HDPE Pipe Systems: Advancements for Water Supply Efficiency

HDPE Pipe Evolution

High-density polyethylene (HDPE) pipe systems have undergone significant evolution since their introduction in the 1950s. Initially developed as a lightweight and corrosion-resistant alternative to traditional metal pipes, HDPE pipes have continuously improved in terms of material properties, manufacturing techniques, and application versatility.

In the early stages, HDPE pipes were primarily used for low-pressure applications due to limitations in material strength and processing capabilities. However, advancements in polymer science and manufacturing technologies have led to the development of high-performance HDPE resins with enhanced mechanical properties, allowing for the production of pipes capable of withstanding higher pressures and more demanding operating conditions.

The introduction of bimodal HDPE resins in the 1990s marked a significant milestone in HDPE pipe evolution. These resins, characterized by a unique molecular weight distribution, offered improved stress crack resistance, long-term strength, and processability. This innovation enabled the production of pipes with thinner walls while maintaining or even improving performance, resulting in material savings and increased flow capacity.

Another crucial development in HDPE pipe evolution has been the improvement of joining techniques. Early methods relied on mechanical couplings, which were prone to leaks and failures. The advent of heat fusion joining techniques, such as butt fusion and electrofusion, revolutionized the installation process, creating leak-free, monolithic pipe systems with joints as strong as the pipe itself.

The evolution of HDPE pipes has also been driven by advancements in manufacturing processes. The introduction of continuous extrusion technologies and improved die designs has led to more consistent pipe dimensions, smoother inner surfaces, and higher production rates. These improvements have contributed to better hydraulic performance and increased cost-effectiveness of HDPE pipe systems.

In recent years, the focus of HDPE pipe evolution has shifted towards sustainability and environmental considerations. The development of recycled and recyclable HDPE materials has gained traction, addressing growing concerns about plastic waste and circular economy principles. Additionally, research into bio-based HDPE resins derived from renewable resources is paving the way for more environmentally friendly pipe solutions.

The integration of smart technologies has also played a role in the evolution of HDPE pipe systems. The incorporation of sensors and monitoring devices within the pipe structure allows for real-time data collection on flow rates, pressure, and potential leaks, enabling proactive maintenance and improved water supply management.

As water scarcity becomes an increasingly pressing global issue, the evolution of HDPE pipes has focused on enhancing water supply efficiency. Recent developments include the optimization of pipe inner surfaces to reduce friction and improve flow characteristics, as well as the design of specialized fittings and connections to minimize pressure losses in the system.

Water Supply Demand

The global water supply demand is experiencing significant growth due to population increase, urbanization, and industrial expansion. This rising demand puts immense pressure on existing water infrastructure, necessitating more efficient and reliable water distribution systems. HDPE pipe systems have emerged as a crucial solution to address these challenges, offering numerous advantages over traditional materials.

Water scarcity is a pressing issue affecting many regions worldwide, with an estimated 2 billion people living in water-stressed areas. This situation is expected to worsen as climate change impacts water availability and quality. Consequently, there is an urgent need for water supply systems that minimize losses and ensure efficient distribution.

The water supply industry is witnessing a shift towards more sustainable and cost-effective solutions. HDPE pipes are gaining traction due to their durability, flexibility, and resistance to corrosion. These properties contribute to reduced water losses through leakage, which is a significant problem in aging infrastructure. Studies have shown that water loss in distribution systems can range from 10% to 50% in some areas, highlighting the potential for improvement through advanced pipe systems.

Municipalities and water utilities are increasingly recognizing the long-term benefits of investing in HDPE pipe systems. The market for HDPE pipes in water supply applications is projected to grow steadily, driven by infrastructure renewal projects and expansion of water networks in developing regions. This growth is further supported by government initiatives and regulations aimed at improving water supply efficiency and reducing water loss.

The demand for HDPE pipes in water supply is also influenced by their ability to withstand various environmental conditions and soil types. This versatility makes them suitable for both urban and rural water distribution networks. Additionally, the ease of installation and lower maintenance requirements of HDPE pipes contribute to their growing adoption in water supply projects.

As water stress becomes more prevalent, there is an increasing focus on water reuse and recycling systems. HDPE pipes play a crucial role in these applications due to their resistance to chemicals and ability to maintain water quality. This trend is expected to further drive the demand for advanced HDPE pipe systems in the water supply sector.

