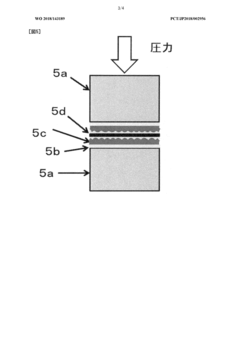

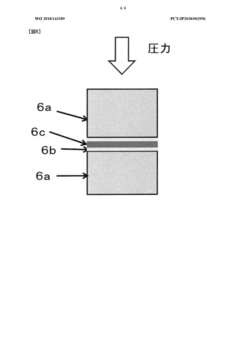

- An interlayer thermal bonding member comprising a thin graphite film with a fluid material covering its surface, allowing the graphite film to curve and make contact with surface irregularities, while the fluid material fills recesses to remove air spaces, achieving a multi-point bonding effect and low pressure dependence.

Environmental Impact of Graphene Oxide TIMs

The environmental impact of Graphene Oxide Thermal Interface Materials (TIMs) is a critical consideration in their development and application. As these materials gain prominence in electronic cooling solutions, it is essential to assess their potential effects on ecosystems and human health throughout their lifecycle.

The production of graphene oxide involves chemical processes that may generate hazardous waste. The use of strong oxidizing agents and acids in the synthesis of graphene oxide can lead to the release of toxic byproducts if not properly managed. Manufacturers must implement stringent waste treatment protocols to mitigate these risks and comply with environmental regulations.

During the application and use phase, graphene oxide TIMs demonstrate potential environmental benefits. Their superior thermal conductivity allows for more efficient heat dissipation in electronic devices, potentially reducing energy consumption and extending device lifespan. This improved efficiency can contribute to a decrease in electronic waste and associated environmental burdens.

However, the long-term stability and potential degradation of graphene oxide TIMs in various environmental conditions remain areas of concern. As these materials are exposed to heat, moisture, and mechanical stress over time, there is a possibility of nanoparticle release into the environment. The behavior and toxicity of graphene oxide nanoparticles in air, water, and soil ecosystems are subjects of ongoing research.

End-of-life management of graphene oxide TIMs presents both challenges and opportunities. The recyclability of these materials is an important factor in their overall environmental impact. While the recovery of graphene oxide from composite materials can be complex, advancements in recycling technologies may enable the reclamation and reuse of these valuable materials, reducing the demand for virgin production.

Biodegradability is another crucial aspect to consider. Unlike traditional polymer-based TIMs, graphene oxide may persist in the environment for extended periods. Research into the development of biodegradable graphene oxide composites is ongoing, aiming to address this concern and improve the material's environmental profile.

The potential for bioaccumulation of graphene oxide nanoparticles in food chains and their effects on aquatic and terrestrial organisms are areas that require further investigation. Preliminary studies have shown varying degrees of toxicity to different species, highlighting the need for comprehensive ecological risk assessments.

As the adoption of graphene oxide TIMs increases, life cycle assessments (LCAs) become essential tools for evaluating their overall environmental impact. These assessments consider all stages of the material's life, from raw material extraction to disposal, providing a holistic view of its environmental footprint compared to conventional TIMs.

Scalability and Cost Analysis of Graphene Oxide TIMs

The scalability and cost analysis of graphene oxide thermal interface materials (TIMs) is crucial for their widespread adoption in industrial applications. The production of graphene oxide TIMs can be scaled up through various methods, including chemical exfoliation, electrochemical exfoliation, and mechanical exfoliation. Each method presents unique challenges and opportunities for large-scale manufacturing.

Chemical exfoliation, the most common method, offers good scalability but faces challenges in maintaining consistent quality across large batches. The process involves oxidizing graphite using strong oxidants, which can be scaled up by increasing reactor size and optimizing reaction conditions. However, the cost of high-purity graphite and chemical reagents remains a significant factor in overall production expenses.

Electrochemical exfoliation shows promise for scalability due to its relatively simple setup and lower chemical consumption. This method can be scaled by increasing electrode size and optimizing electrolyte composition. While it offers better control over the oxidation process, the initial equipment cost and energy consumption need careful consideration for large-scale implementation.

Mechanical exfoliation, though less common for mass production, has potential for scaling through the use of high-shear mixers or ball milling techniques. This method's main advantage lies in its lower chemical requirements, potentially reducing production costs. However, achieving consistent quality and high yield remains challenging at larger scales.

The cost analysis of graphene oxide TIMs must consider raw material expenses, production costs, and potential economies of scale. Raw graphite prices vary significantly based on purity and source, impacting the final product cost. Chemical reagents used in oxidation processes contribute substantially to production expenses, necessitating efficient recycling and waste management systems to minimize costs.

Energy consumption during production and post-processing stages, such as purification and functionalization, also plays a crucial role in overall costs. Implementing energy-efficient technologies and optimizing process parameters can lead to significant cost reductions in large-scale production.

As production scales up, economies of scale come into play, potentially lowering per-unit costs. However, this must be balanced against the increased complexity of quality control and the need for specialized equipment. Investments in automation and process control systems can improve efficiency and consistency but require substantial upfront capital.

The market demand for high-performance TIMs in electronics and other industries drives the need for cost-effective, large-scale production of graphene oxide TIMs. As manufacturing processes mature and become more efficient, the cost of graphene oxide TIMs is expected to decrease, making them more competitive with traditional thermal management solutions.