In conclusion, the water supply demand for HDPE pipe systems is driven by the need for efficient, reliable, and sustainable water distribution infrastructure. The market outlook remains positive, with growing recognition of the long-term benefits and cost-effectiveness of HDPE solutions in addressing global water supply challenges.

HDPE Pipe Challenges

Despite the numerous advantages of HDPE pipe systems for water supply efficiency, several challenges persist in their widespread adoption and optimal performance. One of the primary concerns is the higher initial cost of HDPE pipes compared to traditional materials like PVC or ductile iron. This cost factor can be a significant barrier for municipalities and water utilities operating under tight budgets, especially in developing regions.

The installation process of HDPE pipes also presents challenges. While fusion joining techniques provide excellent joint integrity, they require specialized equipment and skilled operators. This necessity for specialized labor and equipment can increase installation costs and may limit the availability of qualified contractors in some areas. Additionally, the fusion process can be time-consuming, potentially extending project timelines.

Environmental factors pose another set of challenges for HDPE pipe systems. Although HDPE is resistant to many chemicals, it can be susceptible to degradation from prolonged exposure to certain substances, such as chlorine and ultraviolet radiation. This vulnerability necessitates careful consideration of pipe selection and installation methods in areas with high chlorine content in water or significant UV exposure.

The thermal expansion properties of HDPE can also be problematic in certain applications. HDPE pipes have a higher coefficient of thermal expansion compared to metal pipes, which can lead to issues with pipe movement and potential stress on connections in environments with significant temperature fluctuations.

Long-term performance and durability concerns exist, particularly regarding the potential for slow crack growth in HDPE pipes under sustained stress. While modern HDPE materials have improved resistance to this phenomenon, it remains a consideration in system design and material selection, especially for high-pressure applications.

Quality control during manufacturing and installation is crucial for HDPE pipe systems. Inconsistencies in material quality or improper fusion techniques can lead to premature failures. Ensuring consistent quality across large-scale projects can be challenging, requiring rigorous inspection and testing protocols.

Lastly, the recycling and end-of-life management of HDPE pipes present environmental challenges. While HDPE is recyclable, the process of separating and recycling large-diameter pipes can be complex and energy-intensive. Developing efficient recycling methods and promoting circular economy practices in the HDPE pipe industry remains an ongoing challenge.

Current HDPE Solutions

01 Improved HDPE pipe design for enhanced efficiency

Advanced designs in HDPE pipe systems focus on optimizing flow characteristics and reducing friction losses. These improvements include modifications to internal pipe surfaces, innovative joint designs, and optimized pipe diameters. Such enhancements result in increased hydraulic efficiency, reduced pumping costs, and improved overall system performance.- Improved pipe design for enhanced efficiency: HDPE pipe systems can be optimized through innovative designs that improve flow characteristics and reduce friction losses. This includes modifications to the internal surface of pipes, optimized pipe diameters, and advanced joint designs that minimize turbulence and pressure drops, resulting in increased overall system efficiency.

- Advanced material formulations: The efficiency of HDPE pipe systems can be enhanced through the development of advanced HDPE formulations. These may include additives or modified polymer structures that improve the pipe's mechanical properties, chemical resistance, and long-term performance, leading to reduced maintenance and increased lifespan of the piping system.

- Smart monitoring and control systems: Integration of smart technologies for real-time monitoring and control of HDPE pipe systems can significantly improve efficiency. This includes sensors for leak detection, pressure monitoring, and flow rate optimization, as well as automated control systems that can adjust system parameters based on demand and environmental conditions.

- Innovative joining and installation techniques: Efficiency in HDPE pipe systems can be improved through advanced joining and installation methods. This includes development of quick-connect fittings, improved welding techniques, and modular design approaches that reduce installation time and enhance system integrity, leading to better overall performance and reduced maintenance needs.

- Energy recovery and sustainability features: Incorporating energy recovery systems and sustainable features into HDPE pipe networks can enhance overall efficiency. This may include technologies for harvesting energy from water flow, integrating renewable energy sources for pumping systems, and designing pipe layouts that minimize energy consumption while maximizing resource utilization.

02 Integration of smart technologies in HDPE pipe systems

Incorporation of smart technologies such as sensors, monitoring systems, and data analytics into HDPE pipe networks enhances operational efficiency. These technologies enable real-time monitoring of flow rates, pressure, and potential leaks, allowing for proactive maintenance and optimized resource management in water distribution and wastewater systems.Expand Specific Solutions03 Enhanced joining techniques for HDPE pipes

Development of advanced joining methods for HDPE pipes, including improved heat fusion techniques and mechanical coupling systems. These innovations result in stronger, more reliable connections, reducing the risk of leaks and improving the overall efficiency and longevity of HDPE pipe systems in various applications.Expand Specific Solutions04 Composite HDPE pipe materials for increased performance

Research into composite HDPE pipe materials, incorporating reinforcing fibers or other additives, aims to enhance the mechanical properties and performance of pipe systems. These advanced materials offer improved strength, durability, and resistance to environmental factors, leading to more efficient and longer-lasting pipe installations.Expand Specific Solutions05 Optimization of HDPE pipe manufacturing processes

Advancements in HDPE pipe manufacturing processes, including improved extrusion techniques and quality control measures, contribute to the production of higher quality pipes with more consistent properties. These optimizations result in pipes with better dimensional accuracy, reduced defects, and enhanced overall performance in various applications.Expand Specific Solutions

HDPE Industry Leaders

The HDPE pipe systems market for water supply efficiency is in a growth phase, driven by increasing demand for durable and cost-effective water infrastructure solutions. The market size is expanding globally, with significant potential in developing regions. Technologically, HDPE pipe systems are mature but continue to evolve, with companies like Composite Fluid Transfer LLC, Guizhou Lianchuang Pipe Industry Co., Ltd., and CCCC Fourth Harbor Engineering Co., Ltd. leading innovations. These advancements focus on improving material properties, joint technologies, and installation methods. The competitive landscape is diverse, featuring both established players and emerging companies, with a trend towards specialized solutions for specific water supply challenges.

Guizhou Lianchuang Pipe Industry Co., Ltd.

Shenzhen Sanxin Water Environment Technology Co., Ltd.

HDPE Pipe Innovations

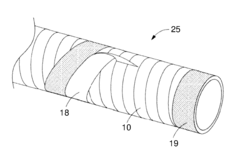

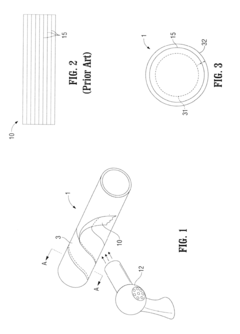

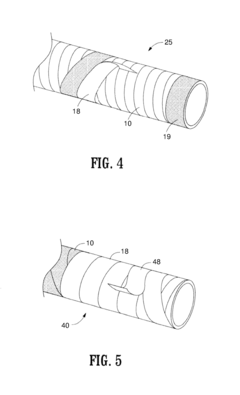

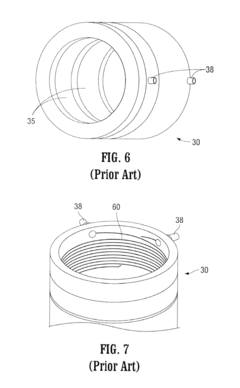

- A lightweight, high-density polyethylene (HDPE) piping system reinforced with thermoplastic fiber tape, which is wrapped and bonded to the pipe for added strength, and a coupling connector system that secures the pipe ends for leak-resistant connections.

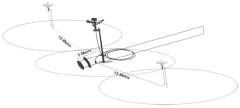

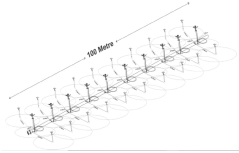

- The development of HDPE/PP laminated woven fabric lay-flat tubes with a lay-flat connector and lock ring system, which are lightweight, flexible, and easy to install, eliminating the need for joints and reducing the complexity of transportation and installation.

Environmental Impact

The environmental impact of HDPE pipe systems for water supply efficiency is a critical consideration in the adoption and advancement of this technology. HDPE pipes offer several environmental benefits compared to traditional materials such as metal or concrete. Firstly, HDPE pipes have a significantly longer lifespan, often exceeding 50 years, which reduces the need for frequent replacements and minimizes waste generation. This longevity contributes to resource conservation and reduces the overall carbon footprint associated with pipe manufacturing and installation.

Furthermore, HDPE pipes are highly resistant to corrosion and chemical degradation, eliminating the need for protective coatings or treatments that may contain harmful substances. This characteristic not only extends the pipe's service life but also prevents the leaching of potentially toxic materials into the surrounding soil and water systems. The smooth interior surface of HDPE pipes also reduces friction, leading to improved flow efficiency and lower energy requirements for water pumping, thereby contributing to reduced energy consumption and associated greenhouse gas emissions.

HDPE pipes are also fully recyclable at the end of their service life, supporting circular economy principles and reducing landfill waste. The recycling process for HDPE is well-established and can be repeated multiple times without significant loss of material properties. This recyclability factor significantly reduces the environmental impact compared to materials that are difficult or impossible to recycle.

In terms of installation, HDPE pipes often require less excavation and disturbance to the surrounding environment due to their flexibility and the ability to use trenchless installation methods. This results in reduced soil disruption, preservation of natural habitats, and lower emissions from construction equipment. Additionally, the lightweight nature of HDPE pipes compared to traditional materials reduces transportation-related emissions during the distribution and installation phases.

However, it is important to note that the production of HDPE pipes does have some environmental considerations. The manufacturing process relies on petrochemical resources, which are non-renewable and contribute to carbon emissions. Efforts are being made to incorporate recycled HDPE and bio-based materials into pipe production to mitigate these impacts. Additionally, ongoing research is focused on improving the energy efficiency of HDPE pipe manufacturing processes and exploring more sustainable raw material sources.

Overall, while there are some environmental concerns associated with HDPE pipe production, the long-term benefits in terms of durability, efficiency, and recyclability make HDPE pipe systems a more environmentally favorable option for water supply infrastructure compared to many traditional alternatives. As advancements continue in material science and manufacturing processes, the environmental profile of HDPE pipe systems is expected to further improve, solidifying their role in sustainable water management solutions.

Regulatory Framework

The regulatory framework surrounding HDPE pipe systems for water supply efficiency is a critical aspect of their implementation and widespread adoption. Governments and industry bodies worldwide have established comprehensive standards and regulations to ensure the safety, reliability, and performance of these systems.

In the United States, the American Water Works Association (AWWA) has developed specific standards for HDPE pipes in water distribution systems. AWWA C906 is the primary standard governing the use of HDPE pipes for potable water transmission and distribution. This standard outlines requirements for materials, dimensions, testing, and quality control procedures. Additionally, the American Society for Testing and Materials (ASTM) has published several standards, including ASTM F714 and ASTM D3035, which provide specifications for HDPE pipe manufacturing and testing.

The European Union has implemented its own set of regulations through the European Committee for Standardization (CEN). EN 12201 is the key standard for HDPE piping systems for water supply, covering aspects such as general requirements, pipes, fittings, valves, and system fitness for purpose. This standard ensures consistency and quality across EU member states.

In many countries, national water authorities play a crucial role in regulating HDPE pipe systems. For instance, the UK Water Industry Research (UKWIR) has developed guidelines for the use of PE pipes in the water industry, which are widely adopted by water companies across the United Kingdom.

Environmental regulations also significantly impact the use of HDPE pipe systems. Many jurisdictions require environmental impact assessments before the installation of new water supply infrastructure. HDPE pipes often fare well in these assessments due to their long service life, low leakage rates, and recyclability.

Health and safety regulations are paramount in water supply systems. Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the European Food Safety Authority (EFSA) have established strict guidelines for materials that come into contact with drinking water. HDPE pipes must meet these requirements to ensure they do not leach harmful substances into the water supply.

The regulatory landscape is not static; it continues to evolve as new research emerges and technology advances. For instance, recent updates to regulations have focused on improving the resistance of HDPE pipes to disinfectants like chlorine, which can degrade certain plastics over time. This has led to the development of enhanced HDPE materials that offer greater longevity in chlorinated environments.

Compliance with these regulations is typically verified through third-party certification programs. Organizations like NSF International in the United States and DVGW in Germany provide certification services that ensure HDPE pipe systems meet all relevant standards and regulations. These certifications are often required by local authorities before HDPE pipes can be used in public water supply projects.